Contact selectivity is a key parameter for enhancing and improving the power conversion efficiency (PCE) of crystalline silicon (c-Si)-based solar cells. Carrier selective contacts (CSC) are the key technology which has the potential to achieve a higher PCE for c-Si-based solar cells closer to their theoretical efficiency limit. A recent and state-of-the-art approach in this domain is the tunnel oxide passivated contact (TOPCon) approach, which is completely different from the existing classical heterojunction solar cells. The main and core element of this contact is the tunnel oxide, and its main role is to cut back the minority carrier recombination at the interface.

- carrier selective contacts

- contact resistance

- tunnel oxide passivated contact

- renewable energy

1. Introduction

2. Structure and Electrostatics of TOPCon Solar Cell

3. Configurations of the TOPCon in c-Si-Based Solar Cells

-

n-TOPCon rear contact for n-type c-Si solar cell

-

p-TOPCon rear contact for p-type c-Si solar cell.

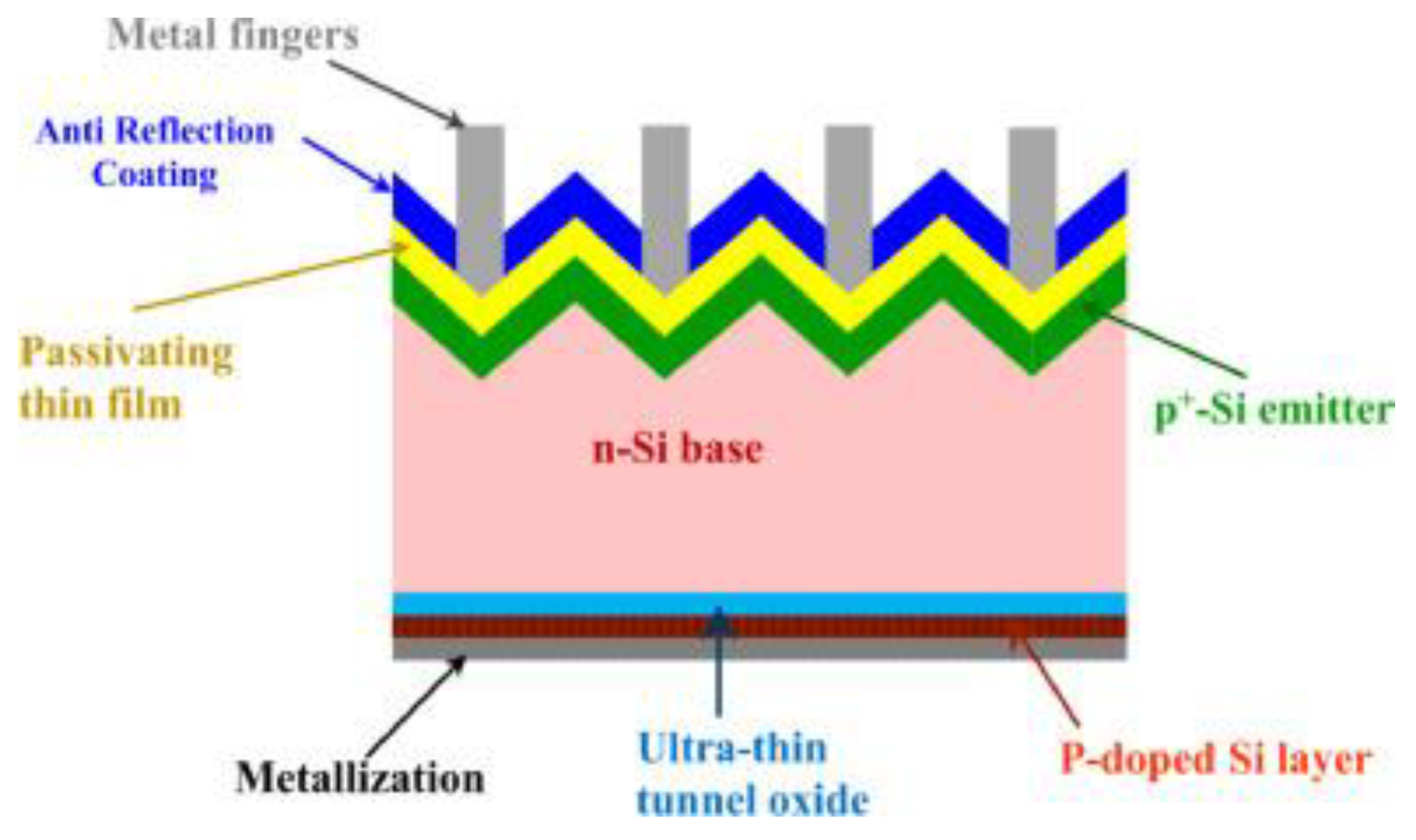

3.1. n-TOPCon Rear Contact for n-Type c-Si Solar Cell

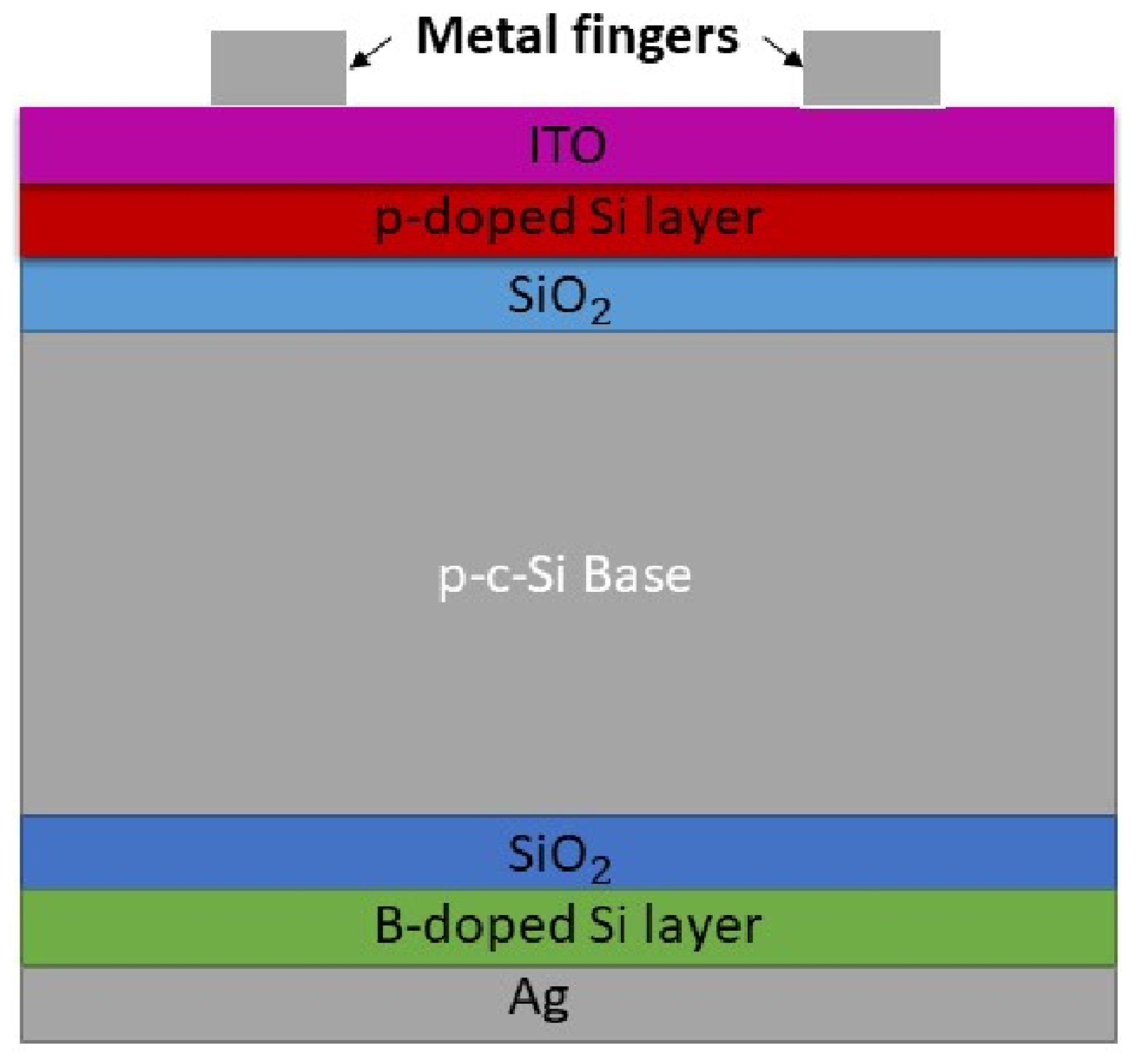

3.2. p-TOPCon Rear Contact for p-Type c-Si Solar Cell

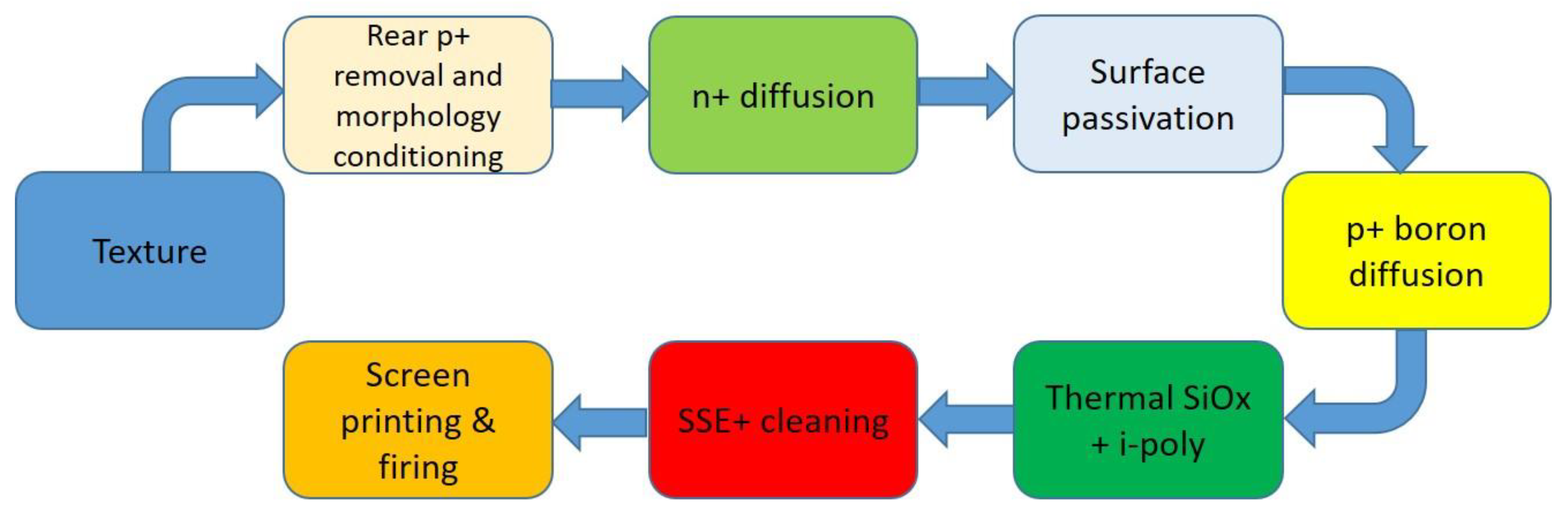

4. Fabrication of TOPCon Solar Cell

This entry is adapted from the peer-reviewed paper 10.3390/en16020715

References

- International Energy Agency (IEA) Home Page. Available online: https://iea.blob.core.windows.net/assets/1a24f1fe-c971-4c25-964a-57d0f31eb97b/Renewables_2020-PDF.pdf (accessed on 26 November 2022).

- The International Renewable Energy Agency (IRENA) Home Page. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2021/Apr/IRENA_-RE_Capacity_Highlights_2021.pdf?la=en&hash=1E133689564BC40C2392E85026F71A0D7A9C0B91 (accessed on 23 November 2022).

- Fraunhofer Institute for Solar Energy Systems (ISE) Home Page. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 23 November 2022).

- Blakers, A. Development of the PERC solar cell. IEEE J. Photovolt. 2019, 9, 629–635.

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J. Photovolt. 2013, 3, 1184–1191.

- Cuevas, A.; Macdonald, D.H. Measuring and interpreting the lifetime of silicon wafers. Sol. Energy 2004, 76, 255–262.

- Green, M.A. The Passivated Emitter and Rear Cell (PERC): From conception to mass production. Sol. Energy Mater Sol. Cells. 2015, 143, 190–197.

- Kumar, A.; Bieri, M.; Reindl, T.; Aberle, A.G. Economic viability analysis of silicon solar cell manufacturing: Al-BSF versus PERC. Energy Procedia 2017, 130, 43–49.

- International Technology Roadmap for Photovoltaic (ITRPV) Home Page. Available online: https://itrpv.vdma.org/documents/27094228/67038244/2021-04-29%20PR%20VDMA%20PV%20ITRPV%202021%20EN_1619690887765.pdf/644380bd-85a3-99d9-e25f-c4ccc6556e64 (accessed on 23 November 2022).

- Wilson, G.M.; Al-Jassim, M.; Metzger, W.K.; Glunz, S.W.; Verlinden, P.; Xiong, G.; Mansfield, L.M.; Stanbery, B.J.; Zhu, K.; Yanfa, Y.; et al. The 2020 photovoltaic technologies roadmap. J. Phys. D. 2020, 53.

- Ghosh, D.K.; Bose, S.; Das, G.; Acharyya, S.; Nandi, A.; Mukhopadhyay, S.; Sengupta, A. Fundamentals, present status and future perspective of TOPCon solar cells: A comprehensive review. Surf. Interfaces 2022, 30, 101917.

- Kafle, B.; Goraya, B.S.; Mack, S.; Feldmann, F.; Nold, S.; Rentsch, J. TOPCon–Technology options for cost efficient industrial manufacturing. Sol. Energy Mater. Sol. Cells 2021, 227, 111100.

- Yang, X.; Weber, K. N-type silicon solar cells featuring an electron-selective TiO2 contact. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC 2015), New Orleans, LA, USA, 14–19 June 2015; pp. 1–4.

- Younas, R.; Imran, H.; Shah, S.I.; Abdolkader, T.M.; Butt, N.Z. Computational modeling of polycrystalline silicon on oxide passivating contact for silicon solar cells. IEEE Trans. Electron. Devices 2019, 66, 1819–1826.

- Yang, X.; Bi, Q.; Ali, H.; Davis, K.; Schoenfeld, W.V.; Weber, K. High-performance TiO2-based electron-selective contacts for crystalline silicon solar cells. Adv. Mater. 2016, 28, 5891–5897.

- Macco, B.; Vos, M.F.; Thissen, N.F.; Bol, A.A.; Kessels, W.M. Low-temperature atomic layer deposition of MoOx for silicon heterojunction solar cells. Phys. Status Solidi RRL Rapid Res. Lett. 2015, 9, 393–396.

- Masuko, K.; Shigematsu, M.; Hashiguchi, T.; Fujishima, D.; Kai, M.; Yoshimura, N.; Yamaguchi, T.; Ichihashi, Y.; Mishima, T.; Matsubara, N.; et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 2014, 4, 1433–1435.

- Bivour, M.; Temmler, J.; Steinkemper, H.; Hermle, M. Molybdenum and tungsten oxide: High work function wide band gap contact materials for hole selective contacts of silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 34–41.

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. A passivated rear contact for high-efficiency n-type silicon solar cells enabling high Vocs and FF > 82%. In Proceedings of the 28th European PV Solar Energy Conference and Exhibition, Villepinte, France, 30 September–4 October 2013; pp. 988–992.

- Battaglia, C.; De Nicolas, S.M.; De Wolf, S.; Yin, X.; Zheng, M.; Ballif, C.; Javey, A. Silicon heterojunction solar cell with passivated hole selective MoOx contact. Appl. Phys. Lett. 2014, 104, 113902.

- Kiaee, Z.; Fellmeth, T.; Steinhauser, B.; Reichel, C.; Nazarzadeh, M.; Nölken, A.C.; Keding, R. TOPCon Silicon Solar Cells with Selectively Doped PECVD Layers Realized by Inkjet-Printing of Phosphorus Dopant Sources. IEEE J. Photovolt. 2021, 13, 31–37.

- Feldmann, F.; Simon, M.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Efficient carrier-selective p-and n-contacts for Si solar cells. Sol. Energy Mater. Sol. Cells 2014, 131, 100–104.