Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Food Science & Technology

Waste generated from the agro-food industry represents a concerning environmental, social and economic issue. The Food and Agriculture Organization of the United Nations defines food waste as all food that decreases in quantity or quality to the extent that it is thrown out by food service providers and consumers. The optimization of agro-food waste as an ingredient will help in the development and innovation of food products to generate functional food and beverages to prevent and treat several diseases in consumers.

- food waste

- agro-food industry

- functional beverages

1. Fruit and Vegetable Waste

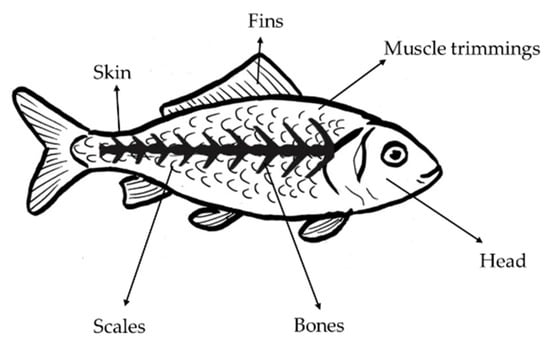

Fruits and vegetables are edible parts of plants. They are essential components of the human diet because they are a great source of vitamins, minerals and fiber [70,71]. The FAO (2018) estimates that the global production of fruits and vegetables is currently 868 Mt and 1089 Mt, respectively. However, their production has been increasing due to population growth and changes in dietary habits. Fruit production is led by bananas, citrus, melons, apples, pears and grapes, and the most produced vegetables are tomatoes, onions, garlic, cabbages, cauliflower, brassicas, cucumbers, pickles, carrots and turnips (Figure 1) [71,72,73].

Figure 1. Global production of fruits and vegetables.

Unfortunately, half of the worldwide fruit and vegetable production ends up as waste, generating environmental problems because these materials are naturally susceptible to microbiological degradation [72,74]. The juice industry is the major generator of vegetable waste [75]. Fruit and vegetable waste (FVW) comprises the inedible parts of food, i.e., the outer layers and extremities of fruits and vegetables that are removed during processing, mainly by peeling and pressing. These parts are discarded during collection, handling, transportation, and processing [75,76]. Utilizing fruit and vegetable waste represents a great opportunity to obtain vitamins, minerals, fiber, oils, dye and bioactive compounds that could be included in the human diet [6,77]. However, its valorization for the recovery of valuable components is limited. In this sense, industry and the research community have been working together to transform fruit waste into high-value-added products [78]. There are some research studies where fruit waste was used as an ingredient in the production of different beverages, showing its important functionality (Table 1) [79,80,81,82,83]. Some of the functionalities in beverages produced from FVW are related to the presence of bioactive compounds such as polyphenols present in fruit peel [84,85,86,87,88,89], seeds [87,89,90] or the final product of fruit processing [91,92,93,94]. In vegetables, the pomace and peel are the main sources of bioactive compounds [74,95,96,97,98,99,100]. They result in excellent antioxidant activity, by radical inhibitions such as DPPH (2,2-Diphenyl-1-picrylhydrazyl), ABTS (2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid)), and anti-inflammatory activity [101]. Additionally, the antimicrobial activity is related to the presence of bioactive compounds in FVW. This activity increases during the storage of beverages, maintaining their physiochemical (lower sedimentation and better viscosity and color) and nutritional properties (high concentration of vitamins and minerals). FVW is rich in fiber, which helps to increase satiety, control the glycemic index, reduce the risk of heart diseases, alleviate constipation and reduce the risk of metabolic syndromes and diabetes. Moreover, it can increase the viscosity and stability of tea, juice and refreshing and other types of beverages [102,103,104,105,106,107].

Table 1. Fruit and vegetable waste used in functional beverages.

| Type of Beverage | Waste Food Ingredient | Functionality | Reference |

|---|---|---|---|

| Apple–peach | Lemon peel (polyphenols) |

Antioxidant and antimicrobial capacity increased during storage | [75] |

| Refreshing beverage | Sea buckthorn waste (phenolic compounds) |

Antioxidant, antimicrobial and nutritional functionality | [81] |

| Tea | Pomegranate peel (flavonoids and tannins) |

Increased antioxidant and bio-accessibility capacity of polyphenols | [76] |

| Energy drink | Melon seeds (flavonoids and phenolic acids) |

DPPH radical inhibition, antimicrobial activity against Staphylococcus aureus, E. coli, Bacillus cereus and Aspergillus niger | [78] |

| Coffee type | Zalaca seeds (flavonoid compounds) |

Antioxidant activity and diuretic effect on white male Wistar rats | [79] |

| Juice | Dragon fruit peel (polyphenol compounds) |

Inhibition of free radicals | [77] |

| Iced tea | Cacao processing waste (phenolic compounds and dietary fiber) |

Antioxidant activity and good nutritional properties |

[82] |

| Juice | Orange and pomegranate peel (polyphenol compounds) |

Antioxidant and antimicrobial activity increased during storage | [80] |

| Infusion | Grape pomace (phenolic acids and flavonoids) |

Antioxidant and anti-inflammatory activity | [101] |

| Verjuice | Unripe grapes (organic acids and phenolic compounds) |

Antimicrobial agent against E. coli, L. monocytogenes, S. typhimurium and S. aureus | [94] |

| Juice | Carrot pomace hydrolysate (β-carotene, polyphenol compounds) |

Rich in polyphenolics, low sedimentation | [96] |

| Isotonic beverage | Lettuce, courgette, carrot, spinach (fiber, protein and minerals) |

Good physicochemical properties | [75] |

| Juice | Cauliflower by-product powder (flavonoid compounds) |

Antioxidant, enhances the nutritional value | [97] |

| Juice | Pumpkin (vitamin C, niacin and carotene) |

High detoxification and antioxidant properties | [106] |

| Juice | Broccoli pomace (polyphenol content) |

Antioxidant, higher content of soluble carbohydrates (lower fiber content) and proteins | [98] |

| Juice | Beetroot (phenolic and flavonoid compounds) |

High amount of all minerals, enhances the beverage’s taste, flavor and antioxidant capacity | [99] |

| Juice | Sweet potato (anthocyanins, gallic acid, catechin, tryptophan) |

High levels of bioactive compounds with antioxidant capacity | [108] |

| Juice | Eggplant peel (anthocyanins) |

Antioxidant capacity against free radicals (ABTS and DPPH) | [102] |

| Juice | Prickly pear peels (pectic polysaccharides) |

Antimicrobial activity during storage | [100] |

| Juice | Tomato waste (lycopene) |

Antioxidant capacity against free radicals | [107] |

2. Dairy Waste

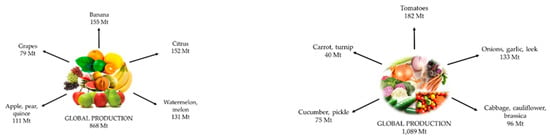

In 2019, world milk production was estimated to be about 852 Mt, and in 2020, the production was 906 Mt. This production is expected to grow 1.7% per year, reaching 1020 Mt by 2030 (FAO 2021). For 2020, the regions with higher milk production were Asia (367 Mt), Europe (225 Mt) and North America (109 Mt), followed by South America, Oceania, Central America and the Caribbean (Figure 3). The principal types of milk produced globally are cow (81.0%), buffalo (15%) and goat, sheep and camel (4.0% combined) [108,109].

Figure 3. Global milk production and principal types of milk consumed and processed around the world [109].

Milk should be processed almost immediately after milking, and it can only be stored for a few days [108]. The majority of dairy products are consumed in fresh, unprocessed or slightly processed (pasteurized or fermented) forms. The main processed dairy products produced around the world are butter (9.3 Mt), cheese (1.8 Mt), whole milk powder (2.7 Mt) and skim milk powder (2.5 Mt). The waste derived from dairy products is around 29 Mt per year, generating an important environmental problem [69,110]. Dairy waste can be classified as wastewater or solid waste [111].

Solid waste: The dairy industry produces around 200–350 kg of sludge for every 500,000 L of milk processed. Sludge contains degradable organic and non-biodegradable solid matter. The amount of sludge produced increases with an increase in wastewater [69,112].

Wastewater: The dairy industry produces 1–3 L of wastewater for every liter of milk produced. It contains a high concentration of organic components such as carbohydrates (lactose), protein, minerals and fats [110,113].

Milk whey is the main by-product of the dairy industry, produced during cheese and casein manufacturing; for every 10 L of milk, 1 kg of cheese and 9 L of milk whey are generated [108]. Milk whey represents an important pollution problem because of its biochemical oxygen demand (BOD) and chemical oxygen demand (COD) in the range of 1–10 g/L and 0.3–5.9 g/L, respectively [69,114]. Whey is a yellowish-to-greenish clear liquid obtained after milk coagulation during the cheese-making process. Whey represents about 85–95% of the milk volume and contains over 55% of milk nutrients such as minerals, proteins and lactose. Although milk whey is considered a waste product, the literature supports that milk whey has relevant nutritional and functional properties that make it suitable for use in functional foods [115,116,117,118].

Table 3 presents fermented beverages produced by dairy waste, mainly whey obtained from different types of cheese production such as Oaxaca, Ricotta and Chhena. Whey can be used in liquid form [26,119,120] or as a functional ingredient in powder form [121,122,123]. Whey beverages show functional activities such as antioxidant, antibacterial and cytomodulatory properties and also inhibit angiotensin-converting enzymes (ACE). The nutritional value of beverages produced using whey is higher; hence, they have good acceptance among consumers [124,125,126,127].

Table 3. Functional beverage processing from dairy waste.

| Type of Beverage | Waste Food Ingredient | Functionality | Reference |

|---|---|---|---|

| Fermented drink | Whey from Oaxaca cheese production | High bioavailability, nutritional value and antioxidant activity | [28] |

| Soursop whey beverage | Powder whey | High concentration of phenolic content; improvement in the antioxidant and antihypertensive activities; reduction in undesired minerals | [125] |

| Sport beverage | Liquid whey | Increase in protein and handgrip strength | [126] |

| Sport beverage | Ricotta cheese whey | Increase in volatile organic compounds; antimicrobial activity | [120] |

| Fruit beverage | Powder whey | Antioxidant activity, ACE (angiotensin-converting enzyme) inhibitory activity and α-glucosidase inhibition | [123] |

| Fermented milk beverage | Powder whey | Antioxidative, antibacterial, immune and cytomodulatory properties; ACE inhibition | [122] |

| Whey dairy beverages | Liquid whey | Inhibition activity on the viability of prostate cancer cells | [127] |

| Fermented probiotic beverage | Chhena cheese whey | Functional and nutritional qualities | [121] |

| Vegetable beverage | Liquid whey | Higher antioxidant activity and content of phenolic compounds, flavonoids and lipophilic pigments | [128] |

| Fermented beverage | Powder whey | Antioxidant and antimicrobial activity; ACE inhibitory activity | [124] |

3. Cereal Waste

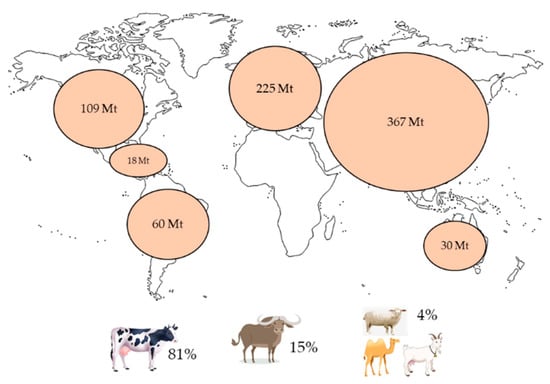

Cereal consumption provides more than 56% of human energy due to its carbohydrates, especially starch, and makes up 50% of the protein consumed worldwide [128]. Cereals are also rich in protein, vitamins and fiber. They also contain a small proportion of minerals (K, P, Mg, Ca and Fe) and unsaturated fatty acids [129,130,131]. The main cereals produced and consumed in the human diet are corn, wheat, rice, barley, oats, sorghum and rye (Figure 4). Cereal processing is one of the most important industries in the agro-food sector because cereal food products cover over 20% of the daily diet [132,133]. Cereal products are obtained by dry milling (wheat and rye), pearling (rice, oat, barley), wet milling (corn, wheat) and malting (barley, corn, wheat). This processing can generate solid waste (corn pericarp, corn grits, brewer’s spent grain, lignocellulosic biomass and baking industry waste) and liquid waste (milling waste water, parboiled rice effluent, corn steep liquor, bakery and tortilla wastewater) [134,135]. Lignocellulosic biomass is particularly suitable as a low-cost carbon substrate for solid-state fermentation [133]. The composition of waste generated in the cereal industry depends on the raw material processed and its operating conditions [110,133,134]. Cereal waste can be used as a low-cost material to extract value-added compounds that have potential health benefits (antioxidant, anti-inflammatory, regulation of hormones, enhancement of the immune system), for example, polyphenols used in nutraceuticals, dietary supplements and functional food formulations [130,133,136].

Figure 4. Global cereal production 2020–2021 [4].

The main objective of waste management in the cereal industry is to improve resource efficiency while protecting the environment. The techniques used for waste treatment modify their physical, chemical or biological characteristics to reduce their toxicity and/or volume and make the waste safer for disposal [135,137,138].

Today, many by-products derived from cereal processing have reached the market as dietary supplements or ingredients in fermented functional beverages [139]. Fermentation is a cheap biotechnological process used worldwide and is also one of the oldest processes used for food preservation and the elaboration of food products as beverages from various cereals worldwide [140,141,142]. This process uses enzymes and microorganisms (lactic acid bacteria, yeasts and molds) to trigger acidification, proteolysis and/or amino acid conversions to obtain products with desirable characteristics linked to texture, taste and odor and to extend the shelf life of beverages [143,144]. Fermented beverages are an optimum vehicle to transport nutrients (dietary fiber, vitamins, fatty acids, probiotics and minerals) and bioactive compounds (phytochemicals, phytoestrogens, phenolic compounds, flavonoids, carotenoids, etc.) into the body [141,142,145]. Fermented functional beverages are suitable for consumption by vegetarians, vegans and lactose-intolerant consumers. Additionally, they have an economic impact on poor diets and the potential to reduce adverse health effects by acting as antioxidant and anti-inflammatory agents, regulating hormones, enhancing the immune system, etc. [25,141,146]. Beverages produced from cereal waste from sorghum, barley, corn, barnyard millet, oats, wheat, rice, rye or quinoa are often high in soluble fiber, which helps to reduce the glycemic index by slowing down digestion and absorption [147]. Phenolic compounds have antioxidant potential and scavenge harmful free radicals in the body, reducing oxidative stress [148,149,150,151,152]. They also show antihypertensive, nutritional and physiochemical properties that promote physicochemical and functional properties [152,153,154,155,156] (Table 4).

Table 4. Functional beverages with cereal waste as an ingredient.

| Type of Beverage | Waste Food Ingredient | Functionality | Reference |

|---|---|---|---|

| Fermented beverage | Blue corn and black beans (phenolic compounds) | Antidiabetic and antihypertensive activity | [151] |

| Alcoholic beverage | Millet bran (vanillic, syringic, coumaric and ferulic acids) |

Antioxidant activity related to the high polyphenol content | [156] |

| Fermented beverage | Quinoa flour (phenolic compounds) |

Antioxidant activity, antihypertensive potential and sensorial acceptability | [157] |

| Juice | Sorghum Stalk (phenolic compounds) |

Reduced oxidative stress and no changes in sensory properties | [149] |

| Fermented beverage | Malted barley (peptides) |

Good physicochemical and antimicrobial properties | [154] |

| Multigrain beverage | Barnyard, foxtail kodo (phenolic compounds) |

Prebiotic activity, low GI (glycemic index), high antioxidant activity in beverage | [148] |

| Fermented beverages | Rice bran (protein and dietary fiber) |

Higher sensory acceptance, best shelf life and nutritional value | [155] |

| Tea | Corn tassel (phenolic compounds) |

Antioxidant and high bioactivity | [150] |

| Multigrain probiotic beverage |

Multigrain (oats, barley, buckwheat, rice) (phenolic compounds) |

Antioxidant activity, excellent nutritional value, great stability | [153] |

4. Fish Processing Waste

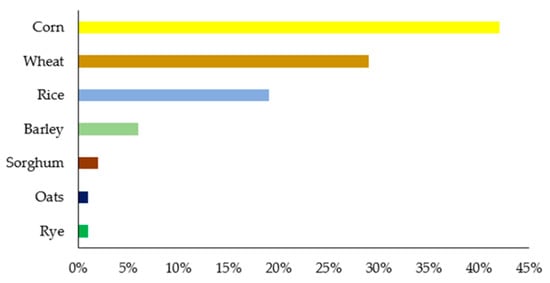

Almost 214 Mt of fish was processed in 2020, with its production expected to decrease to 202 Mt by 2030 [157]. Around 27% of the total catch of fish is lost or unutilized for consumption due to spoilage or deficient management and storage problems [158,159]. Around 65% of the total fish production is converted into waste. The term “fish waste” (FW) refers to the whole fish when it is damaged. It includes heads (9–12%), bones (9–15%), viscera (12–18%), muscle trimmings (15–20%), skin and fins (1–3%) and scales [160,161] (Figure 5). Traditionally, FW is used in animal feed and fertilizer or is discarded in landfills, causing environmental problems, damage to the marine ecosystem and the generation of unpleasant odors [162,163,164]. FW contains approximately 58% protein, 19% fat and minerals. Additionally, approximately 22% of its content is made up of the fatty acids palmitic acid and oleic acid. FW is an important source of by-products (proteins and amino acids, collagen and gelatin, oil and several enzymes) used in several fields and the food industry a functional ingredients [164,165,166,167]. Some studies have demonstrated the use of by-products obtained from FW in beverages with functional properties such as antioxidants against superoxide, ABTS and DPPH radicals and antimicrobial activity [168,169,170]. It possesses great physicochemical and nutritional properties [165,168,171,172,173]. Functional beverages with FW (gelatin and collagen) have been demonstrated to help increase skin hydration, brightness and texture and to decrease the appearance of crow’s feet wrinkles, pores and spots [174,175,176]. (Table 5).

Table 5. Beverages obtained from fish waste.

| Type of Beverage | Waste Food Ingredient | Functionality | Reference |

|---|---|---|---|

| Dairy beverage | Collagen (fish) |

Increased nutritional properties, higher bioavailability and antioxidant capacity (ABTS) | [168] |

| Probiotic dairy beverage | Collagen (donated by industry) |

Good physicochemical and microbiological parameters during storage | [47] |

| Fruit beverage | Collagen (fish) |

Increase in collagen synthesis and improvement in protein folding | [176] |

| Sparkling water | Gelatin (skin, scales and fins) |

Antibacterial properties and antioxidant activity against superoxide and the DPPH radical | [169] |

| Fruit juice | Hydrolysate collagen (cod skin) | Good nutritional and physicochemical properties | [165] |

| Apple juice and djulis extract | Collagen (green caviar) |

Improved skin moisture and elasticity | [171] |

| Apple juice | Collagen (fish) |

Improved skin hydration, brightness, texture | [175] |

| Non-alcoholic rose–apple beverage | Collagen (fish) |

Antioxidant properties | [170] |

| Dairy beverage | Collagen (fish skin) |

Good organoleptic, physicochemical and microbial properties | [172] |

| Omega-3 beverage | Collagen (donated by industry) |

Improved wound healing rate | [174] |

This entry is adapted from the peer-reviewed paper 10.3390/foods12081583

This entry is offline, you can click here to edit this entry!