1. Engagement in Hydrogen

Both the global and the EC strategies consider hydrogen as one of the key fuels of the future. In the transport sector, the competitiveness of hydrogen compared to other fuels depends on the degree pollutions in the entire W2W chain, from fuel production to consumption, so the priority is to reduce pollutions [

85,

86]. Although the hydrogen-powered FCEB emits few pollutants, producing mainly water and heat, the overall W2W chain is associated with creation of a great amount of pollutants in the non-driving stages. This is because the largest number of problems hindering the introduction of FCs in the transport sector is not related to onboard equipment, but to the hydrogen manufacturing, storage, and delivery [

26].

From 1980 to 2018, the use of hydrogen has tripled [

67]. In 2018, the worldwide hydrogen production was valued at over 110 billion euros and its use was amounted to 225 thousand units installed [

67]. Nevertheless, hydrogen still makes up a modest fraction of both the global and the EU energy balances, accounting for less than 2% in energy consumption. Simple estimates show that it means roughly 3000 TWh/year or near 70 Mt of hydrogen from electrolysis and from hydrocarbons reforming worldwide [

85].

The global hydrogen production is expected to grow over 5% annually through 2028 [

87]. However, in order for hydrogen to reduce the pollution of the planet, it must reach a much broader scale. The EU has set a goal to produce up to 1 million cubic meters of industrial hydrogen by 2025 and 10 million cubic meters by 2030. These 10 million will comprise a fairly small share of Europe’s total energy consumption. Herewith, by 2050 hydrogen should already account for more than 60% of seasonal energy storage needs [

39].

In [

74], calculations of worldwide prices are given for hydrogen and other fuel sources from 2017 to 2050. In 2019, the cost of hydrogen, including its manufacturing, distribution, storage, and delivery was estimated from 1.5 to 10 €/kg. This cost depends on whether the production is centralized or decentralized, as well as on the market segment and many other factors. In comparison with gasoline, the hydrogen cost per kilometer was up to three times greater [

44].

To decrease the cost, it is convenient to produce hydrogen in places most closely located to the corresponding energy resources [

88]. For example, in [

89] a situation was considered in which a bus with an ICE costs to the fleet about 0.6 €/km for fueling and maintenance. The BC Transit Company from Vancouver had to spend twice as much on FCEB, about 1.3 €/km, because Vancouver does not have its own supplier of hydrogen fuel and hydrogen was delivered by diesel trucks from Quebec located 4800 km away. This not only doubled operating costs, but also reduced the benefits of the using the “zero-emitting” FCEBs in the first place. As a result, three FCEBs were deactivated and returned back to the Ballard Company producing these FCEBs, and the others were converted to ICE electric hybrids and eventually discarded.

At the same time, hydrogen can be obtained as a by-product in specific energy-intensive industrial processes. It leads to the creation of new jobs and potentially has a multiplier effect, at which hydrogen can be used in combination with other resources (such as ammonia fabrication, iron release, methanol elaboration, oil refining and processing of biofuels for hydrocracking, making diesel and biodiesel fuels, synthetic fuels, electronics, etc.) to export goods with higher added value [

67]. For example, the steel and cement industries currently account for 15–27% of global CO

2 emissions [

90,

91], as well as dust, ash, soot, and smoke. Obtaining hydrogen as a byproduct of these industries predicts great benefits. According to the calculations of [

43], the modernization of heavy industry could reduce greenhouse gas emissions by at least 50–60%, becoming an important contribution to the national economy. Examples are enterprises of this kind in Australia, Chile, Norway, Morocco, China, etc. [

92].

Hydrogen manufacturing concentrated at centralized large enterprises commonly reduces the cost of production, but requires additional costs for storage and delivery to HRSs.

Given the estimates of [

74], the cost of hydrogen storage and distribution ranges from 30 to 170% of the fabrication cost. The authors of [

67] promise that the demand for storage of high volumes of solar and wind energy should increase significantly by 2050 compared to today, and hydrogen should help meet this requirement.

Logistics of imported hydrogen accounts for 30–40% of the total cost of its delivery [

67], which ranged from 0.2 to 3.4 €/kg in 2019 [

74]. In the case of delivery, significant losses are added to the logistics chain, which can multiply the need for electricity for hydrogen supplies.

Analysis of [

9] presumes that over the next decade, the cost of the entire hydrogen manufacturing cycle should decrease by about 60%, and by about 70% if only distribution and retail are taken into account.

The following projects look prospective around the hydrogen W2W costs reduction [

67,

93,

94]:

-

improving the efficiency of the hydrogen fuel chain and search for options to decrease losses;

-

estimation of the potential for reducing greenhouse gas emission in the hydrogen production;

-

solving the problem of transferring pipeline systems from natural gas to hydrogen;

-

assessment of the possibilities for using the best available renewable resources outside the country;

-

assessment of the socio-economic consequences of the hydrogen economy.

2. Leaving behind Fossil Fuels

Hydrogen is absent on earth in its pure form, and must be extracted from other compounds using various approaches. A wide range of fuels can produce hydrogen, including renewable energy, nuclear energy, natural gas, coal, and oil. It can be transported via pipelines or on ships in liquid form. It can be converted into electricity and methane.

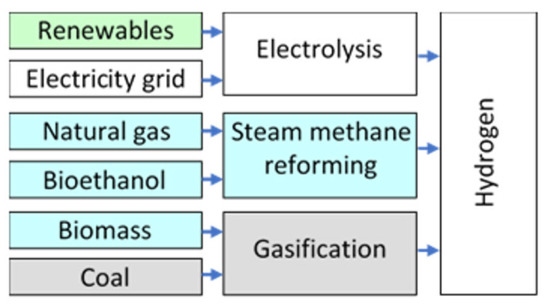

There are various options for generating hydrogen from both non-renewable and renewable energy sources (Figure 1).

Figure 1. Methods for producing hydrogen.

Currently, there are many methods of industrial hydrogen generation from water, garbage, ethanol, metallurgical slag, biomass, etc. Such methods include electrolysis, steam conversion of methane and natural gas, coal gasification, pyrolysis, partial oxidation, biotechnology, and others. A variety of methods is one of the main advantages of the hydrogen supply since it increases energy security and reduces dependence on certain types of raw materials [

95].

Most of the global industrially manufactured hydrogen (80% according to estimates of [

6]) is made from fossil fuels, including natural gas and nuclear energy. Depending on the fabrication method and the carbon footprint, that is, the amount of harmful emissions, hydrogen from fossil fuels is distinguished with color gradation as hydrogen produced without CO

2 capture (“grey” hydrogen), hydrogen from atomic energy (“yellow” hydrogen), and hydrogen from natural gas and fossil fuels produced with CO

2 accumulation in special storage facilities (CCU, “blue” hydrogen) [

95].

Hydrogen from fossil fuels is still largely obtained with harmful emissions entering the atmosphere. While manufacturing, about 830 to 900 Mt of CO

2 are emitted annually in the world [

2,

48]. This means almost 4% of the total global CO

2 emissions. Hydrogen production in EU using this method is associated with 70 to 100 Mt of annual emission of CO

2 [

1,

87].

Its vast majority (96% according to [

87]) is obtained without CO

2 capture (“grey” hydrogen). Hydrogen generation for hydrocracking, used in the manufacturing of gasoline, produces approximately 10% of greenhouse gas emissions [

2,

96], which is equivalent to CO

2 emission in the UK and Indonesia combined [

85,

86]. Hydrogen produced by steam reforming of methane has an emission factor of about 285 g CO

2/kWh (9.5 kg CO

2/kg H

2), and when coal is gasified, the emission factor grows to about 675 g CO

2/kWh [

67]. At that, the amount of hydrogen produced should be calculated, taking into account its losses at transportation, storage, and liquefaction. Moreover, according to the Ford Motor Company, this “grey” hydrogen includes 40% other pollutants besides 60% CO

2 [

96].

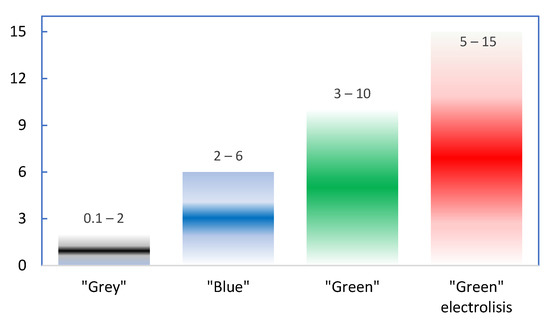

In addition to the inefficient conversion of fossil fuels into a usable form of resources, the common disadvantages of “grey” technologies include political instability in countries rich in fossil fuels and some other variable factors; therefore, costs of “grey” hydrogen oscillates between 0.1 to 2€/kg [

97] (

Figure 2).

Figure 2. Approximate ratios between hydrogen prices (€/kg) in 2020.

Another option is “blue” hydrogen based on natural gas storage and on fossil fuels with carbon capture. According to [

1,

60], the main limiting factors for the utilization of “blue” hydrogen in public transport are higher investment expenses than in the case of direct use of fossil fuels in ICE. These expenses include both operations and additional investments towards hydrogen-based equipment, storage, and facilities. Moreover, the possible impact of risks in the supply chains and uncertainty in the market are amplified due to high margins on final products in the global competition. In 2020, the estimated costs for “blue” hydrogen were from 2 €/kg [

1] to 6 €/kg H

2 and higher [

97]. Now, it highly depends on the current natural gas prices.

Criticism is often related to the high intensity of carbon emissions when hydrogen is released from fossil fuels. In addition, such problems await their solutions as the burden of capital costs, low energy content per unit volume in environmental conditions, and investments in the hydrogen manufacturing and compression, along with the creation of infrastructure for hydrogen distribution, delivery to HRSs, and limited capacity to produce or generate it in the bus-operated territories.

3. Time for Renewable Hydrogen

The most prospective option is the implementation of the “green” hydrogen technology. The future of cleaner energy requires an increase in the supply of hydrogen from renewable resources [

2]. Renewables can replenish themselves, thereby replacing the part depleted at consumption, for a finite period of time on a human timescale, in contrast to fossil fuels that are being consumed at a much faster rate than they are replenished. Transition from the “grey” and “blue” technologies to renewable hydrogen leads to achieving the goal of climate neutrality and “zero emission” in the long term, being the most consistent with an integrated energy system. Climate neutrality refers to the idea of achieving net zero greenhouse gas emissions by balancing these emissions so that they are equal to (or less than) the emissions that are removed by the natural absorption of the planet.

Environmentally friendly renewable hydrogen is an energy carrier obtained either using an electrolyser from water by electrolysis (red bar in

Figure 2) or from renewable energy sources by gasification of the renewable feedstocks, as well as from hydro, tidal, wave, wind, or solar resources (green bar in

Figure 2). Biofuels (biomass and biogas) and waste are also considered renewable energy sources [

12], though they are not environmentally friendly.

In most cases, renewable hydrogen sources are economically unprofitable, and its cost estimated in [

1,

97] oscillates from 2.5 to 15 €/kg.

High installation and storage costs, dependence on weather, and climate are the main barriers for expanding the use of renewables. In most cases, renewable sources are located far enough away from the consumer. In several regions, some of them are completely inaccessible, while in others delivery costs are high. The uncertainty in the energy production capacity of variable renewables aggravates the problem.

Today, the share of renewable energy sources in global energy consumption is about 12%, and about 20% of the electric power generation sector [

85,

86]. It is planned to grow to 25% by 2035 and to 40–50% by 2050. It is also expected that renewable energy sources will occupy an important place, accounting for more than 60% of the newly installed capacities [

12].

Several production plants to produce up to one million tons of “green” hydrogen are designed for the next years. On the way to 2050, renewable hydrogen should be gradually introduced on a large scale along with opening new renewable energy sources as technology is developed and manufacturing costs decrease. According to [

1], by 2030 renewable hydrogen will become economically competitive compared to other forms of hydrogen production. Analyses of [

85,

86] indicate that the cost of hydrogen from renewables may fall by 30% by this time. The priority for the EU is to develop renewable hydrogen, produced using mainly wind and solar energy. The cost of renewable hydrogen in this area is rapidly declining. The cheapest wind power and solar projects can now offer hydrogen at a price comparable to the cost of hydrogen released from several fossil fuels. Already, some renewable energy resources have become competitive with natural gas. The authors of [

67] show that hydrogen from low-cost wind and solar photovoltaic projects will achieve competitiveness with fossil fuels by 2025–2028.

Setting quotas for CO

2 emission from fossil fuels further increases the competitiveness of “green” hydrogen. From 2030 to 2050, renewable hydrogen technologies should reach maturity and be implemented on a large scale to cover all sectors that are difficult to decarbonize and where other alternatives may not be feasible or have higher costs. This is an ambitious plan, given that there are no global examples yet of large-scale “green” hydrogen production [

96]. Elaboration of a large volume of hydrogen from renewable energy sources, in combination with hydrogen storage, should contribute to ensuring long-term seasonal flexibility. Researchers from [

67] consider seasonal storage of renewable electricity, and primarily hydrogen, to be an especially promising direction after 2030.

Since the FC technology offers many advantages when the fuel is hydrogen from renewable sources, multiple global and national policies promote the application of renewables in road transport, including measures to directly support the use of biofuel and “green” electricity in FCEBs and encourage the introduction of “zero-emitting” vehicles [

12].

The transport sector, including FCs, HRSs, and electrolysers, will just benefit from the transition from experimental to mass production. Considering that transport remains the sector with the lowest share of renewable energy sources, the European Chemicals Agency aims to introduce “green” hydrogen technologies to transport by combining renewable and “zero-emitting” hydrogen offering. As a result, as follows from [

31], the share of “green” hydrogen should increase to 13–14% by 2050.

4. Challenges and Prospects of Electrolysis

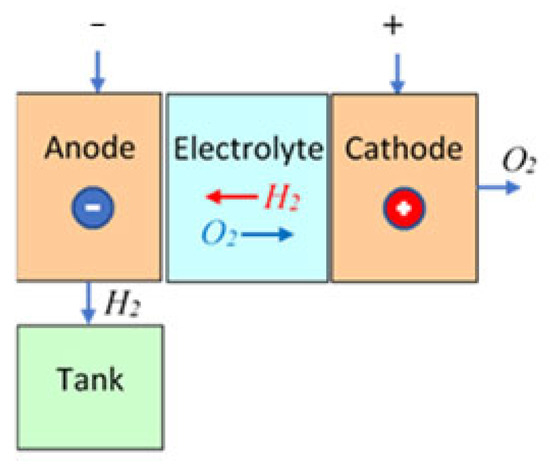

An optimal way is to manufacture hydrogen by direct electrolysis of water by electricity, especially because electricity is easier to deliver to the consumer by wires than hydrogen by pipes.

Electrolyzers are the devices that split water into hydrogen and oxygen, thus issuing hydrogen electrically from water as outlined in Figure 3. Here, a DC voltage source is connected to the negative anode and positive cathode of the electrolyser. Upon the voltage between anode and cathode, a water electrolyte solution is splitting into positively charged hydrogen ions and negatively charged oxygen ions. The former are attracted to the anode and recombine in pairs to form hydrogen. Likewise, the negative oxygen ions are drawn to the cathode and form oxygen there.

Figure 3. Scheme of an electrolyser.

In this way, the HRSs can manufacture hydrogen in urban areas. It is noteworthy that hydrogen generation in HRSs is an energy-intensive process, which makes the hydrogen too expensive (10–15 €/kg H

2 [

97]) and leaves negative the overall balance of energy consumption of this alternative fuel. Hydrogen prices for consumers largely depend on how many HRSs there are, how often they are used, and how much hydrogen is delivered daily. It is probably impossible to manufacture a significant amount of hydrogen using exceptionally cheap or even free water if the electrolysers work about 10% of the time or less. Given this level of use, produced hydrogen turns out to be uncompetitive. To reduce the cost of hydrogen generation from water, electrolyzers must have a much higher utilization factor, which, in turn, is incompatible with the sharply increasing demand for electricity. In this connection, the need to find a balance between buying electricity during periods of low prices and increasing use of electrolyzers is discussed in the literature [

95].

As follows from [

6,

98], the global electricity generation now overcomes 27,000 TWh/year at the total world electricity installed capacity above 7 TW. However, 35% of this capacity come from coal, 23% from natural gas, 11% from nuclear, and 4% from oil. Just 16% come from hydro resources, 5% from wind, 3% from solar stations, 2% from biomass and waste, and 1% from other renewables. In 2020, 20% of 3700 TWh electricity in the USA [

99] and 38% of 2664 TWh electricity in the EU [

100] were obtained from renewables, and in the EU it was the first time when renewables overtook fossil fuels and became the primary source of electricity [

101]. Nevertheless, renewable electricity satisfies as few as 0.3% of total hydrogen needs [

12] whereas biofuels continue to make the largest contribution from renewable energy sources to the road transport sector.

Hydrogen is obtained from both the regional and the local HRSs. Those locations follow a careful analysis of the demands for the fleet and other requirements of FCEBs and heavy-duty vehicles [

67] because any interruption at a hydrogen supply can shut down multiple consumers [

102]. There are various concepts of refueling infrastructure that are suitable for different levels of hydrogen demand, from refueling a single FCEB to large filling stations capable of refueling multiple cars and FCEBs daily [

40]. The regional HRSs are equipped with powerful electrolyzers whereas the local HRSs can be either also equipped with the own electrolyzers or acquire hydrogen from the regional HRSs aiming only to share it in situ among fueling FCEBs with extremely low emissions [

18]. Generated hydrogen is compressed and stored ready for dosing until needed. Many HRSs have a distribution system that allows multiple buses to be used for simultaneous hydrogen refueling. Each refueling in HRS takes 5 to 12 min, which is much faster than BEBs overnight charging.

As an example, the first commercial HRS of the Nation-Energy Company in Yunfu (China) can be considered. The daily capacity of this station is 500 kg of hydrogen, and the storage capacity is 665 kg. Refueling the bus with 22 kg H

2 takes 5–7 min, while the average consumption per bus is about 12 km/kg H

2 [

18].

Over the past decade, the costs of electrolyzation have decreased by 60% and the study [

1] predicts that by 2030 they will be halved compared to today. With the expected reduction in both the cost of electrolyzers and the cost of electricity from renewable sources in the long term, hydrogen produced from water will become competitive with other forms of hydrogen generation. Higher capacity factors of wind and solar farms are also an important factor in reducing overall costs. Thus, the question is how early this competitiveness will be achieved and to what extent new technologies can accelerate this trend.

The EU has presented a hydrogen strategy, whose goal is to issue a set of powerful electrolyzers. The following projects are progressing in this direction [

67,

93,

94]:

-

assessment of the economic efficiency of seasonal storage and flexibility on the electrolyzers’ demand side;

-

assessment of the potential to reduce the electrolyzers’ cost and their ability to work with a partial load, given the availability of variable power;

-

assessment of possible improvement of the characteristics of various electrolyser designs and their degradation under different operating conditions that affect the cost of hydrogen;

-

assessment of the potential and the rate of reduction of investment costs for the electrolyzers.

According to [

12,

67], it is expected that by 2030 the installed capacity of all electrolyzers will be about 700 GW and 1700 GW by 2050. With this development, the cost of electrolyzers should be reduced from 840 to 375 €/kW by 2050.

5. Future-Oriented Initiatives

In 2011, the International Renewable Energy Agency (IRENA) has been established as the principal platform for international cooperation in promoting the widespread adoption and sustainable use of all forms of renewable energy, including bioenergy, geothermal, hydropower, ocean, solar, and wind energy, in the pursuit of sustainable development, energy access, energy security, and low-carbon economic growth and prosperity [

103].

In 2015, a legally binding international treaty on climate change called the “Paris Agreement” was adopted aiming to limit global warming to well below 2, preferably to 1.5 °C, compared to pre-industrial levels [

104].

Five years later, the European Clean Hydrogen Alliance was founded as part of the European new industrial strategy [

29] with a plan to accelerate the reduction of CO

2 emission.

In this connection, the “European Green Deal” project was approved in 2020. Its “Fitfor55 Package” issued by the EC proposes reducing net greenhouse gas emission by at least 55% by 2030 compared to the 1990 level [

39]. This strategy must turn Europe into a climate-neutral continent by 2050 through measures in all areas of its economy, including investments in transport electrification [

12].

Seeking to promote a more efficient and sustainable transport policy, the EC considers the use of hydrogen in the transport sector in its “Strategy for Sustainable and Reasonable Mobility” announced in the “European Green Deal.” To boost the introduction of new technologies, the Package amends the “Renewable Energy Directive” (RED II) [

105] and sets renewable hydrogen quotas for the transport sector by 2030. As a result, all new transport means, including buses, on the European market should become “zero-emitting” from 2035.

In 2020, the world’s largest developers of renewable hydrogen systems joined together to form the “Green Hydrogen Catapult” initiative, aimed at significantly reducing costs to stimulate a faster transition to renewable energy in the most carbon-intensive industries [

12].

For the development of low-carbon technologies, a European Innovation Fund with a volume of about 10 billion euros was created [

1]. The Fund aims to facilitate the demonstration of innovative hydrogen-based systems and to reduce the risk of large and complex projects and, therefore, offers a unique opportunity to prepare such technologies for large-scale implementation in the period of 2020–2030. The first tender of proposals within the framework of the Fund was announced in 2020.

The goals for 2025 and 2030 set out in the “Regulation on CO

2 Emission Standards” [

106] are important factors for creating a leading market for hydrogen solutions as soon as the FC technology becomes sufficiently mature and cost-effective. The “Horizon 2020 FCs” and “Hydrogen Joint Venture” (FCH-JU) projects [

88] are aimed at accelerating Europe’s technological leadership. In the scope of the FCH-JU joint project, the EU is promoting the “Joint Initiative for Hydrogen Vehicles across Europe” (JIVE and JIVE2) programs that support the introduction of large-scale FCEBs and hydrogen HRSs.

A hydrogen strategy for a climate-neutral Europe has been developed in 2020 [

1]. Its most important section is “Promoting research and innovation in the field of hydrogen technologies.” First, as far as hydrogen production is concerned, this entails scaling up to larger, more efficient, and economical gigawatt plants, which, together with fabrication capabilities and new materials, provide hydrogen to large consumers. Second, it is planned to further develop the infrastructure for the distribution, storage, and delivery of hydrogen in large volumes and, possibly, over long distances. Third, an important place is occupied by the creation of large-scale applications for use in transport, including FCEBs. Finally, it is offered to support policy development in a number of cross-cutting areas, in particular to ensure improved and harmonized safety standards, as well as monitoring and assessing the impact on the social sphere and the labor market. Robust methodologies need to be developed to assess the environmental impacts of hydrogen technologies and associated value chains, including lifecycle greenhouse gas emission and sustainability.

The EC also provides targeted support to prepare financially sound and viable hydrogen projects in countries where this is identified as a priority in relevant national and regional programs. During the funding period, a special “Interregional Innovation Investment Tool” with a pilot project on hydrogen technologies in carbon-intensive regions supports the development of innovative value chains in the context of the “European Regional Development Fund” [

107].

Most countries of the world recognize an important role of the transport sector in reducing emissions and include transport modernization in their national energy plans following the “Paris Agreement” [

101,

104]. Herewith, according to [

85], the number of countries that directly support investment in hydrogen technologies is constantly increasing, with most of them focused on transport. To date, 18 countries, whose economies account for 70% of global GDP, have already developed detailed strategies for implementing solutions in the field of hydrogen energy. About 10 thousand HRSs are under construction by 2030 in China, Japan, the USA and South Korea [

9]. This factor may become an important management point for considering the use of hydrogen technology in general.

According to publicly available data, the FCEV stocks in China are expected to reach 50 thousand by 2025 and 1 million by 2030. Japan has set similar ambitious goals regarding FCEVs, aiming for 20 thousand FCEVs by 2025 and 800 thousand by 2030. The most ambitious targets are those of South Korea and Germany, with a total of 18 million FCEVs by 2030s.

The “Green New Deal” of the Republic of Korea outlines the country’s plans to issue 20 thousand FCEVs by 2025 and achieve carbon neutrality by 2050 that include 1.13 million euros. The Korean goal is to provide funding for 65 HRSs by 2035 [

12] by 2040 as a part of the eco-friendly public transportation expansion policy in the scope of “The Roadmap for the Hydrogen Economy” program [

50].

In 2016, the German government adopted the “Climate Action Plan” for 2050, making Germany one of the first countries to adopt the long-term low greenhouse gas emission reduction strategy [

18]. Germany’s hydrogen strategy is planning to increase hydrogen production capacity to 5 GW by 2030 and 10 GW by 2040 using electricity from renewable energy sources. Germany has also pledged to invest up to 7 billion euros in the renewable hydrogen technologies [

12].

As part of the “10-point plan” of the green industrial revolution of the UK, about 12 billion GBP of public investment is allocated for decarburization of the country. The plan includes grants for “zero-“ or ultra-low-emitting vehicles with the phasing out of sales of gasoline and diesel buses and vans by 2030. The UK has also announced the allocation of 28 million GBP to finance five hydrogen-issued projects [

12].

Canada has published a climate plan that includes the goal of banning the sale of new gasoline-powered passenger cars, vans, and pickups by 2035 with their replacement being BEV and FCEV transport.

Norway has allocated 3.6 billion NOK to support the transition from “grey” to “blue” hydrogen and, finally, to “green” hydrogen.

Spain has unveiled a plan to increase hydrogen production from renewable sources and set a target for 300–600 MW of their capacity by 2024 and 4 GW by 2030.

Scotland has announced the allocation of 100 million GPB for new electrolyzers and set a goal to obtain 25 GW of renewable hydrogen by 2050.

The Estonian Transport Administration, coordinating the development of the nationwide public transport, expects that the public transport fleet in Tallinn will be carbon-neutral [

108], assuming that all diesel buses will be replaced by 2025 and gas buses by 2035. At the same time, with the support of the EU, it is planned to create a network of HRSs and to supplement the Tallinn bus fleet with FCEBs.

The Australian government has allocated 70 million AUD to support the deployment of at least two new renewable hydrogen projects and established a new 300 million AUD fund to invest in the renewable hydrogen national industry.

Chile has unveiled a national “green” hydrogen strategy aimed at turning the country into a global producer and exporter of hydrogen by 2040. The strategy consists of a commitment to develop regulation of the use and fabrication of renewable hydrogen, analyze world best practices related to renewable hydrogen, and convene a government sector to develop a roadmap and action plan by 2025, which will identify opportunities for joint financing with the private sector. Chile’s strategy also updates the country’s rules, setting a goal to reduce greenhouse gas emission by 18–27% by switching to renewable fuels.

In several developed countries, more and more active efforts are also being made to expand the use of hydrogen with an emphasis on larger-scale, more environmentally friendly technologies.

This entry is adapted from the peer-reviewed paper 10.3390/en15196945