Single-mode long-wavelength (LW) vertical-cavity surface-emitting lasers (VCSELs) present an inexpensive alternative to DFB-lasers for data communication in next-generation giga data centers, where optical links with large transmission distances are required. The use of long-wavelength (1300–1550 nm) single-mode (SM) VCSELs makes it possible to reduce the modal and chromatic dispersion in an optical link and, as a result, to extend its reach. Moreover, spatial division multiplexing (SDM) transmission by multicore fibers using long-wavelength (LW or short-wavelength infrared, SWIR) VCSELs are enabling many larger-scale data center networks than presently possible. 1300 nm VCSELs are of particularly strong importance for hybrid integration with silicon photonics, providing integrated modulators and InP- and GaAs-based integrated photonic circuits.

- vertical-cavity surface-emitting lasers (VCSELs)

- wafer bonding

- superlattices

- optical modulation

1. Introduction

2. Distributed Bragg Reflectors for the 1300–1550 nm Spectral Range

3. Monolithically Grown VCSELs on GaAs Substrates in the 1300–1550 nm Spectral Range

4. Monolithically Grown VCSELs on InP Substrates for the 1300–1550 nm Spectral Range

5. VCSELs with Hybrid (Metal-Dielectric) Distributed Bragg Reflectors

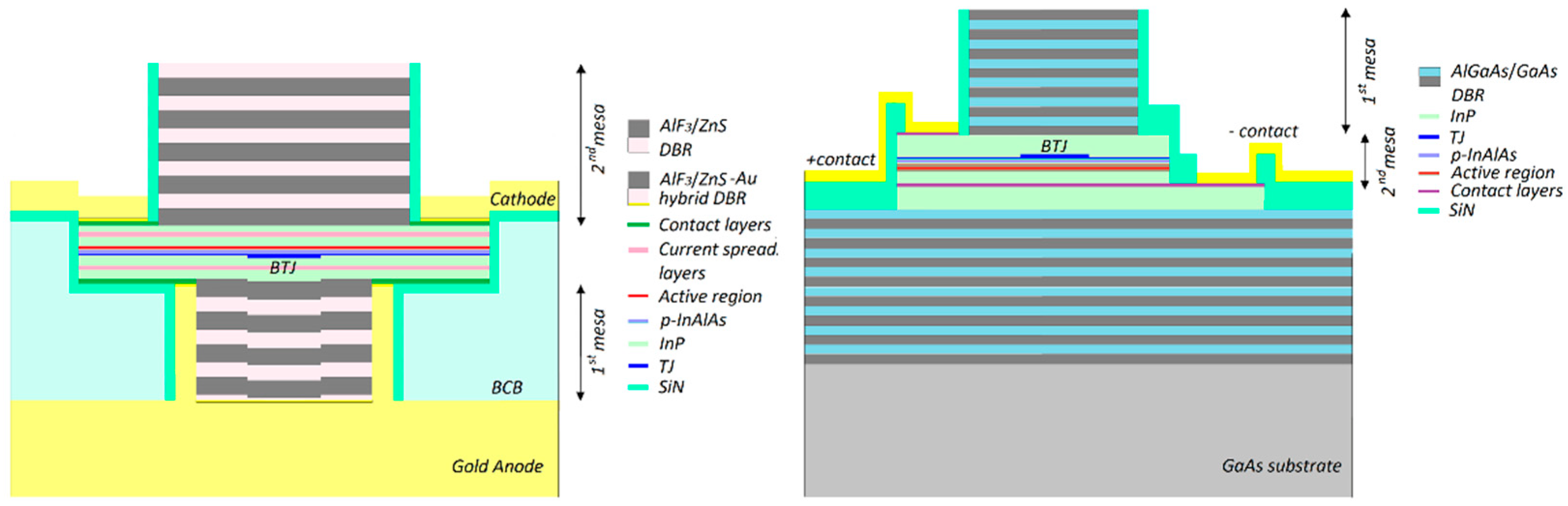

6. VCSELs Fabricated by Wafer Fusion

This entry is adapted from the peer-reviewed paper 10.3390/photonics10030268

References

- VCSEL Market to Grow at 19.2% CAGR from $1.6bn in 2022 to $3.9bn in 2027. Semicond. TODAY Compd. Adv. Silicon 2022, 17, 60–61. Available online: https://www.semiconductor-today.com/news_items/2022/sep/yole-210922.shtml (accessed on 23 January 2023).

- Zhang, L.; Van Kerrebrouck, J.; Lin, R.; Pang, X.; Udalcovs, A.; Ozolins, O.; Spiga, S.; Amann, M.-C.; Van Steenberge, G.; Gan, L.; et al. Nonlinearity Tolerant High-Speed DMT Transmission with 1.5-μm Single-Mode VCSEL and Multi-Core Fibers for Optical Interconnects. J. Light. Technol. 2019, 37, 380–388.

- Spiga, S.; Amann, M.C. High-Speed InP-Based Long-Wavelength VCSELs. In Green Photonics and Electronics; Eisenstein, G., Bimberg, D., Eds.; Springer: Cham, Switzerland, 2017; Volume 3, pp. 17–35.

- Babichev, A.; Blokhin, S.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Bobrov, M.; Maleev, N.; Andryushkin, V.; Kolodeznyi, E.; et al. Single-Mode High-Speed 1550 nm Wafer Fused VCSELs for Narrow WDM Systems. IEEE Photonics Technol. Lett. 2023, 35, 297–300.

- Paul, S.; Haidar, M.T.; Cesar, J.; Malekizandi, M.; Kögel, B.; Neumeyr, C.; Ortsiefer, M.; Küppers, F. Far-field, linewidth and thermal characteristics of a high-speed 1550-nm MEMS tunable VCSEL. Opt. Express 2016, 24, 13142.

- Haidar, M.T.; Preu, S.; Cesar, J.; Paul, S.; Hajo, A.S.; Neumeyr, C.; Maune, H.; Küppers, F. Systematic characterization of a 1550 nm microelectromechanical (MEMS)-tunable vertical-cavity surface-emitting laser (VCSEL) with 7.92 THz tuning range for terahertz photomixing systems. J. Appl. Phys. 2018, 123, 023106.

- Zogal, K.H. MEMS weit Abstimmbare VCSEL bei 1.55 µm und 1.95 µm. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 6 July 2016.

- Padullaparthi, B.D.; Tatum, J.A.; Iga, K. VCSEL Industry: Communication and Sensing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; p. 180.

- NIR VCSELs for Gas Analysis (TDLAS). Available online: https://www.vertilas.com/content/nir-vcsels-gas-analysis-tdlas (accessed on 21 February 2023).

- Blokhin, S.A.; Babichev, A.V.; Gladyshev, A.G.; Karachinsky, L.Y.; Novikov, I.I.; Blokhin, A.A.; Bobrov, M.A.; Maleev, N.A.; Andryushkin, V.V.; Denisov, D.V.; et al. High Power Single Mode 1300-nm Superlattice Based VCSEL: Impact of the Buried Tunnel Junction Diameter on Performance. IEEE J. Quantum Electron. 2022, 58, 1–15.

- Murty, M.V.R.; Wang, J.; Harren, A.L.; Cheng, A.-N.; Dolfi, D.W.; Feng, Z.-W.; Sridhara, A.; Joyo, S.T.; Chu, J.; Giovane, L.M. Development and Characterization of 100 Gb/s Data Communication VCSELs. IEEE Photonics Technol. Lett. 2021, 33, 812–815.

- Ruan, Z.; Zhu, Y.; Chen, P.; Shi, Y.; He, S.; Cai, X.; Liu, L. Efficient Hybrid Integration of Long-Wavelength VCSELs on Silicon Photonic Circuits. J. Light. Technol. 2020, 38, 5100–5106.

- Gębski, M.; Dontsova, D.; Haghighi, N.; Nunna, K.; Yanka, R.; Johnson, A.; Pelzel, R.; Lott, J.A. Baseline 1300 nm dilute nitride VCSELs. OSA Continuum 2020, 3, 1952–1957.

- Ohiso, Y.; Sato, T.; Shindo, T.; Matsuzaki, H. 1.3-µm buried-heterostructure VCSELs with GaAs/AlGaAs metamorphic DBRs grown by MOCVD. Electron. Lett. 2020, 56, 95–97.

- TRUMPF Industrializing High-Volume Production of InP-based SWIR VCSELs above 1300 nm. Semicond. TODAY Compd. Adv. Silicon 2023, 18, 48. Available online: https://www.semiconductor-today.com/news_items/2023/feb/trumpf-010223.shtml (accessed on 1 March 2023).

- Koerner, R.A.; Bader, S.; Herper, M.; Kischkat-Grimm, T.; Tempeler, J.; van der Lee, A.; Moench, H.; Pruijmboom, A.; Rodriguez, M.A.; Weichmann, U.; et al. Polarization multiplexing in VCSEL-arrays. In Proceedings of the SPIE Photonics West 2023, San Francisco, CA, USA, 28 January–2 February 2023; Available online: https://spie.org/photonics-west/presentation/Polarization-multiplexing-in-VCSEL-arrays/12439-1 (accessed on 21 February 2023).

- Francis, D.A.; Young, D.B.; Walker, J.; Verma, A.; Gold, D.; Decker, C. Monolithic 1310 nm buried heterostructure VCSEL using InGaAsP/InP DBR reflectors. In Proceedings of the Optics East, Boston, MA, USA, 23–26 October 2005; Volume 6013, p. 60130A.

- Miyamoto, T.; Uchida, T.; Yokouchi, N.; Iga, K. Surface emitting lasers grown by chemical beam epitaxy. J. Cryst. Growth 1994, 136, 210–215.

- Kim, J.K.; Hall, E.; Sjölund, O.; Almuneau, G.; Coldren, L.A. Room-temperature, electrically-pumped multiple-active-region VCSELs with high differential efficiency at 1.55 µm. Electron. Lett. 1999, 35, 1084–1085.

- Yang, W.; Gerke, S.A.; Zhu, L.; Chase, C.; Rao, Y.; Chang-Hasnain, C.J. Long-Wavelength Tunable Detector Using High-Contrast Grating. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 178–185.

- Lin, C.-K.; Bour, D.P.; Zhu, J.; Perez, W.H.; Leary, M.H.; Tandon, A.; Corzine, S.W.; Tan, M.R.T. High temperature continuous-wave operation of 1.3- and 1.55-μm VCSELs with InP/Air-Gap DBRs. IEEE J. Sel. Top. Quantum Electron. 2003, 9, 1415–1421.

- Feezell, D.; Johansson, L.A.; Buell, D.A.; Coldren, L.A. Efficient Modulation of InP-based 1.3-/spl mu/m VCSELs with AsSb-based DBRs. IEEE Photonics Technol. Lett. 2005, 17, 2253–2255.

- Lauer, C.; Ortsiefer, M.; Shau, R.; Rosskopf, J.; Böhm, G.; Meyer, R.; Amann, M. InP-based long-wavelength vertical-cavity surface-emitting lasers with buried tunnel junction. Phys. Status Solidi C 2004, 1, 2183–2209.

- Shau, R.; Ortsiefer, M.; Rosskopf, J.; Boehm, G.; Lauer, C.; Maute, M.; Amann, M.-C. Long-wavelength InP-based VCSELs with buried tunnel junction: Properties and applications. In Proceedings of the Integrated Optoelectronic Devices 2004, San Jose, CA, USA, 26–29 January 2004; Volume 5364.

- Ortsiefer, M.; Shau, R.; Boehm, G.; Koehler, F.; Rosskopf, J.; Amann, M.-C. Thermal Conductivity Analysis and Device Performance of 1.55 μm InGaAlAs/InP Buried Tunnel Junction VCSELs. Phys. Status Solidi A 2001, 188, 913–919.

- Boehm, G.; Ortsiefer, M.; Shau, R.; Koehler, F.; Meyer, R.; Amann, M.-C. AlGaInAs/InP-epitaxy for long wavelength vertical-cavity surface-emitting lasers. J. Cryst. Growth 2001, 227–228, 319–323.

- Hofmann, W. InP-Based Long-Wavelength VCSELs and VCSELs Arrays for High-Speed Optical Communication. Ph.D. Thesis, Technical University, München, Germany, 2009; p. 60. Available online: https://mediatum.ub.tum.de/node?id=679286 (accessed on 21 February 2023).

- Spiga, S.; Soenen, W.; Andrejew, A.; Schoke, D.M.; Yin, X.; Bauwelinck, J.; Boehm, G.; Amann, M.-C. Single-Mode High-Speed 1.5-μm VCSELs. J. Light. Technol. 2017, 35, 727–733.

- Meyer, R.; Meissner, P.; Amann, M.-C.; Zogal, K.; Nagel, R.D.; Gruendl, T.; Geiger, K.; Grasse, C.; Ortsiefer, M.; Mueller, M.; et al. High-Speed and high-power vertical-cavity surface-emitting lasers based on InP suitable for telecommunication and gas sensing. In Proceedings of the SPIE Remote Sensing 2010, Toulouse, France, 20–23 September 2010; Volume 7828, p. 782807.

- Boehm, G.; Ortsiefer, M.; Shau, R.; Rosskopf, J.; Lauer, C.; Maute, M.; Köhler, F.; Mederer, F.; Meyer, R.; Amann, M.-C. InP-based VCSEL technology covering the wavelength range from 1.3 to 2.0 μm. J. Cryst. Growth 2003, 251, 748–753.

- Spiga, S.; Muller, M.; Amann, M.-C. Energy-efficient high-speed InP-based 1.3 μm short-cavity VCSELs. In Proceedings of the 2013 15th International Conference on Transparent Optical Networks (ICTON), Cartagena, Spain, 23–27 June 2013.

- Tian, S.-C.; Mansoor, A.; Bimberg, D. Progress in Energy-efficient High-Speed Vertical-Cavity Surface-Emitting Lasers for data communication. Photonics 2023. invited paper same issue. Under review.

- Tian, S.-C.; Ahamed, M.; Larisch, G.; Bimberg, D. Novel energy-efficient designs of vertical-cavity surface emitting lasers for the next generations of photonic systems. Jpn. J. Appl. Phys. 2022, 61, SK0801.

- Rao, Y.; Yang, W.; Chase, C.; Huang, M.C.Y.; Worland, D.D.P.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Willner, A.E.; Chang-Hasnain, C.J. Long-Wavelength VCSEL Using High-Contrast Grating. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1701311.

- Chung, I.-S.; Iakovlev, V.; Sirbu, A.; Mereuta, A.; Caliman, A.; Kapon, E.; Mork, J. Broadband MEMS-Tunable High-Index-Contrast Subwavelength Grating Long-Wavelength VCSEL. IEEE J. Quantum Electron. 2010, 46, 1245–1253.

- Han, Y.; Li, Z.; Wu, L.; Mai, S.; Xing, X.; Fu, H.Y. High-Speed Two-Dimensional Spectral-Scanning Coherent LiDAR System Based on Tunable VCSEL. J. Lightwave Technol. 2023, 41, 412–419.

- Markowski, K.; Bojarczuk, J.; Araszkiewicz, P.; Cybulski, R.; Gaska, M.; Golaszewski, A. Analysis of the Performance of WDM-CDM Bragg Grating Interrogation System with High-Contrast Grating VCSEL. J. Light. Technol. 2023, 1–12.

- Zou, J.; Al Houri, M.; Chen, H.-K.; Eiselt, M. Remote Wavelength Tracking of Strongly Chirped Tunable 10G MEMS-VCSEL for Port-Agnostic WDM Fronthaul. In Proceedings of the 2019 Optical Fiber Communication Conference (OFC), San Diego, CA, USA, 3–7 March 2019.

- Chase, C.; Rao, Y.; Huang, M.; Chang-Hasnain, C. Tunable 1550 nm VCSELs using high-contrast grating for next-generation networks. In Proceedings of the SPIE OPTO, San Francisco, CA, USA, 1–6 February 2014; Volume 9008, p. 900807.

- Paul, S.; Gierl, C.; Cesar, J.; Le, Q.T.; Malekizandi, M.; Kogel, B.; Neumeyr, C.; Ortsiefer, M.; Kuppers, F. 10-Gb/s Direct Modulation of Widely Tunable 1550-nm MEMS VCSEL. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 436–443.

- Zhang, J.; Hao, C.; Zheng, W.; Bimberg, D.; Liu, A. Demonstration of electrically injected vertical-cavity surface-emitting lasers with post-supported high-contrast gratings. Photonics Res. 2022, 10, 1170–1176.

- Chang-Hasnain, C.; Wang, J.; Shen, C.; Ji, Y.; Kapraun, J. Recent Advances in VCSELs for Datacom and Sensing Applications. In Proceedings of the 2022 28th International Semiconductor Laser Conference (ISLC), Matsue, Japan, 16–19 October 2022.

- Chang-Hasnain, C.J. High-Contrast Grating VCSELs. In VCSELs Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Michalzik, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 291–317.

- Mateus, C.F.R.; Huang, M.C.Y.; Chen, L.; Chang-Hasnain, C.J.; Suzuki, Y. Broad-Band Mirror (1.12–1.62µm) Using a Subwavelength Grating. IEEE Photonics Technol. Lett. 2004, 16, 1676–1678.

- Mateus, C.F.R.; Huang, M.C.Y.; Deng, Y.; Neureuther, A.R.; Chang-Hasnain, C.J. Ultrabroadband Mirror Using Low-Index Cladded Subwavelength Grating. IEEE Photonics Technol. Lett. 2004, 16, 518–520.

- Karagodsky, V.; Pesala, B.; Chase, C.; Hofmann, W.; Koyama, F.; Chang-Hasnain, C.J. Monolithically integrated multi-wavelength VCSEL arrays using high-contrast gratings. Opt. Express 2010, 18, 694–699.

- Chase, C.; Zhou, Y.; Chang-Hasnain, C.J. Size effect of high contrast gratings in VCSELs. Opt. Express 2009, 17, 24002–24007.

- Huang, M.C.Y.; Zhou, Y.; Chang-Hasnain, C.J. A nanoelectromechanical tunable laser. Nat. Photonics 2008, 2, 180–184.

- Qiao, P.; Cook, K.T.; Li, K.; Chang-Hasnain, C.J. Wavelength-Swept VCSELs. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1700516.

- Moser, P. Energy-Efficient VCSELs for Optical Interconnects. In Springer Theses; Lahee, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2016.

- Ellafi, D.; Yang, M.; Chen, H.K.; Kim, S.S.; Bandyopadhyay, N.; Cheng, S.; Hasnain, G.; Huang, M.; Chase, C. MEMs-HCG VCSELs for emerging sensing and datacoms applications. In Proceedings of the SPIE OPTO, San Francisco, CA, USA, 1–6 February 2020; Volume 11300, p. 113000R.

- Cesar, J.; Paul, S.; Kuppers, F.; Kusserow, T. SiC-SiO2 MEMS-DBR Based Widely Tunable Optical Filters Around 1550 nm with Narrow FWHM. In Proceedings of the 2019 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 23–27 June 2019.

- Cesar, J. SiOx-SiCz MEMS-DBR-Based Tunable Optical Devices. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 17 March 2020.

- Ustinov, V.M.; Zhukov, A.E.; Egorov, A.Y.; Maleev, N.A. Quantum Dot Lasers. In Series on Semiconductor Science and Technology; Oxford University Press: Oxford, UK, 2003.

- Yu, H.C.; Wang, J.S.; Su, Y.K.; Chang, S.J.; Lai, F.I.; Chang, Y.H.; Kuo, H.C.; Sung, C.P.; Yang, H.P.D.; Lin, K.F.; et al. 1.3-μm InAs-InGaAs quantum-dot vertical-cavity surface-emitting laser with fully doped DBRs grown by MBE. IEEE Photonics Technol. Lett. 2006, 18, 418–420.

- Ledentsov, N.N.; Hopfer, F.; Mutig, A.; Shchukin, V.A.; Savel’ev, A.V.; Fiol, G.; Kuntz, M.; Haisler, V.A.; Warming, T.; Stock, E.; et al. Novel concepts for ultrahigh-speed quantum-dot VCSELs and edge-emitters. In Proceedings of the Integrated Optoelectronic Devices 2007, San Jose, CA, USA, 20–25 January 2007; Volume 6468, p. 64681O.

- Westbergh, P.; Söderberg, E.; Gustavsson, J.S.; Modh, P.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M. Single mode 1.3 μm InGaAs VCSELs for access network applications. Proc. SPIE. In Proceedings of the SPIE Photonics Europe, 2008, Strasbourg, France, 7–11 April 2008; Volume 6997, p. 69970Y.

- Westbergh, P.; Gustavsson, J.S.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M.; Söderberg, E. Noise, distortion and dynamic range of single mode 1.3 µm InGaAs vertical cavity surface emitting lasers for radio-over-fibre links. IET Optoelectron. 2008, 2, 88–95.

- Soderberg, E.; Gustavsson, J.S.; Modh, P.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M. High-Temperature Dynamics, High-Speed Modulation, and Transmission Experiments Using 1.3-μm InGaAs Single-Mode VCSELs. J. Lightwave Technol. 2007, 25, 2791–2798.

- Marcks von Würtemberg, R.; Yu, X.; Hammar, M.; Berggren, J. Performance optimisation of epitaxially regrown 1.3-μm vertical-cavity surface-emitting lasers. IET Optoelectron. 2009, 3, 112–121.

- Takeda, K.; Miyamoto, T.; Kondo, T.; Uchiyama, Y.; Kitabayashi, N.; Uchida, T.; Matsutani, A.; Koyama, F. Wavelength Extension Effect on Lasing Characteristics of Highly-Strained GaInAs/GaAs Vertical-Cavity Surface-Emitting Lasers with Cavity Detuning. Jpn. J. Appl. Phys. 2006, 45, 6691–6696.

- Kuo, H.-C.; Chang, Y.-A.; Chang, Y.-H.; Chu, J.-T.; Tsai, M.-Y.; Wang, S.-C. Single mode 1.27-μm InGaAs:Sb-GaAs-GaAsP quantum-well vertical-cavity surface-emitting lasers. In Proceedings of the Integrated Optoelectronic Devices 2005, San Jose, CA, USA, 22–27 January 2005; Volume 5737.

- Harmand, J.C.; Li, L.H.; Patriarche, G.; Travers, L. GaInAs/GaAs quantum-well growth assisted by Sb surfactant: Toward 1.3 μm emission. Appl. Phys. Lett. 2004, 84, 3981–3983.

- Lao, Y.-F.; Cao, C.-F.; Wu, H.-Z.; Cao, M.; Gong, Q. InAsP/InGaAsP quantum-well 1.3 μm vertical-cavity surface-emitting lasers. Electron. Lett. 2009, 45, 105–107.

- Yamada, M.; Anan, T.; Kurihara, K.; Nishi, K.; Tokutome, K.; Kamei, A.; Sugou, S. Room temperature low-threshold CW operation of 1.23 μm GaAsSb VCSELs on GaAs substrates. Electron. Lett. 2000, 36, 637–638.

- Anan, T.; Yamada, M.; Nishi, K.; Kurihara, K.; Tokutome, K.; Kamei, A.; Sugou, S. Continuous-wave operation of 1.30 μm GaAsSb/GaAs VCSELs. Electron. Lett. 2001, 37, 566–567.

- Thompson, L.R.; Chirovsky, L.M.F.; Jackson, A.W.; Naone, R.L.; Galt, D.; Prakash, S.R.; Feld, S.A.; Crom, M.V.; Wasserbauer, J.G.; Lange, M.D.; et al. Performance of monolithic 1.3 μm VCSELs in telecom applications. In Proceedings of the Symposium on Integrated Optoelectronic Devices, 2002, San Jose, CA, USA, 19–25 January 2002; Volume 4649.

- Graham, L.A.; Jewell, J.L.; Maranowski, K.D.; Crom, M.V.; Feld, S.A.; Smith, J.M.; Beltran, J.G.; Fanning, T.R.; Schnoes, M.; Gray, M.H.; et al. LW VCSELs for SFP+ applications. In Proceedings of the Integrated Optoelectronic Devices 2008, San Jose, CA, USA, 12 February 2008; Volume 6808, p. 690802.

- Graham, L.A.; Schnoes, M.; Maranowski, K.D.; Fanning, T.R.; Crom, M.V.; Feld, S.A.; Gray, M.H.; Bowers, K.; Silva, S.L.; Cook, K.; et al. New developments in 850 and 1300 nm VCSELs at JDSU. In Proceedings of the SPIE OPTO: Integrated Optoelectronic Devices, 2009, San Jose, CA, USA, 6 February 2009; Volume 7229, p. 72290B.

- Riechert, H.; Ramakrishnan, A.; Steinle, G. Development of InGaAsN-based 1.3 μm VCSELs. Semicond. Sci. Technol. 2002, 17, 892–897.

- Onishi, Y.; Saga, N.; Koyama, K.; Doi, H.; Ishizuka, T.; Yamada, T.; Fujii, K.; Mori, H.; Hashimoto, J.; Shimazu, M.; et al. Long-Wavelength GaInNAs Vertical-Cavity Surface-Emitting Laser with Buried Tunnel Junction. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 838–843.

- Jewell, J.; Graham, L.; Crom, M.; Maranowski, K.; Smith, J.; Fanning, T.; Schnoes, M. Commercial GaInNAs VCSELs grown by MBE. Phys. Status Solidi C 2008, 5, 2951–2956.

- Naone, R.L.; Jackson, A.W.; Feld, S.A.; Galt, D.; Malone, K.J.; Hindi, J.J. Monolithic GaAs-based 1.3 μm VCSEL directly-modulated at 10 Gb/s. In Proceedings of the Technical Digest. Summaries of papers presented at the Conference on Lasers and Electro-Optics, Postconference Technical Digest (IEEE Cat. No. 01CH37170). Baltimore, MD, USA, 11 May 2001.

- 10 Gbps 1300 nm PBG-VCSEL for 10 Gigabit Ethernet Transmission up to 10 km Reach. Available online: https://www.alight.dk/index.htm?id=3 (accessed on 23 January 2023).

- Gambin, V.; Ha, W.; Wistey, M.; Yuen, H.; Bank, S.R.; Kim, S.M.; Harris, J.S. GaInNAsSb for 1.3–1.6-μm-long wavelength lasers grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 795–800.

- Blume, G.; Hild, K.; Marko, I.P.; Hosea, T.J.C.; Yu, S.-Q.; Chaparro, S.A.; Samal, N.; Johnson, S.R.; Zhang, Y.-H.; Sweeney, S.J. Cavity mode gain alignment in GaAsSb-based near-infrared vertical cavity lasers studied by spectroscopy and device measurements. J. Appl. Phys. 2012, 112, 033108.

- Wistey, M.A.; Bank, S.R.; Yuen, H.B.; Goddard, L.L.; Harris, J.S. Monolithic, GaInNAsSb VCSELs at 1.46 μm on GaAs by MBE. Electron. Lett. 2003, 39, 1822–1823.

- Harris, J.S.; Bae, H.; Sarmiento, T. GaInNAs(Sb) Long-Wavelength VCSELs. In VCSELs Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Rainer Michalzik, R., Ed.; Part of the Book Series: Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 2013; Volume 166, pp. 353–377.

- Wistey, M.A.; Bank, S.R.; Bae, H.P.; Yuen, H.B.; Pickett, E.R.; Goddard, L.L.; Harris, J.S. GaInNAsSb/GaAs vertical cavity surface emitting lasers at 1534 nm. Electron. Lett. 2006, 42, 282–283.

- Sarmiento, T.; Bae, H.P.; O’Sullivan, T.D.; Harris, J.S. GaAs-based 1.53 μm GaInNAsSb vertical cavity surface emitting lasers. Electron. Lett. 2009, 45, 978–979.

- Sarmiento, T.; Zhao, L.; Moser, P.; Li, T.; Huo, Y.; Harris, J.S. Continuous-Wave Operation of GaAs-Based 1.5-μm GaInNAsSb VCSELs. IEEE Photonics Technol. Lett. 2019, 31, 1607–1610.

- Babichev, A.V.; Pirogov, E.V.; Sobolev, M.S.; Denisov, D.V.; Fominykh, N.A.; Baranov, A.I.; Gudovskikh, A.S.; Melnichenko, I.A.; Yunin, P.A.; Nevedomsky, V.N.; et al. Investigation of active regions based on multiperiod GaAsN/InAs superlattices. Semiconductors 2022, 56, 782–790. Available online: https://journals.ioffe.ru/articles/54909?jaccess=63eac4032903b4.15850587 (accessed on 21 February 2023).

- Albrecht, M.; Grillo, V.; Remmele, T.; Strunk, H.P.; Egorov, A.Y.; Dumitras, G.; Riechert, H.; Kaschner, A.; Heitz, R.; Hoffmann, A. Effect of annealing on the In and N distribution in InGaAsN quantum wells. Appl. Phys. Lett. 2002, 81, 2719–2721.

- RayCan Optoelectronic Next 850 nm/1310 nm/1550 nm VCSEL. Available online: http://raycan.koreasme.com/ (accessed on 23 January 2023).

- Products. Available online: https://www.bandwidth10.com/product/ (accessed on 23 January 2023).

- Park, M.-R.; Kwon, O.-K.; Han, W.-S.; Lee, K.-H.; Park, S.-J.; Yoo, B.-S. All-epitaxial InAlGaAs-InP VCSELs in the 1.3–1.6-μm wavelength range for CWDM band applications. IEEE Photonics Technol. Lett. 2006, 18, 1717–1719.

- Park, M.-R.; Kwon, O.-K.; Han, W.-S.; Lee, K.-H.; Park, S.-J.; Yoo, B.-S. All-Monolithic 1.55 µm InAlGaAs/InP Vertical Cavity Surface Emitting Lasers Grown by Metal Organic Chemical Vapor Deposition. Jpn. J. Appl. Phys. 2005, 45, L8.

- Deng, L.; Zhao, Y.; Pang, X.; Tang, M.; Shum, P.; Liu, D. All-VCSEL Transmitters with Remote Optical Injection for WDM-OFDM-PON. IEEE Photonics Technol. Lett. 2014, 26, 461–464.

- Rhew, K.H.; Jeon, S.C.; Lee, D.H.; Yoo, B.-S.; Yun, I. Reliability assessment of 1.55-μm vertical cavity surface emitting lasers with tunnel junction using high-temperature aging tests. Microelectron. Reliab. 2009, 49, 42–50.

- Shin, B.; Jeong, J.; Yoon, W.-S.; Lee, J. 1550 nm VCSEL-based 10 Gb/s optical NRZ signal transmission over 20 km SMF using RSOA gain saturation. Opt. Fiber Technol. 2017, 36, 222–226.

- Chase, C.; Rao, Y.; Hofmann, W.; Chang-Hasnain, C.J. 1550 nm high contrast grating VCSEL. Opt. Express 2010, 18, 15461–15466.

- Rao, Y.; Chase, C.; Huang, M.C.Y.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Worland, D.P.; Willner, A.E.; Chang-Hasnain, C.J. Tunable 1550-nm VCSEL using high contrast gratings. In Proceedings of the IEEE Photonics Conference 2012, Burlingame, CA, USA, 23–27 September 2012.

- Hofmann, W. High-Speed Buried Tunnel Junction Vertical-Cavity Surface-Emitting Lasers. IEEE Photonics J. 2010, 2, 802–815.

- Ortsiefer, M.; Hofmann, W.; Rosskopf, J.; Amann, M.-C. Long-Wavelength VCSELs with Buried Tunnel Junction. In VCSELs. Springer Series in Optical Sciences; Michalzik, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 321–351.

- Hofmann, W.; Amann, M.-C. Long-wavelength vertical-cavity surface-emitting lasers for high-speed applications and gas sensing. IET Optoelectron. 2008, 2, 134–142.

- Hofmann, W.; Muller, M.; Bohm, G.; Ortsiefer, M.; Amann, M.-C. 1.55-μm VCSEL With Enhanced Modulation Bandwidth and Temperature Range. IEEE Photonics Technol. Lett. 2009, 21, 923–925.

- Muller, M.; Hofmann, W.; Bohm, G.; Amann, M.-C. Short-Cavity Long-Wavelength VCSELs With Modulation Bandwidths in Excess of 15 GHz. IEEE Photonics Technol. Lett. 2009, 21, 1615–1617.

- Hofmann, W.; Müller, M.; Wolf, P.; Mutig, A.; Gründl, T.; Böhm, G.; Bimberg, D.; Amann, M.-C. 40 Gbit/s modulation of 1550 nm VCSEL. Electron. Lett. 2011, 47, 270–271.

- Grundl, T.; Debernardi, P.; Muller, M.; Grasse, C.; Ebert, P.; Geiger, K.; Ortsiefer, M.; Bohm, G.; Meyer, R.; Amann, M.-C. Record Single-Mode, High-Power VCSELs by Inhibition of Spatial Hole Burning. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1700913.

- Muller, M.; Debernardi, P.; Grasse, C.; Grundl, T.; Amann, M.-C. Tweaking the Modal Properties of 1.3-μm Short-Cavity VCSEL—Simulation and Experiment. IEEE Photonics Technol. Lett. 2013, 25, 140–143.

- Müller, M.; Wolf, P.; Grasse, C.; Dias, M.P.I.; Ortsiefer, M.; Böhm, G.; Wong, E.; Hofmann, W.; Bimberg, D.; Amann, M.-C. 1.3 μm short-cavity VCSELs enabling error-free transmission at 25 Gbit/s over 25 km fibre link. Electron. Lett. 2012, 48, 1487–1489.

- Muller, M.; Grasse, C.; Amann, M.C. InP-based 1.3 μm and 1.55 μm short-cavity VCSELs suitable for telecom- and datacom-applications. In Proceedings of the 2012 14th International Conference on Transparent Optical Networks (ICTON), Coventry, UK, 2–5 July 2012.

- Muller, M.; Wolf, P.; Grundl, T.; Grasse, C.; Rosskopf, J.; Hofmann, W.; Bimberg, D.; Amann, M.-C. Energy-efficient 1.3 μm short-cavity VCSELs for 30 Gb/s error-free optical links. In Proceedings of the ISLC 2012 International Semiconductor Laser Conference, San Diego, CA, USA, 7–10 October 2012.

- Müller, M.; Grasse, C.; Saller, K.; Gründl, T.; Böhm, G.; Ortsiefer, M.; Amann, M.C. 1.3 μm High-Power Short-Cavity VCSELs for High-Speed Applications. In Proceedings of the Conference on Lasers and Electro-Optics 2012, San Jose, CA, USA, 6–11 May 2012; p. CW3N-2.

- Malacarne, A.; Neumeyr, C.; Soenen, W.; Falconi, F.; Porzi, C.; Aalto, T.; Rosskopf, J.; Bauwelinck, J.; Bogoni, A. Optical Transmitter Based on a 1.3-μm VCSEL and a SiGe Driver Circuit for Short-Reach Applications and Beyond. J. Lightwave Technol. 2018, 36, 1527–1536.

- Breyne, L.; Verplaetse, M.; Neumeyr, C.; De Keulenaer, T.; Soenen, W.; Yin, X.; Ossieur, P.; Torfs, G.; Bauwelinck, J. DSP-Free and Real-Time NRZ Transmission of 50 Gb/s Over 15-km SSMF and 64 Gb/s Back-to-Back With a 1.3-μm VCSEL. J. Lightwave Technol. 2019, 37, 170–177.

- Grasse, C.; Mueller, M.; Gruendl, T.; Boehm, G.; Roenneberg, E.; Wiecha, P.; Rosskopf, J.; Ortsiefer, M.; Meyer, R.; Amann, M.-C. AlGaInAsPSb-based high-speed short-cavity VCSEL with single-mode emission at 1.3 μm grown by MOVPE on InP substrate. J. Cryst. Growth 2013, 370, 217–220.

- Salomonsson, F.; Streubel, K.; Bentell, J.; Hammar, M.; Keiper, D.; Westphalen, R.; Piprek, J.; Sagalowicz, L.; Rudra, A.; Behrend, J. Wafer fused p-InP/p-GaAs heterojunctions. J. Appl. Phys. 1998, 83, 768–774.

- Rapp, S.; Salomonsson, F.; Streubel, K.; Mogg, S.; Wennekes, F.; Bentell, J.; Hammar, M. All-Epitaxial Single-Fused 1.55 µm Vertical Cavity Laser Based on an InP Bragg Reflector. Jpn. J. Appl. Phys. 1999, 38, 1261.

- Jin-Phillipp, N.Y.; Sigle, W.; Black, A.; Babic, D.; Bowers, J.E.; Hu, E.L.; Rühle, M. Interface of directly bonded GaAs and InP. J. Appl. Phys. 2001, 89, 1017–1024.

- Dudley, J.J.; Babić, D.I.; Mirin, R.; Yang, L.; Miller, B.I.; Ram, R.J.; Reynolds, T.; Hu, E.L.; Bowers, J.E. Low threshold, wafer fused long wavelength vertical cavity lasers. Appl. Phys. Lett. 1994, 64, 1463–1465.

- Babić, D.I.; Dudley, J.J.; Streubel, K.; Mirin, R.P.; Bowers, J.E.; Hu, E.L. Double-fused 1.52-μm vertical-cavity lasers. Appl. Phys. Lett. 1995, 66, 1030–1032.

- Syrbu, A.V.; Fernandez, J.; Behrend, J.; Berseth, C.A.; Carlin, J.F.; Rudra, A.; Kapon, E. InGaAs/InGaAsP/InP edge emitting laser diodes on p-GaAs substrates obtained by localised wafer fusion. Electron. Lett. 1997, 33, 866–868.

- Sagalowicz, L.; Rudra, A.; Kapon, E.; Hammar, M.; Salomonsson, F.; Black, A.; Jouneau, P.-H.; Wipijewski, T. Defects, structure, and chemistry of InP–GaAs interfaces obtained by wafer bonding. J. Appl. Phys. 2000, 87, 4135–4146.

- Syrbu, A.V.; Iakovlev, V.P.; Berseth, C.-A.; Dehaese, O.; Rudra, A.; Kapon, E.; Jacquet, J.; Boucart, J.; Stark, C.; Gaborit, F.; et al. 30 °C CW operation of 1.52 μm InGaAsP/AlGaAs vertical cavity lasers with in situ built-in lateral current confinement by localised fusion. Electron. Lett. 1998, 34, 1744–1745.

- Black, A.; Hawkins, A.R.; Margalit, N.M.; Babic, D.I.; Holmes, A.L.; Chang, Y.-L.; Abraham, P.; Bowers, J.E.; Hu, E.L. Wafer fusion: Materials issues and device results. IEEE J. Sel. Top. Quantum Electron. 1997, 3, 943–951.

- Streubel, K. Novel technologies for 1.55-μm vertical cavity lasers. Opt. Eng. 2000, 39, 488–497.

- Black, K.A.; Abraham, P.; Margalit, N.M.; Hegblom, E.R.; Chiu, Y.-J.; Piprek, J.; Bowers, J.E.; Hu, E.L. Double-fused 1.5 μm vertical cavity lasers with record high To of 132 K at room temperature. Electron. Lett. 1998, 34, 1947–1949.

- Margalit, N.M.; Piprek, J.; Zhang, S.; Babic, D.I.; Streubel, K.; Mirin, R.P.; Wesselmann, J.R.; Bowers, J.E. 64 °C continuous-wave operation of 1.5-μm vertical-cavity laser. IEEE J. Sel. Top. Quantum Electron. 1997, 3, 359–365.

- Karim, A.; Abraham, P.; Lofgreen, D.; Chiu, Y.-J.; Piprek, J.; Bowers, J. Wafer bonded 1.55 μm vertical-cavity lasers with continuous-wave operation up to 105 °C. Appl. Phys. Lett. 2001, 78, 2632–2633.

- Karim, A.; Black, K.A.; Abraham, P.; Lofgreen, D.; Chiu, Y.J.; Piprek, J.; Bowers, J.E. Superlattice barrier 1528-nm vertical-cavity laser with 85 °C continuous-wave operation. IEEE Photonics Technol. Lett. 2000, 12, 1438–1440.

- Syrbu, A.; Mircea, A.; Mereuta, A.; Caliman, A.; Berseth, C.-A.; Suruceanu, G.; Iakovlev, V.; Achtenhagen, M.; Rudra, A.; Kapon, E. 1.5-mW Single-Mode Operation of Wafer-Fused 1550-nm VCSELs. IEEE Photonics Technol. Lett. 2004, 16, 1230–1232.

- Jayaraman, V.; Mehta, M.; Jackson, A.W.; Wu, S.; Okuno, Y.; Piprek, J.; Bowers, J.E. High-power 1320-nm wafer-bonded VCSELs with tunnel junctions. IEEE Photonics Technol. Lett. 2003, 15, 1495–1497.

- Mutter, L.; Iakovlev, V.; Caliman, A.; Mereuta, A.; Sirbu, A.; Kapon, E. 1.3 μm-wavelength phase-locked VCSEL arrays incorporating patterned tunnel junction. Opt. Express 2009, 17, 8558–8566.

- Mereuta, A.; Suruceanu, G.; Caliman, A.; Iacovlev, V.; Sirbu, A.; Kapon, E. 10-Gb/s and 10-km error-free transmission up to 100 °C with 1.3-μm wavelength wafer-fused VCSELs. Opt. Express 2009, 17, 12981–12986.

- Sirbu, A.; Iakovelv, V.; Mereuta, A.; Caliman, A.; Suruceanu, G.; Kapon, E. Wafer-fused heterostructures: Application to vertical cavity surface-emitting lasers emitting in the 1310 nm band. Semicond. Sci. Technol. 2010, 26, 014016.

- Sirbu, A.; Suruceanu, G.; Iakovlev, V.; Mereuta, A.; Mickovic, Z.; Caliman, A.; Kapon, E. Reliability of 1310 nm Wafer Fused VCSELs. IEEE Photonics Technol. Lett. 2013, 25, 1555–1558.

- Volet, N.; Czyszanowski, T.; Walczak, J.; Mutter, L.; Dwir, B.; Micković, Z.; Gallo, P.; Caliman, A.; Sirbu, A.; Mereuta, A.; et al. Transverse mode discrimination in long-wavelength wafer-fused vertical-cavity surface-emitting lasers by intra-cavity patterning. Opt. Express 2013, 21, 26983–26989.

- Long, C.M.; Mickovic, Z.; Dwir, B.; Caliman, A.; Iakovlev, V.; Mereuta, A.; Sirbu, A.; Kapon, E. Polarization mode control of long-wavelength VCSELs by intracavity patterning. Opt. Express 2016, 24, 9715–9722.

- Mereuta, A.; Sirbu, A.; Caliman, A.; Suruceanu, G.; Iakovlev, V.; Mickovic, Z.; Kapon, E. Fabrication and performance of 1.3-μm 10-Gb/s CWDM wafer-fused VCSELs grown by MOVPE. J. Cryst. Growth 2015, 414, 210–214.

- Mereuta, A.; Caliman, A.; Sirbu, A.; Iakovlev, V.; Mickovic, Z.; Suruceanu, G.; Kapon, E. Increasing single mode power of 1.3-μm VCSELs by output coupling optimization. Opt. Express 2015, 23, 10900–10904.

- Ellafi, D.; Iakovlev, V.; Sirbu, A.; Grigore, S.; Mickovic, Z.; Caliman, A.; Mereuta, A.; Kapon, E. Effect of Cavity Lifetime Variation on the Static and Dynamic Properties of 1.3-μm Wafer-Fused VCSELs. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 414–422.

- Caliman, A.; Mereuta, A.; Wolf, P.; Sirbu, A.; Iakovlev, V.; Bimberg, D.; Kapon, E. 25 Gbps direct modulation and 10 km data transmission with 1310 nm waveband wafer fused VCSELs. Opt. Express 2016, 24, 16329–16335.

- Wolf, P.; Li, H.; Caliman, A.; Mereuta, A.; Iakovlev, V.; Sirbu, A.; Kapon, E.; Bimberg, D. Spectral Efficiency and Energy Efficiency of Pulse-Amplitude Modulation Using 1.3 μm Wafer-Fusion VCSELs for Optical Interconnects. ACS Photonics 2017, 4, 2018–2024.

- Ishikawa, T.; Bowers, J.E. Band lineup and in-plane effective mass of InGaAsP or InGaAlAs on InP strained-layer quantum well. IEEE J. Quantum Electron. 1994, 30, 562–570.

- Kim, J.M.; Park, C.Y.; Lee, Y.T.; Song, J.D. MBE growth and optical properties of highly tensile-strained In1−xGaxAs/In0.52(Ga0.4Al0.6)0.48As multi-quantum-wells using digital alloy. J. Cryst. Growth 2006, 297, 52–56.

- Bae, S.-J.; Lee, Y.-T. Tensile-strained 1.3 μm InGaAs/InGaAlAs quantum well structure of high temperature characteristics. Opt. Quantum Electron. 2008, 40, 749–756.

- Blokhin, S.; Babichev, A.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Rochas, S.; Denisov, D.; Voropaev, K.; Ionov, A.; et al. Wafer-fused 1300 nm VCSELs with an active region based on superlattice. Electron. Lett. 2021, 57, 697–698.

- Blokhin, S.A.; Ledentsov, N.; Rochas, S.S.; Babichev, A.V.; Gladyshev, A.G.; Chorchos, L.; Makarov, O.Y.; Karachinsky, L.Y.; Novikov, I.I.; Blokhin, A.A.; et al. 1300-nm wafer-fused VCSELs with InGaAs/InAlGaAs superlattice-based active region. In Proceedings of the SPIE OPTO, 2022, San Francisco, CA, USA, 22 January–28 February 2022; Volume 12020, p. 120200K.

- Kryzhanovskaya, N.V.; Likhachev, A.I.; Blokhin, S.A.; Blokhin, A.A.; Pirogov, E.V.; Sobolev, M.S.; Babichev, A.V.; Gladyshev, A.G.; Karachinsky, L.Y.; Novikov, I.I.; et al. 1.3 μm optically-pumped monolithic VCSEL based on GaAs with InGa(Al)As superlattice active region. Laser Phys. Lett. 2022, 19, 075801.

- Blokhin, S.A.; Babichev, A.V.; Gladyshev, A.G.; Novikov, I.I.; Blokhin, A.A.; Bobrov, M.A.; Maleev, N.A.; Andryushkin, V.V.; Denisov, D.V.; Voropaev, K.O.; et al. 20-Gbps 1300-nm range wafer-fused vertical-cavity surface-emitting lasers with InGaAs/InAlGaAs superlattice-based active region. Opt. Eng. 2022, 61, 096109.

- Karachinsky, L.Y.; Novikov, I.I.; Babichev, A.V.; Gladyshev, A.G.; Kolodeznyi, E.S.; Rochas, S.S.; Kurochkin, A.S.; Bobretsova, Y.K.; Klimov, A.A.; Denisov, D.V.; et al. Optical Gain in Laser Heterostructures with an Active Area Based on an InGaAs/InGaAlAs Superlattice. Opt. Spectrosc. 2019, 127, 1053–1056.

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Maleev, N.A.; Kuzmenkov, A.G.; Vasiliev, A.P.; Rochas, S.S.; Babichev, A.V.; Novikov, I.I.; Karachinsky, L.Y.; et al. Influence of lateral optical confinement on the characteristics of vertically emitting lasers in the spectral range 1.55 µm with an overgrown tunnel junction. Tech. Phys. Lett. 2021, 47, 3–8. Available online: https://journals.ioffe.ru/articles/51717 (accessed on 24 February 2023). (In Russian)

- Arafin, S.; Bachmann, A.; Amann, M.C. Transverse-mode characteristics of GaSb-based VCSELs with buried-tunnel junctions. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1576–1583.

- Hadley, G.R. Effective index model for vertical-cavity surface-emitting lasers. Opt. Lett. 1995, 20, 1483–1485.

- Deppe, D.G.; Leshin, J.; Leshin, J.; Eifert, L.; Tucker, F.; Hillyer, T. Transverse mode confinement in lithographic VCSELs. Electron. Lett. 2017, 53, 1598–1600.

- Ortsiefer, M.; Shau, R.; Böhm, G.; Köhler, F.; Amann, M.-C. Low-threshold index-guided 1.5 μm long-wavelength vertical-cavity surface-emitting laser with high efficiency. Appl. Phys. Lett. 2000, 76, 2179–2181.

- Caliman, A.; Mereuta, A.; Suruceanu, G.; Iakovlev, V.; Sirbu, A.; Kapon, E. 8 mW fundamental mode output of wafer-fused VCSELs emitting in the 1550-nm band. Opt. Express 2011, 19, 16996.

- Sirbu, A.; Caliman, A.; Mereuta, A.; Iakovlev, V.; Suruceanu, G.; Kapon, E. Recent progress in wafer-fused VCSELs emitting in the 1550-nm band. In Proceedings of the 2011 13th International Conference on Transparent Optical Networks, Stockholm, Sweden, 26–30 June 2011.

- Ellafi, D.; Iakovlev, V.; Sirbu, A.; Suruceanu, G.; Mickovic, Z.; Caliman, A.; Mereuta, A.; Kapon, E. Control of cavity lifetime of 1.5 µm wafer-fused VCSELs by digital mirror trimming. Opt. Express 2014, 22, 32180–32187.

- Babichev, A.V.; Karachinsky, L.Y.; Novikov, I.I.; Gladyshev, A.G.; Blokhin, S.A.; Mikhailov, S.; Iakovlev, V.; Sirbu, A.; Stepniak, G.; Chorchos, L.; et al. 6-mW Single-Mode High-Speed 1550-nm Wafer-Fused VCSELs for DWDM Application. IEEE J. Quantum Electron. 2017, 53, 1–8.

- Babichev, A.V.; Karachinsky, L.Y.; Novikov, I.I.; Gladyshev, A.G.; Mikhailov, S.; Iakovlev, V.; Sirbu, A.; Stepniak, G.; Chorchos, L.; Turkiewicz, J.P.; et al. Continuous wave and modulation performance of 1550 nm band wafer-fused VCSELs with MBE-grown InP-based active region and GaAs-based DBRs. In Proceedings of the SPIE OPTO, 2017, San Francisco, CA, USA, 28 January–2 February 2017; Volume 10122, p. 1012208.

- Kolodeznyi, E.S.; Rochas, S.S.; Kurochkin, A.S.; Babichev, A.V.; Novikov, I.I.; Gladyshev, A.G.; Karachinskii, L.Y.; Denisov, D.V.; Bobretsova, Y.K.; Klimov, A.A.; et al. Optical Gain of 1550-nm Range Multiple-Quantum-Well Heterostructures and Limiting Modulation Frequencies of Vertical-Cavity Surface-Emitting Lasers Based on Them. Opt. Spectrosc. 2018, 125, 238–242.

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Kuzmenkov, A.G.; Maleev, N.A.; Ustinov, V.M.; Kolodeznyi, E.S.; Rochas, S.S.; Babichev, A.V.; Novikov, I.I.; et al. Influence of Output Optical Losses on the Dynamic Characteristics of 1.55-μm Wafer-Fused Vertical-Cavity Surface-Emitting Lasers. Semiconductors 2019, 53, 1104–1109.

- Larisch, G.; Moser, P.; Lott, J.A.; Bimberg, D. Impact of Photon Lifetime on the Temperature Stability of 50 Gb/s 980 nm VCSELs. IEEE Photonics Technol. Lett. 2016, 28, 2327–2330.

- Bimberg, D.; Larisch, G.; Lott, J.A. Vertical Surface Emitting Laser. Patents issued a. U.S. Patent No.: US 9979158; issued 22 May 2018. b. Europe EP No. 187013990, c. China No.: ZL1880005246.4 issued 18 June 2021, Available online: https://patentimages.storage.googleapis.com/f8/93/eb/7ba0d290723a32/US9979158.pdf (accessed on 1 March 2023).

- Spiga, S.; Schoke, D.; Andrejew, A.; Boehm, G.; Amann, M.C. Effect of cavity length, strain, and mesa capacitance on 1.5-μm VCSELs performance. J. Lightwave Technol. 2017, 35, 3130–3141.

- Arafin, S.; Bachmann, A.; Vizbaras, K.; Hangauer, A.; Gustavsson, J.; Bengtsson, J.; Larsson, A.; Amann, M.C. Comprehensive analysis of electrically-pumped GaSb-based VCSELs. Opt. Express 2011, 19, 17267–17282.