Conventional thermal fluids have found limited application owing to low thermal conductivity (TC). The need for more efficient fluids has become apparent leading to the development of nanofluids as advanced thermal fluids. Nanofluid synthesis by suspending nano-size materials into conventional thermal fluids to improve thermal properties has been extensively studied. TC is a pivotal property to the utilization of nanofluids in various applications as it is strongly related to improved efficiency and thermal performance. Numerous studies have been conducted on the TC of nanofluids using diverse nanoparticles and base fluids.

1. Magnetic Field

Some nanoparticles used in the formulation of nanofluids have magnetic properties that distinct them from other nanoparticles. Magnetic nanofluids are formed by the suspension of ferromagnetic nanoparticles in different base fluids. Depending on the nature of magnetic nanoparticles, magnetic field strength and direction, and type of magnetic field source, particles of magnetic nanofluid form diverse arrangements of chain clusters which tend to affect the thermal properties. The alignment of the particles to form chains on exposure to the magnetic field has been reported to be a veritable tool for the manipulation of the TC of nanofluids [

128]. Tuning of the magnetic field has found potential applications in sealing, heat transfer, sensors, nuclear and solar systems, ink jet printers, biomedical, loud speakers, dampers, etc. [

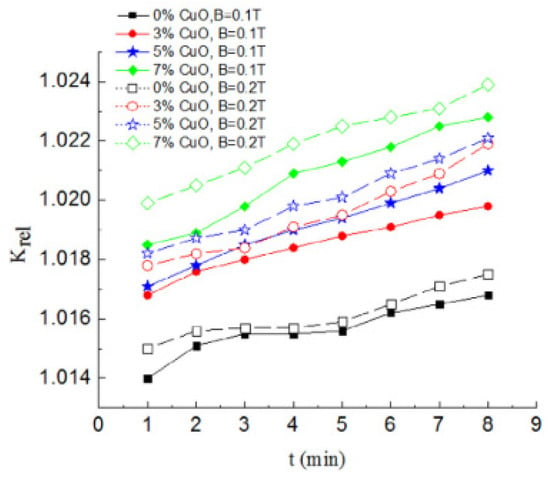

128]. The influence of magnetic field strength on nanofluid TC is presented in

Figure 1.

Figure 1. Effect of increasing magnetic field intensity and CuO + 3 wt% Fe

3O

4 nanofluids on relative thermal conductivity under increasing exposure duration [

129].

Studies on the deployment of the magnetic field to augment the TC of magnetic nanofluids were pioneered using DIW-based Fe and Fe

3O

4 nanofluids with varying volume fractions and under increasing and different orientations of magnetic field [

130]. The TC of water and n-decane based γ-Fe

2O

3 and CoFe

2O

4 nanofluids at 25 °C and exposed to an external magnetic field was examined. A reduction in the TC of the nanofluids (40% by CoFe

2O

4 and 50% by γ-Fe

2O

3) as the magnetic field intensity increased up to 30 mT was observed [

131]. At ambient temperature, the TC of Fe

3O

4/kerosene nanofluids with varying volume fractions (0.031–7.8%) and under different (parallel and perpendicular) and increasing magnetic field (0–500 G) was accessed [

132]. Peak enhancement of 300% for 6.3% concentration when the magnetic field of 82 G was positioned parallel to the temperature gradient was recorded. Exposure of the nanofluid to higher magnetic field strength resulted in TC depreciation. However, no appreciable enhancement was observed when the magnetic field was positioned perpendicular to the temperature gradient. The TC improvement and trend agreed with the results published using a similar nanofluid exposed to the same strength and orientation of magnetic field except that the peak enhancement occurred using volume fraction of 0.078% [

93].

The claim that nanofluid TC was enhanced by exposing a magnetic field parallel to the direction of the temperature gradient is also supported by [

53], and the existence of peak TC enhancement at a certain magnetic field strength is corroborated by [

54]. The parallel arrangement of the magnetic field to the direction of the temperature gradient aids energy transport in the nanofluid as the formed chain structure aligns with the magnetic field direction to quicken energy transportation process [

133].

On exposing Fe

3O

4/kerosene nanofluids with varying volume fraction (1.12–4.7%) and temperature (25–65 °C) to increasing magnetic field strengths (0–1200 G) and different magnetic field directions, the TC was investigated [

133]. Increasing concentration and magnetic field strength (up to 885 G) were observed to enhance the TC with a peak enhancement of 30% when the magnetic field was applied parallel to the temperature gradient direction. The enhancement recorded was attributed to the formation of a zipper-like structure which was reversible. However, temperature increase was noticed to reduce the TC on exposure to increasing magnetic field magnitude. This was in agreement with a later study on the impact of temperature (20–60 °C), volume fraction (0.25–4.8%), and magnetic field (0.021–0.145 T) on the TC of water-based Fe

2O

3 and Fe

3O

4 nanofluids [

134]. Increasing magnetic field strength and volume fraction enhanced Fe

2O

3 and Fe

3O

4 nanofluids by 15–38.5% and 13–176%, respectively, but temperature rise detracted it. However, an improvement in the TC of Fe

3O

4/glycerol nanofluids with temperature (20–40 °C), volume fraction (0.5–3%), and magnetic field strength (120–600 G) rise was reported [

55] which contradicted the findings of reported in previous studies [

115,

133,

134]. A maximum enhancement of 16.9% was observed.

An investigation of the effect of utilizing a constant and oscillating magnetic field on the TC of water-based 1 vol% Fe

3O

4 and 2 vol% CNT–Fe

3O

4 nanofluids was conducted [

135]. The use of a constant magnetic field revealed an up-and-down trend with an increase in magnetic field strength over time which was due to the alignment of chainlike structure leading to increased TC, and the thickening of chains and settling causing TC reduction. However, engaging an oscillating magnet field showed an increment in TC as the magnetic field intensified with time. At magnetic field strength of 700 G, average TC was improved by 24.3% and 22.6% for CNT–Fe

3O

4 and Fe

3O

4 nanofluids, respectively, when the influence of an oscillating magnetic field was compared to that of a constant magnetic field. Similarly, an alternating magnetic field was found to be better than a constant magnetic field for the augmentation of the TC of NiO/DIW nanofluids under increasing volume fraction, temperature, and magnetic field strength [

136]. This was because imposing an alternating magnetic field intensifies the velocity and randomness of nanoparticles leading to TC improvement while the use of a constant magnetic field causes nanoparticle chain formation leading to the magnification of TC. The impact of volume fraction and magnetic field strength was observed to be significant.

The influence of duration (0–8 min), magnetic field strength (0.1–0.2 T), and mass concentration (0.45–1.35 wt%) on the TC of Fe

3O

4, CuO, and Fe

3O

4–CuO nanofluids was examined [

129]. Increasing concentration and magnetic field strength were found to augment the nanofluid TC while increasing duration reduced it. The TC of water-based Fe

3O

4 and Fe

3O

4 + CNT nanofluids under increasing duration (0–60 min), magnetic field strength (330–700 mT), temperature (25–35 °C), and volume fraction (0.45–1.35%) was accessed [

115]. The TC was improved as magnetic field strength (up to 470 mT) and volume fraction increased as duration and temperature reduced. Peak enhancement was 151.3% for 0.9% Fe

3O

4 + 1.35% CNT nanofluid.

The above studies revealed that there exist contradictory results concerning the influence of temperature rise on the TC of nanofluids when exposed to increasing magnetic field intensity, which needs to be further investigated to have a better view of this observation and to have a well-informed understanding of the physics and mechanism behind this. Additionally, maximum TC attained at a certain magnetic field strength is observed to be a function of nanoparticle type, base fluid type, nanoparticle concentration, temperature, magnetic field strength, and magnetic field type.

2. Electric Field

Very limited studies have been performed concerning the influence of electric fields on the TC of nanofluids. In a pioneering work, the impact of temperature (26.6–90 °C) and electric field (0–1000 V/mm) intensity on the TC of 30 vol% Al

2O

3/silicone oil nanofluid was investigated [

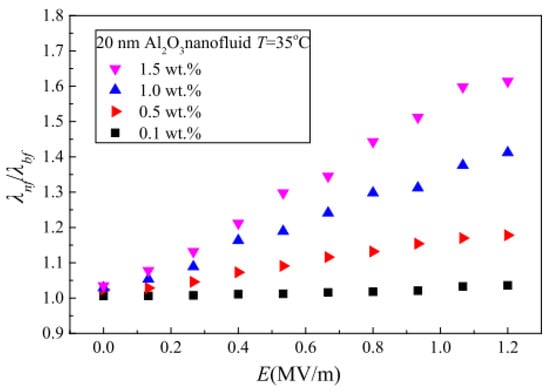

137]. Exposure of the nanofluid at 26.6 °C to an increasing electric field from 0 V/mm to 700 V/mm showed a slight increase in the TC from 0.2454 W/m K to 0.2916 W/m K, which surged by 48% on increasing the electric field to 800 V/mm. The TC remained unchanged with a further rise in the electric field. An increment in the temperature of the nanofluid under exposure to an increasing electric field revealed a reduction in the TC. The effect of nanoparticle size (20 nm and 50 nm), temperature (15–55 °C), concentration (0.1–1.5 wt%), and electric field (0–1.2 MV/m) on the TC of αAl

2O

3/transformer oil nanofluids [

138]. Increasing temperature, concentration, and electric field were observed to augment the nanofluid TC while increment in nanoparticle size has an insignificant effect on the TC. The TC recorded is strongly related to the Brownian motion phenomenon. A contradiction regarding the effect of temperature on the TC of nanofluids exposed to an electric field is observed which calls for further studies on this concern in addition to the scarcity of literature in the public domain. The effect of electric field intensity on nanofluid TC is illustrated in

Figure 2.

Figure 2. Effect of increasing electric field intensity and concentration on thermal conductivity of 20 nm—Al

2O

3 nanofluid at 35 °C [

138].

This entry is adapted from the peer-reviewed paper 10.3390/nano13030597