Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Chemical

Hydrogels have become one of the potential polymers used with great performance for many issues and can be promoted as biomaterials with highly innovative characteristics and different uses. Gelatin is obtained from collagen, a co-product of the meat industry. Thus, converting wastes such as cartilage, bones, and skins into gelatin would give them added value. Gelatin-based hydrogels have been shown to be useful for different applications with important and innovative characteristics.

- hydrogel

- gelatin

- sustainability

- remediation

1. Introduction

Hydrogels are characterized as three-dimensional cross-linked polymeric networks that can be produced with the most variable compounds and with the most variable uses [1]. In the last decade, hydrogels have been used in many applications and with high technical and economic viability which include biomedical and environmental areas.

Gelatin-based hydrogels are one kind of hydrogel in which gelatin is used as the cross-linked polymer and give the gel characteristics such as structure and texture. Many studies have promoted this kind of hydrogel for biomedical uses with promising and important characteristics such as tissue engineering [2,3] and/or drug delivery [4,5] with a high economic impact on society, medicine, and environmental purposes with high applicability.

The market for gelatin in 2020 rose to about USD 3.18 billion and is further expected to reach USD 4.08 billion by 2024 as forecasted in the same report [6]. The market of gelatin in 2013 was the highest in the food and beverages sector (28%), followed by nutraceuticals (25.8%) and pharmaceuticals (21%), while their use in the cosmetic industry was only 5.5% [7]. Along with the advancements in drug delivery, it caused the development of new recipients as novel dosage forms to fulfill specific functions which directly or indirectly influence the extent and or rate of drug release. This enhances the development of new and modified recipient sources that continue to emerge for better drug delivery performance [8].

Several studies have shown the high potential of hydrogels as green and renewable materials, with highly efficient and promising uses [1,9]. Gelatin-based hydrogels have several advantages due to their biocompatibility, biodegradability, and nontoxic features [10]. Furthermore, gelatin is a natural protein-derived material, and it has been used for the synthesis of medical hydrogels because of its non-immunogenicity and capacity for enhancing cell adhesion apart from its excellent biocompatibility [11].

Environmental problems such as pollution and contamination of water and soil have increased over the years of industrialization, mining, and the use of natural resources. Bioremediation and remediation processes come to assuage the contamination and promote environmental sustainability. In this way, hydrogels have a high potential for remediation with a substantial capacity for the adsorption of a wide range of pollutants such as toxic metals [12,13,14,15], organic compounds [16,17], dyes [18,19,20], and others.

2. Gelatin-Based Hydrogels

Traditional gelatin is produced from animal origin, and it has been made from bones, cartilage, tendons, ligaments, and skin of animals such as cattle, pigs, fish, or chickens. As aforementioned, gelatin is derived from the partial hydrolysis of collagen protein presented in the previous sources [40]. Thus, due to the process of obtaining it, it may also be referred to as hydrolyzed collagen, hydrolyzed gelatin, or collagen peptide after it has undergone hydrolysis. After this process, the final product is colorless and soluble.

Gelatin is one of the most used ingredients with non-toxic and biodegradable characteristics in food and non-food industries for many purposes: for promoting gelation, stabilizing, thickening, emulsifying, and film forming [40]. Biodegradability is today an important issue since the sustainability of each product needs to exist; otherwise, the product might have problems with its future use because sanitary treatment is expensive and delimitation of space is a large problem for cities and governments. Even after obtaining the gelatin or the desired product from it, it has been demonstrated to have biodegradable characteristics, and it can contribute to producing new materials with high biodegradability potential inside the human organism [41] and in the environment [42,43].

Gelatin is used for giving consistency and viscosity to the hydrogels and, thanks to its aforementioned biodegradable and renewable nature, it can be an important source of sustainable hydrogels. Nowadays, the use of gelatin for the synthesis of hydrogels for multiple purposes depends on its structure and texture characteristics, and the applications range from the biomedical or biotechnological areas [2,3,30,44] to the most variable water and waste treatments [15,16,27,36,45]. Thus, gelatin-based hydrogels are versatile materials, which makes them very interesting. Some useful aspects of gelatin-based hydrogels employed for all the applications together with some others such as alimentary or environmental ones are displayed in Table 1.

Table 1. Different purposes, applicability areas, and potential uses of gelatin-based hydrogels.

| Hydrogel | Purpose | Field | Potential Use | Reference |

|---|---|---|---|---|

| Poly(vinyl) alcohol-based | Mechanical and physical resistance | Biomedical | Economically high | [28] |

| Antioxidant peptides | Protective for enzyme | Biotechnology | Economically high for food industry | [44] |

| Gelatin nanoparticle | Tissue engineering, cell culture | Biotechnology | Economically high | [2] |

| Chitosan | Drug delivery | Biomedical | Economically | [5] |

| Dopamine grafted/ 1,4-phenylenebisboronic acid and graphene oxide |

Tissue adhesives, wound dressings, and wearable devices | Biomedical | Economically high | [11] |

| Cellulose incorporation | Chromium adsorption | Environmental | Pollution control and waste treatment | [27] |

| Cellulose microcrystals incorporation | Drug delivery | Biomedical | Economically | [46] |

| Oxidized alginate | Cartilage tissue engineering | Biomedical | Economically and healthy high | [47] |

| Carrageenan and potassium sulfate | Foods, materials, and other fields | Multiple uses | Economically and industrially | [10] |

As shown in Table 1, the wide applicability of hydrogels has been studied. In the biomedical field, for instance, purposes such as tissue engineering [3,30], cell culture scaffolding for bacterial growth and further human uses [48], dental pulp regeneration [49], capsules for drug delivery [4], and the treatment of myocardial infarction [31] have been investigated. Gelatin hydrogels are usually permeable to nutrients and oxygen, which enhance the survival rate of cells and their biological functions [48]. So, hydrogels with different compositions combining gelatin with other polymers could be useful for biomedical applications.

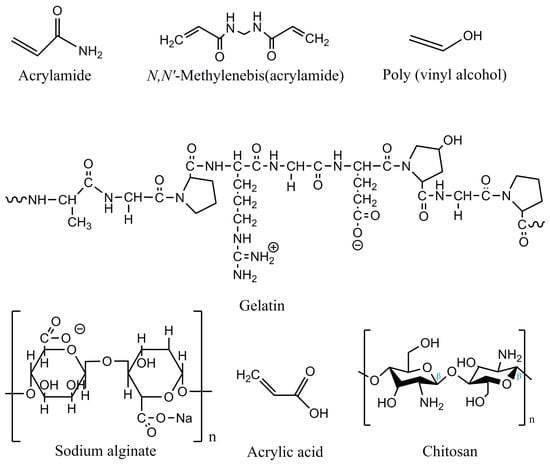

Gelatin is a protein that can easily biodegrade in the environment but has some stability limitations at high temperatures since once it has been dissolved, long durations at temperatures above 40 °C can promote protein denaturation. Moreover, gelatin is soluble in water, and this can also be a problem when synthesizing neat gelatin materials. As shown in Figure 1, gelatin is usually made from repeating units of glycine-X-Y. The high amount of the amino acids proline (12%), hydroxyproline (10%), and hydroxylysine (0.5%) make gelatin particularly special [50]. Depending on its origin, the content of proline and hydroxyproline might vary; in fact, fish gelatin is known for having a lower concentration of these amino acids compared to that coming from mammals. This affects negatively the gelling ability of fish gelatin, leading to a decrease in the gelation and melting temperatures together with a worsening of its mechanical properties, among others [51]. Thus, in order to synthesize more stable and resistant gelatin-based hydrogels, this biopolymer has been combined with many other polymers such as polyvinyl alcohol [28], alginate dialdehyde, alginate dialdehyde-gelatin reinforced with bioactive glass nanoparticles [3], dialdehyde carboxymethyl cellulose-dextrin [30], graphene oxide and laponite [31], collagen [49], chitosan [5], dopamine grafted, 1,4-phenylenebisboronic acid and graphene oxide [11], and oxidized alginate (OA) reinforced by silicon carbide nanoparticles (SiC NPs) and cross-linked with N-hydroxysuccinimide (NHS) and 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) [52]. Figure 1 shows the chemical structure of different compounds used for the synthesis of gelatin-based hydrogels.

Figure 1. Chemical structure of some of the compounds that enable cross-linking with gelatin for the synthesis of gelatin-based hydrogels.

This entry is adapted from the peer-reviewed paper 10.3390/polym15041026

This entry is offline, you can click here to edit this entry!