1. Intelligent Power System Simulation

1.1. Functionality

The power system model is the core of the traditional DTS; similarly, the intelligent power system simulation is a vital subsystem of the IDTS. At present, there are still many problems to be studied in power system simulation, such as the limitations of the model, the enormity of modeling, and the puzzling nature of the results, which can be solved by introducing AI technology. Two major functions of this subsystem are intelligent model generation and intelligent model solving.

- (1)

-

Intelligent model generation.

Compared with the traditional DTS, the primary system to be simulated in the IDTS is the smart grid, and the secondary system to be simulated is the corresponding dispatching system integrated with the substation monitoring. The system should also realize the simulation of online monitoring, analysis, and early warning of interconnected grids, as well as the simulation of renewable energy integration, control, and dispatch [

18]. Currently, research on the application of intelligent simulation techniques in IDTS is widely carried out. Different intelligent simulation techniques enable a complete description of the smart grid, making the simulated grid in IDTS more realistic [

21,

22,

24].

- (2)

-

Intelligent model solving.

Dr. T.E. Dy Liacco, who is known as the father of dispatch automation, has described a beautiful blueprint for intelligent dispatching [

33]. He argued that by continuously generating training sets through pattern recognition and decision tree and by automatically learning the features of the power system, an experienced dispatching robot would eventually be formed. This robot would be able to react faster and more accurately than experienced dispatchers when faced with problems [

34]. With such dispatching robots being trainees, the IDTS will judge trainers’ decisions with better accuracy and efficiency compared with the traditional DTS.

1.2. Techniques

Several AI algorithms and techniques can be adopted to realize the above functions [

35]:

Expert systems are one of the most used AI techniques in the field of power systems and dispatching problems [

36,

37]. Expert systems allow computers to simulate the decision-making process of human experts, solving practical problems that cannot be mathematically modeled and must rely on expert experience [

38]. As shown in

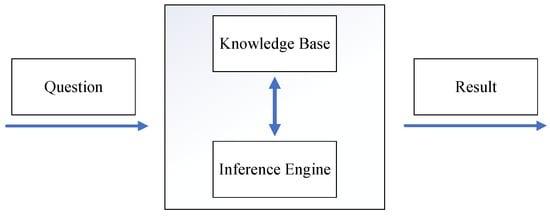

Figure 1, an expert system solves a specific problem with a knowledge base and an inference engine. The knowledge base is an organized collection of all the facts about power dispatching, and the inference engine interprets the input question and provides an answer according to inference rules. The expert system can solve various power dispatching problems in different regions and under different conditions, effectively alleviating the burden of human trainers in IDTS.

Figure 1. Expert systems.

- (2)

-

Artificial neural networks.

Artificial neural networks are inspired by the neural system of humans and can effectively solve nonlinear problems [

39]. In power systems, the classification and parallel processing abilities of artificial neural networks can be used for fault detection [

40], load forecasting [

41,

42], security assessment [

43,

44], automatic control [

45], system restoration [

46], and many other tasks.

- (3)

-

Fuzzy set theory.

Fuzzy set theory can deal with ambiguous, subjective, or imprecise judgments and thus reduce the complexity of the problem [

47]. This theory has been applied extensively in the fields of reliability evaluation [

48], hybrid algorithm [

49], and parameter optimization [

50] of power systems.

- (4)

-

Heuristic search.

Heuristic search obtains a new solution in a randomized manner, compares it with the previous results, keeps the better one, and iterates until an optimal or approximate solution is obtained [

51]. In power system simulation, this method can solve problems with arbitrary objective functions and obtain numerical results with arbitrary precision [

52,

53].

- (5)

-

Cloud computing.

Cloud computing technology, through distributed computing and storage, can reduce hardware investment costs and operation and maintenance costs, as well as enhance the flexibility of the application architecture [

54]. IDTS can be deployed on the cloud platform and use the large grid model on the cloud to conduct joint training among multiple dispatching centers [

12,

13], thus solving the shortcomings of traditional DTS. Practice proves that cloud-IDTS can realize multi-service and multi-scene co-simulation among dispatching centers. Not only does it improve the off-site interactive coordination capability of joint simulation, but it also realizes the flexible deployment of the simulation environment [

55]. The simulation resources are better used and can be better adapted to the rapid development of the power grid.

2. Intelligent Training Control

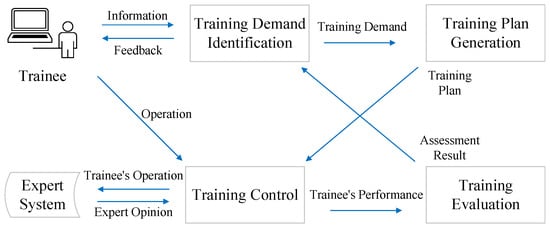

As shown in

Figure 2, the intelligent training control subsystem includes four modules: training demand identification module, training plan generation module, training control module, and training evaluation module [

17]. These four modules cycle to form a complete training process.

Figure 2. Intelligent training control subsystem.

The training demand identification module is the beginning of the training process. The information to be identified includes the trainee’s training records, learning preferences, and the purpose of training.

The training plan generation module develops personalized training strategies and training plans according to the identified training demand. Besides, it will also analyze and modify the training contents to better meet the needs of different trainers.

The training control module controls the training process in real-time according to the training plans. It is the commander of the entire training process. The training control module can use the fuzzy set theory to indicate the understanding level of the trainee and compare the trainee’s operations with the results given by the expert system so as to guide the subsequent training. In regular training, this module monitors each step of the trainee’s operations, pointing out the deficiencies and providing advice after simulation by the expert system; in the fault handling training, it simulates the inference process of the expert and determines the cause, type, and location of the fault, aiding the trainee’s judgment.

The training evaluation module comprehensively assesses the performance of trainees, with the aim of examining the effectiveness of each training phase. At the end of the training, the trainee’s operations on accident management are automatically scored, showing the skills they learned and the problems they exposed. This process greatly reduces the human trainer’s workload and improves the reasonableness of the grading. After that, the assessment results are fed back to the training demand identification module to update the trainee’s record, which then further improves the training plan generation module. The trainee will receive feedback at the end of the training process.

3. Intelligent Database Management

Smart grids contain more components compared with traditional grids for which they are horizontally integrated and vertically coherent [

19]. Therefore, the IDTS contains more data to be processed. This imposes requirements on the intelligent database management subsystem for simple maintenance, convenient expansion, fully functional, real-time control, and easy operation.

The required functions of the intelligent database management subsystem include:

-

Manage all static and dynamic data in the power grid model and support users to query, update, backup, and restore data.

-

Provide data sources for all modules and support data exchange between modules.

-

Support graphic database for editing, saving, and reproducing graphic data.

-

Provide an interface to EMS, which is the key to integrating DTS with EMS.

To fulfill the above requirements, this module should be built as follows.

The database should contain component model parameters, network model parameters, system parameters, simulated SCADA data, training data, graphical data, etc.

Two databases, an offline database, and an online database, need to be established and coordinated with each other [

56]. The training program is set up and initialized with the offline database. Relevant model parameters will be passed into the intelligent power system simulation subsystem to start the simulation, and the simulation results will be read from or written to the online database. The graphic module obtains simulation results from the online database and displays them to the trainer and trainee. The trainee performs operations that modify the online database, and the intelligent power system simulation subsystem simultaneously reads in data and re-simulates.

The offline database is managed by ORACLE and can be exported in various forms as required. It supports creating, retrieving, updating, and deleting (CRUD) operations with high reliability, fault tolerance, and self-recovery capability [

57], which can guarantee the integrity and security of the database.

Data sharing in online databases can be realized through the shared memory mechanism in UNIX systems, which can provide continuous storage that can be accessed by different processes [

58]. The use of an online database can significantly accelerate data access, improving the real-time performance of IDTS.

4. Intelligent Graphic Support

The intelligent graphic support subsystem is oriented to trainees and trainers, mainly consisting of diagrams of electrical wiring, power flow, power generation, device configuration, network topology, etc. [

59]. It displays the operating conditions of the simulated grid and allows trainees to operate directly on the graphic interface.

Traditional graphic support systems often suffer from the following problems:

To deal with these problems, the intelligent graphic support subsystem mainly includes the graphics editing module, data management module, display, and dynamic update module, and printing module.

-

The graphics editing module contains the commonly used basic symbols (points, lines, circles, etc.), electrical components (generators, transformers, etc.), and vector words. An object-oriented approach is used to encapsulate the individual graphic elements in the form of classes, and then different types of data are placed in different layers.

-

The data management module mainly uses large commercial databases, such as ORACLE, to meet security and efficiency requirements.

-

The display and dynamic update module support dynamic graph update, screen switching, and graph zooming. It also allows trainees to perform operations on the graph [

62].

-

The graphics printing module converts vector graphics to PostScript files for direct output or converts graphics windows to X Windows files for output with the XPR command.

This entry is adapted from the peer-reviewed paper 10.3390/en16020706