Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Aerospace

The term “digital thread” refers to the set of data created across the life cycle of a given component. It is called a thread for several reasons. First, for the data to be most useful, it must be collected starting at the beginning of a component’s life cycle, from raw materials, processing, transit, manufacturing, installation, operation, maintenance/repair, and the end-of-life. The “thread” must be pulled for it to maintain its value, and a break in the thread can severely compromise the entire thread’s integrity.

- digital thread

- artificial intelligence

- digital twin

- process control

1. Introduction

To understand how to properly establish a roadmap toward a successful digital thread for aerospace composites, it is first necessary to analyze the current state of the art for digital thread components. While the thread itself is not yet matured [4], it has been a growing core industry focus as data-driven technologies have become more sophisticated [5].

2. Design Using Prior Iteration Knowledge

When designing a new composite structure, it is critical to first understand the requirements of the structure, including various strength attributes, durability, weight, cost, and manufacturability [9]. This is currently possible for requirements that can be modeled and simulated. While having some capability for decades, design optimization using a digital thread has evolved significantly [10], making use of advanced simulations and utilizing methods such as machine learning to optimize all of the requirements in a way that minimizes excess material without compromising key attributes [11]. This use of machine learning—along with the collection of more and more data from previous design iterations—allows these methods to adapt their models to structures that are newly developed, even when uncertainties exist [12]. While this process is continuously improving, there is still a cautious limit to innovation speed due to the limitations of machine learning, optimization models, and the ability to collect and utilize the large amount of data required for novel composites and structures in aerospace [13]. However, the digital threads that do exist have been able to start the connection between the design of an aircraft component and its manufacturability [14].

3. Digital Twins

A term used more frequently in aerospace, as well as other complex manufacturing industries, is “digital twin”. While there have been many interpretations of this term, ranging from monitoring several key metrics to creating a virtual replicate of the original, a more effective way to view a digital twin is in the context of the problem it is meant to solve. For aerospace, a digital twin of a manufacturing machine can be critical for process monitoring and control, predictive maintenance, or even factory simulation [15]. In the context of developing a digital thread, a digital twin is meant to contribute to all of these tasks, providing benefits to multiple steps of the manufacturing process and also contributing compounding benefits as the thread is pulled further along the process.

3.1. Process Monitoring

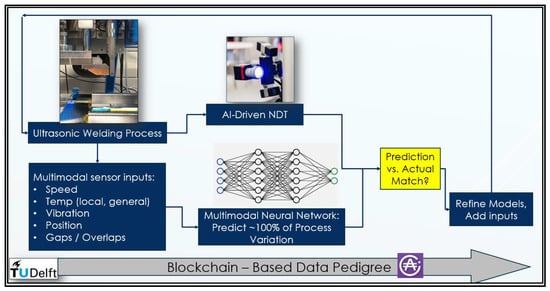

When manufacturing composites for aerospace applications, the tolerance for any type of defect is extremely low, especially for structural components. While current processes often rely on a robust quality inspection protocol, it would be much more efficient to predict any defects and to eventually be able to prevent the defects from happening at all. This begins with process monitoring, and although the state of the art varies significantly by individual manufacturing process, a growing number of processes are developing process monitoring abilities [16]. Figure 1 below illustrates the process of monitoring the development of continuous ultrasonic welding performed at TU Delft and its partner SAM|XL. The key function of the process is to employ a machine learning model trained by identifying the combination of process metrics (settings) as well as the result metrics (thickness, overflow, temperature dissipation, etc.).

Figure 1. AI-driven process monitoring example.

3.2. Process Control

While process monitoring is a critical step toward higher-quality components, by itself, it does not improve the quality [17]. Rather, when developed correctly a process monitoring setup can accurately predict whether a composite component has defects [18], but it cannot prevent the defects. To accomplish this, process control must be added to the monitoring output. With enough data representing the function of the manufacturing machine/process, as well as the data gathered from an accurate process monitoring setup (in other words, a setup that captures approaching 100% of process variation, depending on the manufacturing tolerances of the component being produced), it is possible to develop an in-depth digital twin that can be simulated [19] and used for process control. This is especially possible when the digital twin employs machine learning along with simulation, as the simulation can improve training through techniques such as reinforcement or agent-based learning [20].

First, the system must have the ability to read many different inputs, apply them to a trained model, and determine not just a prediction of quality, but rather a recommended course of action to ensure first-time-right quality. While this is possible for more simple manufacturing processes, many of the digital twin case studies for complex manufacturing of composites rely more on utilizing the digital twin to design a better process overall [21]. While helpful in improving the manufacturing process itself, it does not easily address the variation that inevitably remains in nearly every manufacturing process. Unfortunately, even small amounts of variation during the manufacture of high-quality aerospace composites can be enough to cause unacceptable defects. The process must not only predict the variation but prevent it nearly instantaneously. This requires not just strong computing power, but strong local computing power. The use of edge devices powerful enough to run machine learning models is relatively recent [22], and because these innovations are a result of rapidly improving computational power in smaller edge devices, the aerospace industry is still working to identify all potential use cases for digital twins, process control, and more [23]. In addition to higher first-time-right quality, the use of edge devices in process control could lead to maintaining a minimal material consumption [24]. In the context of the high-level 2050 goals, this outcome of faster (and more efficient) manufacturing processes, higher quality, fewer defects, and less waste all contribute directly to meeting a carbon-neutral aerospace industry.

Second, the system must have the ability to convert the recommended course of action into execution. This varies significantly depending on the manufacturing process, but can be exponentially more complex than process monitoring, and even process monitoring with a recommended course of action.

3.3. Predictive Maintenance

Though it has a completely different objective, the same elements that apply to process monitoring/control also apply to predictive maintenance. The difference is simply the target of the monitoring/control. That said, because process monitoring aims to identify an amount of variation approaching 100%, many of the sensors are already focused on the equipment itself in addition to the composite structure being manufactured. These sensors, along with others located within the equipment, observing the equipment, or even upstream/downstream from the equipment, can supply critical data for evolving the maintenance strategy from reactive to scheduled to predictive. Like the data itself, the process for developing effective predictive maintenance is very similar to process monitoring (plus the recommended action portion of process control). After capturing the data, practitioners can then train a model (most likely using a machine learning architecture) to understand and predict potential variations from the nominal process. Instead of simply identifying “out of bounds” measurements, however, the model—essentially a digital twin of the machine—is trained to predict the potential for failure and provide recommendations for when and how to act.

The economical side of predictive maintenance is similar to process monitoring/control as well. In the case of process control, the practitioner should continue to identify key metrics, install sensors, capture data, and evolve the model. However, at what point should this evolution stop? The target is when the model can accurately predict, prescribe, and correct potential variation in order to ensure an acceptable quality and efficiency threshold. Like any manufacturing process, there is an underlying business decision driven by the return on investment (ROI). In the case of aerospace, the quality requirements are high, rework and scrap costs are high, and each minute of production runtime utilizes significant capital. Therefore, the process evolves significantly.

With predictive maintenance, this process is the same, but instead of quality metrics alone, the process of predicting and prescribing corrective action (maintenance in this case) will continue to evolve until the cost of making the digital twin more accurate outweighs the economic gains. Again, in aerospace composite manufacturing, the cost of failure is significant and the opportunity to invest in an accurate digital twin should depend more on the state of the art than financial restraint. In a representative manufacturing facility for aerospace structures, the machinery producing the structures must have minimum variation to avoid quality issues, rework, and scraps—all of which are prohibitively expensive even at low rates. However, the machinery itself is typically very expensive capital, and maintenance that is overlooked can often cause more damage than just the part that fails. Further costs are incurred when a machine breaks down during high productivity periods, whereas an effective predictive maintenance process allows enough notice to schedule most maintenance at optimum time periods. A “line down” could even cost an organization significantly, and the push for more advanced predictive maintenance is a logical result.

4. Inspection

Ideally, a “first-time-right” environment would eliminate the need for quality inspection. From a purist standpoint, inspection is non-value-added. However, until the design, process monitoring/control, and predictive maintenance are perfect, some form of inspection will likely be necessary. That said, the digital thread can greatly reduce the need for inspection, as well as the cost (in terms of time and resources) [25]. This is in part because the process monitoring/control activity is able to gather much of the necessary data for inspection, and when tied to a machine learning model, even recommendations and summary analysis can be provided to the inspection process. This has been demonstrated with the ultrasonic welding of composites [26] and can also contribute to inspection as well as post-inspection diagnostics and prognostics for composite materials [27], tying to a process further down the digital thread: structural health monitoring.

Inspection innovation for aerospace composites also benefits from digital thread advancements in other methods, such as additive manufacturing [28]. This is critical for the larger benefit of a fully connected digital thread. Though composites are a major area of focus for the aerospace industry, there are growing use cases for additive manufacturing, particularly with metal-based materials [29]. While composite-based manufacturing will continue to be the key driver for aerospace structures, these other methods play a role, and their data-driven processes must be incorporated into the digital thread in order to benefit from exponential benefits such as factory-level optimization.

Another key element of inspection as it relates to improving the digital thread is “explainable artificial intelligence.” This is especially important for composites produced within the aerospace industry, as regulations are extremely strict in order to maximize safety, and any data that is produced as part of the quality inspection must be transparent, explainable, and as a result, it must be able to be trusted [30].

Finally, just as inspection is made more efficient and effective by processes up the digital thread, it can add value to processes further down the thread by assessing through the inspection process not just the current state of a composite structure’s quality, but also (through the use of various machine learning processes) an accurate prediction of fatigue life for that component [31]. This is important for a number of reasons, and its benefit is amplified when part of the digital thread. The component benefits from an initial quality inspection, as well as a fatigue life prediction. This same fatigue life test can be performed throughout the life of the component (depending on its installation and the availability of compatible tests), and this initial test acts as a baseline. Further tests, especially if they differ from the original prediction, can help significantly in honing the initial model’s accuracy. However, if the initial model is indeed accurate but unexpected wear, discrete events, damage [32], or other external elements were experienced by the component, this can provide deep insight into the component as well, showing potential design flaws, opportunities for improvement, or external factors to watch for and capture onto the digital thread when they occur.

5. Work Cell Optimization

The desire for work cell optimization has been a goal for many years, from the first iterations of assembly line work to process improvement methodologies such as TQM, Lean, Six Sigma, and Kanban. Process improvement is just as valid today and should never be substituted for efficiency-driving technology. The two are best used in tandem and often complement each other toward a synergistic result. That said, efficiency-driving technologies have evolved significantly over the last several decades, due in large part to data capture and analysis capabilities. Advanced concepts such as genetic algorithms for optimization have been known and even used (in a limited capacity) during this entire period [33] and continued increase in capability with more access to computing power [34], making use of this technology in many industries, including aerospace.

The advances in machine learning in the last decade have been exponential, with early models relying more on advanced statistics for optimization problems [35]. However, this exponential growth has been possible as multiple elements have been improving continuously during this time. Models have become significantly more efficient as the field of research has spread to industries globally, and more innovations are developed on a daily basis. This, combined with computational and data storage increases, have allowed these models to work with very large sets of data, which helps with learning and accuracy. Moreover, optimization problems in general benefit from several subfields within AI, including general reinforcement learning and in particular, agent-based models.

These advances have allowed practitioners to increase the fidelity of models, allowing discrete setups such as manufacturing cells to be simulated with incredibly high accuracy. This is especially true in the case of a functioning digital thread, whereby key data from upstream tasks are provided, and demand requests from downstream activities help to prioritize how resources are used [36]. By having the critical elements needed for an accurate simulation environment, the optimization outputs become more creative, innovative, and transformative for the larger factory. These elements include inputs and their distribution curves for any variation in timing, action, quantities, etc.; the available actions for any agents, equipment, or processes of the manufacturing cell; any distribution curves for actions that occur within the cell; any potential disruptions, failures, or barriers that can occur (as well as their distribution curves); and the demand curves from downstream processes. These elements can be simulated to provide guidance and recommendations for optimization and can at the same time alert potential risks that can create significant harm to the cell’s objectives.

6. Factory Optimization

Though factory-level optimization is essentially the same problem as cell-level optimization, the true challenge is in scalability. While current technology could feasibly simulate (at high accuracy, detail, and statistical representation) a manufacturing cell, even a moderately complex process could have hundreds of variables, leading to billions of permutations for the manufacture of a single component. Granted, those statistics can be toned down in fidelity and still achieve impressive results [37], but as more details are added within a process, more data are collected, and each variable brings with it a unique distribution curve of possible outcomes, the computational load becomes extremely heavy. Factory simulation can be accomplished, but due to current limitations in data collection, analysis, IoT management, and the overall health of a digital thread reaching the entire length of the factory itself, the current fidelity for factory management is not scalable from the true level of detail that occurs in reality. However, there are still many significant benefits to pursuing factory optimization even at lower fidelity [38]. In order to reach carbon-neutral aviation by 2050, factory optimization must improve significantly for composite structure manufacturing and other aerospace components. Fortunately, by focusing on certain elements of factory operation, such as minimizing energy consumption, organizations can achieve important benefits despite the current limitations of simulating with high fidelity an entire factory operation [39].

When considering near-term innovations such as “Industry 4.0”, “hybrid manufacturing” [40], and “smart manufacturing”, the ability to accurately assess factory operations in order to optimize them is even more critical. The digital thread is the key to collecting the necessary raw data, the analytics and recommendations, and the compounded analysis from optimizing multiple steps in the process. As optimization models continue to improve, data capture becomes easier, and elements such as edge computing/IoT become more standardized, this scalability of fidelity simulation/optimization will become possible [41].

7. Supply Chain Optimization

At first glance, optimizing the supply chain for an industry such as aerospace looks nearly identical to factory optimization [42]. In many ways, this is true; the supply chain steps (acquire raw materials, process them into components, integrate them into assemblies, deliver them to the next step in the process) are the same as those within a factory, at least when observed at a high enough level [43]. There are two key differences that make supply chain optimization an order of magnitude more complex than factory-level optimization.

First, a supply chain is organized in many ways like a fractal, especially for high-complexity products such as aircraft. If you start at the final assembly plant, you see that many different components are delivered from various companies and are then integrated into larger and larger assemblies within the factory until a completed aircraft rolls out the door. However, if you take any of the components that were delivered, each one came from another factory that itself integrated multiple levels of assemblies from other companies who had delivered their components. At each level of this bill of material hierarchy, an entire factory-level optimization is possible (and not just with your components, as each of these companies likely has many different customers and their demand is competing for attention as well). Within each factory, cell-level optimization is possible. In addition, for this fractal-based supply chain, there is an exponential digital thread. Fortunately, like factory-based optimization, there are current methods that use very high-level inputs and distribution curves from the supply chain in order to predict and optimize the delivery of components just in time. However, given the lack of detail—combined with typically wide distribution curves for delivery window—supply chain optimization is still a major complication for upstream operations.

The other difference between factory-level and supply-chain optimization is one of control. Within a high-precision industry such as aerospace, there are some companies within the supply chain that focus entirely on aerospace components and have as part of the organizational culture, the quality, data, and precision standards required for aerospace. However, other companies may produce some aerospace components and other components for industries with much lower standards and requirements. This can create conflict when requesting the amount and types of data needed to create a full digital thread. As one moves further and further down the supply chain, more and more of the suppliers are smaller and more specialized in what they produce. These smaller organizations do not always have the same level of pressure for high efficiency (and high investment) processes such as a digital thread and may not have the specific skill sets to create it. As a result, there can be a degradation in data capture/storage, digital vs. paper-based information flow, and the ability to send key analytics upstream. The lack of control of these processes is a major challenge for an upstream customer, especially the final manufacturer of a large complex product such as a commercial aircraft.

8. Structural Health Monitoring

Once the component has been shipped or installed onto the next higher assembly, it is possible to continue the digital thread by capturing critical metrics for structural health monitoring (SHM) [44]. This is especially important for composites, and there have been significant advances in the sensors used for SHM, making use of embedded piezo-based sensors [45], fiber-optic sensors [46,47], and a multi-sensor suite in order to capture various types of key data [48]. This process is of critical importance in isolation, as it can alert operators to any risks of structural fatigue, damage, and failure. However, it is even more important when taken as part of the greater digital thread. When key information about the design, manufacture, and inspection of that unique component can be accessed, analyzed, modeled, and simulated, then continuous monitoring and analysis become much more valuable, and predictions of potential issues can be even more accurate. This is critical for both simple and advanced composite structures [49] and could potentially increase the rate of innovation for those composite materials that are less tested than traditional aerospace materials. By creating a strong and continuous set of analyses, trends, and risks become much easier to identify, and any elements that may become out of tolerance have a high chance of being identified well in advance. This is especially true when the proper data have been captured and an effective machine learning model is employed in the process [50].

9. Service Life Monitoring and End-of-life Assessment

As with many elements of the digital thread, service life monitoring has been around for decades in some form, but the sophistication and capability of this type of monitoring has improved exponentially, even from just a single decade prior [51]. In aerospace, the ability to use structural health monitoring and embedded sensors on composite structures has greatly improved the ability for continuous service life monitoring. However, even with this capability, there are challenges for components that are installed on complex products such as aircraft [52]. These challenges include the ability to store the data while in flight, the development needed to access the data, the desire to have critical alerts available immediately (for example, warning of impending structural failure as soon as it occurs during a flight so the pilot can take immediate emergency action), and a consistent process for analyzing data that will span years, if not decades depending on the component. In addition, there is the critical need to connect this monitoring step to the rest of the digital thread for full benefits [53].

The end-of-life assessment is critical but is quite possibly the least advanced component of the current state digital thread. Especially in industries such as aerospace, where components often have long service lives and the “reuse” part of the reduce–reuse–recycle process rarely occurs due to high quality requirements (though service life extension does and could be considered a form of reuse), there are often strict guidelines for end-of-life actions that do not take into consideration the individual life and remaining usefulness of a given component [54]. A more thorough “life story” may very well add significant value to good parts that might otherwise be scrapped by default. Potentially more importantly, the “life story” could offer tremendous insight for those responsible for designing the next iteration of that particular component. Better understanding of the manufacturing and service life details would uncover a number of realizations for the improved design and manufacture of the component, and taken together, this information for all components could help drive more radical, innovative, and carbon-neutral designs at a much faster pace than is accomplished today.

10. Digital Thread Management

The direct process steps within the design, manufacture, test, and life cycle monitoring of a composite component are all necessary to create a digital thread, but there are key supporting elements that are critical as well [55]. These include the ability to: capture data at each step using sensors and in-process metrics; utilize edge and IoT elements to capture data on location [56], and this can also allow for not just capture but analysis [23]; create a data mapping process and the architecture that allows for effective remote/cloud access potentially years after its initial capture [57]; effectively track an entire production line [58], optimize processes for both humans and robots [59]; and utilize AI to provide analysis, insight, and recommended action [22].

Another process has made considerable momentum with business, supply chain, and manufacturing use cases: blockchain [60]. While not immediately apparent to non-practitioners, blockchain has a number of unique attributes that can offer solutions for the limited digital thread of today, and the complete digital thread of the near future. One of the earliest blockchain use cases identified within manufacturing was for supply chain management [61,62]. The blockchain ledger’s immutability characteristic can vastly improve the proof-of-origin aspect necessary especially for high precision industries such as aerospace (particularly defense-based aerospace). This type of immutability, along with a cloud-based structure for data management and access privileges [63,64], can strengthen the digital thread’s ability to use data to create a faster certification cycle for innovative materials, products, and manufacturing processes. As digital thread data are captured, they can be hashed. This hash can be placed on a chain as a key to proving immutability for the data, and this process can be carried out as the data themselves are first created, whether along the supply chain, on the factory floor, or as the component is installed and in service. The ability to share these data with authorized partners, government auditors, and customers holds tremendous potential.

While each of these elements continue to make impressive strides, the overall challenge is once again scalability. In a saturated digital thread—for a complex manufacturing facility—that creates composite aerospace structures—with life spans of several decades—the amount of data captured is currently unmanageable, and this does not yet take into account the processing requirements for proper data analytics and insights.

This entry is adapted from the peer-reviewed paper 10.3390/aerospace10020146

This entry is offline, you can click here to edit this entry!