Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Fisheries

Aquaculture is an expanding economic sector that nourishes the world’s growing population due to its nutritional significance as a source of high-quality proteins. However, it has faced severe challenges due to significant cases of environmental pollution, pathogen outbreaks, and the lack of traceability that guarantees the quality assurance of its products.

- plasmonic sensor

- biosensor

- aquaculture

1. Introduction

Nowadays, aquaculture is the fastest-growing food-producing sector in the world, providing about 17% of animal proteins and 7% of all proteins globally by 2019 [1]. This economic activity, referred to as farming aquatic organisms (e.g., fish, molluscs, and crustaceans), contributed in 2020 to the global production of 122.6 million tonnes, worth USD 281.3 billion [1]. Aquaculture activities are practised inland, in coastal or marine environments in various facilities, from ponds and cages to highly sophisticated water reuse systems [2]. In particular, the expansion of aquaculture showed a boost during the late 1980s to 2020, showing a growth in the production of aquatic organisms in inland waters, from 12% to 37%. Meanwhile, it is forecast that by 2030, aquatic food production will increase by a further 15% [1].

However, this growth requires developing and adopting innovative technologies for more efficient and resilient aquaculture. In addition, this industry faces various challenges that complicate its operation [3]. For example, maintaining good water quality throughout the culture is a crucial challenge due to self-pollution by inorganic nutrients, food remnants, and fish faeces, as it causes eutrophication in the surrounding environment due to the high nutrient stimulus [3]. On the other hand, there is the additional challenge of controlling the growth of pathogens, which are directly involved in the infection of the fish, which causes significant loss of profits in the industry, not to mention the risk of generating resistance to antibiotics due to the use of conventional control antimicrobials [4]. Finally, farmed fishes are commonly reared at large scales in high densities, which causes stress and significantly increases the mortality of animals [5].

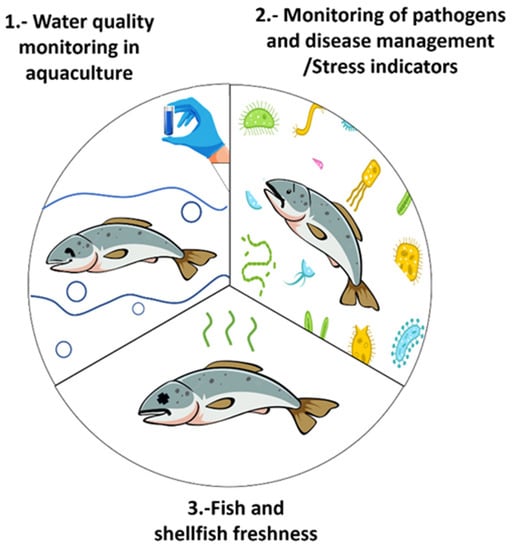

Despite these challenges, aquatic food producers are responsible for ensuring and providing consumers with fresh and safe products. To do so, companies must demonstrate the absence of hazardous compounds in their products. Unfortunately, this is no easy task, as toxin analysis currently takes 24 h up to days from the point of sample to obtain a result. [5]. Therefore, aquaculture operators must conduct their real-time end-product testing for regulatory acceptance to ascertain the safety and release of their products. Consequently, the European market for analytical tests developed for food safety applications, especially for pathogen detection, has grown to an estimated $4 billion by 2018 [6], showing the sector’s economic importance in detecting methods for monitoring each central area in aquaculture systems. In this sense, there is currently a broad range of analytical methods for the concentration assessment of crucial chemical compounds for aquaculture safety, including spectrophotometric, chromatographic, and fluorometric techniques, and electrochemical analysis, among others [7]. Mainly, photonic sensors have gained particular interest as they enable online and continuous monitoring, suitable for in situ and in vivo measurements, making them very advantageous for aquaculture systems. Figure 1 outlines the current plasmonic sensing technologies trialled and applied at the aquaculture process’s main stages, from the species’ farming up to their harvest and previous distribution.

Figure 1. Major areas of interest in aquaculture monitoring.

2. Optical Sensors Based on Plasmonic Techniques

Plasmonic sensors are based on an optical phenomenon generated by incident polarised light between a dielectric and a metallic system, forming an evanescent field from the waving electrons that propagate along the system, known as surface plasmon waves (SPW) [5]. Some of the sensors based on the plasmonic technique are surface plasmon resonance (SPR), localised SPR (LSPR), and fibre-optic SPR (FO-SPR). These sensors are commonly based on noble metallic thin films and nanostructures (gold, silver, platinum, and palladium) due to their property of a higher optical absorption band in the visible–near infrared range, called a plasmonic band [8]. Moreover, the depth and position of the SPR dip are sensitive to the refractive index and employed as analytical parameters in a wide range of applications. Furthermore, plasmonic sensors possess advantages compared to conventional technologies, which include detection with no labels needed, high sensitivity, and real-time analysis. However, they suffer some drawbacks, such as the condition of a p-polarised light to induce the optical phenomenon, the requirement of recognition elements to offset its low selectivity, and a range of RI changes detection around 200 nm [9]. Table 1 summarises some of the advantages and disadvantages of plasmonic sensors compared to other technologies employed in aquaculture applications.

Table 1. Comparison of latest sensing technologies used in aquaculture.

| Sensing Technology | Advantages | Disadvantages | References |

|---|---|---|---|

| Prism-based SPR | Allows the study of binding interactions in a label-free format (i.e., no addition of fluorescent tags is necessary). Highly sensitive to the refractive index (RI) of the medium in contact with the metal film (usually aqueous solution for aquaculture applications). Widely established and commercially available. SPR studies can exist in a multiplexed employing multichannel device. |

The prism can be bulky and difficult to incorporate into miniaturised platforms. Only detects RI changes close to the metal film surface (extends ~200 nm). Temperature control is needed to produce stable SPR signals. The sensing device cannot be used for remote sensing applications. |

[10] |

| LSPR | More amenable to multiplexing and miniaturisation than prism-based SPR. Detection systems can be tuned by varying the nanoparticles’ size, shape, and composition. Allows the use of wavelengths that do not overlap with the spectral features of strongly absorbing samples (natural chromophores). The plasmon resonant nanostructures can be used as fluorophore tags LSPR sensors are susceptible to the RI of the surrounding medium. |

Detects RI changes that happen only tens of nanometers into the surrounding medium. LSPR sensors have dramatically reduced sensing volumes, extending the detection limit to the single-molecule level. Sensing experiments need to ensure that the binding of the target molecule happens within the sensing volume as opposed to outside of it, especially when it involves bulky molecules. |

[11] |

| FO-SPR | SPR probe can be miniaturised. Flexible, can be easily moved, and allow remote sensing application. Temperature control is not needed to produce stable signals. Multiplex analysis can be allowed by the guiding light in different wavelengths simultaneously |

Complex fabrication and surface functionalisation. Damage of sensing elements due to prolonged exposure to incident light. Slow response time due to the diffusion effect of analytes. |

[12] |

| Electrochemical sensors | Low-cost production of electrodes and microelectronic circuits. The straightforward interface of electronic read-out and processing. Multiple enzymatic labels increase the signal per event. |

There are electrical safety hazards and electrical interference. Factors such as pH and ionic strength in fluids can r significantly affect the sensor’s response. The miniaturisation of electrochemical sensors tends to increase the signal-to-noise. These devices use redox molecules that mediate the electrochemical reaction at the working electrode. The lifetime of electrodes diminishes due to fouling effects. |

[13] |

| Quantum dots sensing | Excellent fluorophores, resistant to thermal and photochemical reactions. Simple manufacturing process |

Low fluorescence quantum yield Requires surface passivation process (coating). Sensitivity relies on the recognition element. |

[14,15] |

| Polymerase chain reaction (PCR) | Highly sensitive, accurate, and good repeatability. Real-time analysis. |

Require PCR instrument. Costly reagents. Time-consuming. Requires technical expertise. |

[16,17] |

| Chromatography–mass spectrometry | Highly sensitive, accurate, and good repeatability. | Costly reagents. Time-consuming. Requires technical expertise. Chromatography cannot meet the requirements for in-field detection. |

[7] plasmonic sensor; biosensor; aquaculture; |

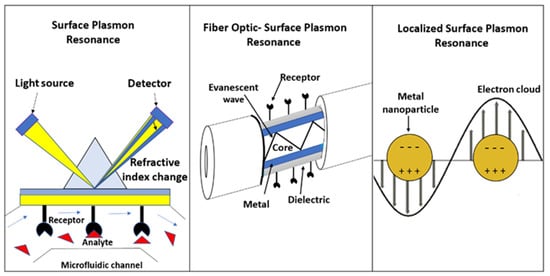

Plasmonic sensors can be presented in different configurations. For example, SPR-prism-based sensors utilise a thin metal film between two transparent media, a glass prism, and a sample solution. The polarised light enters the glass prism and undergoes total internal refraction (above a critical angle of incidence), allowing the evanescent wave to penetrate the gold film [8]. Polarised light is necessary for the excitation of the surface electrons of the noble metal to occur and, thus, the phenomenon of surface plasmon resonance. This light must have a p-polarisation (parallel to the plane of incidence), otherwise, the phenomenon will not happen. S-polarisation (perpendicular to the plane of incidence) cannot excite surface electrons [18]. Thus, the interaction of the evanescent wave and resonating electrons at the gold film surface will cause the excitation of surface plasmons, decreasing the reflected light intensity (the phenomenon of surface plasmon resonance). SPR is observed as a sharp dip in reflected intensity at a certain angle, which shifts when biomolecules bind to the surface, changing the refractive index of the surface (Figure 2).

Figure 2. Schematic representation of prism-based surface plasmon resonance, fibre-optic SPR, and localised SPR.

On the other hand, the optical fibre configuration is also used to implement SPR (FO-SPR), shown in Figure 2. In this sensor, the fibre cladding is removed, leaving the bare core exposed, and coated with a metal film layer to create the sensing region [19]. The sensing length influences the reflections of the light beam in the core, related to the width of the SPR [20]. Under this configuration, a range of guided rays is launched into the fibre, generating the evanescent field by total internal reflection, which excites surface plasmons between the dielectric and metallic system [11]. The wavelength at which the dip occurs by the SPR phenomenon is the resonance wavelength and shifts as the refractive index change (spectral wavelength interrogation) [11]. The fibre-optic sensor can be used in two modes: transmissive and reflective. In the transmissive mode, the sensing region is in the middle of the fibre. The light is coupled from the source to the fibre through one end, and the analyser is connected to the other end [21]. In the reflective configuration, the sensing region (metal coating) is located at one end of the fibre, reflecting the incident light as a result of the mirror effect of the metal coating [22].

In terms of metallic nanostructures, when a light beam incident gets trapped, it causes the waving of dislocated electrons, resulting in the localised surface plasmon effect (LSPR), schematically shown in Figure 2. In this case, the resonance wavelength depends on the shape and size of the nanomaterial, as well as the medium surrounding it [19]. For LSPR, the wavelength interrogation method allows the evaluation of changes in absorbance wavelength caused by the changes in the refractive index [23]. The main disadvantage of LSPR is its lower refractive index sensitivity compared to conventional SPR, which is compensated by its high sensing surface for monitoring binding events between the surface and a single analyte [23]. The sensitivity of plasmonic nanoparticles is dependent on their size and geometry. For example, nanostructures with intense absorption or scattering properties are closely related to the increasing size of gold nanoparticles. Small-size particles (∼40 nm) are preferred for high-absorption cross-sections. Meanwhile, a dominant scattering property will be observed in relatively big-size nanoparticles (∼80 nm) [24].

Regarding nanoparticle geometries, previous reports have established that anisotropic structures show higher sensitivity than spherical-shaped structures [25,26]. For instance, nanorods, nanocubes, nanoshells, and nanoholes have been studied, showing higher yields than conventional spheres [24]. In this sense, gold nanorods present a refractive index sensitivity of ∼250 nm compared to ∼60 nm for gold spheres [27]. Meanwhile, exotic shapes such as trimmers and nanopillars have been reported to provide adjustable wavelengths from ultraviolet to near-infrared, enhancing the LSPR sensitivity up to 675 nm/refractive index units. Moreover, it allows sharp resonances and a well-localised electromagnetic field that improves plasmonic sensing properties [28]. In addition, plasmonic geometries with chiral properties have been reviewed, reporting the improvement of light-adjusting interactions [29]. For example, twisted, gammadion, or shuriken 3D structures have been reported to allow the change of circular dichroism of molecules from ultraviolet to the visible region, simplifying the analysis in sensing applications [29].

On the other hand, LSPR-based sensors have also benefited by integrating semiconductor particles called quantum dots (QDs) [30]. These particles (commonly up to 10 nm) emit extended fluorescence when excited by light. The QDs are usually based on carbon, silicon, cadmium, or indium complexes [31]. Due to QDs having been extensively used as fluorescent labels, in combination with the surface plasmon properties of gold nanoparticles, they can enhance the sensitivity of plasmonic detection systems [32]. When they are adjacent to metallic nanoparticles they can affect the fluorescence signal and, therefore, be quenched depending on the analyte amount [33].

Despite the progress on plasmonic materials, geometries, and set-up configurations [34], little has been applied to aquaculture activities, leading to broad development perspectives. Regardless of the type of plasmonic sensor or their configuration scheme, their performance is still subject to modifying the meta

This entry is adapted from the peer-reviewed paper 10.3390/bios13010090

This entry is offline, you can click here to edit this entry!