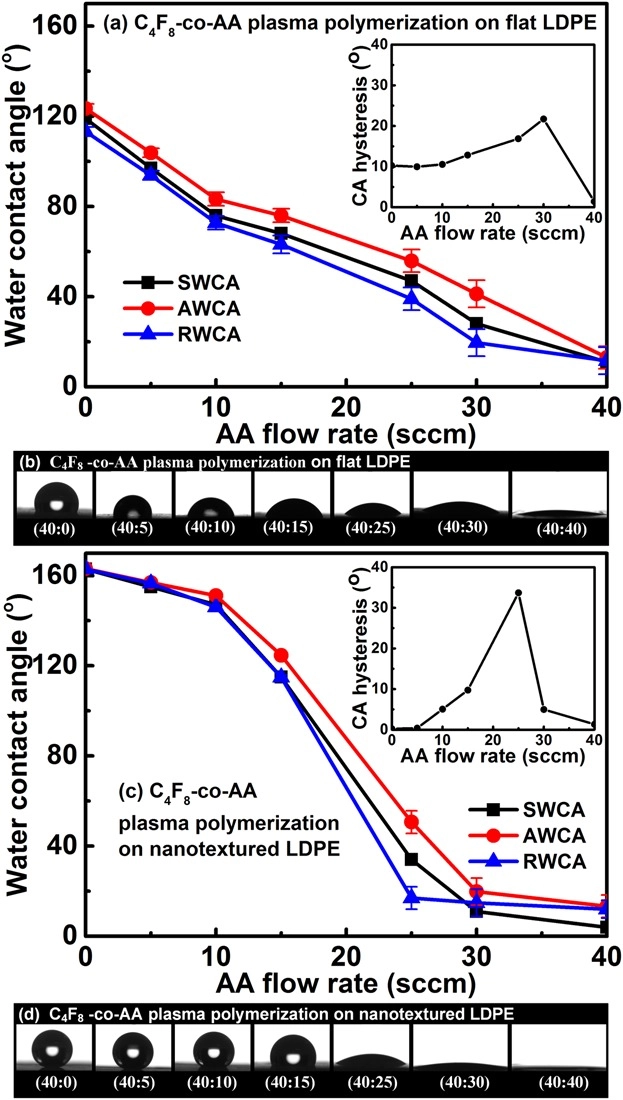

Novel and intelligent plasma copolymers based on hydrophilic/hydrophobic monomers with tunable wettability and pH‐responsiveness are demonstrated. A series of plasma copolymer coatings with various carboxylic acid and fluorocarbon group ratio are prepared on the low‐density polyethylene (LDPE) surfaces via capacitively coupled radio frequency plasma (CCP). The static water contact angles (SWCA) of C4F8‐co‐AA plasma polymer coatings on nanotextured LDPE surfaces tuned from 163 to 4°. These C4F8‐co‐AA plasma polymer coatings showed different pH‐responsiveness by the combined effect of the carboxylic acid to fluorocarbon group ratios and surface nanotexture. The increase of carboxylic acid groups of C4F8‐co‐AA plasma polymers shifted the reversibly switchable wettability of pH‐responsiveness towards low SWCA range. The magnifying effect of surface nanotexture on pH‐responsiveness was also observed.

- Plasma

- Surface

- Wettability

- surface modifcition

- tunable wettability

- surface modification

- plasma copolymers

he tunable wettability of plasma copolymer coating is the primary concern in this study. The wettability of C4F8‐co‐AA plasma polymer coatings can be controlled from superhydrophobicity to superhydrophilicity by tuning surface chemistry and surface morphology. The hydrophilic carboxylic acid group controls the wetting state and hydrophobic fluorocarbon group dewtting state as the presence of polar carboxylic acid group allow polar water to penetrate into plasma copolymer coatings and the presence of nonpolar groups like CF2 and CF3 of low surface energy repel water. C4F8plasma polymer coating on LDPE surface shows static water contact angle (SWCA) of 119°. As carboxylic acid group concentration increases, SWCA of C4F8‐co‐AA plasma polymer coatings decreases. For C4F8‐co‐AA (40:5) plasma polymer coatings SWCA decrease to 97°. The advancing contact angle (ACA) and the receding contact angle (RCA) also drop from 123 to 103° and 113 to 93° as presented in Figure a. Optical SWCA images of a water droplet of C4F8‐co‐AA plasma polymer on flat LDPE presented in Figure b. With further increase of carboxylic acid groups, more rapid decrees in RWCA as compared to AWCA is observed because RWCA is most sensitive to the polar character. It leads to increase in contact angle hysteresis that indicated an increase in relative adhesion. C4F8‐co‐AA (40:40) plasma polymer coatings show rapid decrees in AWCA leading to lower hysteresis as water spread on the hydrophilic surface due to increasing polar interaction between water and carboxylic acid groups. These results suggest that as AA feed ratio increases carboxylic acid group content compared to CFx also increases and this leads to lower SWCA.

[1]

References

- Iqbal Muzammil; Yupeng Li; Mingkai Lei; Tunable wettability and pH-responsiveness of plasma copolymers of acrylic acid and octafluorocyclobutane. Plasma Processes and Polymers 2017, 14, 1700053, 10.1002/ppap.201700053.