Pulses are in the forefront as protein-rich sources to aid in providing sufficient daily protein intake and may be used as binders to reduce meat protein in meat product formulations. Use of pulse-derived ingredients in meat processing can lower formulation costs, improve nutritional value and enhance meat product quality. Pulses are seen as clean-label multi-functional ingredients that bring benefits to meat products beyond protein content. Their broader use as ingredients in meat products may be enhanced by various processes such as thermal pre-treatment.

- meat products

- pulses

- multi-functional ingredients

- infrared treatment

1. Composition and Nutritional Value

| Nutrient | Dry Peas | Lentils | Chickpeas |

|---|---|---|---|

| Carbohydrates (g) | 61.6 | 63.4 | 63 |

| Dietary fiber (g) | 22.2 | 10.7 | 12.2 |

| Total sugars (g) | 3.14 | 2.03 | 10.7 |

| Protein (g) | 23.1 | 24.6 | 20.5 |

| Fat (g) | 3.89 | 1.06 | 6.04 |

| Calcium (mg) | 46 | 35 | 57 |

| Iron (mg) | 4.73 | 6.51 | 4.31 |

| Potassium (mg) | 852 | 677 | 718 |

| Zinc (mg) | 3.49 | 3.27 | 2.76 |

| Vitamin A (µg) | 7 | 2 | 3 |

| Vitamin C (mg) | 1.8 | 4.5 | 4 |

| Thiamin (mg) | 0.719 | 0.87 | 0.47 |

| Riboflavin (mg) | 0.244 | 0.21 | 0.21 |

| Niacin (mg) | 3.61 | 2.60 | 1.54 |

| Vitamin B-6 (mg) | 0.14 | 0.54 | 0.53 |

| Folate (µg) | 15 | 479 | 577 |

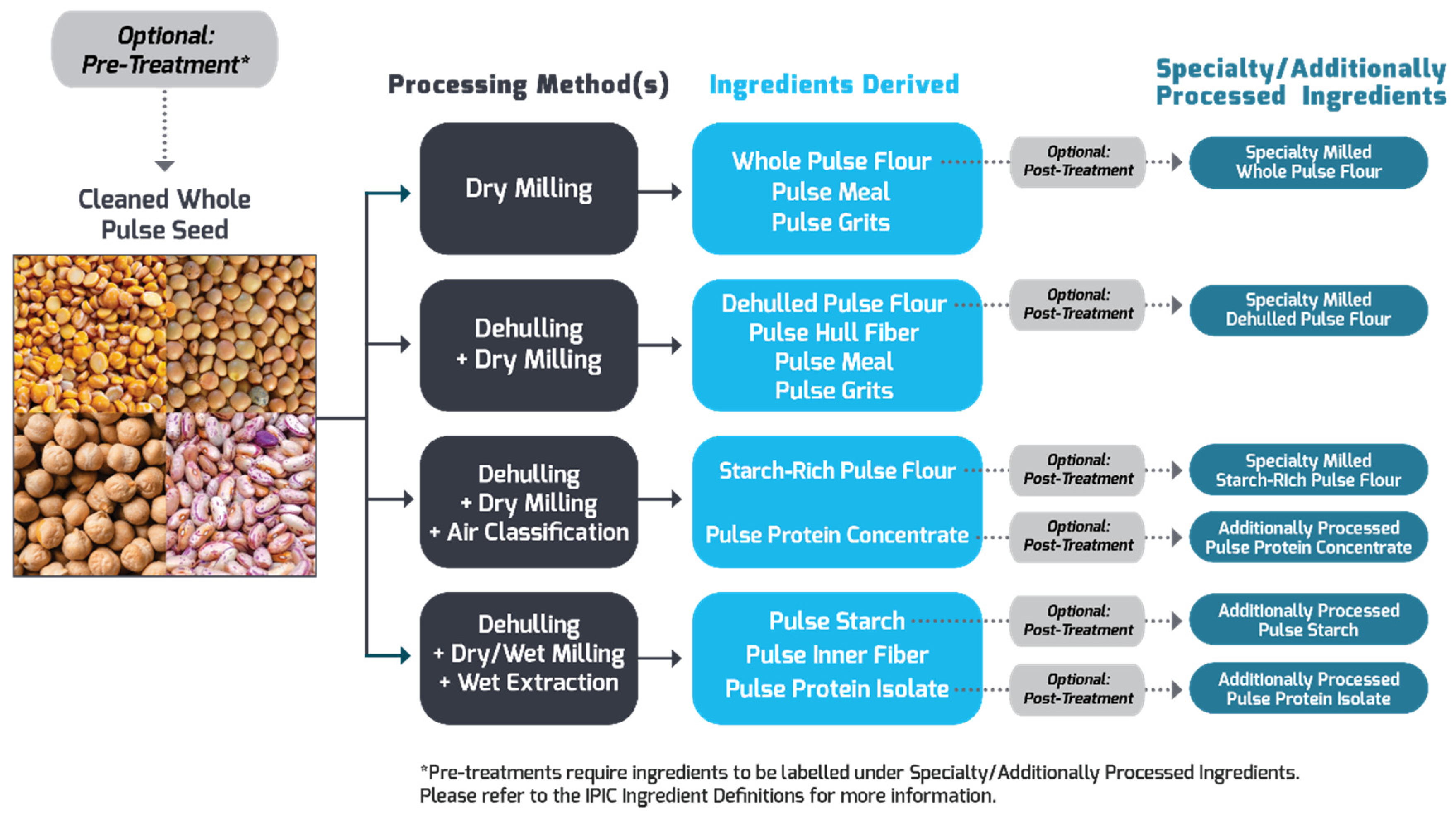

2. Pulse Processing

foods12081722 [# XX and add to reference list]

3. Pulses and Pulse-Derived Ingredients for Use in Processed Meat Products

| Property or Function of Pulses | Potential Effect on Meat Products |

|---|---|

| Advantages Water and oil retention properties |

Improved juiciness, moist mouthfeel, flavor, and product yield, provide firmer texture |

| Contribution of protein | Increase protein content |

| Contribution of fiber | Increase dietary fiber content |

| Contribution of antioxidant compounds (ex: phenolic compounds, antioxidative enzymes etc.) | Increase oxidative stability of lipids, protein, and pigments, improve color stability, increase bioactivity |

| Disadvantages | |

| Contribution of pro-oxidative compound (ex: oxidative enzymes) | Increase lipid, protein, and pigment oxidation, reduce color acceptability, development of off-flavor |

| Contribution of color | Reduce redness of fresh meat products, increase dark color of cooked meat products |

| Contribution of antinutritive factors | Affects availability and digestibility of proteins and minerals |

| Contribution of fiber | Products become softer and less juicy |

3.1. Pulse Flours

3.2. Pulse Proteins

3.3. Pulse Fibers

4. Bioactive Compounds of Interest in Pulses and Pulse-Derived Ingredients

4.1. Non-Enzymatic Bioactives

4.2. Endogenous Enzymes

5. Sensory Properties of Pulses to Consider When Formulating Meat Products

6. Thermal Treatments to Improve Pulse Flour Characteristics

NOver the past decade, research has focused on IR heating as one of the thermal treatments for pulses to increase their suitability as ingredients for different foods. IR treatment is a rapid heating technique that employs IR electromagnetic radiation. IR heating is considered an advanced thermal process with reported benefits such as environmental friendliness and homogeneity of heating with low energy consumption. IR heating enhances liquid-binding and emulsifying properties, inactivates oxidative enzymes, reduces antinutritional factors, and protects antioxidative properties of pulses [16 17 18 103 117]. Meat products that contain fresh-comminuted meat or further processed to be ready-to-eat benefit from IR-treated pulse ingredients, showing improvements in product appearance, cook yield, oxidative stability, and nutrient availability while maintaining desired flavour and texture [16 17 18]. Thus, IR heating could serve as a viable treatment that can be used in pulse processing as a pre-treatment to enhance their functional properties for meat product applications.

This entry is adapted from the peer-reviewed paper 10.3390/foods12081722

References

- Singh, N. Pulses: An overview. J. Food Sci. Technol. 2017, 54, 853–857.

- Tiwari, B.K.; Singh, N. Pulse Chemistry and Technology; Royal Society of Chemistry: London, UK, 2012.

- Chigwedere, C.M.; Nkonkola, C.M.; Rai, S.; Kyomugasho, C.; Kermani, Z.J.; Pallares, A.P.; Hendrickx, M.E. Cotyledon pectin molecular interconversions explain pectin solubilization during cooking of common beans (Phaseolus vulgaris). Food Res. Int. 2019, 116, 462–470.

- Gwala, S.; Kyomugasho, C.; Wainaina, I.; Rousseau, S.; Hendrickx, M.; Grauwet, T. Ageing, dehulling and cooking of Bambara groundnuts: Consequences for mineral retention and in vitro bioaccessibility. Food Funct. 2020, 11, 2509–2521.

- USDA. FoodData Central. 2023. Available online: https://fdc.nal.usda.gov/fdc-app.html#/food-details/173756/nutrients (accessed on 2 March 2023).

- Egbert, W.R.; Payne, C.T. Plant proteins. In Ingredients in Meat Products: Properties, Functionality and Applications; Tarte, R., Ed.; Springer Science Business Media, LLC.: New York, NY, USA, 2009; pp. 111–129.

- Singh, J.; Basu, P.S. Non-nutritive bioactive compounds in pulses and their impact on human health: An overview. Food Nutr. Sci. 2012, 3, 1664–1672.

- World Cancer Research Fund and American Institute for Cancer Research. Keeping the Science Current: Colorectal Cancer 2011 Report Food, Nutrition, Physical Activity, and the Prevention of Colorectal Cancer. 2011. Available online: https://www.wkof.nl/sites/default/files/Colorectal-Cancer-2011-Report (accessed on 12 October 2022).

- Health Canada. Eating Well with Canada’s Food Guide—A Resource for Educators and Communicators; Health Canada: Ottawa, ON, Canada, 2011.

- Jain, A.K.; Kumar, S.; Panwar, J.D.S. Antinutritional factors and their detoxification in pulses-a review. Energy 2009, 139, 90–94.

- Chang, L.; Lan, Y.; Bandillo, N.; Ohm, J.B.; Chen, B.; Rao, J. Plant proteins from green pea and chickpea: Extraction, fractionation, structural characterization and functional properties. Food Hydrocoll. 2022, 123, 107165.

- International Pulse Ingredient Consortium. Definitions of Ingredients. 2022. Available online: https://www.pulseingredients.com/ (accessed on 12 October 2022).

- Prinyawiwatkul, W.; McWatters, K.H.; Beuchat, L.R.; Phillips, R.D. Physicochemical and sensory properties of chicken nuggets extended with fermented cowpea and peanut flours. J. Agric. Food Chem. 1997, 45, 1891–1899.

- Modi, V.K.; Mahendrakar, N.S.; Rao, D.N.; Sachindra, N.M. Quality of buffalo meat burger containing legume flours as binders. Meat Sci. 2004, 66, 143–149.

- Serdaroğlu, M.; Yıldız-Turp, G.; Abrodímov, K. Quality of low-fat meatballs containing legume flours as extenders. Meat Sci. 2005, 70, 99–105.

- Kurt, Ş.; Kilincceker, O. The effects of cereal and legume flours on the quality characteristics of beef patties. Kafkas Üniversitesi Vet. Fakültesi Derg. 2012, 18, 725–730.

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 2020, 102, 51–61.

- Keeton, J.T. Formed and emulsion products. In Poultry Meat Processing; CRC Press: Boca Raton, FL, USA, 2000; pp. 205–236.

- Pintado, T.; Delgado-Pando, G. Towards more sustainable meat products: Extenders as a way of reducing meat content. Foods 2020, 9, 1044.

- Argel, N.S.; Ranalli, N.; Califano, A.N.; Andrés, S.C. Influence of partial pork meat replacement by pulse flour on physicochemical and sensory characteristics of low-fat burgers. J. Sci. Food Agric. 2020, 100, 3932–3941.

- Boye, J.; Zare, F.; Pletch, A. Pulse proteins: Processing, characterization, functional properties and applications in food and feed. Food Res. Int. 2010, 43, 414–431.

- Lu, Z.X.; He, J.F.; Zhang, Y.C.; Bing, D.J. Composition, physicochemical properties of pea protein and its application in functional foods. Crit. Rev. Food Sci. Nutr. 2019, 60, 2593–2605.

- Karaca, A.C.; Low, N.; Nickerson, M. Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res. Int. 2011, 44, 2742–2750.

- Shevkani, K.; Singh, N.; Kaur, A.; Rana, J.C. Structural and functional characterization of kidney bean and field pea protein isolates: A comparative study. Food Hydrocoll. 2015, 43, 679–689.

- Lam, A.C.Y.; Can Karaca, A.; Tyler, R.T.; Nickerson, M.T. Pea protein isolates: Structure, extraction, and functionality. Food Rev. Int. 2018, 34, 126–147.

- Anderson, E.T.; Berry, B.W. Effects of inner pea fiber on fat retention and cooking yield in high fat ground beef. Food Res. Int. 2001, 34, 689–694.

- Besbes, S.; Ghorbel, R.; Salah, R.B.; Masmoudi, M.; Jedidi, F.; Attia, H.; Blecker, C. Date fiber concentrate: Chemical compositions, functional properties and effect on quality characteristics of beef burgers. J. Food Drug Anal. 2010, 18, 3.

- Pereira, J.; Sathuvan, M.; Lorenzo, J.M.; Boateng, E.F.; Brohi, S.A.; Zhang, W. Insight into the effects of coconut kernel fiber on the functional and microstructural properties of myofibrillar protein gel system. LWT 2021, 138, 110745.

- Hu, H.; Pereira, J.; Xing, L.; Zhou, G.; Zhang, W. Thermal gelation and microstructural properties of myofibrillar protein gel with the incorporation of regenerated cellulose. LWT-Food Sci. Technol. 2017, 86, 14–19.

- Xu, R. Assessment of Physicochemical and Functional Properties of Fibre-Rich Fractions of Yellow Pea and Red Lentil to Use in Low-Fat Pork Bologna. Master’s Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2017.

- Matallana-González, M.C.; Cámara, M.; Fernández-Ruiz, V.; Morales, P. Antioxidant phytochemicals in pulses and their relation to human health: A Review. Curr. Pharm. Des. 2020, 26, 1880–1897.

- Rice-Evans, C.A.; Miller, N.J.; Paganga, G. Structure-antioxidant activity relationships of flavonoids and phenolic acids. Free Radic. Biol. Med. 1996, 20, 933–956.

- Li, H. The Lentil-Meat System: Investigating the Antioxidant Effect of Lentil on Colour and Lipid Oxidation of Raw Beef Burgers. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2017.

- Xu, B.J.; Yuan, S.H.; Chang, S.K.C. Comparative analyses of phenolic composition, antioxidant capacity, and color of cool season legumes and other selected food legumes. J. Food Sci. 2007, 72, S167–S177.

- Mirali, M.; Purves, R.W.; Vandenberg, A. Profiling the phenolic compounds of the four major seed coat types and their relation to color genes in lentil. J. Nat. Prod. 2017, 80, 1310–1317.

- Pathiraja, D.; Wanasundara, J.P.; Elessawy, F.M.; Purves, R.W.; Vandenberg, A.; Shand, P.J. Water-soluble phenolic compounds and their putative antioxidant activities in the seed coats from different lentil (Lens culinaris) genotypes. Food Chem. 2022, 407, 135145.

- Al-Wesali, M.; Lambert, N.; Welham, T.; Domoney, C. The influence of pea seed trypsin inhibitors on the in vitro digestibility of casein. J. Sci. Food Agric. 1995, 68, 431–437.

- Muzquiz, M.; Varela, A.; Burbano, C.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive compounds in legumes: Pronutritive and antinutritive actions. Implications for nutrition and health. Phytochem. Rev. 2012, 11, 227–244.

- Gemede, H.F.; Ratta, N. Anti dietary factors in plant foods: Potential health benefits and adverse effects. Adv. Res. J. Micro. 2018, 5, 100–113.

- Roy, F.; Boye, J.I.; Simpson, B.K. Bioactive proteins and peptides in pulse crops: Pea, chickpea and lentil. Food Res. Int. 2010, 43, 432–442.

- Barbana, C.; Boye, J.I. In vitro protein digestibility and physico-chemical properties of flours and protein concentrates from two varieties of lentil (Lens culinaris). Food Funct. 2013, 4, 310–321.

- Vijayakumari, K.; Siddhuraju, P.; Pugalenthi, M.; Janardhanan, K. Effect of soaking and heat processing on the levels of antinutrients and digestible proteins in seeds of Vigna aconitifolia and Vigna sinensis. Food Chem. 1998, 63, 259–264.

- Erba, D.; Angelino, D.; Marti, A.; Manini, F.; Faoro, F.; Morreale, F.; Pellegrini, N.; Casiraghi, M.C. Effect of sprouting on nutritional quality of pulses. Int. J. Food Sci. Nutr. 2019, 70, 30–40.

- Avezum, L.; Rondet, E.; Mestres, C.; Achir, N.; Madode, Y.; Gibert, O.; Lefevre, C.; Hemery, Y.; Verdeil, J.-L.; Rajjou, L. Improving the nutritional quality of pulses via germination. Food Rev. Int. 2022, 1–34.

- Rehman, Z.U.; Shah, W.H. Thermal heat processing effects antinutrients, protein and starch digestibility of food legumes. Food Chem. 2005, 91, 327–331.

- Patterson, C.A.; Curran, J.; Der, T. Effect of processing on antinutrient compounds in pulses. Cereal Chem. 2017, 94, 2–10.

- Newcomer, M.E.; Brash, A.R. The structural basis for specificity in lipoxygenase catalysis. Protein Sci. 2015, 24, 298–309.

- Shi, Y.; Mandal, R.; Singh, A.; Singh, A.P. Legume lipoxygenase: Strategies for application in food industry. Legume Sci. 2020, 2, e44.

- Loiseau, J.; Vu, B.L.; Macherel, M.H.; Le Deunff, Y. Seed lipoxygenases: Occurrence and functions. Seed Sci. Res. 2001, 11, 199–211.

- Kermasha, S.; Metche, M. Changes in lipoxygenase and hydroperoxide isomerase activities during the development and storage of French bean seed. J. Sci. Food Agric. 1987, 40, 1–10.

- Gardner, H.W.; Deighton, N. Effect of 4-hydroxy-2 (E)-nonenal on soybean lipoxygenase-1. Lipids 2001, 36, 623–628.

- Chigwedere, C.M.; Wanasundara, J.P.; Shand, P.J. Sensory descriptors for pulses and pulse-derived ingredients: Toward a standardized lexicon and sensory wheel. Compr. Rev. Food Sci. Food Saf. 2022, 21, 999–1023.

- Szczygiel, E. Aroma Chemistry and Consumer Acceptance of Navy Bean Powder as Prepared by Commercial or Extrusion Processing. Master’s Thesis, Michigan State University, East Lansing, MI, USA, 2016.

- Paladugula, M.P. Application of Yellow Pea (Pisum sativum) Flour into Baked Goods. Master’s Thesis, University of Idaho, Moscow, ID, USA, 2020.

- Roland, W.S.U.; Pouvreau, L.; Curran, J.; van de Velde, F.; de Kok, P.M.T. Flavor aspects of pulse ingredients. Cereal Chem. 2017, 94, 58–65.

- Dzudie, T.; Scher, J.; Hardy, J. Common bean flour as an extender in beef sausages. J. Food Eng. 2002, 52, 143–147.

- Pietrasik, Z.; Janz, J.A.M. Utilization of pea flour, starch-rich and fiber-rich fractions in low fat bologna. Food Res. Int. 2010, 43, 602–608.

- Shand, P.J. Textural, water holding, and sensory properties of low-fat pork bologna with normal or waxy starch hull-less barley. J. Food Sci. 2000, 65, 101–107.

- Pathiraja, P.M.H.D. Investigating the Potential Applications of Lentil Seed Components in Mechanically Separated Chicken Meat Systems. Ph.D. Dissertation, University of Saskatchewan, Saskatoon, SK, Canada, 2020.

- Sathe, S.K.; Salunke, D.K.; Cheryan, M. Technology of removal of unwanted components of dry beans. Crit. Rev. Food Sci. Nutr. 1984, 21, 263–287.

- Barampama, Z.; Simard, R.E. Effects of soaking, cooking and fermentation on composition, in-vitro starch digestibility and nutritive value of common beans. Plant Foods Hum. Nutr. 1995, 48, 349–365.

- Nayak, B.; Liu, R.H.; Tang, J. Effect of processing on phenolic antioxidants of fruits, vegetables, and grains—A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 887–918.

- Xiong, Y.L. Nonmeat ingredients and additives. In Handbook of Meat and Meat Processing; CRC Press: Boca Raton, FL, USA, 2012; pp. 573–588.