Oil-contaminated soil is one of the most concerning problems due to its potential damage to humans, animals, and the environment. In recent years, surfactant foam and nanoparticles have shown high removal of oil pollutants from contaminated soil. Researchers provide an overview on the remediation of oil pollutants in soil using nanoparticles, surfactant foams, and nanoparticle-stabilized surfactant foams. In particular, the fate and transport of oil compounds in the soil, the interaction of nanoparticles and surfactant foam, the removal mechanisms of nanoparticles and various surfactant foams, the effect of some factors (e.g., soil characteristics and amount, nanoparticle properties, surfactant concentration) on remediation efficiency, and some advantages and disadvantages of these methods are evaluated.

- soil remediation

- oil pollutants

- surfactant

- biosurfactant

- surfactant foam

- nanoparticles

- contaminated soil

1. Introduction

2. Remediation Methods of Oil Pollutants in Soil

2.1. Application of Nanoparticles for Remediating Oil Pollutants in Soil

2.1.1. Effect of Nanoparticles on Soil Properties

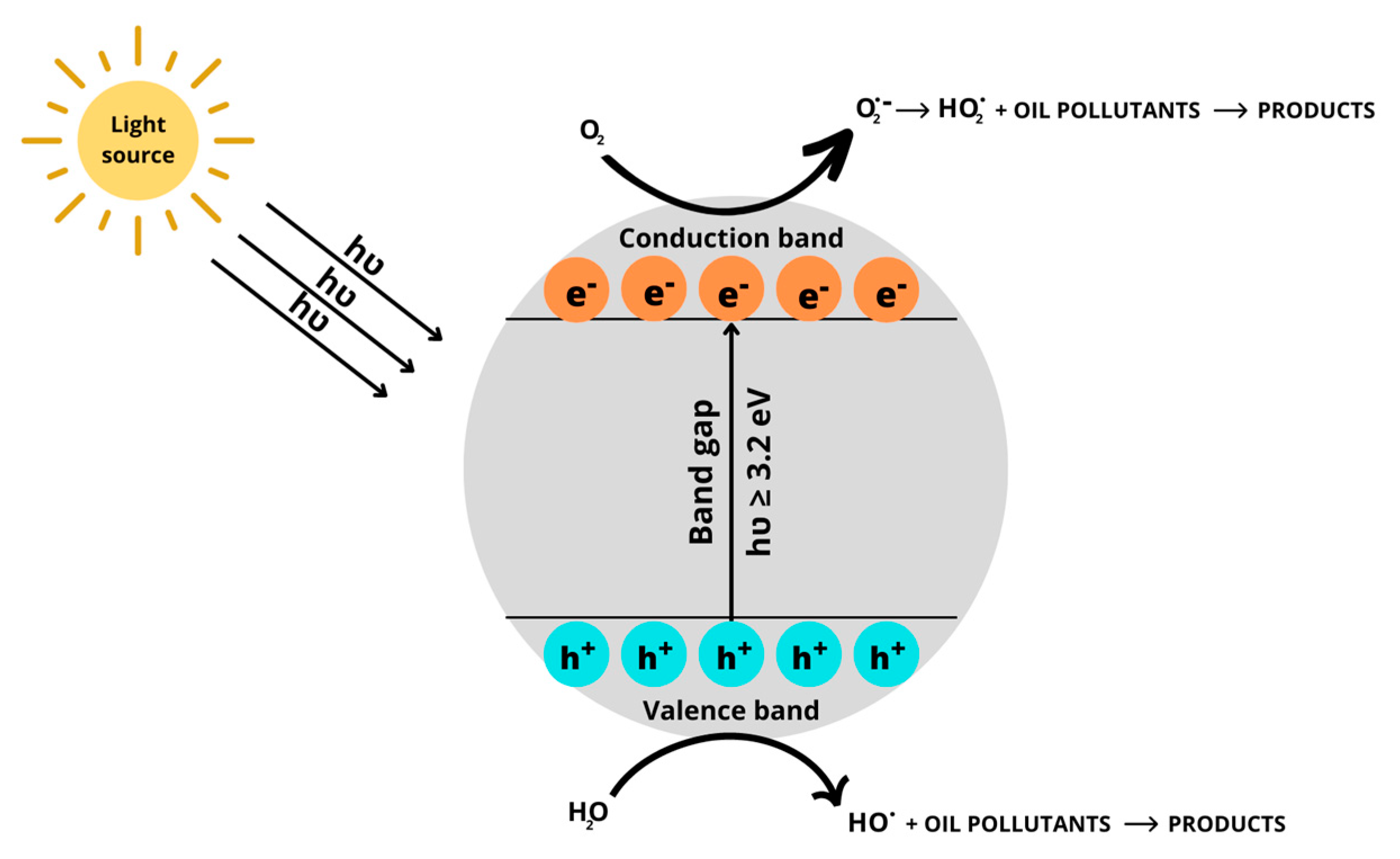

2.1.2. Removal Mechanisms

2.1.3. Treatment of Oil Pollutants in Soil by Nanoparticles

| Nanoparticle Name | Pollutant Name | Treatment Time, Day | Treatment Efficiency, % | Reference |

|---|---|---|---|---|

| MWCNTs 1 | Phenanthrene | 21 | 54.2 | [61] |

| MWCNTs | PAHs 2 | 5 | 79 | [62] |

| nZVI 3 | Phenol | 12 h | 9 | [63] |

| nZVI/BFN 4 | Phenol | 7 h | 98.5 | [63] |

| Iron nanoparticles | PCBs 5 | 6 h | 95 | [64] |

| nZVI | PAHs | 1 h | 70 | [65] |

| APU nanoparticles 6 | PAHs | 5 | 67 | [66] |

| nZVI/biosurfactant | Oil compounds | 1 h | 83 | [40] |

| nZVI/biosurfactant foam | Oil compounds | 30 min | 67 | [34] |

| nZVI | PCBs | 15 | 42 | [67] |

| nZVI-Pd | PCBs | 15 | 64 | [67] |

| nFe3O4 | PCBs | 15 | 68 | [67] |

| Fe-Cu/biochar/geopolymer | Naphthalene | 2 h | 68 | [68] |

| nZVI/bioattenuation | Diesel fuel | 75 | 41.0 | [21] |

| nZVI/biostimulation | Diesel fuel | 45 | 64.6 | [21] |

| nZVI/bioaugmentation | Diesel fuel | 15–30 | 85.3 | [21] |

| nZVI/biostimulation + bioaugmentation | Diesel fuel | 30–60 | 89.5 | [21] |

| Iron oxide nanoparticles | Crude oil | 1 | N/A | [42] |

| Nano rutile TiO2 | Pyrene | 25 h | 52.2 | [69] |

| Nano rutile TiO2 | Phenanthrene | 25 h | 38.9 | [69] |

| Iron oxide nanoparticles | PAHs | 5 | 70 | [70] |

| Akaganeite nano-rods | PAHs | 1 | 65 | [71] |

| Iron oxide nanoparticles | Anthracene | 10 | 99 | [41] |

| Graphene oxide | PAHs | 7 min | ~100 | [72] |

| Fe-doped TiO2 nanocatalyst | PAHs | 35 min | 80 | [73] |

| TiO2-based ZnHCF nanocomposite | PAHs | 1 | 86 | [74] |

| C3N4/Fe3O4 nanocomposite | Phenanthrene | 2 h | 92.3 | [75] |

| Cu2OPLA composite nanofiber | Fluoranthene | 8 h | 67.6 | [76] |

3. Remediation of Oil Pollutants in Soil by Surfactant Foam/Nanoparticle Mixture

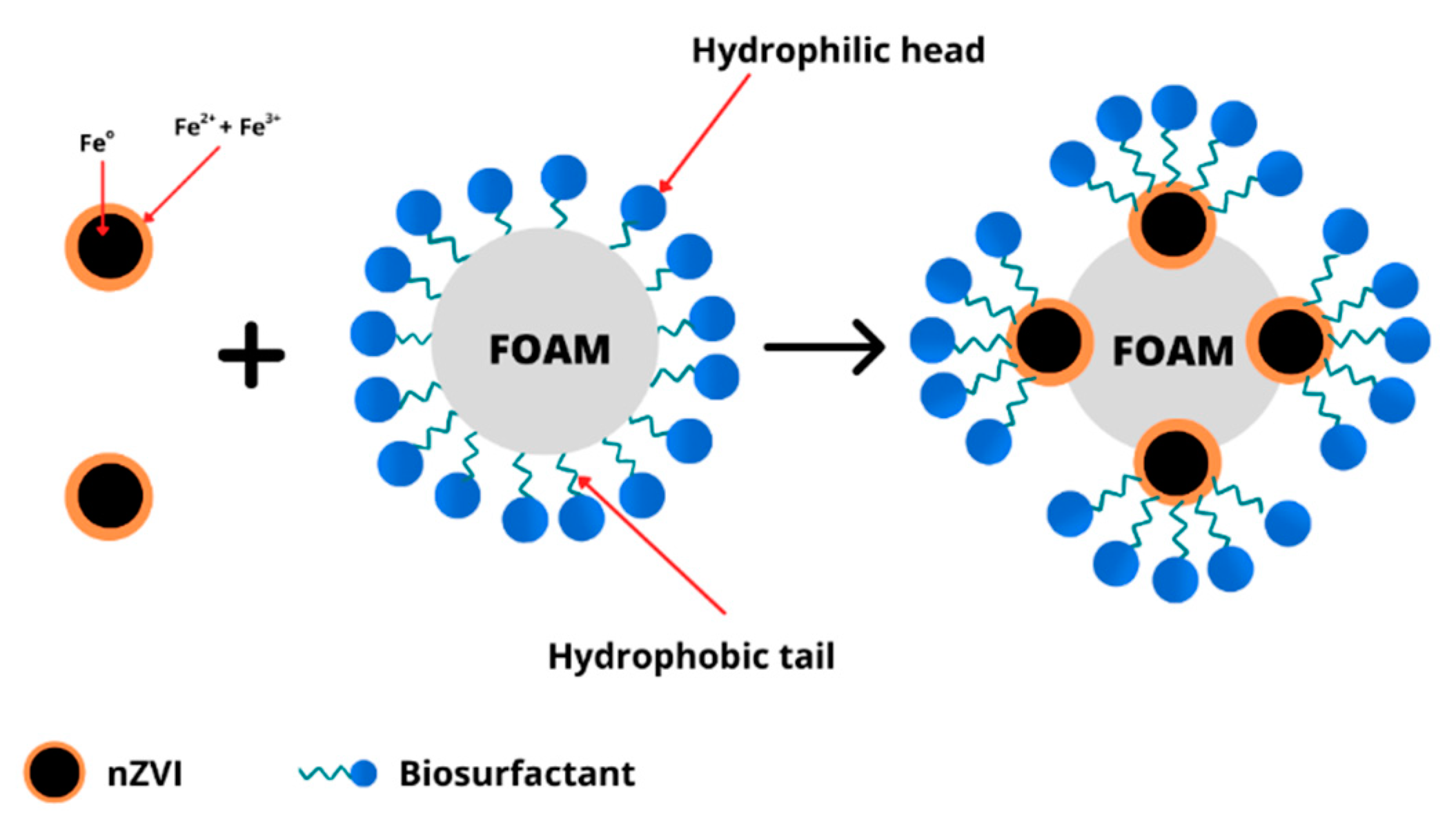

3.1. Interaction of Surfactant Foam and Nanoparticles

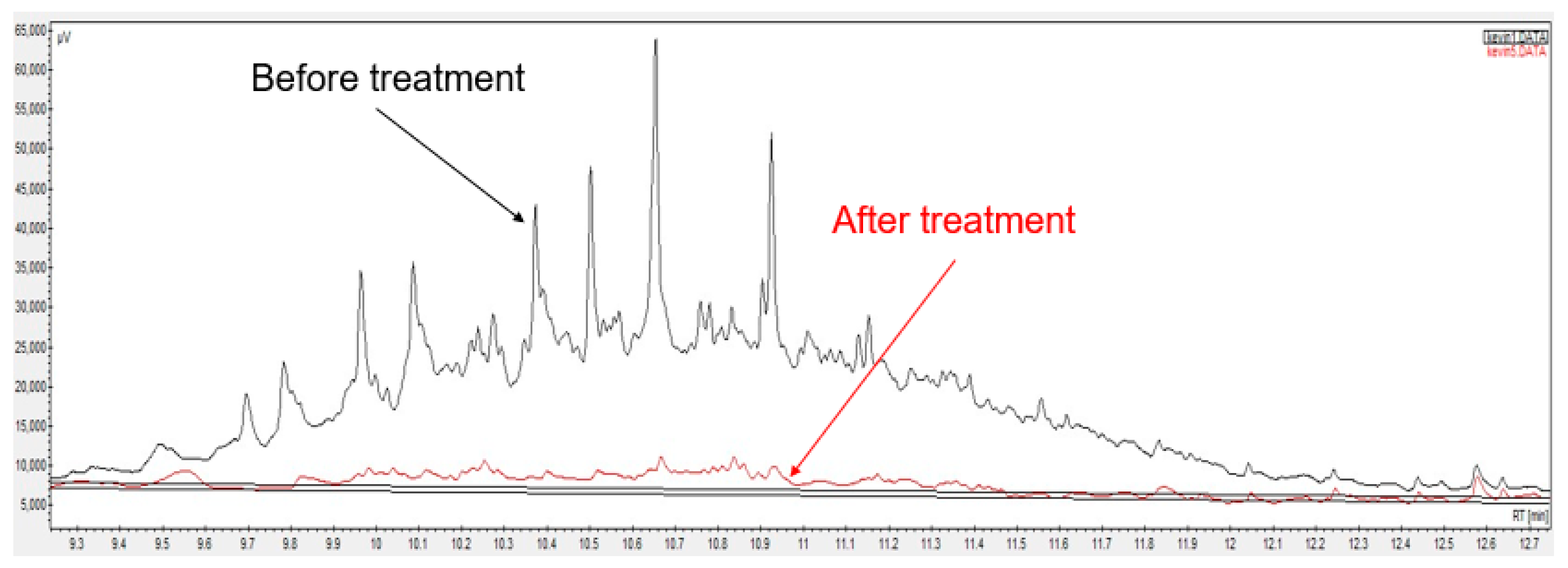

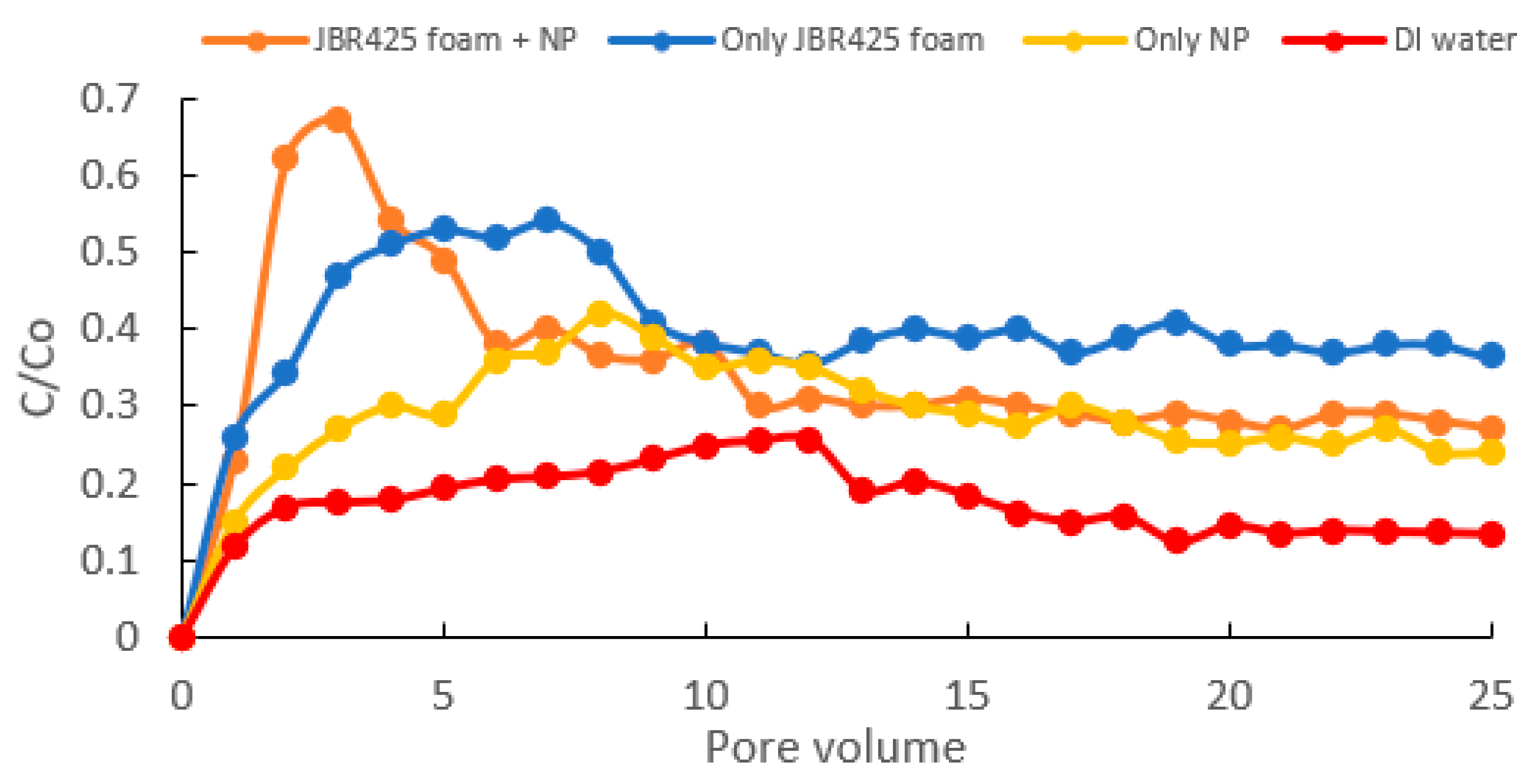

3.2. Use of Surfactant Foam–Nanoparticle Mixture in Soil Remediation

3.3. Effect of Some Factors on Soil Remediation Performance by Surfactant Foam–Nanoparticles

3.3.1. Effect of Environmental Conditions

3.3.2. Effect of Soil Characteristics

3.3.3. Effect of Nanoparticle Properties

3.3.4. Effect of Surfactant Concentration

3.4. Limitations

This entry is adapted from the peer-reviewed paper 10.3390/ijms24031916

References

- Fate and Transport of Petroleum Hydrocarbons in Soil and Ground Water at Big South Fork National River and Recreation Area, Tennessee and Kentucky. 2002–2003. Available online: https://pubs.er.usgs.gov/publication/sir20055104 (accessed on 11 November 2022).

- Varjani, S.J. Microbial degradation of petroleum hydrocarbons. Bioresour. Technol. 2017, 223, 277–286.

- Vu, K.A.; Tawfiq, K.; Chen, G. Rhamnolipid transport in biochar-amended agricultural soil. Water Air Soil Pollut. 2015, 226, 256–264.

- Vu, K.A. Rhamnolipid Biosurfactant Adsorption and Transport in Biochar Amended Agricultural Soil. Mater’s Thesis, Florida State University, Tallahassee, FL, USA, 1 November 2013.

- Vandana; Priyadarshanee, M.; Mahto, U.; Das, S. Mechanism of toxicity and adverse health effects of environmental pollutants. In Microbial Biodegradation and Bioremediation, 2nd ed.; Das, S., Dash, H.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 1, pp. 33–53.

- BP Statistical Review of World Energy. Available online: www.bp.com/statisticalreview (accessed on 16 November 2022).

- Ogunneye, A.L.; Omoboyowa, D.A.; Sonibare, A.L.; Adebusuyi, A.J.; Faniran, T.P. Hepatotoxic and nephrotoxic effects of petroleum fumes on petrol attendants in Ibadan, Nigeria. Niger. J. Basic Appl. Sci. 2014, 22, 57–62.

- Treatment Technologies for Site Cleanup: Annual Status Report. Available online: https://www.epa.gov/remedytech/treatment-technologies-site-cleanup-annual-status-report-twelfth-edition (accessed on 16 November 2022).

- Vu, K.A.; Mulligan, C.N. Synthesis of carbon-based nanomaterials and their use in nanoremediation. In Bio and Nanoremediation of Hazardous Environmental Pollutants, 1st ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2023; accepted.

- Zheng, M.; Ahuja, M.; Bhattacharya, D.; Clement, T.P.; Hayworth, J.S.; Dhanasekaran, M. Evaluation of differential cytotoxic effects of the oil spill dispersant Corexit 9500. Life Sci. 2014, 95, 108–117.

- Vázquez-Luna, D. Chronic toxicity of weathered oil-contaminated soil. In Environmental Risk Assessment of Soil Contamination, 1st ed.; Hernamdez-Soriano, C., Ed.; IntechOpen: London, UK, 2014; Volume 1, pp. 8–103.

- Yuanyuan, W.; Qixing, Z.; Shengwei, P.; Lena, Q.M.; Xiaowei, N. Toxic effects of crude-oil-contaminated soil in aquatic environment on Carassius auratus and their hepatic antioxidant defense system. J. Environ. Sci. 2009, 21, 612–617.

- Li, X.; Karakashev, S.I.; Evans, G.M.; Stevenson, P. Effect of environmental humidity on static foam stability. Langmuir 2012, 28, 4060–4068.

- Mulligan, C.N. Sustainable remediation of contaminated soil using biosurfactants. Front. Bioeng. Biotechnol. 2021, 9, 635196.

- Ossai, I.C.; Ahmed, A.; Hassan, A.; Hamid, F.S. Remediation of soil and water contaminated with petroleum hydrocarbon: A review. Environ. Technol. Innov. 2020, 17, 100526.

- Zhang, M.; He, F.; Zhao, D.; Hao, X. Degradation of soil-sorbed trichloroethylene by stabilized zero valent iron nanoparticles: Effects of sorption, surfactants, and natural organic matter. Water Res. 2011, 45, 2401–2414.

- Chen, X.; Yao, X.; Yu, C.; Su, X.; Shen, C.; Chen, C.; Huang, R.; Xu, X. Hydrodechlorination of polychlorinated biphenyls in contaminated soil from an e-waste recycling area, using nanoscale zerovalent iron and Pd/Fe bimetallic nanoparticles. Environ. Sci. Pollut. Res. 2014, 21, 5201–5210.

- Wang, J.; Chen, Z.; Chen, B. Adsorption of polycyclic aromatic hydrocarbons by graphene and graphene oxide nanosheets. Environ. Sci. Technol. 2014, 48, 4817–4825.

- Chaillan, F.; Chaineau, C.H.; Point, V.; Saliot, A.; Oudot, J. Factors inhibiting bioremediation of soil contaminated with weathered oils and drill cuttings. Environ. Pollut. 2006, 144, 255–265.

- Jeong, S.W.; Jeong, J.; Kim, J. Simple surface foam application enhances bioremediation of oil-contaminated soil in cold conditions. J. Hazard. Mater. 2015, 286, 164–170.

- Kahraman, B.F.; Altin, A.; Ozdogan, N. Remediation of Pb-diesel fuel co-contaminated soil using nano/bio process: Subsequent use of nanoscale zero-valent iron and bioremediation approaches. Environ. Sci. Pollut. Res. 2022, 29, 41110–41124.

- Ren, H.; Zhou, S.; Wang, B.; Peng, L.; Li, X. Treatment mechanism of sludge containing highly viscous heavy oil using biosurfactant. Colloids Surf. A Physicochem. Eng. Asp. 2020, 585, 124117.

- Perfumo, A.; Banat, I.M.; Marchant, R.; Vezzulli, L. Thermally enhanced approaches for bioremediation of hydrocarbon-contaminated soils. Chemosphere 2007, 66, 179–184.

- Wang, L.; Peng, L.; Xie, L.; Deng, P.; Deng, D. Compatibility of surfactants and thermally activated persulfate for enhanced subsurface remediation. Environ. Sci. Technol. 2017, 51, 7055–7064.

- Zhang, X.; Zhang, X.; Wang, S.; Zhao, S. Improved remediation of co-contaminated soils by heavy metals and PAHs with biosurfactant-enhanced soil washing. Sci. Rep. 2022, 12, 3801.

- Huguenot, D.; Mousset, E.; van Hullebusch, E.D.; Oturan, M.A. Combination of surfactant enhanced soil washing and electro-Fenton process for the treatment of soils contaminated by petroleum hydrocarbons. J. Environ. Manag. 2015, 153, 40–47.

- Rongsayamanont, W.; Tongcumpou, C.; Phasukarratchai, N. Diesel-contaminated soil washing by mixed nonionic surfactant emulsion and seed germination test. Water Air Soil Pollut. 2020, 231, 267.

- Souza, L.R.R.; Pomarolli, L.C.; da Veiga, M.A.M.S. From classic methodologies to application of nanomaterials for soil remediation: An integrated view of methods for decontamination of toxic metal(oid)s. Environ. Sci. Pollut. Res. 2020, 27, 10205–10227.

- Pan, B.; Xing, B. Applications and implications of manufactured nanoparticles in soils: A review. Eur. J. Soil Sci. 2012, 63, 437–456.

- Nador, F.; Moglie, Y.; Vitale, C.; Yus, M.; Alonso, F.; Radivoy, G. Reduction of polycyclic aromatic hydrocarbons promoted by cobalt or manganese nanoparticles. Tetrahedron 2010, 66, 4318–4325.

- Verma, Y.; Singh, S.K.; Jatav, H.S.; Rajput, V.D.; Minkina, T. Interaction of zinc oxide nanoparticles with soil: Insights into the chemical and biological properties. Environ. Geochem. Health 2022, 44, 221–234.

- Xue, W.; Huang, D.; Zeng, G.; Wan, J.; Zhang, C.; Xu, R.; Cheng, M.; Deng, R. Nanoscale zero-valent iron coated with rhamnolipid as an effective stabilizer for immobilization of Cd and Pb in river sediments. J. Hazard. Mater. 2018, 341, 381–389.

- Huang, H.; Chen, J.; Liu, S.; Pu, S. Impact of ZnO nanoparticles on soil lead bioavailability and microbial properties. Sci. Total Environ. 2022, 806, 150299.

- Vu, K.A.; Mulligan, C.N. Utilization of a biosurfactant foam/nanoparticle mixture for treatment of oil pollutants in soil. Environ. Sci. Pollut. Res. 2022, 29, 88618–88629.

- Vu, K.A.; Mulligan, C.N. Oil removal from contaminated soil by biosurfactants and Fe/Cu nanoparticles. In Proceedings of the Canadian Society for Civil Engineering Annual Conference, Whistler, BC, Canada, 25–28 May 2022.

- Vu, K.A.; Mulligan, C.N. Preparation of a biosurfactant foam/nanoparticle mixture for removing the oil from soil. In Proceedings of the 44th AMOP Technical Seminar on Environmental Contamination and Response, Edmonton, AB, Canada, 7–9 June 2022.

- Kumar, R.; Raizada, P.; Khan, A.A.P.; Nguyen, V.; Van Le, Q.; Ghotekar, S.; Selvasembian, R.; Gandhi, V.; Singh, A.; Singh, P. Recent progress in emerging BiPO4-based photocatalysts: Synthesis, properties, modification strategies, and photocatalytic applications. J. Mater. Sci. Technol. 2022, 108, 208–225.

- Vu, K.A.; Mulligan, C.N. Remediation of Organic Contaminated Soil by Fe-Based Nanoparticles and Surfactants: A review. Environ. Technol. Rev. 2022, accepted.

- Chen, X.; Chen, B. Macroscopic and spectroscopic investigations of the adsorption of nitroaromatic compounds on graphene oxide, reduced graphene oxide, and graphene nanosheets. Environ. Sci. Technol. 2015, 49, 6181–6189.

- Vu, K.A.; Mulligan, C.N. Remediation of oil-contaminated soil using Fe/Cu nanoparticles and biosurfactants. Environ. Technol. 2022, 44, 1–13.

- Gupta, H.; Kumar, R.; Park, H.; Jeon, B. Photocatalytic efficiency of iron oxide nanoparticles for the degradation of priority pollutant anthracene. Geosyst. Eng. 2017, 20, 21–27.

- Konnova, S.A.; Lvov, Y.M.; Fakhrullin, R.F. Nanoshell assembly for magnet-responsive oil-degrading bacteria. Langmuir 2016, 32, 12552–12558.

- Barzegar, G.; Jorfi, S.; Soltani, R.D.C.; Ahmadi, M.; Saeedi, R.; Abtahi, M.; Ramavandi, B.; Baboli, Z. Enhanced Sono-Fenton-like oxidation of PAH-contaminated soil using Nano-sized magnetite as catalyst: Optimization with response surface methodology. Soil Sediment Contam. Int. J. 2017, 26, 538–557.

- Hou, L.; Wang, L.; Royer, S.; Zhang, H. Ultrasound-assisted heterogeneous Fenton-like degradation of tetracycline over a magnetite catalyst. J. Hazard. Mater. 2016, 302, 458–467.

- Bai, H.; Zhou, J.; Zhang, H.; Tang, G. Enhanced adsorbability and photocatalytic activity of TiO2-graphene composite for polycyclic aromatic hydrocarbons removal in aqueous phase. Colloids Surf. B Biointerfaces 2017, 150, 68–77.

- Marquès, M.; Mari, M.; Audí-Miró, C.; Sierra, J.; Soler, A.; Nadal, M.; Domingo, J.L. Photodegradation of polycyclic aromatic hydrocarbons in soils under a climate change base scenario. Chemosphere 2016, 148, 495–503.

- Li, S.; Anderson, T.A.; Green, M.J.; Maul, J.D.; Cañas-Carrell, J.E. Polyaromatic hydrocarbons (PAHs) sorption behavior unaffected by the presence of multi-walled carbon nanotubes (MWNTs) in a natural soil system. Environ. Sci. Process. Impacts 2013, 15, 1130–1136.

- El-Temsah, Y.S.; Joner, E.J. Effects of nano-sized zero-valent iron (nZVI) on DDT degradation in soil and its toxicity to collembola and ostracods. Chemosphere 2013, 92, 131–137.

- Yu, K.; Sheng, G.D.; McCall, W. Cosolvent effects on dechlorination of soil-sorbed polychlorinated biphenyls using bentonite clay-templated nanoscale zero valent iron. Environ. Sci. Technol. 2016, 50, 12949–12956.

- Jorfi, S.; Rezaee, A.; Moheb-Ali, G. Pyrene removal from contaminated soils by modified Fenton oxidation using iron nano particles. J. Environ. Health Sci. Eng. 2013, 11, 17.

- Karam, F.F.; Hussein, F.H.; Baqir, S.J.; Halbus, A.F.; Dillert, R.; Bahnemann, D. Photocatalytic degradation of anthracene in closed system reactor. Int. J. Photoenergy 2014, 2014, 503825.

- Gu, H.; Hu, K.; Li, D.; Long, Y. SERS detection of polycyclic aromatic hydrocarbons using a bare gold nanoparticles coupled film system. Analyst 2016, 141, 4359–4365.

- Shanker, U.; Jassal, V.; Rani, M. Green synthesis of iron hexacyanoferrate nanoparticles: Potential candidate for the degradation of toxic PAHs. J. Environ. Chem. Eng. 2017, 5, 4108–4120.

- Sannino, F.; Pirozzi, D.; Vitiello, G.; D’errico, G.; Aronne, A.; Fanelli, E.; Pernice, P. Oxidative degradation of phenanthrene in the absence of light irradiatiion by hybrid ZrO2-acetylacetonate gel-derived catalyst. Appl. Catal. B Environ. 2014, 156, 101–107.

- Zhao, S.; Jia, H.; Nulaji, G.; Gao, H.; Wang, F.; Wang, C. Photolysis of polycyclic aromatic hydrocarbons (PAHs) on Fe3+-montmorillonite surface under visible light: Degradation kinetics, mechanism, and toxicity assessments. Chemosphere 2017, 184, 1346–1354.

- Dong, D.; Li, P.; Li, X.; Zhao, Q.; Zhang, Y.; Jia, C.; Li, P. Investigation on the photocatalytic degradation of pyrene on soil surfaces using nanometer anatase TiO2 under UV irradiation. J. Hazard. Mater. 2010, 174, 859–863.

- Moussawi, R.N.; Patra, D. Nanoparticle self-assembled grain like curcumin conjugated ZnO: Curcumin conjugation enhances removal of perylene, fluoranthene and chrysene by ZnO. Sci. Rep. 2016, 6, 24565.

- Xia, S.; Zhang, L.; Zhou, X.; Shao, M.; Pan, G.; Ni, Z. Fabrication of highly dispersed Ti/ZnO-Cr2O3 composite as highly efficient photocatalyst for naphthalene degradation. Appl. Catal. B Environ. 2015, 176, 266–277.

- Liao, W.; Ma, Y.; Chen, A.; Yang, Y. Preparation of fatty acids coated Fe3O4 nanoparticles for adsorption and determination of benzo (a) pyrene in environmental water samples. Chem. Eng. J. 2015, 271, 232–239.

- Vu, K.A.; Mulligan, C.N. Synthesis and application of nanoparticles and biosurfactant for oil-contaminated soil removal. In Proceedings of the 73rd Canadian Geotechnical Conference, Calgary, AB, Canada, 14–16 September 2020.

- Xia, X.; Li, Y.; Zhou, Z.; Feng, C. Bioavailability of adsorbed phenanthrene by black carbon and multi-walled carbon nanotubes to Agrobacterium. Chemosphere 2010, 78, 1329–1336.

- Wang, X.; Tao, S.; Xing, B. Sorption and competition of aromatic compounds and humic acid on multiwalled carbon nanotubes. Environ. Sci. Technol. 2009, 43, 6214–6219.

- Kuang, Y.; Zhou, Y.; Chen, Z.; Megharaj, M.; Naidu, R. Impact of Fe and Ni/Fe nanoparticles on biodegradation of phenol by the strain Bacillus fusiformis (BFN) at various pH values. Bioresour. Technol. 2013, 136, 588–594.

- Varanasi, P.; Fullana, A.; Sidhu, S. Remediation of PCB contaminated soils using iron nano-particles. Chemosphere 2007, 66, 1031–1038.

- Chang, M.; Shu, H.; Hsieh, W.; Wang, M. Remediation of soil contaminated with pyrene using ground nanoscale zero-valent iron. J. Air Waste Manag. Assoc. 2007, 57, 221–227.

- Tungittiplakorn, W.; Lion, L.W.; Cohen, C.; Kim, J. Engineered polymeric nanoparticles for soil remediation. Environ. Sci. Technol. 2004, 38, 1605–1610.

- Gil-Díaz, M.; Pérez, R.A.; Alonso, J.; Miguel, E.; Diez-Pascual, S.; Lobo, M.C. Iron nanoparticles to recover a co-contaminated soil with Cr and PCBs. Sci. Rep. 2022, 12, 3541.

- Zhu, Y.; Ji, S.; Liang, W.; Li, C.; Nie, Y.; Dong, J.; Shi, W.; Ai, S. A low-cost and eco-friendly powder catalyst: Iron and copper nanoparticles supported on biochar/geopolymer for activating potassium peroxymonosulfate to degrade naphthalene in water and soil. Chemosphere 2022, 303, 135185.

- Dong, D.; Li, P.; Li, X.; Xu, C.; Gong, D.; Zhang, Y.; Zhao, Q.; Li, P. Photocatalytic degradation of phenanthrene and pyrene on soil surfaces in the presence of nanometer rutile TiO2 under UV-irradiation. Chem. Eng. J. 2010, 158, 378–383.

- Gupta, H.; Gupta, B. Photocatalytic degradation of polycyclic aromatic hydrocarbon benzo pyrene by iron oxides and identification of degradation products. Chemosphere 2015, 138, 924–931.

- Gupta, H. Photocatalytic degradation of phenanthrene in the presence of akaganeite nano-rods and the identification of degradation products. RSC Adv. 2016, 6, 112721–112727.

- Yang, X.; Cai, H.; Bao, M.; Yu, J.; Lu, J.; Li, Y. Insight into the highly efficient degradation of PAHs in water over graphene oxide/Ag3PO4 composites under visible light irradiation. Chem. Eng. J. 2018, 334, 355–376.

- Theerakarunwong, C.D.; Phanichphant, S. Visible-light-induced photocatalytic degradation of PAH-contaminated soil and their pathways by Fe-doped TiO2 nanocatalyst. Water Air Soil Pollut. 2018, 229, 291.

- Rachna; Rani, M.; Shanker, U. Degradation of tricyclic polyaromatic hydrocarbons in water, soil and river sediment with a novel TiO2 based heterogeneous nanocomposite. J. Environ. Manag. 2019, 248, 109340.

- Wang, J.; Luo, Z.; Song, Y.; Zheng, X.; Qu, L.; Qian, J.; Wu, Y.; Wu, X.; Wu, Z. Remediation of phenanthrene contaminated soil by g-C3N4/Fe3O4 composites and its phytotoxicity evaluation. Chemosphere 2019, 221, 554–562.

- Xu, Q.; Huang, Z.; Ji, S.; Zhou, J.; Shi, R.; Shi, W. Cu2O nanoparticles grafting onto PLA fibers via electron beam irradiation: Bifunctional composite fibers with enhanced photocatalytic of organic pollutants in aqueous and soil systems. J. Radioanal. Nucl. Chem. 2020, 323, 253–261.

- Kumari, B.; Singh, D.P. A review on multifaceted application of nanoparticles in the field of bioremediation of petroleum hydrocarbons. Ecol. Eng. 2016, 97, 98–105.

- Khatoon, H.; Rai, J.P.N. Optimization studies on biodegradation of atrazine by Bacillus badius ABP6 strain using response surface methodology. Biotechnol. Rep. 2020, 26, e00459.

- Bebić, J.; Banjanac, K.; Ćorović, M.; Milivojević, A.; Simović, M.; Marinković, A.; Bezbradica, D. Immobilization of laccase from Myceliophthora thermophila on functionalized silica nanoparticles: Optimization and application in lindane degradation. Chin. J. Chem. Eng. 2020, 28, 1136–1144.

- Simjoo, M.; Rezaei, T.; Andrianov, A.; Zitha, P.L.J. Foam stability in the presence of oil: Effect of surfactant concentration and oil type. Colloid. Surf. A Physicochem. Eng. Asp. 2013, 438, 148–158.

- Schramm, L.L.; Novosad, J.J. Micro-visualization of foam interactions with a crude oil. Colloids Surf. 1990, 46, 21–43.

- Hurtado, Y.; Beltrán, C.; Zabala, R.D.; Lopera, S.H.; Franco, C.A.; Nassar, N.N.; Cortés, F.B. Effects of surface acidity and polarity of SiO2 nanoparticles on the foam stabilization applied to natural gas flooding in tight gas-condensate reservoirs. Energy Fuels 2018, 32, 5824–5833.

- Binks, B.P. Colloidal particles at a range of fluid–fluid interfaces. Langmuir 2017, 33, 6947–6963.

- Horozov, T.S.; Aveyard, R.; Clint, J.H.; Neumann, B. Particle zips: Vertical emulsion films with particle monolayers at their surfaces. Langmuir 2005, 21, 2330–2341.

- Xie, W.; Vu, K.; Yang, G.; Tawfiq, K.; Chen, G. Escherichia coli growth and transport in the presence of nanosilver under variable growth conditions. Environ. Technol. 2014, 35, 2306–2313.

- Gonzenbach, U.T.; Studart, A.R.; Tervoort, E.; Gauckler, L.J. Stabilization of foams with inorganic colloidal particles. Langmuir 2006, 22, 10983–10988.

- Sun, Q.; Li, Z.; Wang, J.; Li, S.; Li, B.; Jiang, L.; Wang, H.; Lü, Q.; Zhang, C.; Liu, W. Aqueous foam stabilized by partially hydrophobic nanoparticles in the presence of surfactant. Colloids Surf. A Physicochem. Eng. Asp. 2015, 471, 54–64.

- Li, Q.; Prigiobbe, V. Measuring and modeling nanoparticle transport by foam in porous media. J. Contam. Hydrol. 2021, 243, 103881.

- Li, Q.; Prigiobbe, V. Studying the generation of foam in the presence of nanoparticles using a microfluidic system. Chem. Eng. Sci. 2020, 215, 115427.

- Oliveira, R.C.; Oliveira, J.F.; Moudgil, B.M. The effect of hydrophobic fine particles on the foam flushing remediation process. Surf. Colloid Sci. 2004, 128, 293–297.

- Garbin, V.; Jenkins, I.; Sinno, T.; Crocker, J.C.; Stebe, K.J. Interactions and stress relaxation in monolayers of soft nanoparticles at fluid-fluid interfaces. Phys. Rev. Lett. 2015, 114, 108301.

- Zargartalebi, M.; Kharrat, R.; Barati, N. Enhancement of surfactant flooding performance by the use of silica nanoparticles. Fuel 2015, 143, 21–27.

- Yu, H.; He, Y.; Li, P.; Li, S.; Zhang, T.; Rodriguez-Pin, E.; Du, S.; Wang, C.; Cheng, S.; Bielawski, C.W. Flow enhancement of water-based nanoparticle dispersion through microscale sedimentary rocks. Sci. Rep. 2015, 5, 8702.

- Shearer, L.T.; Akers, W.W. Foam stability. J. Phys. Chem. 1958, 62, 1264–1268.

- Ju, B.; Fan, T.; Ma, M. Enhanced oil recovery by flooding with hydrophilic nanoparticles. China Particuol. 2006, 4, 41–46.

- Otto, M.; Floyd, M.; Bajpai, S. Nanotechnology for site remediation. Remediat. J. Environ. Cleanup Costs Technol. Tech. 2008, 19, 99–108.

- Worthen, A.J.; Bagaria, H.G.; Chen, Y.; Bryant, S.L.; Huh, C.; Johnston, K.P. Nanoparticle-stabilized carbon dioxide-in-water foams with fine texture. J. Colloid Interface Sci. 2013, 391, 142–151.

- Lv, Q.; Li, Z.; Li, B.; Li, S.; Sun, Q. Study of nanoparticle-surfactant-stabilized foam as a fracturing fluid. Ind. Eng. Chem. Res. 2015, 54, 9468–9477.

- Zheng, X.; Jang, J. Hydraulic properties of porous media saturated with nanoparticle-stabilized air-water foam. Sustainability 2016, 8, 1317.

- Ding, Y.; Liu, B.; Shen, X.; Zhong, L.; Li, X. Foam-assisted delivery of nanoscale zero valent iron in porous media. J. Environ. Eng. 2013, 139, 1206–1212.

- Shen, X.; Zhao, L.; Ding, Y.; Liu, B.; Zeng, H.; Zhong, L.; Li, X. Foam, a promising vehicle to deliver nanoparticles for vadose zone remediation. J. Hazard. Mater. 2011, 186, 1773–1780.

- Chattopadhyay, P.; Karthick, R.A. Characterization and Application of Surfactant Foams Produced from Ethanol-Sodium Lauryl Sulfate-Silica Nanoparticle Mixture for Soil Remediation. Macromol. Symp. 2017, 376, 1600182.

- Karthick, R.A.; Chattopadhyay, P. Remediation of diesel contaminated soil by tween-20 foam stabilized by silica nanoparticles. Int. J. Chem. Eng. Appl. 2017, 8, 194–198.

- Quinn, J.; Geiger, C.; Clausen, C.; Brooks, K.; Coon, C.; O’Hara, S.; Krug, T.; Major, D.; Yoon, W.; Gavaskar, A. Field demonstration of DNAPL dehalogenation using emulsified zero-valent iron. Environ. Sci. Technol. 2005, 39, 1309–1318.

- Zhao, X.; Liu, W.; Cai, Z.; Han, B.; Qian, T.; Zhao, D. An overview of preparation and applications of stabilized zero-valent iron nanoparticles for soil and groundwater remediation. Water Res. 2016, 100, 245–266.

- He, F.; Zhao, D.; Paul, C. Field assessment of carboxymethyl cellulose stabilized iron nanoparticles for in situ destruction of chlorinated solvents in source zones. Water Res. 2010, 44, 2360–2370.

- Bennett, P.; He, F.; Zhao, D.; Aiken, B.; Feldman, L. In situ testing of metallic iron nanoparticle mobility and reactivity in a shallow granular aquifer. J. Contam. Hydrol. 2010, 116, 35–46.

- Scott, M.J.; Jones, M.N. The biodegradation of surfactants in the environment. Biochim. Biophys. Acta BBA Biomembr. 2000, 1508, 235–251.

- Jahan, K.; Balzer, S.; Mosto, P. Toxicity of nonionic surfactants. WIT Trans. Ecol. Environ. 2008, 110, 281–290.

- Ishiguro, M.; Koopal, L.K. Surfactant adsorption to soil components and soils. Adv. Colloid Interface Sci. 2016, 231, 59–102.

- Ramprasad, C.; Philip, L. Sorption of surfactants and personal care products in Indian soils. Int. J. Environ. Sci. Technol. 2017, 14, 853–866.

- Brandt, K.K.; Hesselsoe, M.; Roslev, P.; Henriksen, K.; Sorensen, J. Toxic effects of linear alkylbenzene sulfonate on metabolic activity, growth rate, and microcolony formation of Nitrosomonas and Nitrosospira strains. Appl. Environ. Microbiol. 2001, 67, 2489–2498.

- Volkering, F.; Breure, A.M.; Rulkens, W.H. Microbiological aspects of surfactant use for biological soil remediation. Biodegradation 1997, 8, 401–417.

- Mnif, I.; Sahnoun, R.; Ellouz-Chaabouni, S.; Ghribi, D. Application of bacterial biosurfactants for enhanced removal and biodegradation of diesel oil in soil using a newly isolated consortium. Process Saf. Environ. Prot. 2017, 109, 72–81.

- Karthick, A.; Roy, B.; Chattopadhyay, P. Comparison of zero-valent iron and iron oxide nanoparticle stabilized alkyl polyglucoside phosphate foams for remediation of diesel-contaminated soils. J. Environ. Manag. 2019, 240, 93–107.

- Yen, C.; Chen, K.; Kao, C.; Liang, S.; Chen, T. Application of persulfate to remediate petroleum hydrocarbon-contaminated soil: Feasibility and comparison with common oxidants. J. Hazard. Mater. 2011, 186, 2097–2102.

- Li, J.; He, N.; Wei, X.; Gao, Y.; Zuo, Y. Changes in temperature sensitivity and activation energy of soil organic matter decomposition in different Qinghai-Tibet Plateau grasslands. PLoS ONE 2015, 10, e0132795.

- Li, G.; Guo, S.; Hu, J. The influence of clay minerals and surfactants on hydrocarbon removal during the washing of petroleum-contaminated soil. Chem. Eng. J. 2016, 286, 191–197.

- Vu, K.A.; Mulligan, C.N. Treatment of oil pollutants in soil using a biosurfactant/nanoparticle suspension. In Proceedings of the 20th Global Joint Seminar on Geo-Environmental Engineering, Osaka, Japan, 19–20 May 2022.

- Xinhong, G.; Ying, T.; Wenjie, R.; Jun, M.A.; Christie, P.; Yongming, L. Optimization of ex-situ washing removal of polycyclic aromatic hydrocarbons from a contaminated soil using nano-sulfonated graphene. Pedosphere 2017, 27, 527–536.

- Mańko, D.; Zdziennicka, A.; Jańczuk, B. Thermodynamic properties of rhamnolipid micellization and adsorption. Colloids Surf. B Biointerfaces 2014, 119, 22–29.

- Wang, Y.; Zhou, D.; Wang, Y.; Wang, L.; Cang, L. Automatic pH control system enhances the dechlorination of 2,4,4′-trichlorobiphenyl and extracted PCBs from contaminated soil by nanoscale Fe0 and Pd/Fe0. Environ. Sci. Pollut. Res. 2012, 19, 448–457.

- Gil-Díaz, M.; Alonso, J.; Rodríguez-Valdés, E.; Gallego, J.R.; Lobo, M.C. Comparing different commercial zero valent iron nanoparticles to immobilize As and Hg in brownfield soil. Sci. Total Environ. 2017, 584, 1324–1332.

- Blanco, E.; Lam, S.; Smoukov, S.K.; Velikov, K.P.; Khan, S.A.; Velev, O.D. Stability and viscoelasticity of magneto-pickering foams. Langmuir 2013, 29, 10019–10027.

- Harikrishnan, A.R.; Dhar, P.; Agnihotri, P.K.; Gedupudi, S.; Das, S.K. Effects of interplay of nanoparticles, surfactants and base fluid on the surface tension of nanocolloids. Eur. Phys. J. E 2017, 40, 53.

- Bhuiyan, M.; Saidur, R.; Amalina, M.A.; Mostafizur, R.M.; Islam, A. Effect of nanoparticles concentration and their sizes on surface tension of nanofluids. Procedia Eng. 2015, 105, 431–437.

- Sharma, N.; Ghosh, A.; Fortner, J.D.; Giammar, D.E. Modeling performance of rhamnolipid-coated engineered magnetite nanoparticles for U (vi) sorption and separation. Environ. Sci. Nano 2020, 7, 2010–2020.

- Gong, X.; Huang, D.; Liu, Y.; Zeng, G.; Wang, R.; Wan, J.; Zhang, C.; Cheng, M.; Qin, X.; Xue, W. Stabilized nanoscale zerovalent iron mediated cadmium accumulation and oxidative damage of Boehmeria nivea (L.) Gaudich cultivated in cadmium contaminated sediments. Environ. Sci. Technol. 2017, 51, 11308–11316.

- Liang, J.; Xia, X.; Yuan, L.; Zhang, W.; Lin, K.; Zhou, B.; Hu, S. The reproductive responses of earthworms (Eisenia fetida) exposed to nanoscale zero-valent iron (nZVI) in the presence of decabromodiphenyl ether (BDE209). Environ. Pollut. 2018, 237, 784–791.

- Burketová, L.; Martinec, J.; Siegel, J.; Macůrková, A.; Maryška, L.; Valentová, O. Noble metal nanoparticles in agriculture: Impacts on plants, associated microorganisms, and biotechnological practices. Biotechnol. Adv. 2022, 58, 107929.

- Pawlett, M.; Ritz, K.; Dorey, R.A.; Rocks, S.; Ramsden, J.; Harris, J.A. The impact of zero-valent iron nanoparticles upon soil microbial communities is context dependent. Environ. Sci. Pollut. Res. 2013, 20, 1041–1049.

- Saccà, M.L.; Fajardo, C.; Nande, M.; Martín, M. Effects of nano zero-valent iron on Klebsiella oxytoca and stress response. Microb. Ecol. 2013, 66, 806–812.

- Diao, M.; Yao, M. Use of zero-valent iron nanoparticles in inactivating microbes. Water Res. 2009, 43, 5243–5251.

- Vanzetto, G.V.; Thomé, A. Toxicity of nZVI in the growth of bacteria present in contaminated soil. Chemosphere 2022, 303, 135002.

- Fajardo, C.; Ortíz, L.T.; Rodríguez-Membibre, M.L.; Nande, M.; Lobo, M.C.; Martin, M. Assessing the impact of zero-valent iron (ZVI) nanotechnology on soil microbial structure and functionality: A molecular approach. Chemosphere 2012, 86, 802–808.

- El-Temsah, Y.S.; Sevcu, A.; Bobcikova, K.; Cernik, M.; Joner, E.J. DDT degradation efficiency and ecotoxicological effects of two types of nano-sized zero-valent iron (nZVI) in water and soil. Chemosphere 2016, 144, 2221–2228.

- Ortega-Calvo, J.; Jimenez-Sanchez, C.; Pratarolo, P.; Pullin, H.; Scott, T.B.; Thompson, I.P. Tactic response of bacteria to zero-valent iron nanoparticles. Environ. Pollut. 2016, 213, 438–445.

- Vu, K.; Yang, G.; Wang, B.; Tawfiq, K.; Chen, G. Bacterial interactions and transport in geological formation of alumino-silica clays. Colloids Surf. B Biointerfaces 2015, 125, 45–50.