1. Metal–Support Interaction Effect

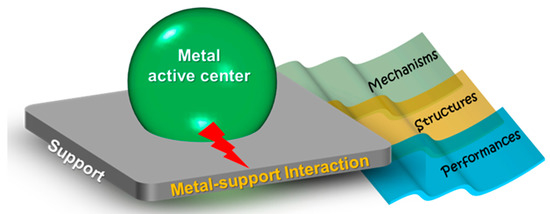

MSI describes the influence of the interaction of metals and their compounds on carriers on the catalytic reaction process, especially OER mechanisms; the interrelationship between the key performance indicators, such as activity, selectivity, and stability; and the intrinsic structures of catalysts, such as electronic and geometric structures [

21,

22] (

Figure 2). Strong interactions such as electronic interaction, chemical bond, and functional groups can stabilize metals on supports via chemical bonding and physical adsorption. Covalent states of metal active centers can be changed by MSI by charge transfer and electron redistribution, improving the intrinsic activity for OER. The MSI can modulate the O-intermediates’ adsorption energy and change the reaction pathway of OER. Modulation of MSI between the metals and supports provides guidelines for the rational design of electrocatalysts.

1.1. Stabilization Effect

The interaction between metals and carbon supports can enhance the electrocatalytic stability of metals during OER. Metal species with high surface free energy tend to aggregate to reduce surface free energy. Supporting active metals on conductive carbon supports can improve stability via MSI. A strong interaction between metal species and carbon matrix can prevent metals from aggregating, enhancing the stability of electrocatalysts. The stabilization effect is the most basic influence of MSI and has been applied in enhancing electrocatalyst stability. The stability of noble metal (Pt, Ru, Ir) electrocatalysts is of great significance for the practical application of noble metal catalysts. The degradation mechanisms of noble metals on carbon supports include particle detachment, agglomeration, carbon corrosion, noble metal dissolution, and Ostwald ripening. Anchoring the active metal phases on carbon–based supports with high stability through MSI can improve the stability of catalysts. The stability of Pt particles supported on carbon supports has been improved via strengthening the MSI [

23]. A CoIr alloy supported on N–doped carbon showed high activity for OER. A strong metal–carbon interaction can optimize the properties of CoIr alloy and improve long–term stability [

24]. The MSI effect was applied to prevent electrochemical degradation of CoIr alloy, and a negligible decay was observed after long-term stability measurement for OER. Transition metal selenides Ni

3Se

4 was supported on ultrathin carbon through a strong electronic interaction [

25]. An ultrathin carbon layer protected Ni

3Se

4 from aggregation and corrosion, endowing electrochemical catalysts with long–term stability. The stabilization effect has been achieved in supported metal catalysts featured with MSI, making the supported catalysts stable under reaction conditions for OER.

Figure 2. Schematic diagram of metal–support interaction effects: mechanisms, structures, and performances.

1.2. Electronic Structure Regulation

1.2.1. Metal–Carbon Electron Transfer

Electron transfer occurs on the interface of metal and carbon substrates. The magnitude and direction of the charge transfer are driven by the E

F difference between metals and carbon supports, which ultimately seeks to balance the electronic chemical potential. The equalization of E

F relies on the transfer of electrons between the two materials [

26]. When the E

F level of metals is higher than supports, electrons are transferred from metals to supports. When the E

F level of carbon supports is higher than metals, electrons transfer from carbon supports to metals until reaching an equilibrium. The electron transfer between metals and carbon supports greatly affects the OER process and mechanism by modulating the activation energies of intermediates and adsorption energies of the reactants [

27]. Electron transfer to graphene tunes the π electron occupancy, which can affect the catalytic ability. The binding energy of O–intermediates (∆E

ads) versus an extra π electron can modulate the adsorption strength of oxygenated species. Too many or too few π electrons induces a stronger adsorption strength, and the extra π electron occupancy has more influence on the value of ∆E

O*, affecting the OER mechanism. For single-atom-supported catalysts, electron transfer from carbon support to metal atom is evaluated as the differential charge density of metal centers [

29]. For nanoparticle-supported catalysts, electron transfer is across the interface between metal components and amorphous carbon. FeNi

3 nanoparticles encapsulated with NC layers induced electron transfer and the interfacial electron structure analyzed via first-principles calculation. The differential charge density of the FeNi

3 and NC layers indicated electron transfer from the FeNi

3 layer to the NC layer, which is attributed to the metal–carbon interaction between FeNi

3 and NC. The NC layers with a charge-rich state facilitated the formation of surface catalytic active centers [

30]. The more conductive platform facilitates faster electron transfer at the interface. In a Sn

4P

3–SWCNT heterostructure, electron migration can reduce the charge density of the Sn site, minimize the O–intermediates’ Gibbs free energy, and affect the OER mechanism [

31]. The magnitude and direction of electron transfer are critical in the design of efficient electrocatalysts for enhanced OER catalytic capability.

1.2.2. Redistribution of Electron Density

Rearrangement of electrons between metal components and supports induces the redistribution of electron density. Redistribution of electron density can modulate the d–band center. According to the d–band center theory, the d–band center energy level indicates the degree of electron filling in an antibonding state [

32]. Atoms with different radii and electronegativities lead to different degrees of electron redistribution. The d-band center of the Co atom in CoNi/Co–N

4–CNTs (−0.84 eV) was lower than that of Co/Co–N

4–CNTs and Co–N

4–CNTs [

33]. The downshifted d–band center was beneficial to the desorption behavior and subsequent reactions, modulating and accelerating the OER process. The redistribution of electron density can be affected by the properties of supports. Metal oxides [

34], hydroxides [

35], nitrides [

36], MXenes [

37], and carbon materials [

38] are commonly used as supports. Heteroatom doping in a carbon support can affect the charge redistribution. The charge density between Co

2P

2O

7 and N, P co-doped carbon was confirmed by electron density difference analysis. The yellow and green represent charge depletion and accumulation in the space. The electron transfer from Co

2P

2O

7 to N, P co–doped carbon induced electron density redistribution and changed the electronic structure [

39]. Redistribution of electron density of supported catalysts has proved to be a critical factor for catalytic enhancement [

40]. BG and G were prepared with and without the addition of an aqueous solution of bacterial strain pandoraea sp. B-6 into graphene oxide (GO). The catalytic performance of BG@Ni/Ni

3S

2 has been improved due to electron density redistribution. Four-electron transfer processes for the OER mechanism were adopted to clarify the high catalytic ability [

41]. BG@Ni/Ni

3S

2 showed the highest capacity with an overpotential of 250 mV at 20 mA/cm

2. Tuning electron rearrangement and regulating MSI are feasible approaches to optimize the OER mechanism and improve catalytic performance.

2. Geometric Structure Modulation

2.1. Coordination by Functional Groups

MSI can be coordinated by the functional groups on the supports. Support surface functionalization can change the characteristics of the supports, strengthening the interaction between the metals and the supports and modulating the geometric structure. Surface functionalization of carbon supports can be achieved by covalent or non-covalent interactions between supports and functional groups/molecules. Covalent interaction implies the formation of covalent bonds. Functional groups commonly covalently attached to carbon supports’ surfaces include –OH, –COOH, –NH

2, and –OCH

3 [

42]. Non-covalent interactions are in the forms of van der Waals force, coordination bonds, hydrogen bonds, and π–π stacking interactions [

43]. Functional groups on supports’ surfaces can adsorb metal precursors through electrostatic interactions, which can serve as anchoring sites for metals to attach to the supports. The metal phase connects with the functional groups by replacing the H in –OH, –COOH, –NH

2, and –OCH

3. The functional groups on carbon support surfaces can accelerate electron transfer, improving the electrocatalytic performance of catalysts for OER. Functional groups with various numbers and types have various effects on catalytic reactions. In our previous work, we constructed –OH functional groups on biomass-derived microtubes for surface bonding of CoP (CoP@BCMTs) [

12]. The surface –OH functional groups acted as the anchoring sites for the even distribution of CoP through C–O–Co bonds. Carbon supports with functional groups can modulate the strength of MSI, which affects the geometric structure and catalytic ability. Thiocyanate groups on carbon surfaces can alter catalytic performance by modulating the adsorption energies of intermediates. Thiocyanate groups were proposed to enhance the electrocatalytic activity for OER catalysts. The thiocyanate groups firstly electrostatically interacted with Ru

3+ and formed SCN covered with Ru–RuO

2 nanoparticles after annealing treatment. Fourier transform infrared spectroscopy (FTIR) was applied to detect the chemical interaction of SCN and Ru-RuO

2 [

44]. The thiocyanate groups were beneficial to accelerate H

2O and *OH dissociation, reduce the energy barrier, and decrease the overpotential for OER. Functional groups arousing strong interaction can regulate electronic and geometric structures, improving catalytic performance. Electron-withdrawing groups (–COOH and –NO

2, etc.) and electron-giving groups (–OH, –NH

2, –OCH

3, etc.) were discussed for OER performance. Anisole, benzene, nitrobenzene, 2,5 dihydroterephthalic acid, terephthalic acid, aniline, and 2-aminoterephthalic acid acted as ligands to introduce various functional groups [

45]. The 2-aminoterephthalic acid with electron-withdrawing groups (-COOH) and electron-giving groups (–NH

2) showed a stronger ability to bond to metal. A high density of electron-giving groups (–NH

2) gave away electrons to combine H

+, and electron-withdrawing groups (–COOH) absorbed electrons to combine OH

−, ascribing to the highest OER electrocatalytic activity. Surface functionalization can also lead to the introduction of heteroatoms in the carbon framework, including oxygen, nitrogen, phosphorus, sulfur, and so on. Heteroatom doping can regulate catalysts’ electronic structure, coordinating the MSI between metals and supports. Functional groups have adopted superaerophobic/superhydrophilic and superaerophilic/superhydrophobic surfaces into their design [

46]. The superhydrophilic/superaerophobic surface facilitated electrolyte transport and bubble desorption, accelerating the OER kinetics.

4.2. Chemical Covalent Bonding

Chemical bonding is a strong interaction form between metals and supports. A strong chemical covalent bond can improve the stability and activity of electrocatalysts. Chemical covalent bonding enables uniform distribution of metals on the support substrates. Since the surface energy increases dramatically with decreasing particle size, metallic species tend to grow into larger crystals. Chemical bonding can prevent metals from growing into large crystallites and improve exposure of metal active sites [

47]. Construction of covalent bonds between metals and carbon supports can endow catalysts with a unique geometric structure. The chemical covalent bonds between metals and carbon materials include metal–O–C, metal–N–C, metal–P–C, and metal–S–C bonds [

48]. In situ generated Co-O-C bonds can act as an oxygen bridge between CoP nanoparticles and the carbon layer [

49]. Co-O-C bonds can decrease energy barriers to improve OER activity and induce charge transfer to strengthen chemical adsorption. M–N–C and M–P–C bridged the N, P co–doped carbon spheres and Co

2NiO

x nanoparticles to form a strong interaction between the Co

2NiO

x and N, P co–doped carbon. Electron transfer through covalent bonds from metal oxides to carbon supports increases the oxidation state of active metals [

50]. The strategies for the formation of chemical covalent bonds between supports and metals include heteroatom doping, defect engineering, functional groups, metal-organic framework derivatization, and clicking confinement [

51,

52]. Click confinement based on click chemistry showed high reaction selectivity. Zinc (II) phthalocyanine and single–walled carbon nanotube (SWCNT) were represented as a metal-containing molecule and support, respectively. Zinc (II) phthalocyanine with multi–functional groups was anchored on SWCNT through azide-alkyne Huisgen cycloaddition [

53]. The chemical covalent bonding of a Zn active center can improve electron transfer rate and conductivity, which can be ascribed to the high OER activity performance. For single-atom catalysts, the N–coordinated MN

4 sites in carbon are deemed as candidate noble metals for electrocatalytic reactions. Co hydroxide after Co

2+ adsorption at room temperature decomposed to an oxide at 523 °C, shifted to CoN

4 with small Co metal particles at about 700 °C, and achieved atomically dispersed CoN

4 when the temperature increased to 800 °C. The Co–O and Co–OH species were converted into CoN

4 sites with the temperature increase, increasing the CoN

4 sites’ density and optimizing mass transport properties.

3. Modulation Strategies of Metal-Support Interaction

3.1. Metal Properties

The metal properties including metal species, particle size and metal morphology can induce MSI changes, affecting the adsorption energy of intermediates and reactants. The MSI would be maximized when the metal nanoparticle size reduced to atomic level, enhancing catalytic stability and adjusting OER reaction mechanism. Various metal morphologies with varied crystals faces in contact with the supports would modulate the charge transfer direction and adjust reaction mechanism. The modulation of metal properties is significant in optimizing the MSI for enhanced catalytic ability.

3.2. Carbon Support

The supports can stabilize the metal nanoparticles, adjust the electronic structure and coordination environment on the catalysts surface. Carbon materials are the most promising supports for stabilizing the metal compounds and reducing agglomeration due to their large surface area and porous structure. The chemical environment and physical structure of carbon supports can alter the charge transfer between metals and carbon materials, impacting the MSI. The modulation strategies for carbon supports include heteroatom doping, defect engineering and morphography engineering.

3.3. Coordination Effect

Tailoring the local chemistry environment of supported metal electrocatalysts for optimal electronic and geometric structures has been applied in regulating the MSI and improving the catalytic performance. Local chemistry environment, including coordination atoms and coordination numbers, have great effects on catalytic performance. The changes in local chemistry environment can change the reaction pathways and construct new catalytic sites. The factors affecting the local chemistry environment include the location (edge or in-plane), the surrounding heteroatoms and the surrounding ligands.

In summary, the MSI effect occurring at the interface of metals and carbon supports interface affects the electrocatalytic kinetics and reaction pathway for OER. As far as non-precious metal supported carbon-based catalysts, the stability, electronic and geometric structures can be modulated by MSI effect using charge transfer, electron redistribution, functional groups coordination and chemical covalent bonding. Integrating OER mechanism and MSI effect together can provide theoretical guidance and a practical approach to the design of efficient catalysts, including the modulations of the particle size, morphology, heteroatom doping, defect engineering, and coordination atom and number. Whether these approaches can effectively improve the catalytic effect can be summed up in three aspects: the electronic structure, geometric structure and reaction process of the catalyst. Briefly, the charge transfer and redistribution, and the central position of the d-band are important factors affecting the catalytic process, which are directly related to the efficiency of electron directional transport in the reaction. Whether there is a reliable solid configuration and efficient charge transport between the surface functional groups of the support and the active metal species, and whether the overall configuration is conducive to mass transfer, will affect the efficiency and stability of the catalytic reaction process.

MSI modulation is a meaningful strategy for synthesis of efficient catalysts. Modulating of MSI to optimize OER reaction kinetics and pathway is still in its infancy, and some challenges need to be addressed in the future as displayed in Figure 12:

(1) Improving the intrinsic catalytic activity and atom utilization efficiency. Decreasing the metal size from nanoparticles to single atoms can expose more active sites and improve the atom utilization efficiency. Changing the coordination atoms, coordination number and local chemical environment can regulate active centers intrinsic activity.

(2) Controllable adjustment of MSI to change OER reaction mechanism. The covalent state of M-O bond can be altered by MSI via charge transfer and electron redistribution, shifting OER reaction mechanism form AEM to LOM. The difficulty in controllable modulation of MSI through a simple process hampers the application of MSI in reaction mechanism optimization.

(3) Enhancing the stability of electrocatalysts during OER process. Catalytic activity and stability are mutually restricted for most reported catalysts. Carbon-supported catalysts can improve the dispersion of metal nanoparticles and modulate MSI strength the electron coupling between carbon supports and metals for enhanced stability.

(4) Developing advanced characterization techniques. The limited characterization techniques including in situ/operando experimental study and theoretical calculations inhibit the accurate analysis of MSI across the interfaces of catalysts. The development of advanced detection methods and simulation techniques to realize in situ analysis in the catalytic process is conducive to understanding the mechanism and effects of MSI.

This entry is adapted from the peer-reviewed paper 10.3390/nanoenergyadv3010004