2. MEPS & Labeling Policies

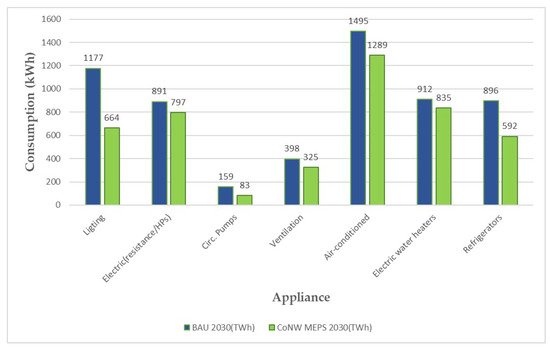

Figure 2 hows consumption by sector in Latin America and the Caribbean for the year 2020, in which the transport sector participates with 34.8% of the total, followed by the industrial sector (30.2%) and the residential sector (18.2%). In addition to other sectors such as commercial and services, agriculture and mining, construction and others, which together cover the remaining 16.8%.

Figure 2. Share by sector of final energy consumption in Latin America and the Caribbean for the year 2020. Adapted from [

36].

The refrigerator is one of the appliances with the greatest presence in homes and it is estimated that annually consumes 6% of the total energy in the world [

37], hence the importance of MEPS implementation as a method of controlling energy consumption and expenditure that allows controlling the distribution of inefficient products in the market and thus encourage users to acquire equipment taking efficiency over cost as a decision criterion. The MEPS implements labeling as a mechanism to inform the user about the energy consumption and the efficiency index of the equipment they are purchasing. In this way, it is possible to make a general projection of the energy consumption of the equipment and how it will impact it economically. Similarly, the label commits the manufacturer to provide relevant technical information that allows evaluation of the energy efficiency of the equipment acquired under previously established technical regulations [

38].

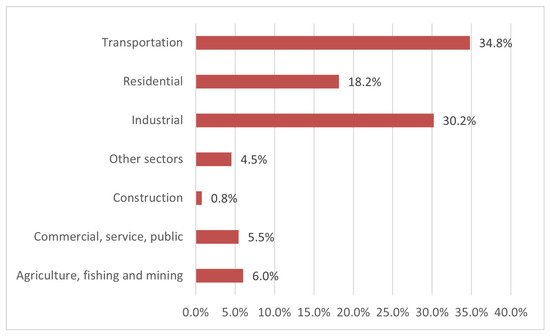

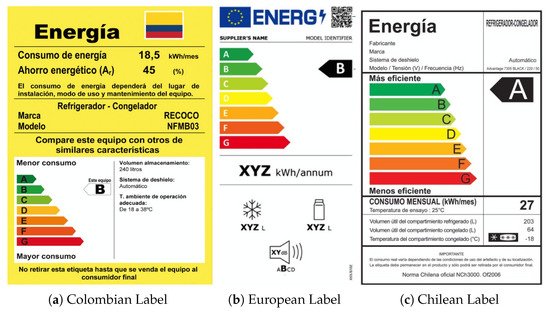

Figure 3 and

Figure 4 illustrate the energy labels used by Colombia and the reference countries, where some similarities can be observed, such as the label of the European Union and Chile, where it is observed that their categorization of energy efficiency is from A++ to G.

Figure 3. Energy Labels for Domestic Refrigeration in Colombia, EU and Chile.

Figure 4. Energy labels for domestic refrigeration in Mexico, US and Brazil.

In the case of Mexico, the energy guide label of the United States is adopted, it can also be noted that the European Union label incorporates the refrigerator noise index.

2.1. European Union

In the European Union, the implementation of the appliance labeling program for the first time was in 1992 with the EU Directive 92/75/EC on the «Indication Through Labeling and Standard Information of the Consumption of Energy and Other Resources by the Appliances» [

39] establishing an initial classification of categories from A to G, in which category A represents the most efficient equipment and G would be the least efficient category, It is noteworthy that the label does not provide the IEE given by the manufacturer, but rather the category where the IEE is found. Later the European Union would migrate to an update of its labeling policies by changing the categorization of the label categories [

40]. In the year 2000, new, more efficient equipment emerged, for which the EU Delegated Regulation 1060/2010 was updated, incorporating categories A+, A++ and A+++ [

41]. In 2016, this Delegated Regulation of 2010 is updated again, eliminating the categories from E to G and adding the noise level categorization on the label [

42]. this update hardened the distribution of less efficient equipment in the European Union countries.

The preliminary review of the MEPS process in Europe shows that the implementation in the different EU countries is not the same, revealing marked differences due to the promotion that governments make about efficient equipment and the subsequent removal of equipment with higher consumption from the market. The reason for these differences is given, according to the criteria of some authors and the heterogeneity in the composition of the stocktaking of electrical appliances between countries that directly influence the effectiveness in the MEPS application and energy labels [

10,

43]. From 1 September 2021, categories A +, A++ and A+++ were included again, recategorizing [

44], which generated confusion in the population. In addition to the MEPS and the labeling regulation, the EU adopted the Climate Change Plan determined by the European Directive 20/20/20 [

45], the main objective of this Plan is to reduce GHG emissions by 20%, and improve the energy efficiency of buildings by 20% [

46].

An important indicator on the implementation of MEPS in Europe is an improvement of around 27% in the efficiency of domestic refrigeration appliances, compared to prelabeling efficiency levels. According to EU reports, the average energy consumption of refrigerators fell from approximately 450 kWh/year in the period from 1990 to 1992 to an estimated 364 kWh/year immediately after MEPS was adopted [

47].

Emissions derived from the use of electrical appliances represented 25% of total emissions in 2010, increasing equally to the emissions produced by the industrial sector [

48]. The growing increase in the purchase of household appliances leads to the creation of new control policies that help mitigate the effects produced by the use of residential appliances, among which are domestic refrigerators [

49], for example, the comparative label, which has a high impact on home appliance buyers and provides better decisions in the acquisition of new and more efficient products [

50,

51,

52]. See

Figure 3b, in which the current label is shown.

The review of energy efficiency policies and MEPS labeling shows a more comprehensive trend on the part of the EU when assessing the energy performance of the equipment, including regulations related to ecodesign, thus seeking to integrate environmental aspects in the design, production, distribution, use and final disposal of the product throughout its life cycle [

53,

54]. Among the novelties proposed in the energy label, there is a QR link that expands the information and provides more details about the product, such as its materials and manufacturing processes in general. Additionally, it has been proposed to include standards on repairability and availability of spare parts. Finally, it promotes the use of recycled materials in the manufacture of new models [

55].

An additional element that stands out in the EU energy label is the inclusion of the noise parameter, which links to the application of compartment design strategies and the control of refrigerant fluids, thus achieving a reduction in noise emissions and an improvement in sound quality in non-Frost type refrigerators, which are the most commercialized [

56,

57].The noise regulation extends to other devices such as air conditioners and is undoubtedly an important criterion at the time of purchase, not only due to aspects of comfort during the operation of appliances but also due to the close correlation that exists between the decreased noise and energy efficiency [

58,

59].

2.2. United States

One of the main barriers to improving the energy efficiency of US household appliances for residential use is the high cost of acquiring new technologies by manufacturers to produce more efficient equipment. One of the strategies to address this barrier is by implementing incentives for both manufacturers and consumers, lowering the production cost and equipment acquisition [

60]. Mechanisms such as electrical appliance labeling programs (MEPS) have influenced the purchase by users of more efficient refrigerators. Mechanisms such as electrical appliance labeling programs (MEPS) have influenced the purchase by users of more efficient refrigerators. Studies such as the one by Zainudina et al. show that there are close relationships between knowledge, attitude, social norms, and the energy efficiency label of users with the purchase intention [

61].

In the United States, the first MEPS standards were applied in 1974 for refrigerators at the state level. However, until 1978 through the NECPA, it established the obligation of minimum standards at the national level. Between 1974 and 2004 there was a reduction in energy consumption of 74% associated with the implementation of measures such as MEPS [

62]. This country implemented the EnergyStar seal in 1992 as a complementary measure to the MEPS, which represented the most significant government effort in the country, and which would represent a saving of 164 million dollars annually in electricity costs in homes, with a reduction in carbon emissions of approximately 1.1 million metric tons per year [

63,

64].

In the development of labeling programs comes the Energy Guide label (a comparison label), administered by the FTC. Later, in 2001, the DOE, together with the EPA, were in charge of exercising control over the EnergyStar label [

65]. At the end of the same year, the NAEWG group was created, with the aim to improve the commercialization, development, and interconnections of North America [

66]. The participating countries (Mexico, Canada and the United States), created this working group specifically to study and improve the policies, energy efficiency, renewable energy, clean energy and nuclear energy of these countries. For 2020, EnergyStar established updates in terms of trial and test methodologies [

67], an example of US Energy Label is shown in

Figure 4b.

2.3. Mexico

Over the last few years, energy consumption in the residential sector in Mexico has had a considerable increase. Studies reveal that the kitchen is the main factor in final energy use and that water heaters and other appliances are the ones that show the higher growth [

68]. Strategies have been seeking to meet the demand of the different country regions through energy generation from renewable sources and developing new energy efficiency standards that can be applied in government policies to control energy use [

69].

In 1992, the Mexican Energy Efficiency Standardization System began with the Federal Metrology and Standardization Law, coordinated by the National Consultative Committee for Official Mexican Energy Efficiency Standards (NOM-ENER), which are mandatory [

20]. These standards establish the testing procedures, the MEPS, as well as the labeling requirements [

34]. In 2002, the Nom-015-Ener-2002 standard was proposed, which establishes the parameters for evaluating the energy efficiency of refrigerators and freezers, the limits, test methods, and labeling [

70]. The energy label used in Mexico, its testing procedures and MEPS are adapted from the United States energy guide model, including a continuous scale that indicates the relative savings of the product concerning the threshold defined by the standard [

71].

In 2012, the CONUEE enacted the update of the NOM-ENER-2002, updating the maximum limits of energy consumption of refrigerators and freezers for domestic use, operated by a hermetic compressor motor, according to the type of refrigerator and its defrost system [

72]. As of 2018, 29 standards are current, including specifications for refrigeration appliances, as well as standards that control CO

2

emissions and fuel efficiency of automobiles. In addition, the standards and mandatory labeling program of the CONUEE and the Fiduciary FIDE [

73] offer manufacturers the possibility of acquiring a FIDE endorsement-seal label for equipment that exceeds the minimum level of energy efficiency defined by the NOM [

74]. A Mexican energy label is presented in

Figure 4a. In that same year, the Nom-015-Ener-2018 was published, and the program to replace old and inefficient refrigerators with modern and high-efficiency models was proposed. In this way, Mexico would save 4.7 TWh/year [

34,

75,

76], projecting a decrease in total residential electricity consumption of 9.9%, and the associated expense decreases by 11.3%. Additionally, the electricity subsidy decreases by 7500 million Mexican pesos per year (that is, 403 million dollars at the average exchange rate registered in 2017), and there is an annual decrease of 3.9 million tons of CO

2

equivalent emissions [

77].

2.4. Chile

In early 2005, the Chilean government established the Energy Efficiency Standards and Labeling Program (PPEE), to be implemented in 2006. This was one of the most visible and comprehensive energy efficiency programs in the region. In 2007, the energy efficiency labeling came about and with it the first rational energy use program «Use Energy Well—Follow the Current», creating regional energy efficiency tables and diagnosing several productive sectors in the country [

78]. In 2008, the implementation of energy labeling for refrigerators-freezers was carried out, according to efficiency standards ISO 15502 [

79], IEC60335-2-24 [

80], and according to the NCh3000 [

81].

Subsequently, the Ministry of Energy received technical assistance from the Division of Environmental Energy Technologies of the LBNL and issued in 2012 the regulation that defines the criteria and procedures that will be applied to establish MEPS. The regulation requires, among other things, the preparation of a regulatory impact assessment, consultation procedures and coordination between government entities and the public [

82]. In 2014, Decree No. 64 was established, which approves the regulations that establish the procedure for the elaboration of technical specifications for energy consumption labels and the necessary standards for their application [

83].

In the 2016 follow-up report, the Chilean government reaffirms its commitment that 100% of commercialized appliances are energy-efficient equipment, as promoted in one of the goals for the year 2050 [

84]. For 2018, the total consumption of refrigerants in the domestic refrigeration and air conditioning sector reached 70% of the substance bench-marking in Chile [

83].

More recent studies show how the Chilean government has proposed campaigns to diagnose the current situation in the refrigeration sector, based on the quantification of equipment. Thus, in 2019 it was estimated that the installed fleet of refrigerators in Chile of around 6.8 million units as part of the Baseline Report for the project entitled «Accelerating the Transition to a Market of Efficient Refrigerators in Chile» which 43% belonged to energy efficiency category B or lower. The predominant EE categories in Chile are category A+ and category A with 28% and 25% participation, respectively. A Chilean domestic refrigerator energy label appears in Figure 3c.

Additionally, this report considers the refrigerants used in this equipment, which cause a high environmental impact, so they must be regulated by applying mitigation policies [

85]. Currently, these standards are mandatory and introduced through protocols and resolutions issued by the Superintendence of Electricity and Fuels (SEC). This one is in charge of adapting to the test conditions related to the labeling apply to products such as motorized vehicles and boilers in the industrial mining sector, among others [

86].

2.5. Brazil

As antecedents of energy expenditure produced in the residential sector, since 1980, the Brazilian government has worked on policies that reduce energy losses and on programs that encourage energy efficiency in end-use equipment [

87]. In 1993, the National Energy Conservation Program (PROCEL) voluntarily introduces the labeling program, adopting a classification ranging from category A to E, with A being the most efficient category and E the least efficient [

87]. A decade later, the PEB emerged, incorporating mandatory labels (please see

Figure 4c), with as main objective of informing the consumer about specific characteristics of consumption, temperature, and additional information, such as: brand, model, defrost type, refrigerator size (usually in liters), freezer size and temperature, to end users. It is noteworthy that the form of the labels implemented in Brazil based on the US model, adapting the Energy Guide label [

88].

Brazil is considered one of the pioneering countries in programs related to climate change, which acquired the commitment to reduce its carbon footprint between 36% and 39% by 2020. This carbon footprint receives a considerable contribution from part of the residential sector. In 2013, household energy consumption represented around 9% of total energy consumption in Brazil and accounted for about 994 PJ due to an increase in energy consumption in this sector since 2005 [

89].

Due to the significant energy consumption by refrigerators for residential use in 2007 corresponding MEPS were established, taking as a starting point the «Energy Efficiency Law» enacted in 2001 [

90]. This year they were achieved energy savings of approximately 1379 GWh and a reduction of 197 MW in Brazilian demand, as a result of efficiency labeling in refrigerators and freezers [

91]. As a consequence of the labeling and MEPS policies introduced in Brazil in 2009, complementary policies to labeling emerge, such as the national refrigerator exchange program, which encourages the replacement of inefficient refrigerators [

92]. The annual energy consumption of domestic refrigerators in 2010 was 182.8 GWh, and according to the projections made, the future impacts of the Energy Efficiency Law. It is estimated that the energy savings for the year 2030 would be close to 14,325 GWh, which represents 9% of the installed capacity for the electricity generation in 2010 [

87]. According to the Energy Efficiency Indicators Management Committee (CGIEE), these standards must be undergoing a review process every two years, being updated for the last time in 2011 [

93].

Since 2013, Brazil has had an electrical energy conservation program (PROCEL), distinguishing the most efficient products in the market, industry, buildings, government and public lighting. This seal was successfully applied to more than 36 appliances from more than 150 manufacturers [

62]. Since the enactment of Law 13 280/2016, PROCEL has been able to count on energy providers to dedicate 20% of their resources to energy efficiency through the PROCEL resource application plan [

94]. By 2018, 7.3% of final energy use was covered by mandatory energy efficiency policies [

95]. With the implementation of PROCEL actions, it was possible to save a total of 23 TWh, which in Brazil’s energy consumption was equivalent to 4.87% of consumption for 2018 [

94].

2.6. Colombia

In Colombia, the residential sector represented 40% of electricity consumption in 2015, of this percentage refrigerators represent 43.25% [

28,

32]. In 2015, the RETIQ was launched, establishing the energy label (as is shown in

Figure 3a) for household appliances for residential use and an information label for equipment for commercial use [

29]. Seven energy efficiency categories are stipulated, from A to G, with A being the most efficient and G the least efficient. As of 1 September 2021, the last three categories will disappear and along with them, the domestic refrigerators thus categorized. In

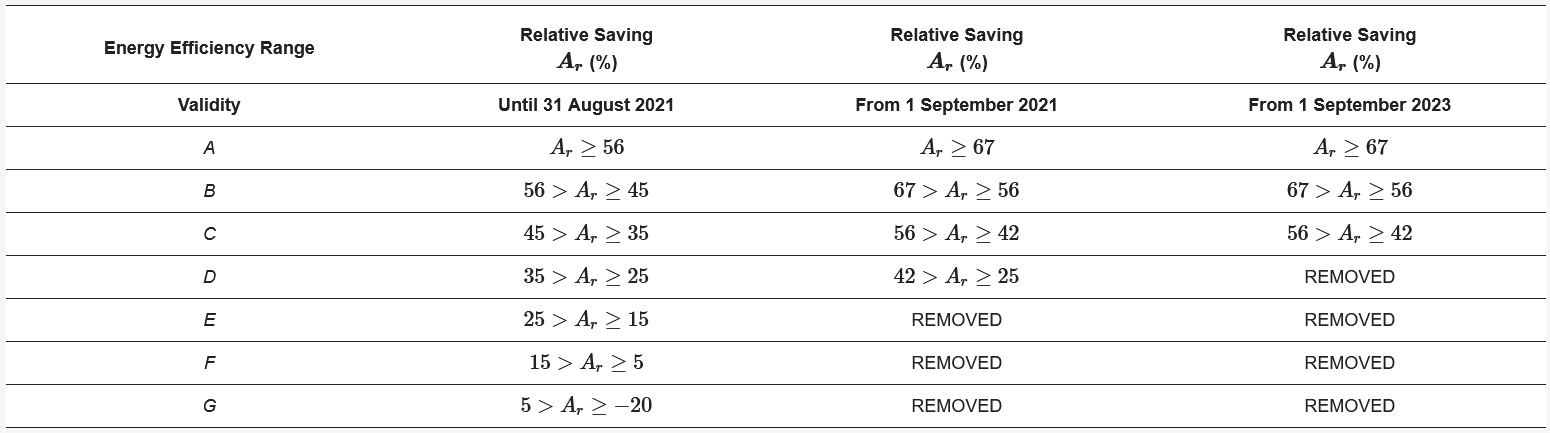

Table 1, you can see the ranges of energy efficiency and the relative savings levels with which household refrigeration equipment is categorized for the year 2021 and the perspective towards the year 2023, where category D is expected to be eliminated.

Table 1. Energy efficiency ranges for domestic refrigeration equipment for Colombia from 2021 to 2023.

Historical references in Colombia show that there have been some programs that directly offer incentives to replace and dispose of old refrigerators, such as «Deliver it and Save», which encouraged the replacement of about one million refrigerators that were an average of 10 or more years of use. This initiative was enacted through Decree 2143 of 2017 [

96], establishing, among other guidelines, a VAT of 5% to replace 19% for the purchase of efficient and environmentally friendly equipment [

97]. This same year, the MME defined the strategic and sectoral actions to meet the goals established in terms of energy efficiency within the action framework of the PAI PROURE, in the period between the years 2017 to 2022, presenting the consumption characteristics of sectors such as: transportation, industrial, commercial, government, public services and residential [

26].

Labeling for domestic refrigeration equipment, reference monthly consumption data in kWh/month, Relative Savings (

) in percentage, storage volume in liters, defrost system (manual, semi-automatic or automatic), ambient temperature and the minimum operating temperature in

∘C is shown in

Figure 3. Within the framework of international agreements such as the 2030 Agenda and the SDG, it establishes as one of the priorities the promotion of use of efficient appliances and lighting, in addition to affordable and nonpolluting energy, as formulated in goal seven of the SDGs [

13]. To be in accordance with these international initiatives, RETIQ is in the process of being updated in accordance with technical regulations, such as IEC 62552, with the aim of improving energy consumption [

98,

99,

100]. The IEC 62552 standard deals with about 11 types of tests and trials, among which there are some such as tightness of doors and drawer seals, storage temperatures (according to the climatic class to which they correspond), in addition, to tests of water vapor condensation and evaluation of energy consumption by a loading plan in the freezer and food compartments with test packs of different weights and alternation in freezing and recovery times.