1. WDHS Control Systems: Dispatch Strategies

Conventional dispatch (CD) control is a standard hybrid system control strategy, at which the system operation is governed by the predetermined rules. Such a system is not flexible and is unable to timely respond to the changing mode parameters, so the system operation in this mode is not optimal.

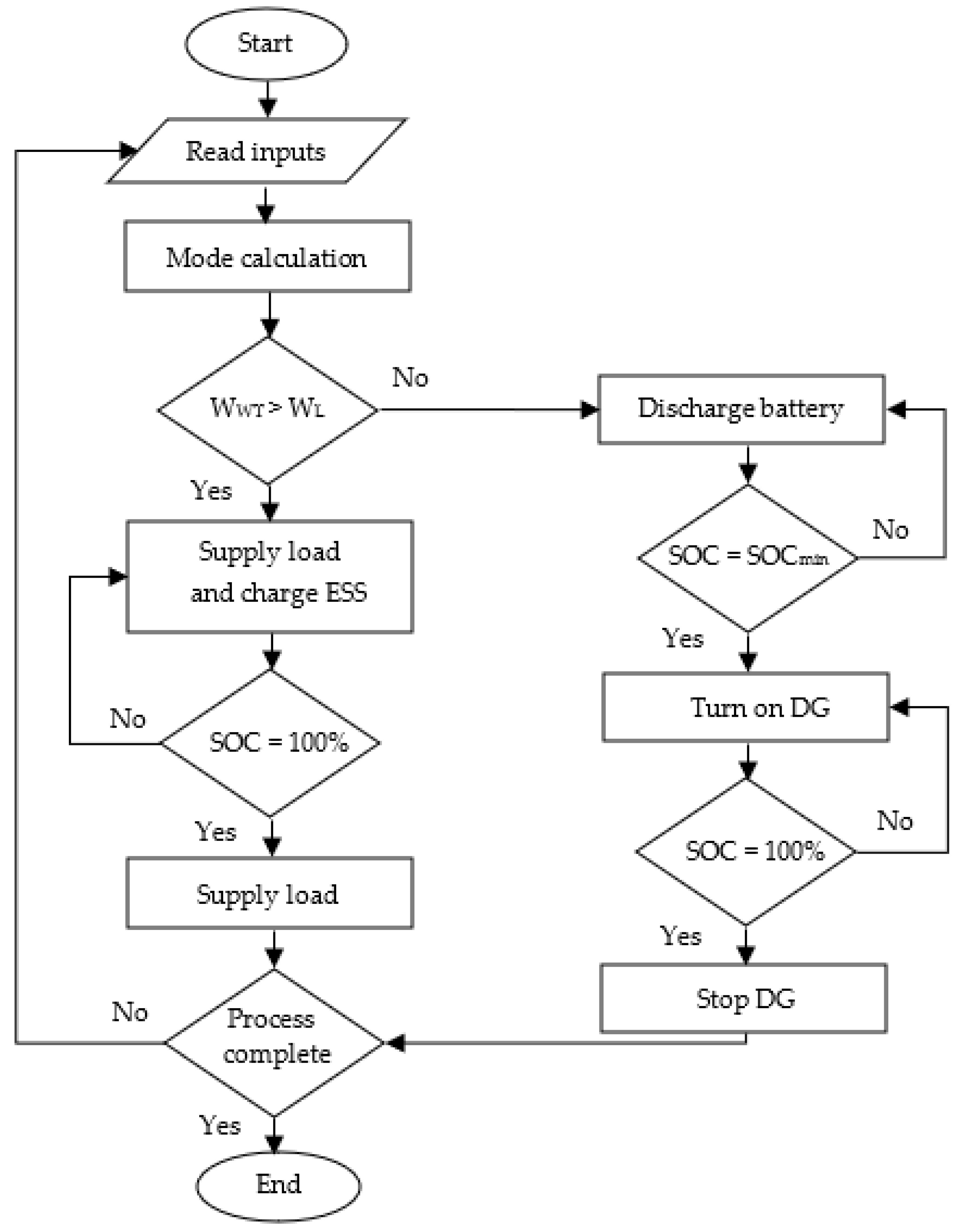

WDHS with the ESS standard operation algorithm is shown in Figure 1. At high WDHS penetration, the DG operates as a reserve power source, charging up discharged or low-charged batteries.

Figure 1. Flowchart of the WDHS with the high penetration operation algorithm: W

WT — wind turbine energy generation; W

L — load energy consumption; SOC — battery state of charge; SOC

min — minimum allowable value of SOC

[1].

When wind power if sufficient to satisfy consumer demand, DG can be cut off and WT energy surplus can be accumulated in ESS. However, if RES power is insufficient, the hybrid system operating mode is determined by selecting an appropriate dispatch strategy determining the practicability of switching on/off each system element at a given moment. WDHS basic operating modes and corresponding dispatch strategies are described by Drouilhet et al. (2002)

[2].

Ishraque et al. (2021) singled out several basic dispatch strategies: load following (LF), cycle charging (CC), generator order (GO), and combination dispatch (CmD). When selecting load following (LF), the generator provides enough capacity to satisfy load demand. Providing reliable electric power supply to consumers is a high-priority task. In CC, the generator runs at its full capacity when it is on, while energy surplus is used to charge the ESS. The ESS plays a key role here. Such a strategy can be effective in regions with low RES potential. In the GO strategy, a predefined order of generator combinations of relevant power satisfies consumer demand. ESS are used only when urgently needed. CmD does not require load prediction methods. Accumulators’ charging mode selection is determined by the current load. CmD specifies the lowest cost power source option in order to select in which mode (LF or CC) to operate at the current mode parameters. Optimal strategy selection depends on the sources’ power, load demand and environmental conditions

[3].

DG and ESS operation algorithms vary with each control strategy. Thus, its optimum equipment configuration and power correspond to each control strategy; therefore, technical and economic parameters of the whole system operation will be different. Shezan et al. (2021) presented island hybrid microgrid optimal sizing for various dispatch strategies. Comparing the calculation results in HOMER showed that the island hybrid microgrid optimal strategy is LF which provides lowest the COE and NPC. The GO strategy is the best to reduce operating costs, NPC and CO

2 emissions, and, therefore, allows the maximum fuel saving to be achieved. CO

2 emissions go down by 8, 21 and 22% on average compared to LF, CC and CmD, respectively

[4].

Control systems’ algorithms should take into account WDHS equipment layout and configuration. Elistratov et al. (2021) put forward an improved intelligent automatic control system of WDHS operated in the Arctic, considering weather, wind and blades icing forecast. The control system hardware component uses two dynamic power redistribution devices between the system elements: a bi-directional current transducer with batteries connected to it and controlled dump load. The developed algorithm efficiency was compared with WDHS with LF control strategy and DG only operation, allowing 34% and 60% of fuel to be saved, respectively. The proposed control strategy was named CC with short-term forecasting including icing effects

[5].

WT shut down at wind speeds lower than cut-in speed and higher than cut-off speed. However, if WT run at low wind speeds (higher than cut-in, but lower than the nominal one), their operation can be inefficient because the effect of the energy produced can be levelled down by operational costs. Thus, for WDHS with several WT, there is a problem of determining the optimal number of simultaneously running installations. Hu et al. (2013) used a dynamic programming method to select the optimum WT operational option with switching options for maximizing the WDHS net cash flow. This method allows to determine the effective number of running WT depending on the wind speed

[6].

Yang et al. (2021) suggested using the multidimensional firefly algorithm (MDFA) to solve the problem of economic dispatch (ED) and hybrid power plant day-ahead scheduling optimization. The task of ED is to lower the energy generation cost. The algorithm determines the optimal number and type of running generators for every hour of a 24 h period. The proposed algorithm allows energy generation cost over 24 h period to be reduced by 36.1 and 5.3% compared to genetic algorithm and particle swarm optimization, respectively

[7].

Tiwari et al. (2019) suggested a control system of WDHS with ESS. Doubly fed induction generator (DFIG) is used as a WT generator, while DG loading is regulated in such a way as to ensure its operation in a fuel-efficient zone. A battery ESS (BESS) is connected to the DC bus providing buffer storage. Rotor side converter (RSC) provides turbine MPPT using field-oriented vector control, while grid-side converter (GSC) provides power exchange with ESS. GSC also controls DG and WT currents so that they remain balanced and sinusoidal. The proposed control provides DG operation in all modes with a 0.65 to 1.05 load ratio of the nominal power

[8].

Shuai et al. (2013) applied differential evolution algorithm for hybrid WSDHS operation optimization for desalination aimed at minimizing island microgrid operation costs

[9].

1.1. Energy Management System (EMS)

EMS is a key component of the hybrid plant and solves the task of keeping power balance between the system elements, thus ensuring reliable and efficient operation of the system as a whole. The simplest energy management strategy is a rule-based EMS. It determines the system operation mode and decides which energy source to use according to the predefined rules.

An et al. (2018) proposed an EMS which is based on forecasting energy resources data, load demand and market cost of electricity in each hour on the next day. The dynamic programming (DP) method is used. The objective function is environmental emission reduction. In comparison with rule-based EMS, this method’s economy is 38.3–46.4% and depends on the ESS initial power level

[10].

Yahyaoui et al. (2022) presented an EMS of a stand-alone hybrid power plant aimed at reliable, controllable loads supply. The EMS is focused on the maximum use of RES power, reducing DG penetration and maintaining the charge of ESS within an allowable range. The EMS produces signals to connect the necessary power supply source depending on the load and using fuzzy logic

[11].

Phan et al. (2022) presented an EMS based on deep Q network (DQN) for an island hybrid power plant with energy storage based on batteries and electrolyzed hydrogen. The EMS task is to lower fuel consumption, providing the lowest cost of energy (COE). According to algorithm-based findings, it is possible for fuel consumption to be reduced by 28% in comparison with the CD-based EMS

[12].

1.2. Frequency and Voltage Control

A large number of studies are devoted to frequency control in systems with WDHS. This problem is particularly acute for isolated WDHS with high wind power penetration rate. In the process of WDHS operation, frequency deviations are observed which are caused by power imbalance due to unexpected and abrupt load and wind speed change. Frequency deviations exceeding the admissible limits lead to the system instability.

Solving the problem of maintaining frequency within the admissible limits, reducing its deviations and improving dynamic characteristics will allow the expansion of the range of admissible WT operation modes, and the increase in WT penetration and energy production rate while lowering diesel fuel consumption.

Arzani et al. (2021) suggest using frequency control ancillary services (FCAS) in order to mitigate transient processes at considerable operation point change and disconnection from the main power grids. Each generation source receives a frequency control signal based on distribution coefficients which are calculated by solving multi-objective optimization. A metaheuristic approach, the artificial bee colony (ABC) algorithm, is used to find the optimal solution. System operating conditions, under which frequency deviations appear, are simulated in PSCAD: switching operation and disconnection from the main power grid, load disturbance and the microgrid total inertia reduction. According to the simulation results, selecting optimum coefficients using the ABC algorithm can reduce the frequency nadir point, overshoot and settling time of the frequency response

[13].

Takahashi et al. (2020) suggested cooperative frequency control of a DFIG generator integrated into DG for adjustable speed diesel engine-driven power plant ESS in order to improve the frequency stability of the isolated small-scale power system with WT. A proportional–differential (PD) controller based on fuzzy logic is used in the frequency control system. Simulation modelling results show that using the DFIG generator together with a WT permanent magnet generator can effectively reduce frequency fluctuations. DFIG and ESS combined control can further increase frequency control possibilities

[14].

Voltage maintenance in systems with WDHS is equally important. This problem is particularly acute for stations in which control strategies permit cutting off DG at their low load. ESS can effectively solve this problem; reactive power sources can also be used.

2. WT Control System Improvement

This section deals with various approaches to provide efficiency by improving the WT control system.

2.1. Wind Prediction

The possibility to know the system behavior in advance plays an important role in solving the problem of cost-effective load dispatch and maintaining stable frequency value. Herewith, prediction methods are used. An essential role is played by a short-term prediction several minutes or hours ahead.

A back propagation (BP) algorithm is traditionally used for prediction. Xiong et al. (2022) proposed a hybrid algorithm based on gradient descent and metaheuristic optimization for short-term wind power prediction. BP data are used as input data in a shuffled frog leaping algorithm. Next, the results are once more optimized by a root mean square propagation algorithm, and thereafter they are introduced in the artificial neural network as source data for prediction. Such an algorithm is called BP-SFLA-RMSprop-ANN. Comparison results with similar algorithms confirm the high accuracy of prediction and the least errors at an acceptable convergence speed. The mean absolute percentage error (MAPE) was 18.41% at the value of R

2 = 0.9539

[15].

Chen et al. (2012) suggested rolling an auto-regressive and moving-average (ARMA) model to predict wind speed 24 h ahead. MAPE was 16.23%. The data obtained are used to determine the optimum mode of the low-carbon dispatch model based on hybrid particle swarm optimization with a simulated annealing (SA) algorithm. For this, the authors introduce the term “energy-environment efficiency” which is the function of CO

2 emissions. The proposed algorithm allows to make an optimum compromise satisfying the conditions of both reducing operation costs and environmental impact

[16].

A comparison of wind power prediction models by machine learning methods was presented by Alkesaiberi et al. (2022). Gaussian process regression (GPR) and ensemble learning (EL) models showed the best results among other statistic models. The best results can be achieved by dynamic models using the data of both prior and current wind power. The best results among these were shown by GPR with Bayesian optimization and EL models. The bagging trees model is optimum to predict wind power relying exclusively on meteorological data of wind speed and direction

[17].

Shojaee et al. (2022) proposed a decentralized model-predictive controller to control frequency and power of isolated WDHS with mechanically coupled WT and DG. The optimal control action is determined over a predefined prediction horizon at every sampling interval. Algorithm optimization is aimed at minimizing the difference between the predicted and reference response. The proposed closed-loop system performs best when damping the undesired oscillations at load and wind speed change, and has a larger stability margin compared to the linear quadratic Gaussian controller

[18].

2.2. Maximum Power Point Tracking (MPPT)

The WT optimum operating mode is set by the MPPT controller. The MPPT is focused on maintaining the maximum possible turbine power factor and, consequently, the maximum power output. In order to achieve this, it is necessary to precisely monitor the desirable turbine rotor speed, which is a difficult task, taking into account stochastic change of wind speed.

MPPT algorithms fall into three categories: tip speed ratio (TSR) algorithm, hill-climbing search (HCS)/perturb and observe (P&O) algorithm, and optimal torque (OT)/power signal feedback (PSF) algorithm. Zhang et al. (2022) presented MPPT control based on precise monitoring of the rotor speed probability density function (PDF) shape. The MPPT control law is designed in such a way so that PDF shape of rotor speed precisely matches the desired PDF shape. For this, a combination of the OT algorithm and Fokker–Planck–Kolmogorov (FPK) equation was used, which is solved by the linear least-square (LLS) method. The proposed nonlinear MPPT optimal control allows WT output to be increased, reducing speed and rotor moment fluctuations

[19].

Meng et al. (2017) presented a model predictive control method with dynamic weights in the cost function for large-inertia WT. The results showed a considerable decrease in power fluctuations in all modes while maintaining the maximum turbine power factor

[20].

2.3. Pitch Control

WT cut-off at wind speeds exceeding the cut-off speed considerably lowers energy production efficiency. For solving the tasks of effective WT management, it is necessary to find a compromise between the maximum power output and meeting structural and operational safety requirements. In order to maintain high efficiency, HAWT should operate in the optimal mode within the whole range of wind speed change. In order to control the turbine power, pitch angle control is used so that the rotor speed is maintained within the preset range.

Habibi et al. (2022) suggested a pitch actuator controller to maintain horizontal axis wind turbine (HAWT) optimum speed. The controller uses limited control with the Lyapunov barrier function employed. A Nussbaum-type function is used to avoid uncertain wind speed variation effects; precise wind measurement is not required for its operation. The use of a controller prevents rotor overspeeding and mechanical brake engagement when wind speeds are above cut-off

[21].

3. ESS Control Algorithms

Phelan et al. (2013) showed that when DG and WT operate simultaneously, the load and ESS are not always capable of utilizing all the energy produced. Therefore, the energy is wasted, being discharged at damper load. Such a situation is observed at final stages of the charging cycle when the BESS is unable to accept any more charge. This power fraction (usually wasted) can be saved by more efficient generator operation scheduling. The DG cut-off is optimal when the wind power is sufficient for the power supply load; however, it is not always possible to be realized. A charging algorithm was proposed, which is based on wind speed prediction according to the change in measured barometric pressure. This algorithm makes it possible to achieve a reduction in fuel consumption by 2.5% and in DG run hour by 3.4%. The efficiency increases to 7% when using this algorithm for WDHS with a low capacity of ESS

[22].

This entry is adapted from the peer-reviewed paper 10.3390/en16010184