Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Food Science & Technology

An efficient microbiological decontamination protocol is required to guarantee safe food products for the final consumer to avoid foodborne illnesses. Ultrasound and non-thermal technology combinations represent innovative methods adopted by the food industry for food preservation and safety. Ultrasound power is commonly used with a frequency between 20 and 100 kHz to obtain an “exploit cavitation effect”. Microbial inactivation via ultrasound derives from cell wall damage, the oxidation of intracellular amino acids and DNA changing material.

- ultrasound

- hurdle technologies

- foodborne pathogens

1. Introduction

The European Food Safety Authority (EFSA) reported 5175 foodborne outbreaks from 2015 to 2019 [1]; the Centers for Disease Control and Prevention (CDC) publishes yearly reports that highlight interesting data: 48 million people become ill due to foodborne diseases (128,000 are hospitalized, with 3000 deaths [2]). Due to the increase in outbreak numbers, it is necessary to develop efficient food chain surveillance and adequate microbiological decontamination protocols to guarantee safe food products for consumers. To achieve safety and genuineness, food processing technologies represent essential tools for microbiological control and products’ shelf-life enhancement [3,4]. Due to consumers’ growing requests for “minimally processed products”, the food industry applies new technologies to produce safe food matrices that maintain “fresh-like” characteristics [5].

Indeed, in conventional technologies, such as thermal treatments, this concept is not applicable: pasteurization and sterilization, commonly used in food industries, cause color alterations, characteristic flavors and a decrease in nutritional value [6,7,8].

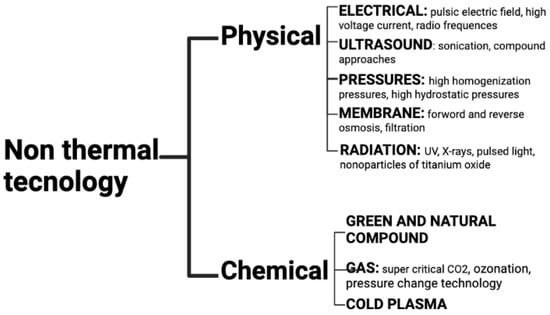

Therefore, the food industry and scientific researchers have evaluated alternative non-thermal technologies (NTTs) that maintain the aroma, nutrient value, texture and color while decreasing bacteria that cause spoilage. Tiwari and coworkers defined NTTs as procedures, performed at efficient sublethal or ambient temperatures, that lead to minimal or no impacts on nutritional and quality food parameters [9] (see Figure 1).

Figure 1. Overview of non-thermal technologies (created with Biorender.com).

2. Ultrasound: Mechanisms of Action Applied in Food Industry

Ultrasound is a form of vibrational energy produced by a transducer converting electrical energy into acoustic energy. It is a wave that exceeds the human hearing threshold [10]. Basing on the frequency, ultrasound can be classified as follows: power ultrasound (20–100 kHz), high-frequency ultrasound (100 kHz–1 MHz), and diagnostic ultrasound (1–500 MHz) [11]. At medium frequencies (200–500 kHz), chemical effects are prevalent, and collapse is less violent. On the other hand, at high frequencies (>1 MHz), chemical and physical effects decrease and cavitation is minimal; in this case, acoustic flow is predominant [11,12]. In the food industry, power ultrasound is commonly used with a frequency between 20 and 100 kHz to obtain an “exploit cavitation effect” [13]. The molecules are compressed and rarefactive when ultrasound is spread through any medium. Alternative pressure changes cause bubble formation in a liquid medium. There are physical and chemical effects correlated with ultrasound: agitation, vibration, pressure, shock waves, shear forces, microjets, compression and rarefaction, acoustic streaming, cavitation, and the formation of free radicals [14].

This phenomenon of the creation of small vapor bubbles (cavities), expansion, and implosive collapse in ultrasonically irradiated liquids is named “acoustic cavitation” [13,15,16]. There are two types of bubbles: transient and stable [17]. Under ultrasound action, bubbles oscillate, grow, and collapse asymmetrically, forming microjets. Outburst produces pressure shocks up to several 1000 atm, strong shock waves with 400 km/h microjets, and the production of hot spots with a 5000 K temperature; the mechanical effects predominate over the chemical ones [18,19]. In the reaction environment, three different phases have been identified: inside the bubble cavity gas environment, the liquid–bubble interface, and the liquid. In the first phase, there are pyrolysis reactions. In the second and third ones, radicals can occur. In the aqueous environment, the most frequently encountered phenomenon is the formation of the hydroxide radical OH-. It is highly reactive and attacks organic substrates or OH- and recombines with another OH- radical, forming H2O2. In the interphase area, the temperature is very high; therefore, the occurring reactions are thermal degradation and solute reactions with OH- radicals. Small bubbles are generated by the diffusion of these radicals due to the cavitation bubble’s disruption. In the interphase zone or in liquid nonvolatile solutes, reactive and volatile solids penetrate the bubble and degrade during collapse [19]. Physical and chemical effects are the basis for ultrasound’s application in the food industry [12].

New technologies, such as as vacuum cooling technology, high-pressure processing, ultrasound, and pulsed electric field technology, could guarantee safe and high-quality products. The aim of these new technologies is to reduce processing times, save energy and solvents, and improve the products’ shelf-life. From a “green” methodological point of view, ultrasound-assisted extraction has huge potential as an emergent and innovative technology. It has a low environmental impact, due to decreasing CO2 emissions, reducing time, and not presenting toxic effects towards human health [20]. There are two types of ultrasound systems applied in the food industry: contact and non-contact [21]. The first one employs liquids as transmission media and generates waves that have chemical and physical effects in food matrices. This technology is employed for different activities: the extraction of bioactive substances [22], the enhancement of drying rates [23] and freezing rates [24], the degassing of liquids [25], fat separation [26], power hydration [27], the intensification of heat and mass transfer [28], emulsification [29], and liquid food pasteurization [30,31]. Nevertheless, when using this technology, erosion could produce effects on the radiating surfaces and cause the consequent contamination of sonicated food [32]. However, new inert materials such as quartz, Pyrex, ceramics, and polyether could limit the use of metal horns, which are instruments used to evaluate ultrasonic irradiation in different materials (see Table 1).

Table 1. Use of ultrasound in food industry: mechanisms, advantages, products.

| Application | Conventional Method | Advantages | Ultrasound Principle | Products | Reference |

|---|---|---|---|---|---|

| Cutting | Knife | Small deformation Less cracks and crumbling |

Cavitation phenomenon | Fragile and frozen foods Viscoelastic products Heterogenous products |

[33] [34,35] [36] |

| Cooking | Stove Fried Water |

Homogeneous cooking Less time |

Uniform heat transfer |

Poultry Beef Vegetables Fruit Crustaceans |

[37,38] [39] [40] [39] [41] |

| Freezing | Ice | Less freezing time Homogeneous cooking Less damage to cells |

Cavitation Fragmentation of large ice crystals Triggering secondary ice nucleation |

Vegetables Meat Fish |

[42] [39] [43] |

| Drying | Hot gas streaming Pulverization |

Less time Improved heat transfer |

Uniform heat transfer | Vegetables Meat Fish Fruit |

[44] [45] [46] [47] |

| Pickling/marinating | Brine | Improved organoleptic quality Less time |

Uniform heat transfer Microchannel |

Meat Vegetables Cheese Fish |

[48] [49] [50] [51] |

| Tenderization | Time | Improved meat tenderization |

Acoustic cavitation | Meat Fish |

[52] [53] |

Wang and coworkers [39] underlined that US has a positive effect in decreasing frying times, in the improvement of cooking yields, and improving the sensory evaluation of meat. The major consequences of ultrasound’s irradiation within a liquid are cavitation and agitation. These two factors are useful in improving heat transfer and freezing rates and accelerating freezing processes [54,55]. In the last mentioned process, there are primary and secondary nucleations: the first allows crystal formation in a solution where crystals are not detected. Primary nucleation can take place in two categories: homogenous and heterogeneous. Homogeneous nucleation occurs when the nuclei are formed spontaneously from the random density fluctuation. On the other hand, heterogeneous nucleation occurs due to the presence of solid impurities that form stable surfaces for nuclei formation, and secondary nucleation takes place where pre-existing crystals are present [56]. Ultrasonic application improves drying in all food matrices [56,57].

There are many advantages: water is removed easily, improving water diffusion from the interior to the product surface; intracellular and extracellular cavitation provides new microchannels; US creates air turbulence to remove moisture; it accelerates the process without a temperature increase [57]. This technology can be employed as a pre-treatment: in fact, many authors underlined that US pre-treatment improved the drying period [58]. As previously mentioned, waves involve a rate mass transfer by physically breaking down tissues and the formation of microchannels [20]. Ozuna and coworkers [59] evaluated the improvement in solute distribution during marination, and changes in water retention capability. McDonnel et al. [60] also underlined the possibility of conserving food sensory properties through these methods.

Iguglia et al. [61] investigated how different US frequencies can influence chicken marination times in terms of meat quality, texture, and lipid oxidation.

The applicability of US in seafood products has been evaluated: Pedròs- Garrido et al. [62] investigated US usage (30 kHz for 5 to 45 min) in different fish (salmon, mackerel, cod, hake). They noticed a major reduction in microbiological spoilage in oily fish, due to having higher fat content, which impacted bacterial decontamination. After 45 min of US treatment, there was a reduction in thiobarbituric acid reactive substances; on the other hand, lipids did not show changes.

US has been used for the tenderization of fish: Chang and Wang [53] found that US application for 60 to 90 min in cobia (Rachycentron canadum) improved the time required for tenderizing compared with the traditional aging process and optimized the firmness.

Non-contact technology, known also as the “air-couple technique”, uses a medium to ensure a gap between the transducer and the foodstuff. However, there are some drawbacks, such as the mismatch of the acoustic impedance magnitude between air and matrices [63].

This entry is adapted from the peer-reviewed paper 10.3390/foods12061212

This entry is offline, you can click here to edit this entry!