Human–robot collaboration is an innovative area aiming to construct an environment for safe and efficient collaboration between humans and robots to accomplish a specific task. Collaborative robots cooperate with humans to assist them in undertaking simple-to-complex tasks in several fields, including industry, education, agriculture, healthcare services, security, and space exploration. These robots play a vital role in the revolution of Industry 4.0, which defines new standards of manufacturing and the organization of products in the industry. Incorporating collaborative robots in the workspace improves efficiency, but it also introduces several safety risks.

- collaborative control

- robots

- architectures

1. Human–Robot Collaboration

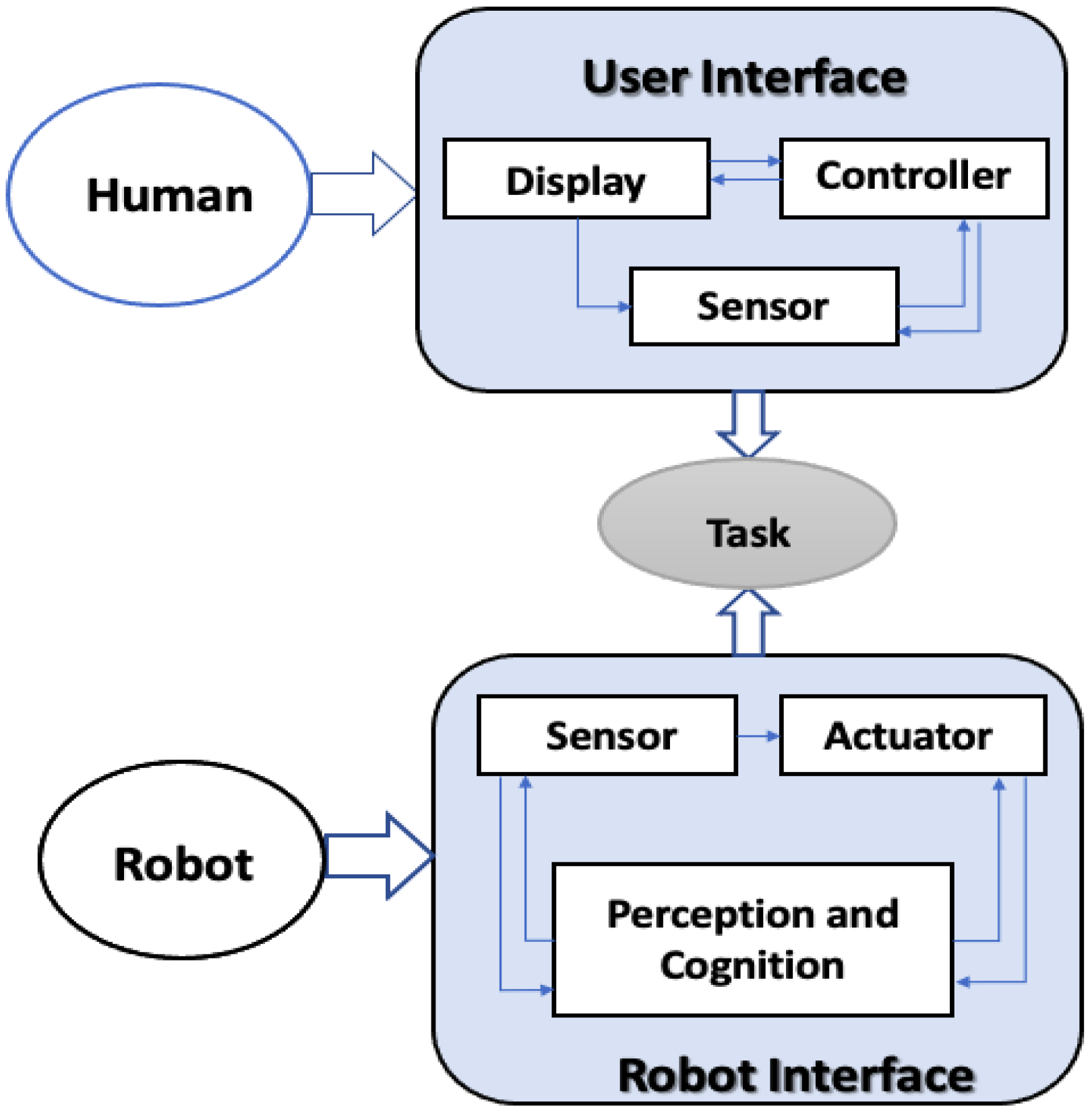

1.1. Human–Robot Interaction

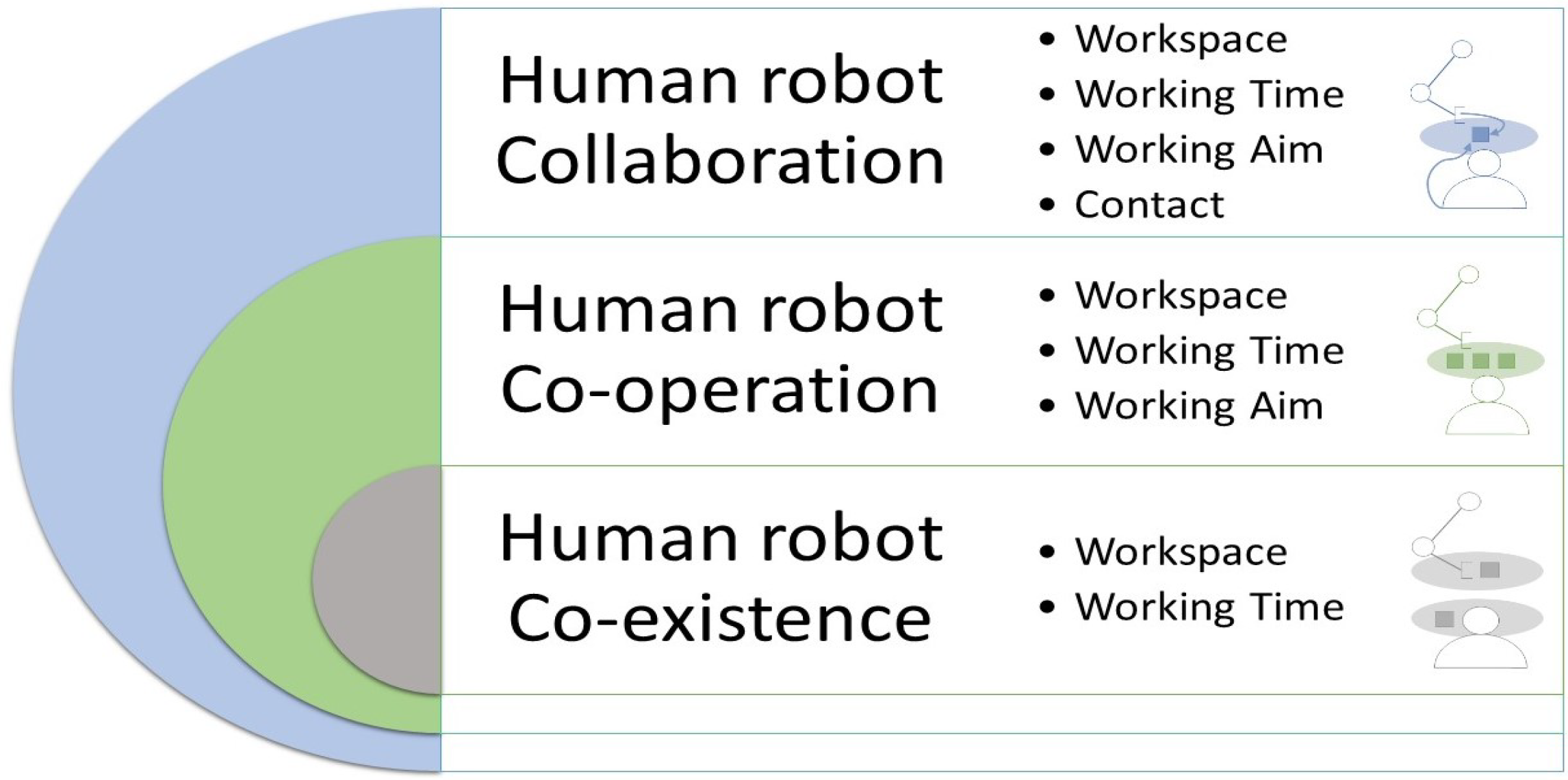

1.2. Human–Robot Collaboration Types

1.3. Collaborative Robotic Operations

| Robotic Operation | Human Input | Speed | Techniques | Torques |

|---|---|---|---|---|

| Power- and force-limiting | Application-dependent | Maximum determined speed to limit forces | The robot cannot exceed power excessive force | Max. determined torques |

| Speed and separation monitoring | No human control in collaborative workspace | Safety-rated monitored speed | Limited contact between robot and human | Necessary to establish a minimum separation distance and to execute the application |

| Hand guiding | Emergency stop | Safety-rated monitored speed | Motion controlled with direct operator input | Operator input |

| Safety-rated monitored stop | Operator has no control | When human is in collaborative workspace, speed is zero | Robotic operation stops, if the human is present | Gravity and load compensation only |

2. Control Design of Human–Robot Collaboration

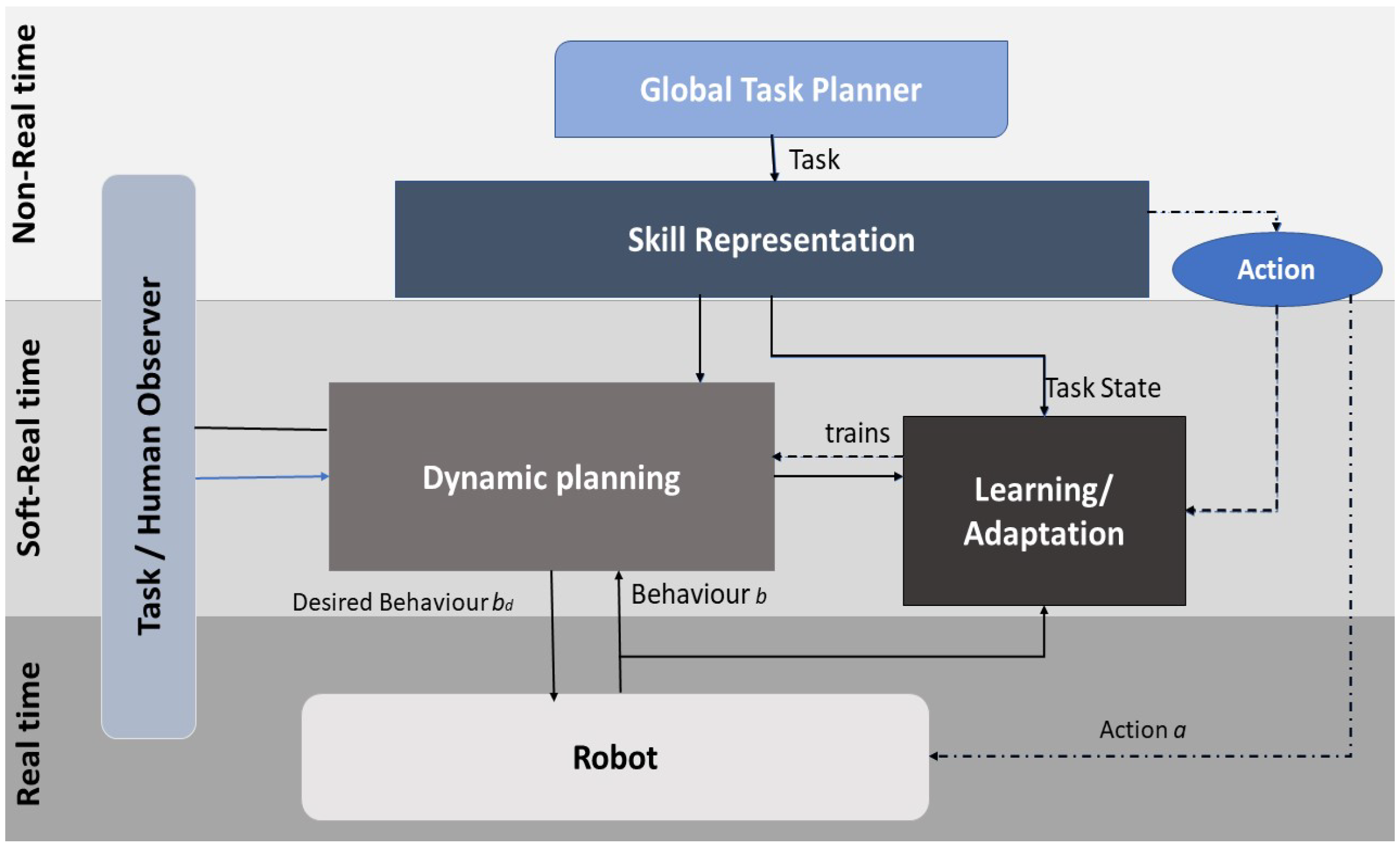

2.1. Collaborative Control System Architectures

2.1.1. Non-Real-Time Layer

2.1.2. Soft Real-Time Layer

2.1.3. Real-Time Layer

2.2. Controller Challenges

2.2.1. Estimation of Human Intention

2.2.2. Safety

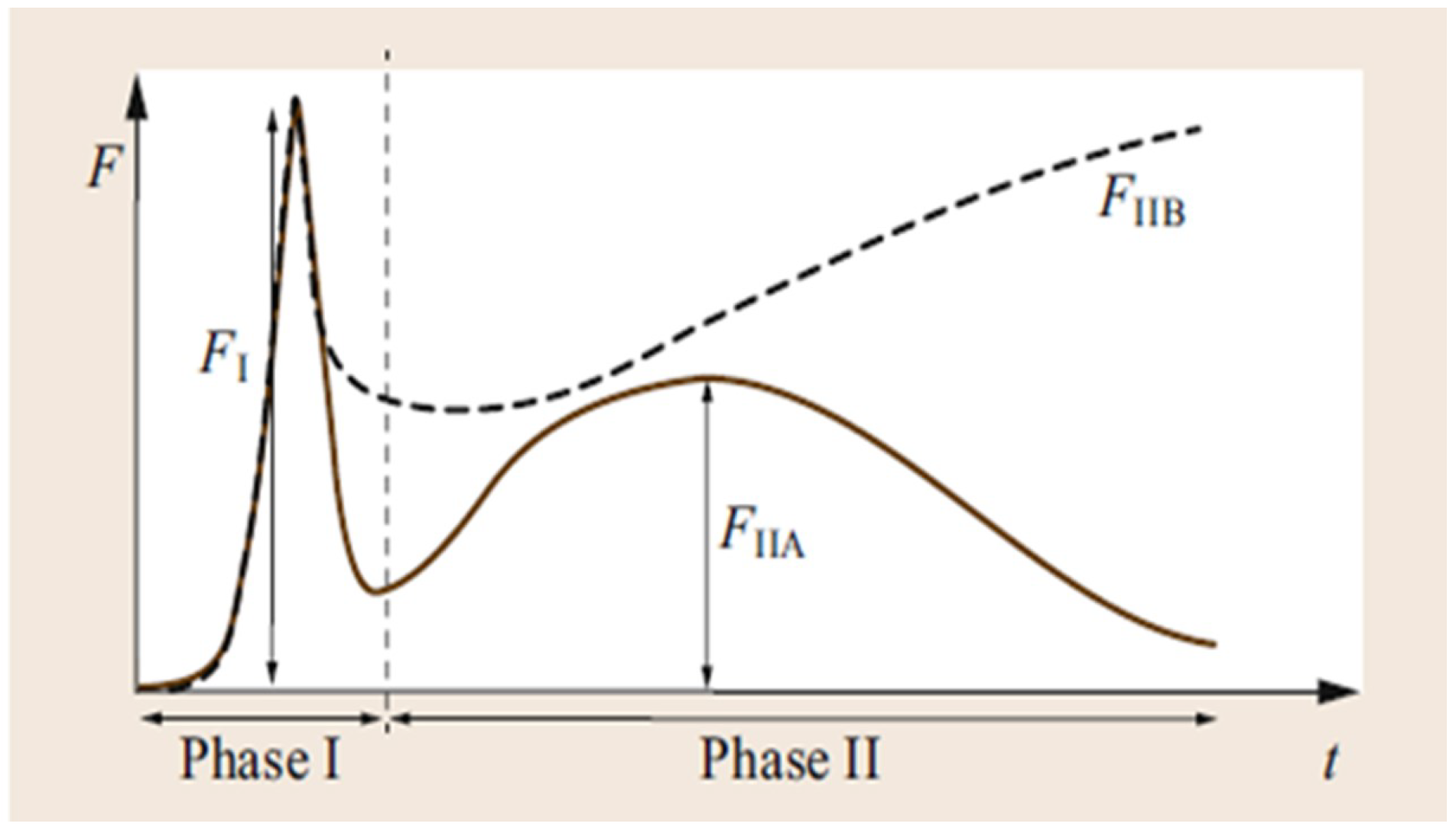

2.2.3. Human-Caused Disturbances

This entry is adapted from the peer-reviewed paper 10.3390/app13010675

References

- Schmidtler, J.; Knott, V.; Hölzel, C.; Bengler, K. Human Centered Assistance Applications for the working environment of the future. Occup. Ergon. 2015, 12, 83–95.

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human–Robot Collaboration in Manufacturing Applications: A Review. Robotics 2019, 8, 100.

- Wang, L.; Gao, R.; Váncza, J.; Krüger, J.; Wang, X.; Makris, S.; Chryssolouris, G. Symbiotic human–robot collaborative assembly. CIRP Ann. 2019, 68, 701–726.

- Al-Yacoub, A.; Zhao, Y.; Eaton, W.; Goh, Y.; Lohse, N. Improving human robot collaboration through Force/Torque based learning for object manipulation. Robot. Comput.-Integr. Manuf. 2021, 69, 102111.

- Rahman, S.M.; Wang, Y. Mutual trust-based subtask allocation for human–robot collaboration in flexible lightweight assembly in manufacturing. Mechatronics 2018, 54, 94–109.

- Jiang, J.; Huang, Z.; Bi, Z.; Ma, X.; Yu, G. State-of-the-Art control strategies for robotic PiH assembly. Robot. Comput.-Integr. Manuf. 2020, 65, 101894.

- Cheng, C.; Liu, S.; Wu, H.; Zhang, Y. Neural network–based direct adaptive robust control of unknown MIMO nonlinear systems using state observer. Int. J. Adapt. Control Signal Process. 2020, 34, 1–14.

- Li, S.; Wang, H.; Zhang, S. Human-Robot Collaborative Manipulation with the Suppression of Human-caused Disturbance. J. Intell. Robot. Syst. 2021, 102, 1–11.

- Chen, Z.; Huang, F.; Chen, W.; Zhang, J.; Sun, W.; Chen, J.; Gu, J.; Zhu, S. RBFNN-Based Adaptive Sliding Mode Control Design for Delayed Nonlinear Multilateral Telerobotic System With Cooperative Manipulation. IEEE Trans. Ind. Inform. 2020, 16, 1236–1247.

- Abadi, A.S.S.; Hosseinabadi, P.A.; Mekhilef, S. Fuzzy adaptive fixed-time sliding mode control with state observer for a class of high-order mismatched uncertain systems. Int. J. Control Autom. Syst. 2020, 18, 2492–2508.

- Scholtz, J. Theory and evaluation of human robot interactions. In Proceedings of the 36th Annual Hawaii International Conference on System Sciences, Big Island, HI, USA, 6–9 January 2003; p. 10.

- Cherubini, A.; Passama, R.; Meline, A.; Crosnier, A.; Fraisse, P. Multimodal control for human–robot cooperation. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 2202–2207.

- Hua, C.; Yang, Y.; Liu, P.X. Output-feedback adaptive control of networked teleoperation system with time-varying delay and bounded inputs. IEEE/ASME Trans. Mechatron. 2014, 20, 2009–2020.

- Zhai, D.H.; Xia, Y. Adaptive fuzzy control of multilateral asymmetric teleoperation for coordinated multiple mobile manipulators. IEEE Trans. Fuzzy Syst. 2015, 24, 57–70.

- Chen, Z.; Huang, F.; Sun, W.; Gu, J.; Yao, B. RBF-neural-network-based adaptive robust control for nonlinear bilateral teleoperation manipulators with uncertainty and time delay. IEEE/ASME Trans. Mechatron. 2019, 25, 906–918.

- Rosenstrauch, M.J.; Krüger, J. Safe human–robot-collaboration-introduction and experiment using ISO/TS 15066. In Proceedings of the 3rd International Conference on Control, Automation and Robotics (ICCAR), Nagoya, Japan, 24–26 April 2017; pp. 740–744.

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266.

- Asfour, T.; Kaul, L.; Wächter, M.; Ottenhaus, S.; Weiner, P.; Rader, S.; Grimm, R.; Zhou, Y.; Grotz, M.; Paus, F.; et al. ARMAR-6: A Collaborative Humanoid Robot for Industrial Environments. In Proceedings of the 2018 IEEE-RAS 18th International Conference on Humanoid Robots (Humanoids), Beijing, China, 6–9 November 2018; pp. 447–454.

- Tang, L.; Jiang, Y.; Lou, J. Reliability architecture for collaborative robot control systems in complex environments. Int. J. Adv. Robot. Syst. 2016, 13, 17.

- Ye, Y.; Li, P.; Li, Z.; Xie, F.; Liu, X.J.; Liu, J. Real-Time Design Based on PREEMPT_RT and Timing Analysis of Collaborative Robot Control System. In Proceedings of the Intelligent Robotics and Applications; Liu, X.J., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 596–606.

- Dumonteil, G.; Manfredi, G.; Devy, M.; Confetti, A.; Sidobre, D. Reactive planning on a collaborative robot for industrial applications. In Proceedings of the 2015 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Colmar, France, 21–23 July 2015; Volume 2, pp. 450–457.

- Parusel, S.; Haddadin, S.; Albu-Schäffer, A. Modular state-based behavior control for safe human-robot interaction: A lightweight control architecture for a lightweight robot. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 4298–4305.

- Xi, Q.; Zheng, C.W.; Yao, M.Y.; Kou, W.; Kuang, S.L. Design of a Real-time Robot Control System oriented for Human-Robot Cooperation. In Proceedings of the 2021 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Guangzhou, China, 14–16 May 2021; pp. 23–29.

- Gambao, E.; Hernando, M.; Surdilovic, D. A new generation of collaborative robots for material handling. In Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Eindhoven, The Netherlands, 2012; Volume 29, p. 1.

- Fong, T.; Thorpe, C.; Baur, C. Advanced Interfaces for Vehicle Teleoperation: Collaborative Control, Sensor Fusion Displays, and Remote Driving Tools. Auton. Robot. 2001, 11, 77–85.

- Haddadin, S.; Croft, E. Physical human-obot interaction. In Springer Handbook of Robotics; Springer: Cham, Switzerland, 2016; pp. 1835–1874.

- Skrinjar, L.; Slavič, J.; Boltežar, M. A review of continuous contact-force models in multibody dynamics. Int. J. Mech. Sci. 2018, 145, 171–187.

- Ahmadizadeh, M.; Shafei, A.; Fooladi, M. Dynamic analysis of multiple inclined and frictional impact-contacts in multi-branch robotic systems. Appl. Math. Model. 2021, 91, 24–42.

- Korayem, M.; Shafei, A.; Seidi, E. Symbolic derivation of governing equations for dual-arm mobile manipulators used in fruit-picking and the pruning of tall trees. Comput. Electron. Agric. 2014, 105, 95–102.

- Shafei, A.; Shafei, H. Planar multibranch open-loop robotic manipulators subjected to ground collision. J. Comput. Nonlinear Dyn. 2017, 12, 06100.