Thermophilic anaerobic digestion (TAD) technology has been adopted worldwide mainly due to it being a pathogen-free process in addition to the enhanced biogas yield and short hydraulic retention time (HRT). Taking the high metabolic rate of the thermophilic microbial community with highly efficient enzymatic systems into consideration, thermophiles are being widely explored as efficient inocula for lignocellulosic biomass (LCB) degradation and improved biomethane production. The advantages of TAD over mesophilic anaerobic digestion (MAD), including improved kinetics, efficient degradation of organic matter, and economic and environmental sustainability, make it one of the best strategies to be operated at moderately high temperatures.

1. Development of Robust Microbiome: Selection, Acclimatization, and Bioaugmentation of Inoculum

A robust inoculum in AD refers to one which provides stable and abundant microbiota to degrade the substrate efficiently into a useable product such as methane. The source of origin plays a vital role in shaping a robust inoculum characteristic, such as its adaptation to the substrate and/or the operating conditions. In the case of LCB, the hydrolysis step requires longer time periods because the inoculum employed is not adapted to lignocelluloses and/or the thermophilic conditions. TAD performs well with the inocula that are already acclimated to thermophilic temperature due to the presence of active thermophiles, which can shorten the start-up period considerably [

93]. However, the limited availability of thermophilic inocula compelled the incubation of mesophilic inocula at a high temperature to allow the microbiota to adapt to thermophilic conditions. Similarly, many strategies have been reported in the literature for the shifting of inoculum from mesophilic to thermophilic conditions, such as the single-step increase in temperature from 35 to 55 °C along with an initial drop in OLR and then a gradual increase, which improved the digester performance [

94,

95]. Palatsi et al. [

96] performed a similar temperature transition study where a single-step increase in temperature from 35 to 55 °C was adapted, and the system recovered after 20 days in terms of methane yield, with 0.371 L-CH

4/g-VS, although the temperature transition caused higher VFA accumulation and propionate/acetate ratio. On the other hand, the slow and gradual increase in the temperature at a constant OLR requires longer transition times to adapt and stabilize the process. Tian et al. [

97] also applied the one-step strategy to directly increase the temperature of their mesophilic CSTR to thermophilic conditions (55 °C) within a day; the effect was observed on the methanogenic communities in ~11 days, with the start-up period shortened to 20 days. However, it is possible that the optimum inoculum source may vary with the composition of the substrate as well as the operating conditions of digesters.

Bioaugmentation is used as an approach to provide a boost in a variety of microbes in the reactor by co-inoculation from different sources. It helps in reducing the start-up period of the process by reducing the time of rate-limiting steps (i.e., hydrolysis and methanogenesis) in TAD. The consistent increment in the biogas and methane yields could be considered for analyzing the adequate adaptation of co-inoculated consortia. Strang et al. [

71] worked on two stable thermophilic mixed cellulolytic consortia marked as AD1 and AD2, enriched from an industrial-scale biogas fermenter and used for bioaugmentation. The corn stover was used as a substrate in the laboratory-scale batch reactors, and reported an enhanced methane yield by 22–24%. Next-generation sequencing revealed the predominant microbial strains as

Thermoanaerobacterium thermosaccharolyticum, Caldanaerobacter subterraneus, Thermoanaerobacter pseudethanolicus, and

Clostridium cellulolyticum. The effect of these strains, cultivated in the pure cultures, was investigated with the aim of reconstructing the defined cellulolytic consortium. The addition of the four bacterial strains and their mixture to the biogas digesters enhanced the methane yield by 10–11%, but it was not as efficient as the original communities, indicating the significant contribution by the members of the enriched communities present in low abundance. Therefore, mixing inocula from different sources can be selected as another strategy to promote a diverse and robust microbial consortium in TAD with enhanced buffering capacity and lower propionate accumulation [

48,

98] (

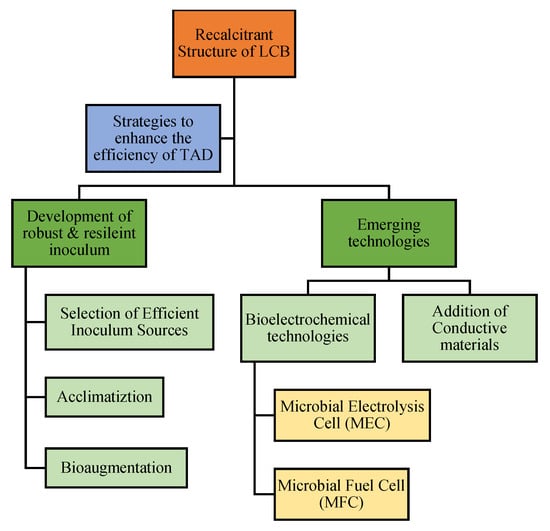

Figure 2).

Figure 2. Strategies to enhance the efficiency of thermophilic anaerobic digestion (TAD).

2. Adoption of Emerging Technologies

2.1. Bioelectrochemical Technologies

The bioelectrochemical system refers to an electrochemical interaction involved with at least one electrode, i.e., an anode or cathode, with the electroactive bacteria or microorganism. The presence of microorganisms on an anode yields the electrons from an organic substrate [

91]. The reported bioelectrochemical technologies are microbial electrolysis cells (MECs) and microbial fuel cells (MFCs) coupled with a thermophilic anaerobic digester in a single- or double-chambered manner or in series [

99,

100,

101,

102]. These technologies have been recently adopted to promote the methane yield enhancement, and to overcome the organic as well as ammonia inhibitions (

Figure 2).

Cerrillo et al. [

99] investigated the effects of doubling OLR and the ammonia loading in TAD of pig slurry by hydraulically connecting an MEC with an AD reactor to demonstrate how the MEC could be used to alleviate ammonia inhibition. The independent TAD reactor failed when the OLR was doubled from 3.02 to 6.25 kg COD/(m

3-d) due to severe inhibition by ammonia accumulation. However, when the recirculation loop was established to recirculate effluent from the dual-chamber MEC back to the AD reactor, recovery of the AD process was observed. The benefits of the recirculation loop were due to the contribution of MEC to decrease ammonia loading by in situ ammonia recovery to the cathode, as well as decreasing total organic load due to the removal of 20–30% of COD occurring within the MEC. In a dual-chamber MEC having a cation exchange membrane (CEM), ammonium ions can transport from the anode chamber to the cathode chamber to maintain charge neutrality in the system [

103,

104]. Zhang and Angelidaki [

105] developed another strategy to lower the ammonia levels in a continuously stirred tank digester and recover ammonia by submerging a bioelectrochemical cell inside a thermophilic digester. The system, named the submersible microbial desalination cell (SMDC), was designed to carry out in situ ammonia recovery and electricity production. The anode chamber is continuously fed with an acetate-modified nutrient solution and generates a supply of electron flow to the cathode; the aerated cathodic chamber takes in ammonium ions (NH

4+) through a CEM from the surrounding ammonia-rich wastewater, which is then recovered as ammonia (NH

3). They achieved an average recovery rate of 80 g-N/(m

2-d) over 30 days by decreasing the TAN concentration from 6 to 0.7 g/L. However, the current status of SMDC applications is limited to synthetic waste streams, and further efforts need to be made to test it on real ammonia-rich substrates such as livestock manures. Compared to conventional technologies such as air-stripping or electrodialysis, the SMDC is highly advantageous because of the lower energy costs and because there is no need for chemical additives. Thus, the integration of MEC is promising for increasing the robustness of the TAD process. However, this application is still in its early stages, especially regarding scale-up issues associated with bioelectrochemical technologies [

106,

107].

Zhang et al. [

108] studied single-chambered MECs combined with thermophilic anaerobic digesters for the digestion of ammonia-rich synthetic substrates and sludge under high FAN concentrations. The results showed that the highest methane yields from both the substrates were obtained at an applied voltage of 0.7 V as 25 and 97.8 mL g

−1 VSS

added for synthetic substrates and sludge, respectively.

Methanosarcina and

Methanothermobacter were the predominant archaea, but coupling of MECs with a thermophilic digester indicated that it could increase the number and mass of microbial species in the digesters under ammonia inhibition. A similar study was conducted by Cerrillo et al. [

99] for TAD of pig slurry as substrate combined with a two-chambered MEC reactor, which was coupled to an ammonia stripping unit as a post-treatment of effluent and a loop configuration recirculation. The MEC allowed the system to achieve chemical oxygen demand (COD) removal of 46 ± 5% after doubling the overload of inhibitors and recovered 40 ± 3% of ammonia. However, the AD-MEC system in loop configuration recovered the system with a more stable and robust operation (55% increase in the methane productivity). The microbial population assessment revealed an enhancement of AD methanogenic archaea numbers and a shift in the eubacterial population. Tremouli et al. [

100] explored the usage of MFC technology (in four air cathode MFC units) for processing digestate post-AD from thermophilic and mesophilic anaerobic digesters fed with fermentable food waste. This approach helped facilitate COD removal from the digestate by 80–90% within the first 24 to 48 h of each cycle of operation to convert it into power as the product. The power obtained from mesophilic fed cells (~0.24 mW) was lower than the thermophilic fed cells (~0.42 mW).

Therefore, it can be concluded from the above studies that the bioelectrochemical technologies, viz., MEC-TAD or MFC-TAD, could be proven as the best paths forward due to their high energy efficiency combined with their overcoming of inhibitions and power output from post-AD digestate treatment, but they are not commercialized at a large scale.

2.2. Addition of Conductive Materials

The addition of conductive materials (CMs), such as granular activated carbon (GAC), biochar, carbon cloth, carbon-based nanomaterials, magnetite (Fe

3O

4), stainless steel, and conductive polymeric material, is considered as one of the emerging strategies to enhance the efficiency of the TAD process. It has been shown that the growth of microorganisms involved in the AD process depends on the electron transfer among the syntrophic community through an intermediate such as hydrogen or formic acid. This direct interspecies electron transfer (DIET) can be stimulated by adding conductive materials into the digester which act as conduits for electron exchange between syntrophic partners [

107]. DIET is one of the alternative ways of electron transfer without hydrogen involvement and is reported to be 10

6 times faster than interspecies hydrogen transfer (IHT) [

109,

110]. This advantage of DIET allows a much more rapid conversion of organic waste into methane, which ultimately can be an effective solution to accelerate and stabilize the TAD start-up process. Recently, to create a DIET environment in the TAD system, CMs, i.e., activated carbon, carbon nano-tubes, biochar, magnetite particles, graphene, carbon fibers, etc., were reported to be capable of serving as conduits for electron transfer, enriching electro-active bacteria and accelerating the methanogenesis process [

111]. Yan et al. [

112] reported in their study that the methane production rate in CM-supplemented reactors was almost two times higher than the control reactors.

Caloramator sp., a candidate of electro-active bacteria, was significantly enriched in the carbon nano-tube (CNT)-supplemented groups (12.89%) as compared to control groups (only 1.26%). Together with the doubled abundance of

Methanosaeta and

Methanosarcina methanogens in CM groups, it is highly possible that

Caloramator sp. and

Methanosaeta/Methanosarcina have established syntrophic DIET by adopting CMs as electron conduits. Microbial community analysis indicates that DIET was likely to be an unstable condition and trigger the syntrophic process. This study demonstrated that conductive materials could promote microbial activity and shorten the start-up period for the thermophilic anaerobic system. There are few studies which report the advantages of adding CMs, such as magnetic particles which triggered the fast and robust syntrophic pathway of methanogenic propionate degradation [

109].

Tiwari et al. [

113] studied the TAD of recalcitrant agro-waste (wheat husk and sewage sludge) co-digestion supplemented with CMs such as granular activated carbon (GAC) and granular biochar (GBC) to enhance the biogas yield. The results revealed that samples amended with GAC and GBC at 20 g/L dosage of CM yielded the maximum biogas production of 263 and 273 mL/g VS

added, respectively, with an additional advantage of a shorter lag phase than the control. However, these studies have shown that supplementing thermophilic digesters with various CMs facilitate the ability to control acidification and control the accumulation of common inhibitors, such as ammonia [

58,

59]. The purpose of CM addition is to accelerate and stabilize the TAD process start-up and methane production [

109,

114,

115,

116].

This entry is adapted from the peer-reviewed paper 10.3390/su15031859