机械响应式智能窗户具有结构简单、成本低、稳定性好等优点。

- energy saving

- smart window

- mechanoresponsive

- driving mode

1. 简介

2. 机械响应智能窗户的结构

2.1. 基于微/纳米阵列的机械响应智能窗口

2.2. 基于皱纹的机械响应智能窗户

2.3. 基于裂缝的机械响应智能窗户

2.4. 新颖界面引入机械响应智能窗口

2.5. 基于可调接口参数的机械响应智能窗口

2.6. 基于表面-界面协同效应的机械响应智能窗口

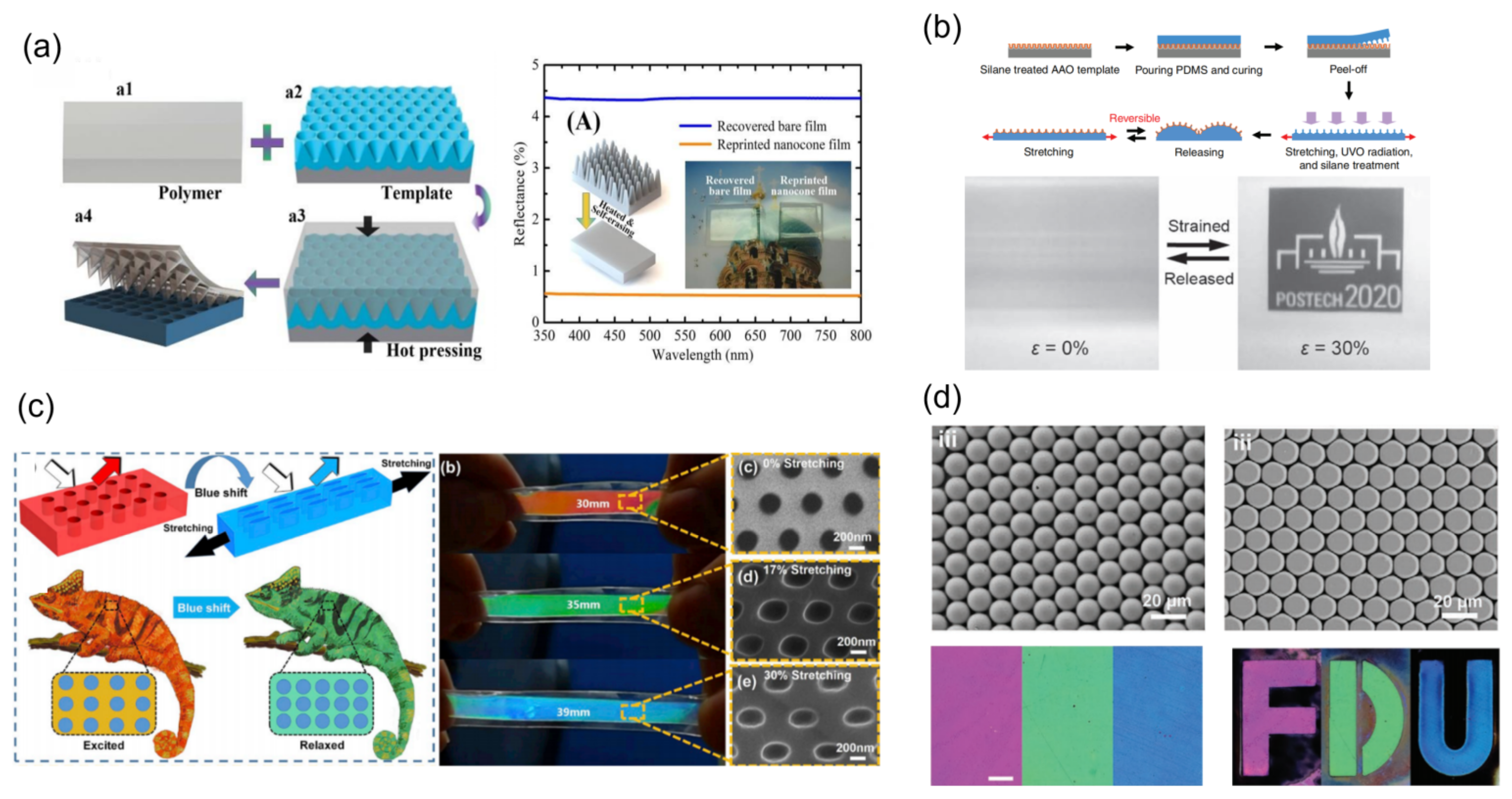

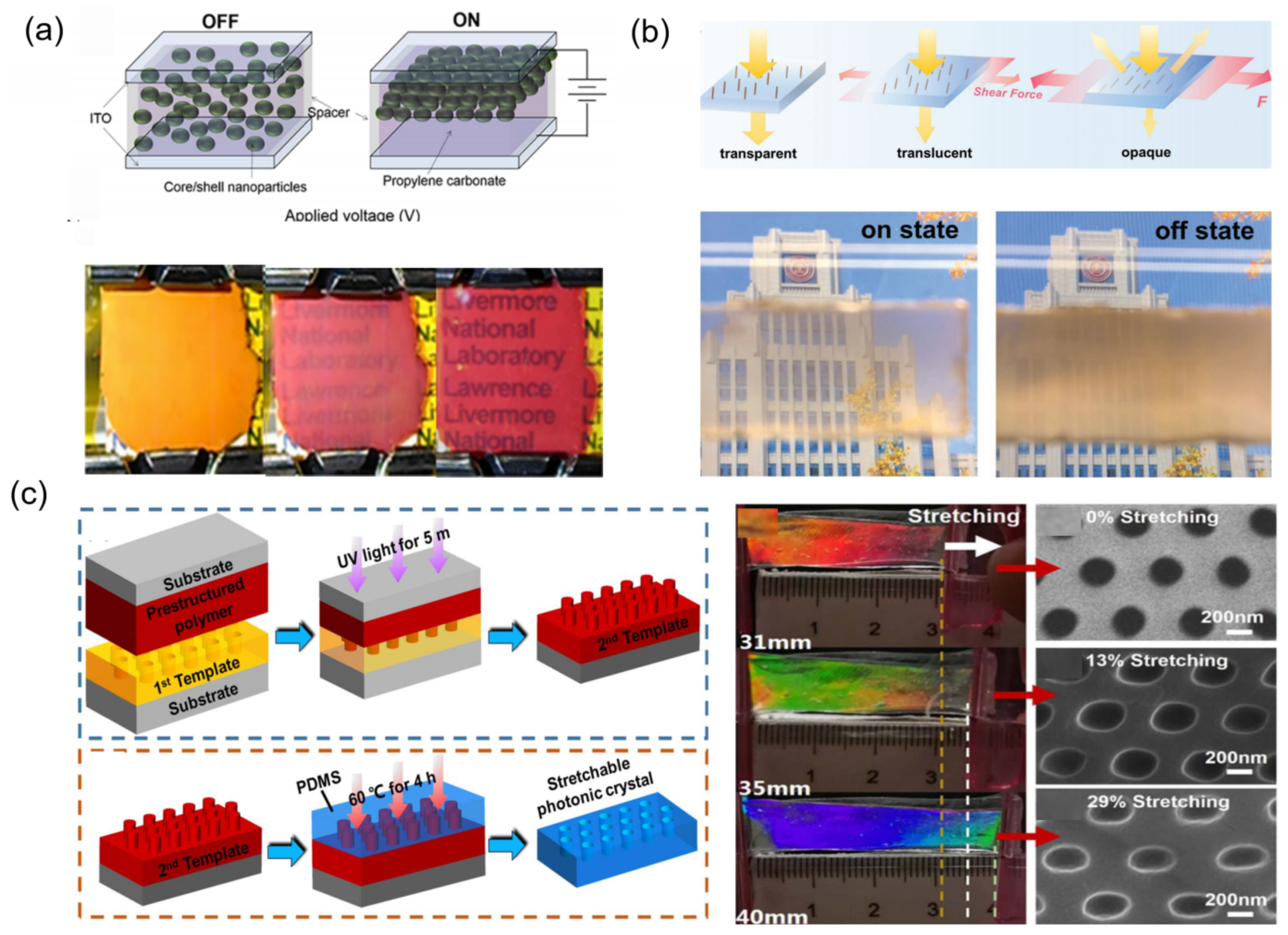

Figure 1a. The strategies of mechanoresponsive smart windows based on nanoarrays: nanocone[20], Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S., Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers (Basel) 2018, 10, 756-765.

Figure 1b. The strategies of mechanoresponsive smart windows based on nanoarrays: nanopillar[21], Lee, S. G.; Lee, D. Y.; Lim, H. S.; Lee, D. H.; Lee, S.; Cho, K., Switchable transparency and wetting of elastomeric smart windows. Adv Mater 2010, 22, 5013-5017.

Figure 1c. The strategies of mechanoresponsive smart windows based on nanoarrays: nanoholes[22], Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y., Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Optical Materials 2019, 94, 378-386.

图 1d.基于纳米阵列的机械响应智能窗策略:纳米球 [23], 季春;陈敏;Wu,L.,可图案和可重写的逆反射结构颜色形状记忆聚合物。先进光学材料2021,94, 2100739.

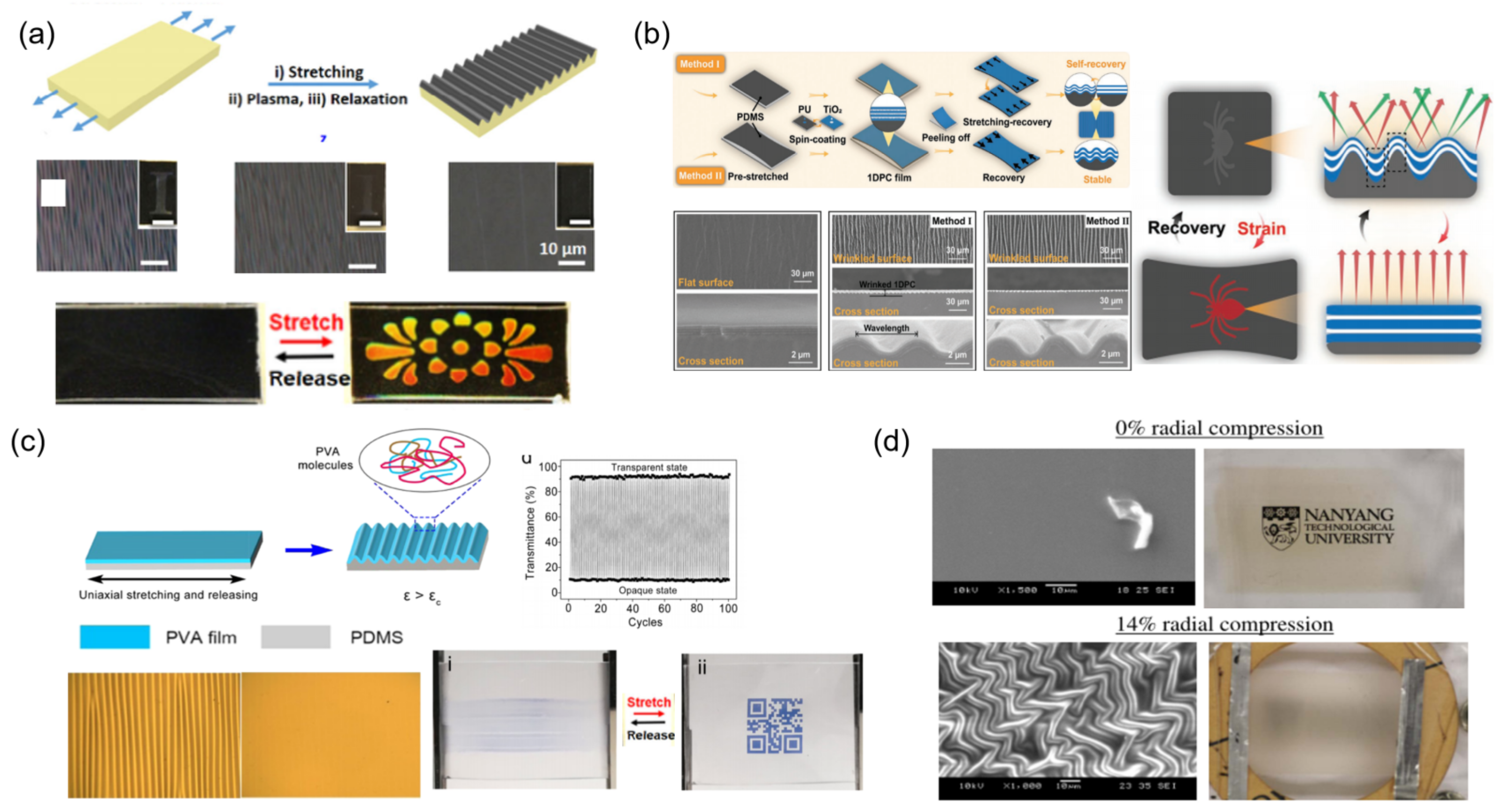

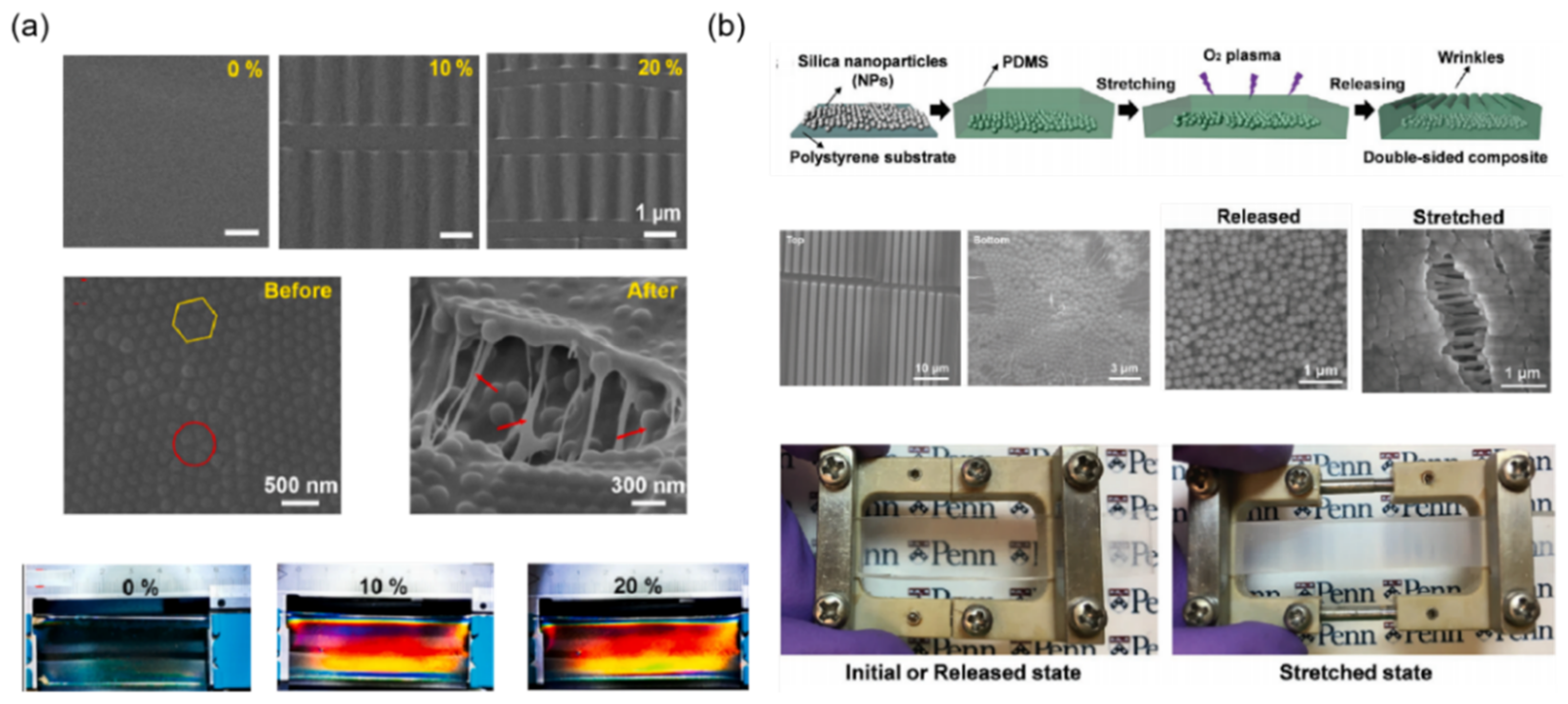

Figure 2a. The strategies of mechanoresponsive smart windows based on wrinkling: stretching to form wrinkles[29], Li, Z. W.; Liu, Y.; Marin, M.; Yin, Y. D., Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res 2020, 13, 1882-1888.

Figure 2b. The strategies of mechanoresponsive smart windows based on wrinkling: wrinkled photonic elastomer structure[30], Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S., Bio‐Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi‐Mode Color Display. Advanced Functional Materials 2022, 32, 2207691.

Figure 2c. The strategies of mechanoresponsive smart windows based on wrinkling: Double-layer film wrinkle[31], Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W., Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl Mater Interfaces 2019, 11, 40406-40415.

Figure 2d. The strategies of mechanoresponsive smart windows based on wrinkling: biaxial compression to form wrinkles[32], Shrestha, M.; Lau, G. K., Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt Lett 2016, 41, 4433-4436.

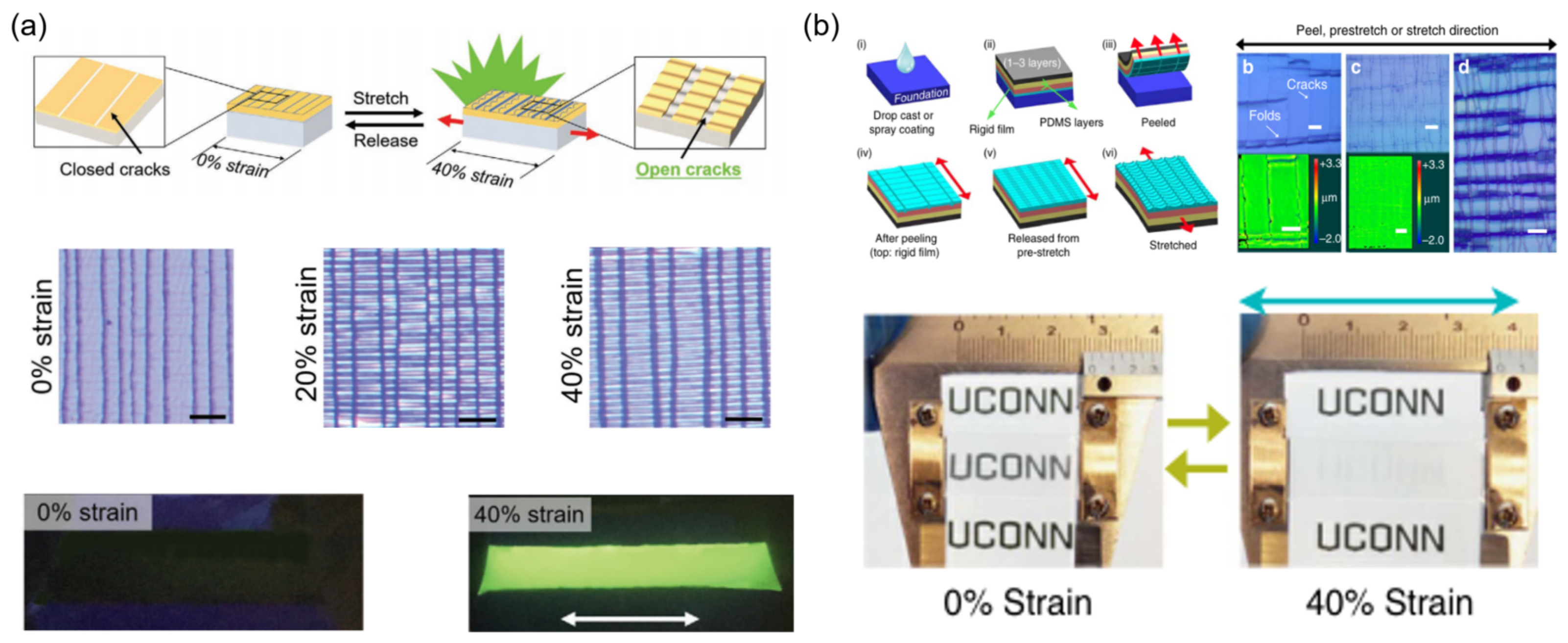

Figure 3a. Construction paths of mechanoresponsive smart windows based on surface crack: surface deposition of metal coating[34], Mao, Z.; Zeng, S.; Shen, K.; Chooi, A. P.; Smith, A. T.; Jones, M. D.; Zhou, Y.; Liu, X.; Sun, L., Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain‐Responsive Digit Display. Advanced Optical Materials 2020, 8, 2001472.

Figure 3b. Construction paths of mechanoresponsive smart windows based on surface crack: soft substrate/ hard shell[35], Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G. M.; Yin, X.; Xiao, J., Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Advanced Optical Materials 2017, 5, 1700425.

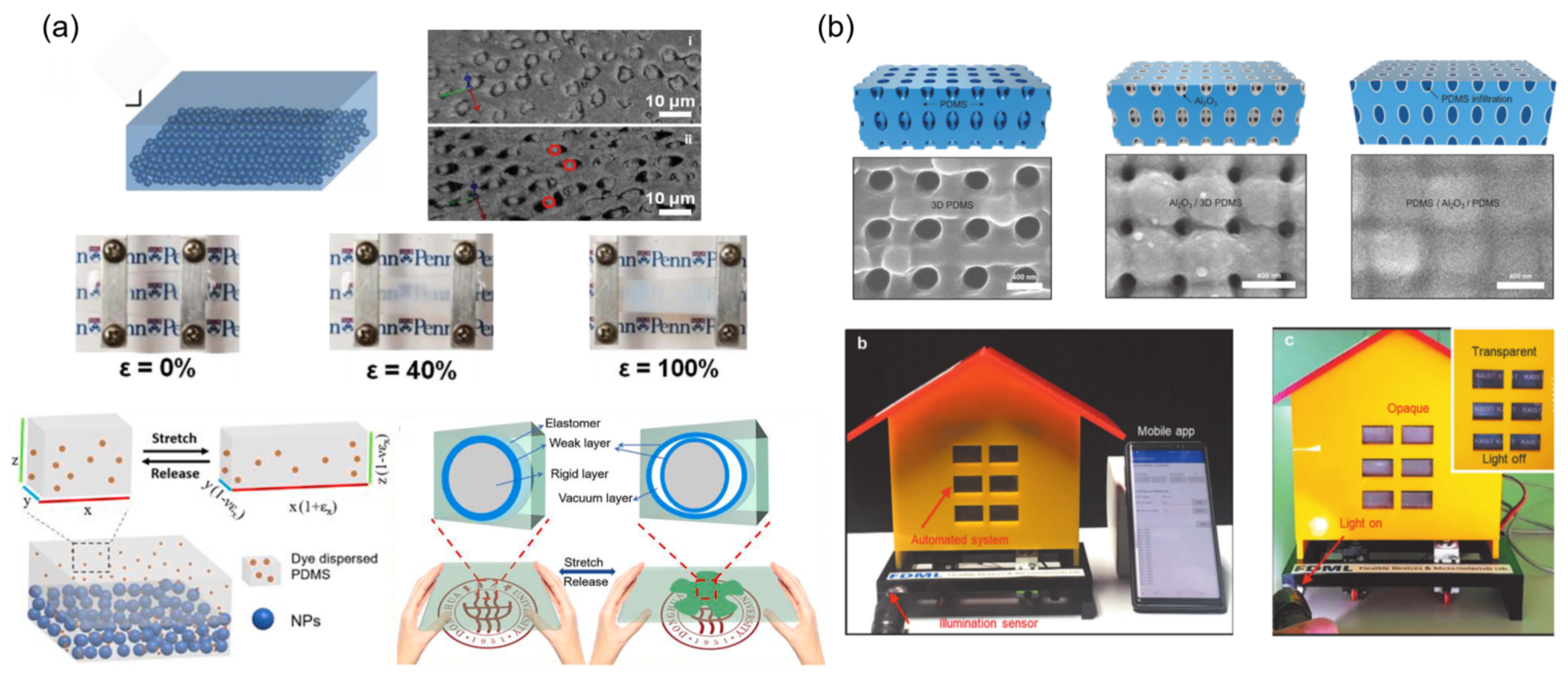

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[38], Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D. S.; Yang, S., A robust smart window: reversibly switching from high transparency to angle-independent structural color display. Adv Mater 2015, 27, 2489-95.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[39], Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-w.; Yoon, H.; Yang, L.; Ge, D., Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chemical Engineering Journal 2022, 429, 132159.

Figure 4b. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[40], Cho, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; Hong, J. W.; Jeon, S., High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv Sci (Weinh) 2020, 7, 1903708.

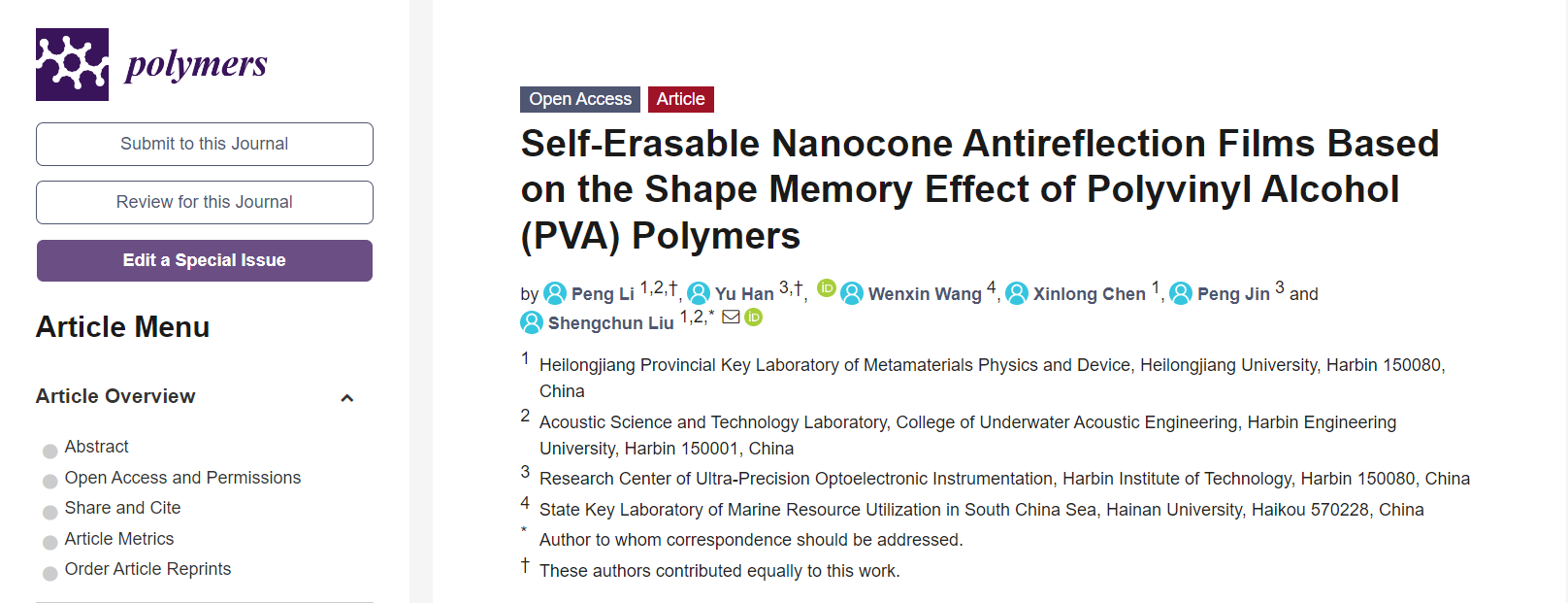

Figure 5a. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle spacing[41], Han, J.; Freyman, M. C.; Feigenbaum, E.; Yong-Jin Han, T., Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343-1350.

Figure 5b. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle direction[42], Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S., Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Advanced Functional Materials 2021, 31, 2102350.

Figure 5c. Mechanoresponsive smart windows with dynamic control of interface parameters: spacing and shape of hole[17]. Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H., Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Materials and Structures 2019, 28, 075037.

Figure 6a. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle, novel interface dynamic formation dynamic control of interface parameters[43], Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B., Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes and Pigments 2021, 189, 109264.

Figure 6b. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle and novel interface dynamic generation[44], Kim, H. N.; Ge, D.; Lee, E.; Yang, S., Multistate and On-Demand Smart Windows. Adv Mater 2018, 30, e1803847.

Figure 7a. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[45], López Jiménez, F.; Kumar, S.; Reis, P. M., Soft Color Composites with Tunable Optical Transmittance. Advanced Optical Materials 2016, 4, 620-626.

Figure 7b. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[46], Kim, S. U.; Lee, Y. J.; Liu, J.; Kim, D. S.; Wang, H.; Yang, S., Broadband and pixelated camouflage in inflating chiral nematic liquid crystalline elastomers. Nat Mater 2022, 21, 41-46.

Figure 7c. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic stretching to adjust transparency[47]; Rotzetter, A. C. C.; Fuhrer, R.; Grass, R. N.; Schumacher, C. M.; Stoessel, P. R.; Stark, W. J., Micro Mirror Polymer Composite Offers Mechanically Switchable Light Transmittance. Advanced Engineering Materials 2014, 16, 878-883.

Figure 7d. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic drive mode mechanochromic hydrogels[48]. Zhu, Q.; Vliet, K.; Holten‐Andersen, N.; Miserez, A., A Double‐Layer Mechanochromic Hydrogel with Multidirectional Force Sensing and Encryption Capability. Advanced Functional Materials 2019, 29, 1808191.

Figure 8a. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[49], Li, F.; Hou, H.; Yin, J.; Jiang, X., Near-infrared light–responsive dynamic wrinkle patterns. Science Advances 4, eaar5762.

Figure 8b. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[50], Xie, M.; Lin, G.; Ge, D.; Yang, L.; Zhang, L.; Yin, J.; Jiang, X., Pattern Memory Surface (PMS) with Dynamic Wrinkles for Unclonable Anticounterfeiting. ACS Materials Letters 2019, 1, 77-82.

Figure 8c. The approaches for optical-driving mechanoresponsive smart windows: (c) based on metal nanoparticles[51], Cao, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S., Sunlight-Driven Photo-Thermochromic Smart Windows. Solar RRL 2018, 2, 1700219.

Figure 8d. The approaches for optical-driving mechanoresponsive smart windows: based on inverse opal scaffold structure[52]. Wang, Y.; Zhang, Z.; Chen, H.; Zhang, H.; Zhang, H.; Zhao, Y., Bio-inspired shape-memory structural color hydrogel film. Science Bulletin 2022, 67, 512-519.

Figure 9a. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of surface wrinkles structure[58], Li, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S., Deformable Thermo-Responsive Smart Windows Based on a Shape Memory Polymer for Adaptive Solar Modulations. ACS Appl Mater Interfaces 2021, 13, 61196-61204.

Figure 9b. The strategy of thermal driving mode of mechanoresponsive smart windows: (a) formation of dynamic network structure[59], Zhao, J.; Zhang, L.; Du, X.; Xu, J.; Lin, T.; Li, Y.; Yang, X.; You, J., Panther chameleon-inspired, continuously-regulated, high-saturation structural color of a reflective grating on the nano-patterned surface of a shape memory polymer. Nanoscale Adv 2022, 4, 2942-2949.

Figure 9c. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of nanostripes structure[60], Xu, Z.-Y.; Li, L.; Du, L.; Wang, L.; Shi, L.-Y.; Yang, K.-K.; Wang, Y.-Z., Multiscale shape-memory effects in a dynamic polymer network for synchronous changes in color and shape. Applied Materials Today 2022, 26, 101276.

Figure 9d. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of dynamic network structure[61], Zhang, W.; Wang, H.; Wang, H.; Chan, J. Y. E.; Liu, H.; Zhang, B.; Zhang, Y. F.; Agarwal, K.; Yang, X.; Ranganath, A. S.; Low, H. Y.; Ge, Q.; Yang, J. K. W., Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat Commun 2021, 12, (1), 112-120.

Figure 10a. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[64], Wang, J. L.; Liu, J. W.; Sheng, S. Z.; He, Z.; Gao, J.; Yu, S. H., Manipulating Nanowire Assemblies toward Multicolor Transparent Electrochromic Device. Nano Lett 2021, 21, 9203-9209.

Figure 10b. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[65], Liu, S.; Zhang, D.; Peng, H.; Jiang, Y.; Gao, X.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J., High-efficient smart windows enabled by self-forming fractal networks and electrophoresis of core-shell TiO2@SiO2 particles. Energy and Buildings 2021, 232, 110657.

Figure 10c. The strategy of electric driving mode mechanoresponsive smart windows: based on carbon nanotube materials to adjust transmittance[66], Zhang, W.; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S., Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. Carbon 2017, 116, 625-632.

Figure 10d. The strategy of electric driving mode mechanoresponsive smart windows: based on surface wrinkle to modulate transmittance[67], Shrestha, M.; Asundi, A.; Lau, G.-K., Smart Window Based on Electric Unfolding of Microwrinkled TiO2 Nanometric Films. ACS Photonics 2018, 5, 3255-3262.

Figure 11a. The strategy of magnetic driving mode mechanoresponsive smart windows: adjusting the ratio of magnetic nanoparticles to change transmittance[70], Yang, J.; Lee, H.; Heo, S. G.; Kang, S.; Lee, H.; Lee, C. H.; Yoon, H., Squid‐Inspired Smart Window by Movement of Magnetic Nanoparticles in Asymmetric Confinement. Advanced Materials Technologies 2019, 4, 1900140.

Figure 11b. The strategy of magnetic driving mode mechanoresponsive smart windows: forming the magnetic nanopillars array to adjust transmittance[71], Luo, Z.; Evans, B. A.; Chang, C. H., Magnetically Actuated Dynamic Iridescence Inspired by the Neon Tetra. ACS Nano 2019, 13, 4657-4666.

Figure 11c. The strategy of magnetic driving mode mechanoresponsive smart windows: forming magnetothermal hydrogel to modulate transmittance[72], Wang, W.; Fan, X.; Li, F.; Qiu, J.; Umair, M. M.; Ren, W.; Ju, B.; Zhang, S.; Tang, B., Magnetochromic Photonic Hydrogel for an Alternating Magnetic Field-Responsive Color Display. Advanced Optical Materials 2018, 6, 1701093.

Figure 12a. The strategy of humidity driving mode mechanoresponsive smart windows: based on thermosensitive hydrogels[73], Wang, M.; Gao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X., Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows. Industrial & Engineering Chemistry Research 2014, 53, , 18462-18472.

Figure 12b. The strategy of humidity driving mode mechanoresponsive smart windows: based on the humidity driving mode wrinkles[74] Zeng, S.; Li, R.; Freire, S. G.; Garbellotto, V. M. M.; Huang, E. Y.; Smith, A. T.; Hu, C.; Tait, W. R. T.; Bian, Z.; Zheng, G.; Zhang, D.; Sun, L., Moisture-Responsive Wrinkling Surfaces with Tunable Dynamics. Adv Mater 2017, 29, 1700828.

Figure 12c. The strategy of humidity driving mode mechanoresponsive smart windows: base on humidity sensitive porous structure[75],Castellón, E.; Zayat, M.; Levy, D., Novel Reversible Humidity-Responsive Light Transmission Hybrid Thin-Film Material Based on a Dispersive Porous Structure with Embedded Hygroscopic and Deliquescent Substances. Advanced Functional Materials 2018, 28, 1704717.

This entry is adapted from the peer-reviewed paper 10.3390/ma16020779

References

- Searchinger, T.D.; Beringer, T.; Holtsmark, B.; Kammen, D.M.; Lambin, E.F.; Lucht, W.; Raven, P.; van Ypersele, J.-P. Europe’s renewable energy directive poised to harm global forests. Nat. Commun. 2018, 9, 3741.

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398.

- Shin, M.; Baltazar, J.-C.; Haberl, J.S.; Frazier, E.; Lynn, B. Evaluation of the energy performance of a net zero energy building in a hot and humid climate. Energy Build. 2019, 204, 109531.

- Ma, Z.Y.; Guan, B.W.; Liu, X.H.; Zhang, T. Performance analysis and improvement of air filtration and ventilation process in semiconductor clean air-conditioning system. Energy Build. 2020, 228, 110489.

- Dussault, J.-M.; Gosselin, L.; Galstian, T. Integration of smart windows into building design for reduction of yearly overall energy consumption and peak loads. Sol. Energy 2012, 86, 3405–3416.

- Wang, M.; Xing, X.; Perepichka, I.F.; Shi, Y.H.; Zhou, D.Y.; Wu, P.H.; Meng, H. Electrochromic Smart Windows Can Achieve an Absolute Private State through Thermochromically Engineered Electrolyte. Adv. Energy Mater. 2019, 9, 1900433.

- Ke, Y.J.; Chen, J.W.; Lin, C.J.; Wang, S.C.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066.

- Zhou, Y.; Fan, F.; Liu, Y.P.; Zhao, S.S.; Xu, Q.; Wang, S.C.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613.

- Svensson, J.S.E.M.; Granqvist, C.G. Electrochromic Coatings for Smart Windows. Sol. Energy Mater. 1985, 12, 391–402.

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828.

- Wang, X.J.; Narayan, S. Thermochromic Materials for Smart Windows: A State-of-Art Review. Front. Energy Res. 2021, 9, 837–841.

- Chun, S.Y.; Park, S.; Lee, S.I.; Nguyen, H.D.; Lee, K.-K.; Hong, S.; Han, C.-H.; Cho, M.; Choi, H.-K.; Kwak, K. Operando Raman and UV-Vis spectroscopic investigation of the coloring and bleaching mechanism of self-powered photochromic devices for smart windows. Nano Energy 2021, 82, 105721.

- Liu, S.; Tso, C.Y.; Lee, H.H.; Zhang, Y.; Yu, K.M.; Chao, C.Y.H. Bio-inspired TiO2 nano-cone antireflection layer for the optical performance improvement of VO2 thermochromic smart windows. Sci. Rep. 2020, 10, 11376.

- Quan, Y.-J.; Kim, Y.-G.; Kim, M.-S.; Min, S.-H.; Ahn, S.-H. Stretchable Biaxial and Shear Strain Sensors Using Diffractive Structural Colors. ACS Nano 2020, 14, 5392–5399.

- Lee, E.; Zhang, M.; Cho, Y.; Cui, Y.; Van der Spiegel, J.; Engheta, N.; Yang, S. Tilted Pillars on Wrinkled Elastomers as a Reversibly Tunable Optical Window. Adv. Mater. 2014, 26, 4127–4133.

- Fan, Z.; Razavi, H.; Do, J.W.; Moriwaki, A.; Ergen, O.; Chueh, Y.L.; Leu, P.W.; Ho, J.C.; Takahashi, T.; Reichertz, L.A. Three-dimensional nanopillar-array photovltaics on low-cost and flexible substrates. Nat. Mater. 2009, 8, 648–653.

- Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H. Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Mater. Struct. 2019, 28, 075037.

- Li, J.; Shim, J.; Deng, J.; Overvelde, J.T.B.; Zhu, X.; Bertoldi, K.; Yang, S. Switching periodic membranes via pattern transformation and shape memory effect. Soft Matter. 2012, 8, 10322–10328.

- Wang, K.; Li, C.; Li, Z.; Li, H.; Li, A.; Li, K.; Lai, X.; Liao, Q.; Xie, F.; Li, M.; et al. A facile fabrication strategy for anisotropic photonic crystals using deformable spherical nanoparticles. Nanoscale 2019, 11, 14147–14154.

- Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers 2018, 10, 756.

- Lee, S.G.; Lee, D.Y.; Lim, H.S.; Lee, D.H.; Lee, S.; Cho, K. Switchable transparency and wetting of elastomeric smart windows. Adv. Mater. 2010, 22, 5013–5017.

- Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y. Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Opt. Mater. 2019, 94, 378–386.

- Ji, C.; Chen, M.; Wu, L. Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Adv. Opt. Mater. 2021, 9, 2100739.

- Thomas, A.V.; Andow, B.C.; Suresh, S.; Eksik, O.; Yin, J.; Dyson, A.H.; Koratkar, N. Controlled Crumpling of Graphene Oxide Films for Tunable Optical Transmittance. Adv. Mater. 2015, 27, 3256–3265.

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325.

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G.; Liu, X.; Dai, Z.; Yan, J.; Yin, J.; et al. Cephalopod-inspired versatile design based on plasmonic VO2 nanoparticle for energy-efficient mechano-thermochromic windows. Nano Energy 2020, 73, 104785.

- Lin, G.; Chandrasekaran, P.; Lv, C.; Zhang, Q.; Tang, Y.; Han, L.; Yin, J. Self-similar Hierarchical Wrinkles as a Potential Multifunctional Smart Window with Simultaneously Tunable Transparency, Structural Color, and Droplet Transport. ACS Appl. Mater. Interfaces 2017, 9, 26510–26517.

- Cao, C.; Chan, H.F.; Zang, J.; Leong, K.W.; Zhao, X. Harnessing localized ridges for high-aspect-ratio hierarchical patterns with dynamic tunability and multifunctionality. Adv. Mater. 2014, 26, 1763–1770.

- Li, Z.W.; Liu, Y.; Marin, M.; Yin, Y.D. Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res. 2020, 13, 1882–1888.

- Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S. Bio-Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi-Mode Color Display. Adv. Funct. Mater. 2022, 32, 2207691.

- Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W. Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl. Mater. Interfaces 2019, 11, 40406–40415.

- Shrestha, M.; Lau, G.-K. Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt. Lett. 2016, 41, 4433–4436.

- Zeng, S.; Zhang, D.; Huang, W.; Wang, Z.; Freire, S.G.; Yu, X.; Smith, A.T.; Huang, E.Y.; Nguon, H.; Sun, L. Bio-inspired sensitive and reversible mechanochromisms via strain-dependent cracks and folds. Nat. Commun. 2016, 7, 11802.

- Mao, Z.; Zeng, S.; Shen, K.; Chooi, A.P.; Smith, A.T.; Jones, M.D.; Zhou, Y.; Liu, X.; Sun, L. Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain-Responsive Digit Display. Adv. Opt. Mater. 2020, 8, 2001472.

- Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G.M.; Yin, X.; Xiao, J. Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Adv. Opt. Mater. 2017, 5, 1700425.

- Jiang, Y.; Zeng, S.; Yao, Y.; Xu, S.; Dong, Q.; Chen, P.; Wang, Z.; Zhang, M.; Zhu, M.; Xu, G.; et al. Dynamic Optics with Transparency and Color Changes under Ambient Conditions. Polymers 2019, 11, 103.

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable Cavitation in Silicone Coatings for Energy-Saving Cooling and Heating. Adv. Mater. 2020, 32, e2000870.

- Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D.S.; Yang, S. A Robust Smart Window: Reversibly Switching from High Transparency to Angle-Independent Structural Color Display. Adv. Mater. 2015, 27, 2489–2495.

- Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-W.; Yoon, H.; Yang, L.; Ge, D. Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chem. Eng. J. 2021, 429, 132159.

- Cho, D.; Shim, Y.S.; Jung, J.W.; Nam, S.H.; Min, S.; Lee, S.E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; et al. High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv. Sci. 2020, 7, 1903708.

- Han, J.; Freyman, M.C.; Feigenbaum, E.; Han, T.Y.-J. Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343–1350.

- Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S. Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Adv. Funct. Mater. 2021, 31, 2102350.

- Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B. Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes Pigments 2021, 189, 109264.

- Kim, H.N.; Ge, D.; Lee, E.; Yang, S. Multistate and On-Demand Smart Windows. Adv. Mater. 2018, 30, e1803847.