Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Three-dimensional printed concrete (3DPC) is emerging as a new building material. Due to automation, this method dramatically decreases construction time and material wastage while increasing construction quality.

- 3D printed fiber reinforced concrete

- mechanical properties

- fresh properties

- steel fiber

1. Introduction

Today more than ever, the construction industry must evolve in the same way as the industrial sector. The advancement of the construction industry has always been supported by the standard method of conventional construction [1]. However, as the construction field has grown, challenges have developed, and this industry needs to modernize and adapt. As a result, there is potential for the conventional construction sector to undergo a change and upgrade with the help of 3D printing technology used in the industrial sector [2][3].

The idea of the digital fabrication of concrete was presented in 2004 by Behrokh Khoshnevis, termed ‘Contour Crafting’ [4]. Later, in 2011, researchers at Loughborough University, UK developed 3DPC by depositing layers of fresh concrete as per the digital structure model [5][6]. The integration of 3D printing into the building construction process has resulted in an innovative new construction technology: 3D printing for buildings. Compared to the time-consuming and expensive method of pouring molds, 3D printing reduces construction costs and increases productivity [7]. In addition, high-end, curving structures that are impossible to construct with other methods are simple to print. Fast progress has been made in this area by more than 30 research organizations throughout the world in the last decade [8]. Since Pegna’s groundbreaking work, there has been a general trend toward expanding applications of 3D printing in architectural design all across the world [9]. Due to the limitation of these technologies, 3DPC is generally unable to install a reinforcing steel bar [10][11]. In addition, 3DPC is exposed to quick shrinkages, which are drying, self-drying and especially plastic shrinkage in the early hours after printing [12][13][14][15].

In recent years, the application of FRC in engineering structures has gained worldwide interest because of its superior material properties compared to conventional reinforced concrete, such as its high first-crack [16][17] and tensile strength [18][19], high fracture toughness [20][21], excellent energy absorption capacity [21], improvement of ductility [22][23][24] and great impact resistance [25][26][27]. In addition, using fibers in FRC can enhance resistance to shrinkage cracking. Fibers can limit excessive expansion [28][29][30], improve resistance to the propagation of plastic shrinkage cracking [31][32], and restrain drying shrinkage [33][34][35][36].

2. Overview

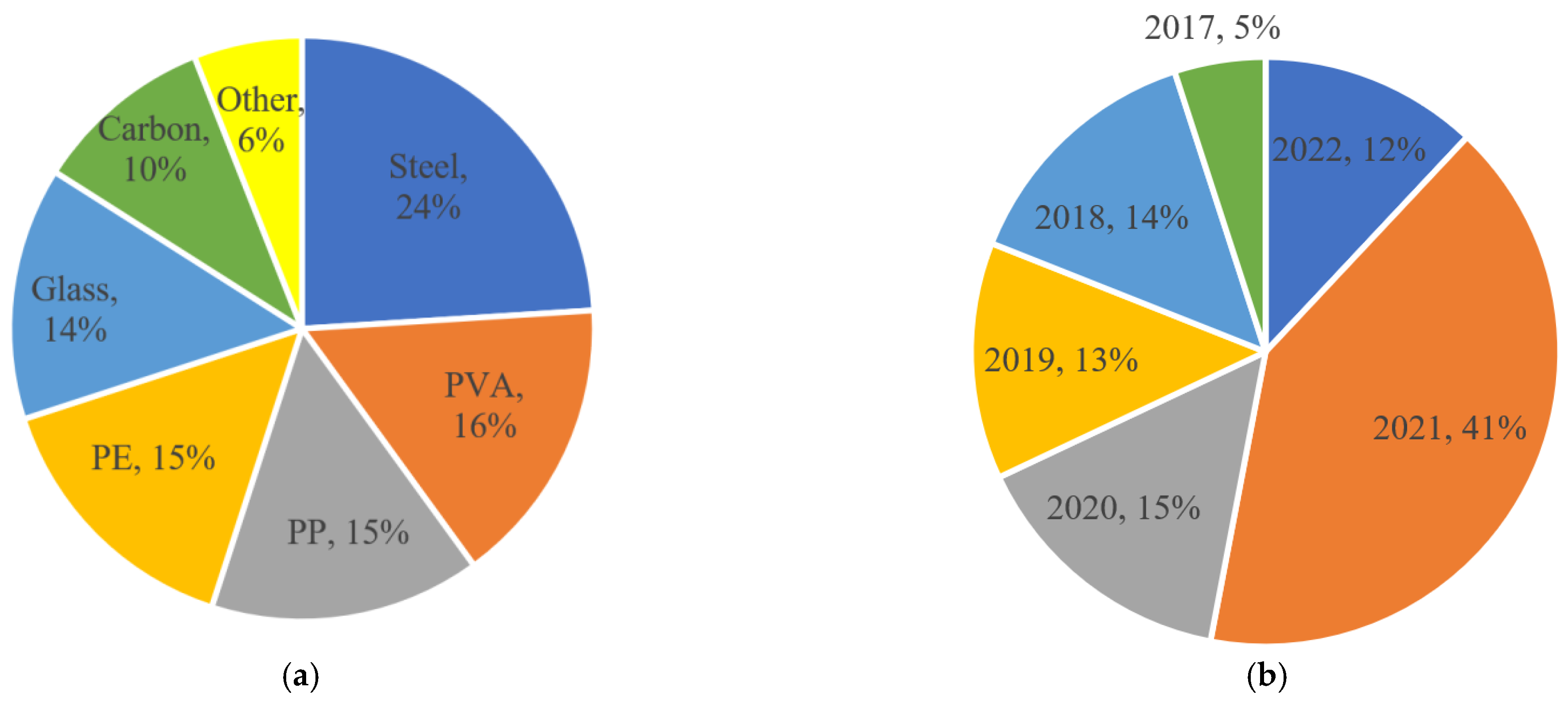

In recent years, many researchers have published articles about 3DPC. In this regard, the effect of different fibers on fresh and mechanical properties has been investigated. The cited bibliographic references were selected from various sources such as Scopus, Elsevier and Google Scholar. Significant articles were analyzed without considering repetitions. As the summarized statistics in Figure 1 show, more than 40% of articles are related to 2021; therefore, this statistic shows that researchers are currently interested in this field. The primary purpose of this research is to consider the effects of various types of fibers on the properties of 3DPC; therefore, academia and industry can use this research to enhance their information about the role of different fibers in 3DPC. The statistics illustrate that the researchers work with steel fibers more than other fibers; hence, it is an excellent opportunity for other scholars to use other types of fibers. Additionally, the statistics demonstrate that developed countries such as China and Australia are attending this field; thus, investigating the challenges of 3DPC could be an exciting subject for universities in other countries.

Figure 1. Summarized statistics about 3DPC: (a) Proportion of fibers used in articles; (b) Percent of articles published in different years; (c) Different countries’ participation in the 3DPC essay.

3. Fibers

Fibers that can be used as reinforcements in 3DPC are steel, carbon, glass, polyvinyl alcohol (PVA), polyethylene (PE), and polypropylene (PP). A summary of the typical characteristics of various fibers is shown in Table 1. Different reinforcing fibers might bring various qualities to concrete and play multiple roles in enhancing the functionality of cement-based materials. High-tensile strength fibers such as steel can significantly increase the bending and tensile strength of concrete mixtures, as well as their fatigue and impact resistance. In addition, they can enhance the material’s energy absorption capacity, toughness, and strain capacity [37][38]. The downside of steel fibers is that they rust easily and are relatively expensive [39]. Carbon fibers are lightweight, strong, resistant to corrosion, high temperatures, and fatigue, and have a high strength-to-weight ratio. They can also enhance the concrete’s electrical conductivity, pressure, and magnetic sensitivity [40][41][42][43]. However, they have inadequate impact resistance and weak toughness. Glass fibers offer decent heat insulation and corrosion resistance. Still, they have low alkali resistance and must be coated when used in concrete [44][45][46]. Polymer fibers are high-strength synthetic monofilament bundle fibers. When these fibers are added to mixtures, they can effectively limit the formation and growth of fractures, as well as increase their impermeability and impact resistance [47]. PVA [48], PE [49], and PP [50] are common types of used synthetic polymer fibers. Other fibers, such as basalt, recycled, and natural, may lessen the brittle failure of composites, but their performance is not as good as that of the mentioned fibers. Therefore, less research has been conducted on using these fibers [51]. Figure 2 shows several types of fibers.

Figure 2. Several types of fibers: (a) Steel; (b) PP; (c) Carbon.

Table 1. Characteristics of fibers.

| Fiber Type | Tensile Strength (MPa) | Young’s Modulus (GPa) |

Elongation (%) | Specific Gravity | Melting Point (°C) |

|---|---|---|---|---|---|

| Steel | 200–2760 | 200 | 0.5–0.35 | 7.8 | 1370 |

| PE | 690 | 0.14–0.41 | 10 | 0.95 | 141.4 |

| Glass | 1034–3792 | 72 | 1.5–3.5 | 2.5–2.7 | 860 |

| PVA | 1000–1600 | 22–42 | 6–7 | 1.3 | 220–240 |

| PP | 552–690 | 3.45 | 25 | 0.9 | 170 |

| Carbon | 1550–6960 | 159–965 | 2.5–3.2 | 1.8 | over 3000 |

| Basalt | 872–2800 | 40–89 | 3.15 | 2.8 | 1500–1700 |

4. Fresh Properties

The fresh properties of 3DPC mostly pertain to workability performance. Workability performance includes fluidity, cohesiveness, and water retention. By incorporating fibers into the 3DPC mixtures, it is possible to avoid spalling, restrict deformation and achieve a uniform and continuous printing sample. Furthermore, the key to determining whether the concrete can be continuously and evenly extruded and ensure pouring molding is to manage its thixotropy and setting time due to the needs of the concrete printing process. In addition, it is essential to note that fiber content can block the nozzle when it reaches a sensitive volume [2]. The summarized information about different types of tests in order to determine the fresh concrete properties and their results of them are shown in Table 2.

4.1. Influence of the Steel Fibers

The fresh properties of 3DPC reinforced with steel fibers, length of 13 mm, diameter of 0.2 mm and density of 8.7 kg/m3, at the contents of 0.25, 0.5, 0.75 and 1 wt.%, were investigated by Singh et al. [52]. In this study, the researchers used natural river sand with a particle size smaller than 1.18 mm and nano clay (nC). The results about the slump flow demonstrated that with the addition of steel fibers, the slump flow decreased. Additionally, when the fiber ratio increased, the slump flow at an early age compared with the control specimen reduced by 4.76, 5.71, 5.71 and 6.61% for specimens that contain 0.25, 0.5, 0.75 and 1 wt.% fibers, respectively. Moreover, adding nano clay increased structural rebuilding during the extrusion of 3DPC because it behaved as an interlocked web, leading to increase in friction and adhesion among particles.

Yang et al. investigated the printing quality of 3D printed ultra-high-performance fiber-reinforced concrete 3DPUHPFRC [53]. The two kinds of round copper-plated steel fibers with a length of 6 and 10 mm were used in the research. Moreover, using the fly ash improved the workability and durability of 3DPC [53]. In this study, the researchers used 24 kg/m3 nano calcium carbonate in the mix ratio of 3DPUHPFRC so as to improve the properties of the 3D printed paste. The results about the quality of printability illustrated that the 3DPUHPFRC without steel fibers had better quality than that with 1 vol.% 6 mm and 1 vol.% 10 mm steel fibers. This outcome was caused by the difficulties that 3DPUHPFRC had when extruding steel fibers from the nozzle.

4.2. Influence of the PE Fibers

Ye et al. investigated the workability and buildability of 3D printed ultra-high ductile concrete (3DPUHDC) reinforced by PE fibers (1.0, 1.5, and 2.0 vol.%) [54]. 3DPUHDC is a particular type of concrete that is made for its better tensile strain capacity [55][56][57][58][59]. In this research, spread diameter and penetration depth were used in order to evaluate workability. The spread diameter and penetration depth figures for the specimens with 1 vol.% fibers were 169 and 86 mm, respectively. The spread diameter for the samples with 2 vol.% fibers was 144 mm, and the penetration depth was 76 mm. For evaluating printability, the overall height of the 10-layer was measured. The height of the 10-layer printed samples with 2 and 1 vol.% fibers were 99 and 97 mm, respectively. It was determined that a reduction in the workability occurred because more and more twisted fiber orientation was noticed as the fiber concentration was raised to 1.5 and 2 vol.%.

4.3. Influence of the Glass Fibers

Li et al., investigated the workability and buildability of 3DPC reinforced by glass fibers (up to 0.61 vol.%) [60]. In this research, 3DPC was made from coral sand. In addition, seawater was used for creating 3DPC samples. Freshwater is scarce in remote islands and coastal areas, and shipping from the mainland is prohibitively expensive, posing a significant barrier to concrete manufacturing in these isolated places. In such a case, using saltwater may be a viable option [61][62][63][64]. The flow table test was used for workability and buildability; the height of 3DPC was measured. Adding 0.6 vol.% glass fibers reduced the flow diameter and the average height of printed samples by 11 and 11.7 mm, respectively [60]. Chu et al., demonstrated that adding 0.5 vol.% glass fibers into 3D printed high-strength fiber-reinforced concrete (3DPHSFRC) decreased the slump flow and flow diameter by less than 10% [65]. 3DPHSFRC can be engineered to have high tensile strength and flexibility. Moreover, researchers can replace all steel bars with fibers in 3DPHSFRC [66][67][68][69].

4.4. Influence of the PVA Fibers

Sun et al. conducted research that added 0.8, 1, 1.2, 1.4 and 1.6 vol.% PVA fibers in the 3D printed paste [70]. The results about the fluidity illustrated that the addition of PVA fibers decreased the fluidity of the mixture so that the fluidity of the mixture with 0.8 vol.% of PVA fibers was 21% more than that of mixtures with 1.6 vol.% of PVA fibers. In this regard, other scholars concluded that a higher amount of fibers reduced the fluidity because of interlocking and entangling among fibers in mixtures [71][72].

Zhang and Aslani added 1 and 1.5 vol.% PVA fibers and 0.5 and 1 wt.% activated carbon powder in order to determine the optimum mix design [73]. The results of the slump flow of mixtures illustrated that adding more PVA fibers reduced the slump flow. The main reason for this result is that the addition of fibers restricted the movement of aggregates; hence, the slump flow was reduced. The slump flow of mixtures with no PVA fibers was 57% and 44% higher than mixtures with 1 and 1.5 vol.% PVA fibers, respectively.

Sun et al. investigated the 3D printed lightweight engineered cementitious composites by incorporating 1.75% PVA fibers by mass ratio to cement [74]. The slump flow results illustrated that the mixtures’ slump flow with 1.75% of PVA was reduced compared to those without fibers. The slump flow of the mixtures without fibers was 80% higher than that of mixtures with 1.75 wt.% fibers. The PVA fibers also decreased the setting time in comparison with mixtures without fibers. Another scholar asserted that this matter is due to fibers overlapping, making a network with each other and causing a reduction in the setting time [75].

The rheological properties of fresh Engineered Cementitious Composite (ECC) are essential in its application in 3DPC. The rheological behaviors determine the pumping ability, extrudability and buildability of 3DP-ECC samples [76][77]. In this regard, Yu et al. evaluated the rheological properties of 3DP-ECC with 26 kg/m3 PVA fibers, 1026 kg/m3 fly ash, 345 kg/m3 silica sand and 30 kg/m3 ordinary cement [78]. The results showed that spread flow decreased with time. In this case, the results of the shape retention test demonstrate that with passing time, the ability of the mixture in buildability and shape retention test increased.

4.5. Influence of the PP Fibers

The effect of adding PP fibers on the fresh properties of 3DPC was investigated by Tran et al. [79]. In this research, the content of PP fibers varied from 1.35 to 5.4 kg/m3. This research used the Bingham model to evaluate the plastic viscosity and the dynamic yield stress [80]. The specimens with 0.22 water-to-binder ratio and 5.4 kg/m3 PP fibers had 282.3 3 Pa viscosity and 1207.6 Pa dynamic yield stress. It was stated that adding PP fibers increased the plastic viscosity and the dynamic yield stress by nearly 400% and 320%, respectively, because the friction of the particles in the fresh concrete immediately influenced the dynamic yield stress and plastic viscosity.

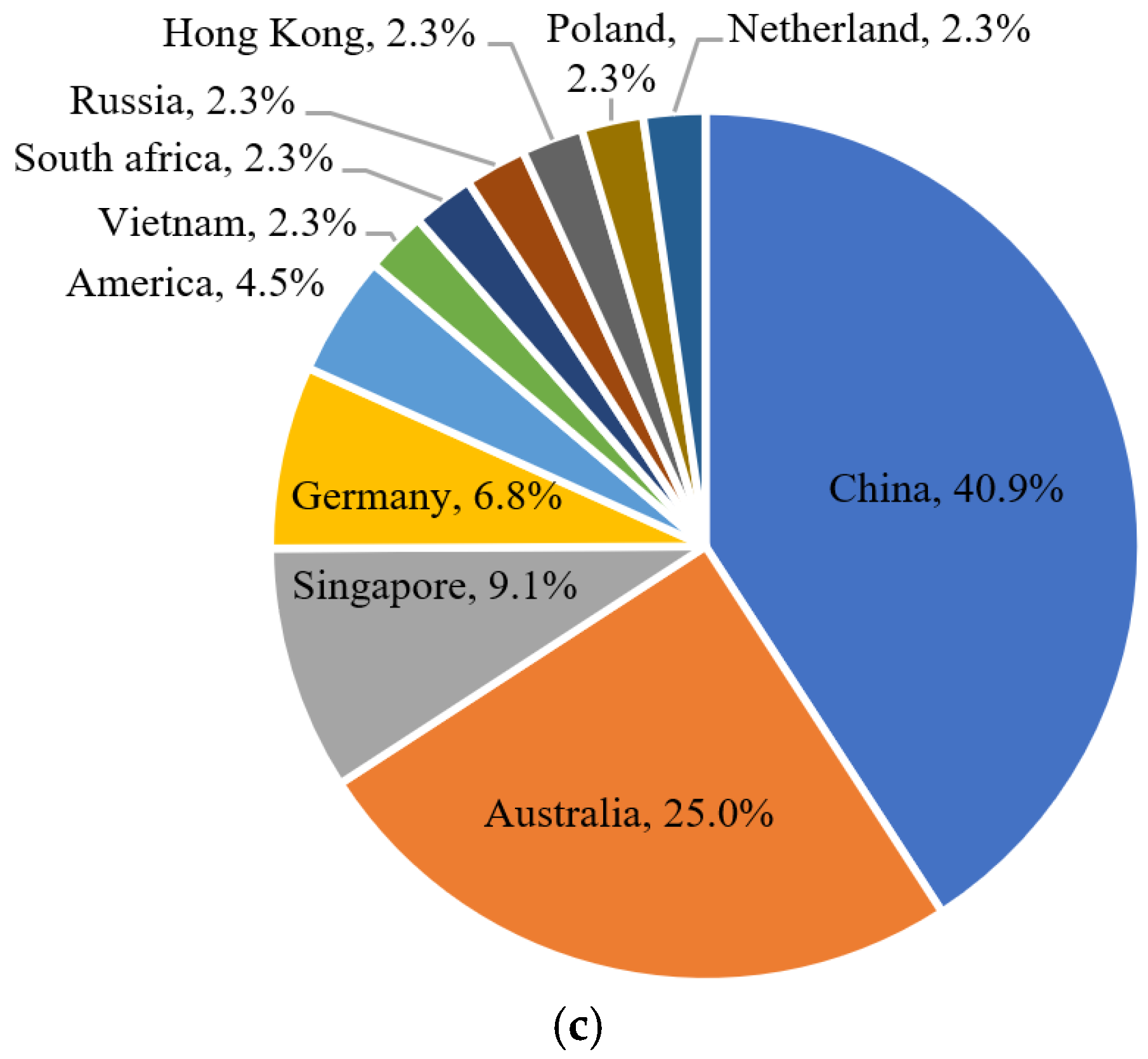

Furthermore, PP fibers served as the needle aggregate in fresh concrete. Thus, adding more PP fibers increased the needle aggregate, resulting in high friction among aggregates. Figure 3 shows the 3DPC samples in this research.

Figure 3. 3DPC samples. (a) The 3DPC mixture with low flowability; (b) The 3DPC mixture with excessive flowability; (c) The 3DPC mixture with proper printability and flowability; (d) The 3DPC mixture with low printability and flowability.

4.6. Influence of the Other Fibers

Chu et al. added 0.5 vol.% carbon fibers into 3DPHSFRC and discovered that slump and flow diameter decreased by less than 5% [65]. Li et al. investigated the effect of basalt fibers (0.21, 0.22, 0.42, 0.43, 0.64, 0.65, 0.85 and 0.86 vol.%) on 3DPC. The addition of 0.85 vol.% basalt fibers decreased the flow diameter from 178 to 162 mm. Conversely, the addition of 0.85 vol.% basalt fibers increased buildability from 52.3 to 52.5 mm [60].

4.7. Discussion about Fresh Properties of 3DPC

Table 2 compares the impact of various fiber types on the 3DPC’s fresh properties. In this table, the percentage, specifications, and types of fibers are shown. In addition, tests and a summary of the results are provided in Table 2.

Table 2. Comparison of 3DPC mixtures’ fresh properties.

| Fibers | 3DPC Mixtures | Fiber-Reinforced 3DPC | Ref. | ||||

|---|---|---|---|---|---|---|---|

| Type | Length | Diameter | Type | Amount of Fiber (%) | Tests | Results Summary | |

| Steel | 13 mm | 200 µm | 3DPC | 0.25, 0.5, 0.75 and 1 vol.% | Slump flow | The slump flow decreased by increasing the fiber content. | [52] |

| Steel | 6 and 10 mm | 120 µm | 3DPUHPFRC | 0.25, 0.5, 0.75 and 1 vol.% | Buildability | Mixtures without fibers had more uniform printing than mixtures with fibers. | [53] |

| Steel | 13 mm | 200 µm | 3DPHSFRC | 0.5 vol.% | Slump flow | The flow diameter of mixtures with steel fibers was less than that of mixtures without fibers. | [65] |

| PP | 6 mm | 50 µm | 3DPC | 0.25, 0.5, 0.75, 1, 1.25, 1.5 and 2 vol.% | Viscoelasticity by shear stress | The viscous module increased when the content of fibers increased. |

[71] |

| PP | 6 mm | - | 3DPC | 1.18 kg/m3 | Layer settlement and cylinder stability | There was no visible deformation in the PP fiber mixtures in the layer settlement test. In the cylinder stability test, the average deformation for mixtures containing PP fibers was 31.3 mm. |

[76] |

| PP | 6 mm | 30 µm | 3DPC | 1.25, 2.7, 54 kg/m3 | Plastic viscosity and yield stress | The dynamic yield stress increased at equal water-to-binder ratio and superplasticizer dosage with increasing the pp fibers. | [79] |

| PVA | 9 mm | 31 µm | 3DPC | 0.8, 1, 1.2, 1.4 and 1.6 vol.% | Flowability | Flowability was reduced by adding PVA fibers. | [70] |

| PVA | 6 mm | 31 µm | 3DPC | 0.25, 0.5, 0.75, 1, 1.25, 1.5 and 2 vol.% | Viscoelasticity by shear stress | The viscous module increased when the content of fibers increased. | [71] |

| PVA | 12 mm | 39 µm | 3DPC | 1 and 1.5 vol.% | Slump flow | The slump flow decreased by adding fibers. | [73] |

| PVA | 18 mm | 39 µm | 3DPLWECC | 1.75 wt.% | Slump flow and setting time | Both slump flow and setting time were reduced by adding fibers. | [74] |

| PVA | 8 mm | 39 µm | 3DP-ECC | 2 vol.% | Flowability and shape retention | Flowability and shape retention decreased by increasing the time after water addition. |

[78] |

| Glass | 12 mm | 14–19 µm | 3DPC | 0.20, 0.21, 0.40, 0.41, 0.60 and 0.61 vol.% | Flow diameter | Increasing the fiber content reduced flow diameter, yet the flow diameter of mixtures with 0.20 vol.% was 9% more than of those without fibers. |

[60] |

| Glass | 12 mm | 7 µm | 3DPHSFRC | 0.5 vol.% | Buildability and slump flow | The flow diameter of mixtures with glass fibers was less than of those without fibers. | [65] |

| Basalt | 12 mm | 13 µm | 3DPC | 0.21, 0.22, 0.42, 0.43, 0.64, 0.65, 0.85 and 0.86 vol.% | Flow diameter | Increasing the fiber content reduced the flow diameter of mixtures. | [60] |

| Carbon | 6 mm | 7 µm | 3DPHSFRC | 0.5 vol.% | Buildability and slump flow | In the buildability test, more extrusion pressure was needed for the mixtures with carbon fibers. Slump flow: the flow diameter of mixtures with carbon fibers was less than of those without fibers. |

[65] |

| PE | 12 mm | 25 µm | 3DPUHDC | 10, 15 and 20 kg/m3 | Spread diameter and penetration depth |

Both spread diameter and penetration depth decreased with increasing the fiber content. |

[54] |

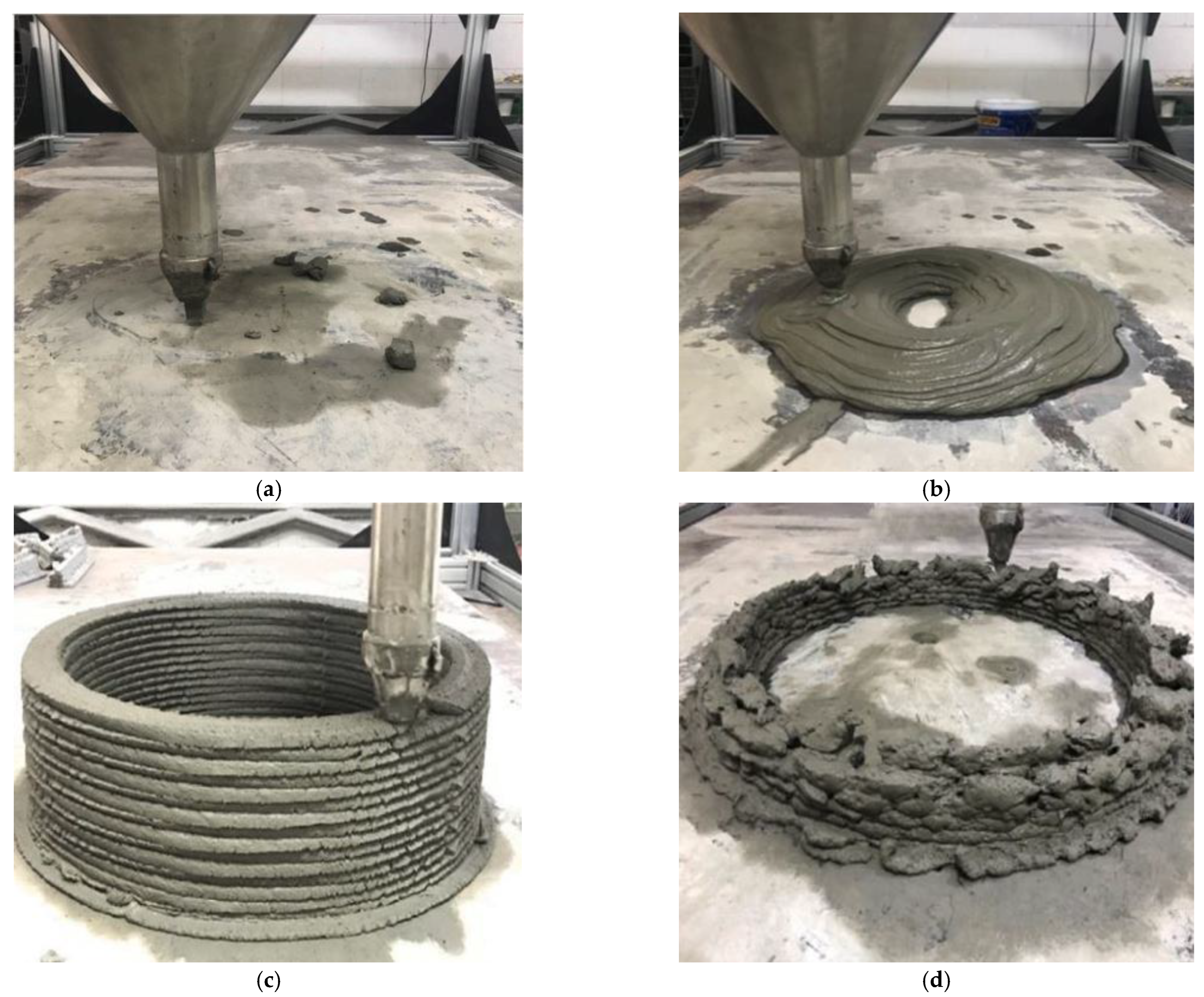

In most studies, the slump flow test was used for measuring the fresh properties of 3DPC because it is easy to operate and it contains valuable results. As a result, Figure 4 displays the effect of types and percentages of fibers on the slump flow test. As it is seen, the results show that the amount of slump flow for most 3DPC reinforced with fibers was in the range of 150–200 mm, which is consistent with the researchers’ findings.

Figure 4. Effect of types and percentage of fibers on the slump flow.

Additionally, the slump flow values and fiber percentage results show that the excessive amount of fibers reduced the slump flow, which can reduce the efficiency of 3DPC, but this is not always the case. The 3DPC’s fiber type selection is crucial and may have a negative impact. Basalt and glass fibers seem to improve the slump flow, whereas steel, PE, and PVA decrease it. Based on the fiber type, the rate of changes in the slump flow will also vary. The findings indicate that PVA fibers had a larger slump flow reduction rate than PE and steel fibers. In addition, compared to basalt fibers, the rate of slump flow increased more rapidly for glass fibers.

For steel and basalt fibers, changes in the rate of slump flow were less than 5%, which shows the fiber percentage cannot substantially alter the slump flow. Regarding PE, glass, and PVA fibers, the rate of change in the slump flow was higher and in the range of 25–35%. Finally, PVA fibers seem to have the highest impact on slump flow, while steel fibers have the least impact. Moreover, in most cases, adding fibers generally improved the buildability of mixtures, which is one of the main characteristics of 3DPC.

This entry is adapted from the peer-reviewed paper 10.3390/buildings13040945

References

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443.

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; de Oliveira, A.P.N. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833.

- Xu, J.; Ding, L.; Love, P.E. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Autom. Constr. 2017, 76, 85–96.

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19.

- Nguyen-Van, V.; Panda, B.; Zhang, G.; Nguyen-Xuan, H.; Tran, P. Digital design computing and modelling for 3-D concrete printing. Autom. Constr. 2021, 123, 103529.

- Panda, B.; Lim, J.H.; Mohamed, N.A.N.; Paul, S.C.; Tay, Y.W.D.; Tan, M.J. Automation of robotic concrete printing using feedback control system. In Proceedings of the ISARC, International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017.

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1, 64–76.

- Lowke, D.; Dini, E.; Perrot, A.; Weger, D.; Gehlen, C.; Dillenburger, B. Particle-bed 3D printing in concrete construction–possibilities and challenges. Cem. Concr. Res. 2018, 112, 50–65.

- Pegna, J. Exploratory investigation of solid freeform construction. Autom. Constr. 1997, 5, 427–437.

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232.

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319.

- Federowicz, K.; Kaszyńska, M.; Zieliński, A.; Hoffmann, M. Effect of curing methods on shrinkage development in 3D-printed concrete. Materials 2020, 13, 2590.

- Tiberti, G.; Mudadu, A.; Barragan, B.; Plizzari, G. Shrinkage Cracking of Concrete Slabs-On-Grade: A Numerical Parametric Study. Fibers 2018, 6, 64.

- Sayahi, F. Plastic Shrinkage Cracking in Concrete: Mitigation and Modelling; Luleå University of Technology: Luleå, Sweden, 2019.

- Moelich, G.; Kruger, P.; Combrinck, R. A plastic shrinkage cracking risk model for 3D printed concrete exposed to different environments. Cem. Concr. Compos. 2022, 130, 104516.

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886.

- Ramesh, B.; Eswari, S. Mechanical behaviour of basalt fibre reinforced concrete: An experimental study. Mater. Today Proc. 2021, 43, 2317–2322.

- Kang, S.-T.; Choi, J.-I.; Koh, K.-T.; Lee, K.S.; Lee, B.Y. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Compos. Struct. 2016, 145, 37–42.

- Larisa, U.; Solbon, L.; Sergei, B. Fiber-reinforced concrete with mineral fibers and nanosilica. Procedia Eng. 2017, 195, 147–154.

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808.

- Solhmirzaei, R.; Kodur, V. Modeling the response of ultra high performance fiber reinforced concrete beams. Procedia Eng. 2017, 210, 211–219.

- Banthia, N.; Nandakumar, N. Crack growth resistance of hybrid fiber reinforced cement composites. Cem. Concr. Compos. 2003, 25, 3–9.

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267.

- Huang, K.; Deng, M.; Mo, L.; Wang, Y. Early age stability of concrete pavement by using hybrid fiber together with MgO expansion agent in high altitude locality. Constr. Build. Mater. 2013, 48, 685–690.

- Yang, L.; Lin, X.; Gravina, R. Evaluation of dynamic increase factor models for steel fibre reinforced concrete. Constr. Build. Mater. 2018, 190, 632–644.

- Yang, L.; Lin, X.; Li, H.; Gravina, R. A new constitutive model for steel fibre reinforced concrete subjected to dynamic loads. Compos. Struct. 2019, 221, 110849.

- Yang, L.; Qi, C.; Lin, X.; Li, J.; Dong, X. Prediction of dynamic increase factor for steel fibre reinforced concrete using a hybrid artificial intelligence model. Eng. Struct. 2019, 189, 309–318.

- Corinaldesi, V.; Nardinocchi, A. Influence of type of fibers on the properties of high performance cement-based composites. Constr. Build. Mater. 2016, 107, 321–331.

- He, H.A.; Dong, W.; Wu, Z.M. Study on long-term expansive deformation of self-stressing concrete with combined restrictions of steel fibers and steel bar. Key Eng. Mater. 2011, 452, 533–536.

- Gong, J.; Zeng, W.; Zhang, W. Influence of shrinkage-reducing agent and polypropylene fiber on shrinkage of ceramsite concrete. Constr. Build. Mater. 2018, 159, 155–163.

- Bertelsen, I.; Ottosen, L.; Fischer, G. Influence of fibre characteristics on plastic shrinkage cracking in cement-based materials: A review. Constr. Build. Mater. 2020, 230, 116769.

- Soroushian, P.; Mirza, F.; Alhozajiny, A. Plastic shrinkage cracking of polypropylene fiber reinforced concrete. Mater. J. 1993, 92, 553–560.

- Voigt, T.; Bui, V.K.; Shah, S.P. Drying shrinkage of concrete reinforced with fibers and welded-wire fabric. Mater. J. 2004, 101, 233–241.

- Banthia, N.; Yan, C.; Mindess, S. Restrained shrinkage cracking in fiber reinforced concrete: A novel test technique. Cem. Concr. Compos. 1996, 26, 9–14.

- Güneyisi, E.; Gesoğlu, M.; Mohamadameen, A.; Alzeebaree, R.; Algın, Z.; Mermerdaş, K. Enhancement of shrinkage behavior of lightweight aggregate concretes by shrinkage reducing admixture and fiber reinforcement. Constr. Build. Mater. 2014, 54, 91–98.

- Koh, K.; Ryu, G.; Kang, S.; Park, J.; Kim, S. Shrinkage properties of ultra-high performance concrete (UHPC). Adv. Sci. Lett. 2011, 4, 948–952.

- Ríos, J.D.; Leiva, C.; Ariza, M.; Seitl, S.; Cifuentes, H. Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater. Des. 2019, 165, 107582.

- Zheng, W.; Luo, B.; Wang, Y. Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures. Constr. Build. Mater. 2013, 41, 844–851.

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Bong, S.H.; Sanjayan, J.G.; Khayat, K.H. Fiber orientation effects on ultra-high performance concrete formed by 3D printing. Cem. Concr. Res. 2021, 143, 106384.

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77.

- Goldfeld, Y.; Rabinovitch, O.; Fishbain, B.; Quadflieg, T.; Gries, T. Sensory carbon fiber based textile-reinforced concrete for smart structures. J. Intell. Mater. Syst. Struct. 2016, 27, 469–489.

- Chen, M.; Gao, P.; Geng, F.; Zhang, L.; Liu, H. Mechanical and smart properties of carbon fiber and graphite conductive concrete for internal damage monitoring of structure. Constr. Build. Mater. 2017, 142, 320–327.

- Sassani, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Arabzadeh, A.; Taylor, P. Influence of mix design variables on engineering properties of carbon fiber-modified electrically conductive concrete. Constr. Build. Mater. 2017, 152, 168–181.

- Korniejenko, K.; Łach, M.; Chou, S.-Y.; Lin, W.-T.; Cheng, A.; Hebdowska-Krupa, M.; Gądek, S.; Mikuła, J. Mechanical properties of short fiber-reinforced geopolymers made by casted and 3D printing methods: A comparative study. Materials 2020, 13, 579.

- Hambach, M.; Rutzen, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. In 3D Concrete Printing Technology; Elsevier: Oxford, UK, 2019; pp. 73–113.

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149.

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314.

- Yang, E.-H.; Li, V.C. Strain-hardening fiber cement optimization and component tailoring by means of a micromechanical model. Constr. Build. Mater. 2010, 24, 130–139.

- Yu, K.-Q.; Yu, J.-T.; Dai, J.-G.; Lu, Z.-D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227.

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288.

- Cao, M.; Xu, L.; Zhang, C. Review on micromechanical design, performance and development tendency of engineered cementitious composite. J. Chin. Ceram. Soc. 2015, 43, 632–642.

- Singh, A.; Liu, Q.; Xiao, J.; Lyu, Q. Mechanical and macrostructural properties of 3D printed concrete dosed with steel fibers under different loading direction. Constr. Build. Mater. 2022, 323, 126616.

- Yang, Y.; Wu, C.; Liu, Z.; Wang, H.; Ren, Q. Mechanical anisotropy of ultra-high performance fibre-reinforced concrete for 3D printing. Cem. Concr. Compos. 2022, 125, 104310.

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dong, F. Effect of polyethylene fiber content on workability and mechanical-anisotropic properties of 3D printed ultra-high ductile concrete. Constr. Build. Mater. 2021, 281, 122586.

- Ma, H.; Zhang, Z. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance. Constr. Build. Mater. 2020, 252, 119048.

- Zhang, Z.; Yuvaraj, A.; Di, J.; Qian, S. Matrix design of light weight, high strength, high ductility ECC. Constr. Build. Mater. 2019, 210, 188–197.

- Wang, Y.; Liu, F.; Yu, J.; Dong, F.; Ye, J. Effect of polyethylene fiber content on physical and mechanical properties of engineered cementitious composites. Constr. Build. Mater. 2020, 251, 118917.

- Wang, Y.; Zhang, Z.; Yu, J.; Xiao, J.; Xu, Q. Using green supplementary materials to achieve more ductile ECC. Materials 2019, 12, 858.

- Zhang, Z.; Hu, J.; Ma, H. Feasibility study of ECC with self-healing capacity applied on the long-span steel bridge deck overlay. Int. J. Pavement Eng. 2019, 20, 884–893.

- Li, L.; Xiao, B.; Fang, Z.; Xiong, Z.; Chu, S.; Kwan, A. Feasibility of glass/basalt fiber reinforced seawater coral sand mortar for 3D printing. Addit. Manuf. 2021, 37, 101684.

- Younis, A.; Ebead, U.; Suraneni, P.; Nanni, A. Fresh and hardened properties of seawater-mixed concrete. Constr. Build. Mater. 2018, 190, 276–286.

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt-and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218.

- Yang, S.; Xu, J.; Zang, C.; Li, R.; Yang, Q.; Sun, S. Mechanical properties of alkali-activated slag concrete mixed by seawater and sea sand. Constr. Build. Mater. 2019, 196, 395–410.

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Structural performance of FRP confined seawater concrete columns under chloride environment. Compos. Struct. 2019, 216, 12–19.

- Chu, S.; Li, L.; Kwan, A. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617.

- Lampropoulos, A.; Paschalis, S.A.; Tsioulou, O.; Dritsos, S.E. Strengthening of reinforced concrete beams using ultra high performance fibre reinforced concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384.

- Yu, K.; Li, L.; Yu, J.; Xiao, J.; Ye, J.; Wang, Y. Feasibility of using ultra-high ductility cementitious composites for concrete structures without steel rebar. Eng. Struct. 2018, 170, 11–20.

- Kwan, A.; Chu, S. Direct tension behaviour of steel fibre reinforced concrete measured by a new test method. Eng. Struct. 2018, 176, 324–336.

- Chu, S.; Kwan, A. Mixture design of self-levelling ultra-high performance FRC. Constr. Build. Mater. 2019, 228, 116761.

- Sun, X.; Zhou, J.; Wang, Q.; Shi, J.; Wang, H. PVA fibre reinforced high-strength cementitious composite for 3D printing: Mechanical properties and durability. Addit. Manuf. 2022, 49, 102500.

- Chen, M.; Yang, L.; Zheng, Y.; Li, L.; Wang, S.; Huang, Y.; Zhao, P.; Lu, L.; Cheng, X. Rheological behaviors and structure build-up of 3D printed polypropylene and polyvinyl alcohol fiber-reinforced calcium sulphoaluminate cement composites. J. Mater. Res. Technol. 2021, 10, 1402–1414.

- Teixeira, R.S.; Santos, S.F.d.; Christoforo, A.L.; Savastano Jr, H.; Lahr, F.A.R. Extrudability of cement-based composites reinforced with curauá (Ananas erectifolius) or polypropylene fibers. Constr. Build. Mater. 2019, 205, 97–110.

- Zhang, Y.; Aslani, F. Development of fibre reinforced engineered cementitious composite using polyvinyl alcohol fibre and activated carbon powder for 3D concrete printing. Constr. Build. Mater. 2021, 303, 124453.

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121.

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473.

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647.

- Mechtcherine, V.; Nerella, V.N.; Kasten, K. Testing pumpability of concrete using Sliding Pipe Rheometer. Constr. Build. Mater. 2014, 53, 312–323.

- Yu, K.; McGee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388.

- Tran, M.V.; Cu, Y.T.; Le, C.V. Rheology and shrinkage of concrete using polypropylene fiber for 3D concrete printing. J. Build. Eng. 2021, 44, 103400.

- Koehler, E.P.; Fowler, D.W.; Ferraris, C.F.; Amziane, S. A new, portable rheometer for fresh self-consolidating concrete. Aci Spec. Publ. 2005, 233, 97.

This entry is offline, you can click here to edit this entry!