Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Offshore wind energy is a sustainable renewable energy source that is acquired by harnessing the force of the wind offshore, where the absence of obstructions allows the wind to travel at higher and more steady speeds. Offshore wind has recently grown in popularity because wind energy is more powerful offshore than on land.

- wind energy

- offshore wind turbine

- numerical models

1. Introduction

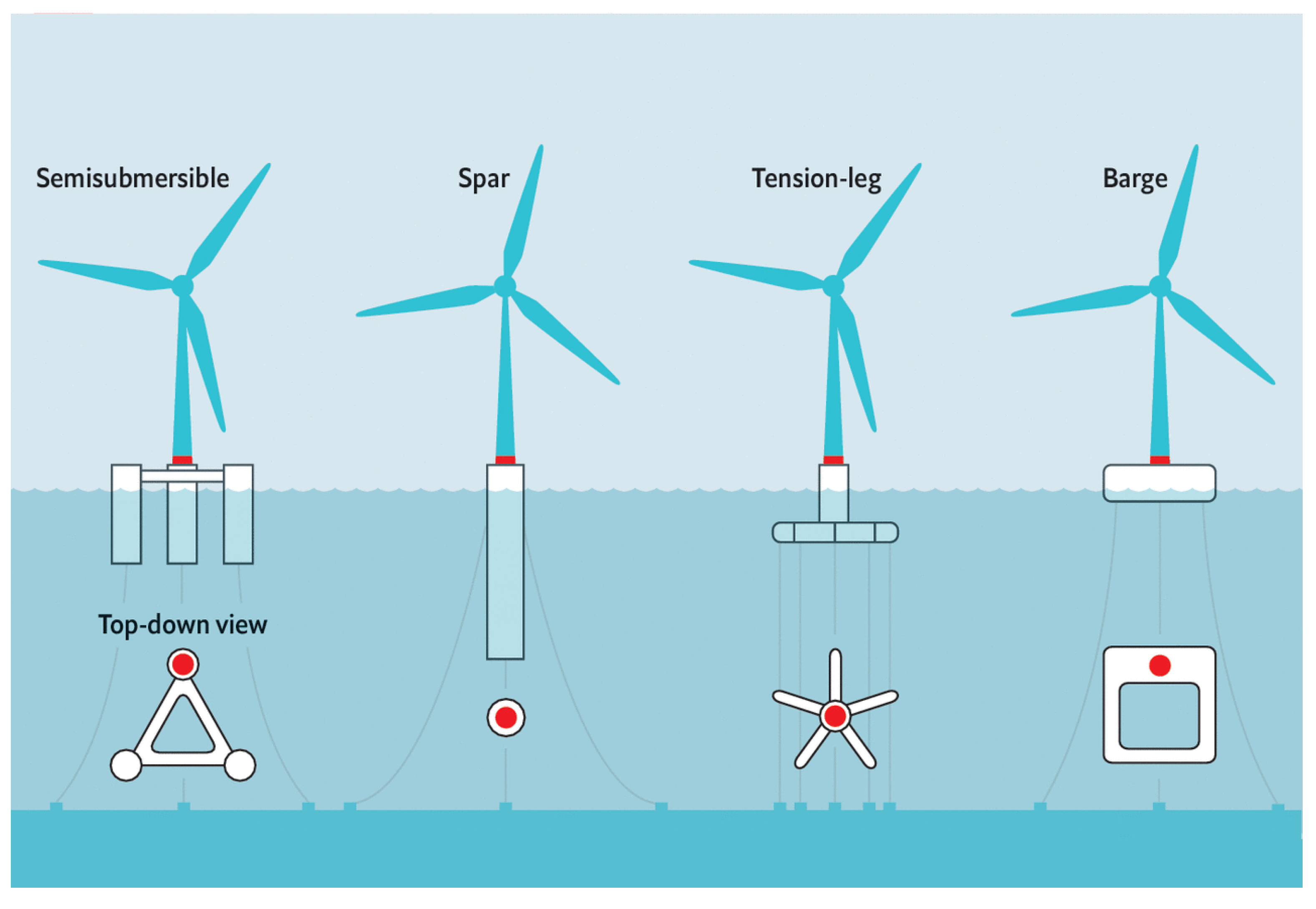

FOWTs are among the concepts that can efficiently and economically capture energy from deep-water offshore wind resources [1][2]. A wind turbine mounted on a floating foundation is part of the FOWT idea, which enables the production of power in deep waters where bottom-fixed wind turbines are not economically feasible. Different floating wind turbine concepts are shown in Figure 1.

Figure 1. Different FOWT design concepts [3].

Several FOWT designs have been developed on barge, spar, TLP, and semisubmersible foundations [4]. Every FOWT design has advantages and disadvantages that should be taken into account depending on the installation site parameters, such as proximity to the shore, water depth, environmental factors, and sea bottom characteristics. A floating offshore wind turbine system consists of the following:

-

Platform and tower;

-

Blades, nacelle and hub;

-

Mooring system with tendons, clump masses, and mooring lines;

-

Fairleads and anchors;

-

Gear box, high-speed and low-speed shafts with a mechanical brake system;

-

Controller and electricity generator;

-

Hydraulics and cooling systems;

-

Pitch and yaw mechanisms.

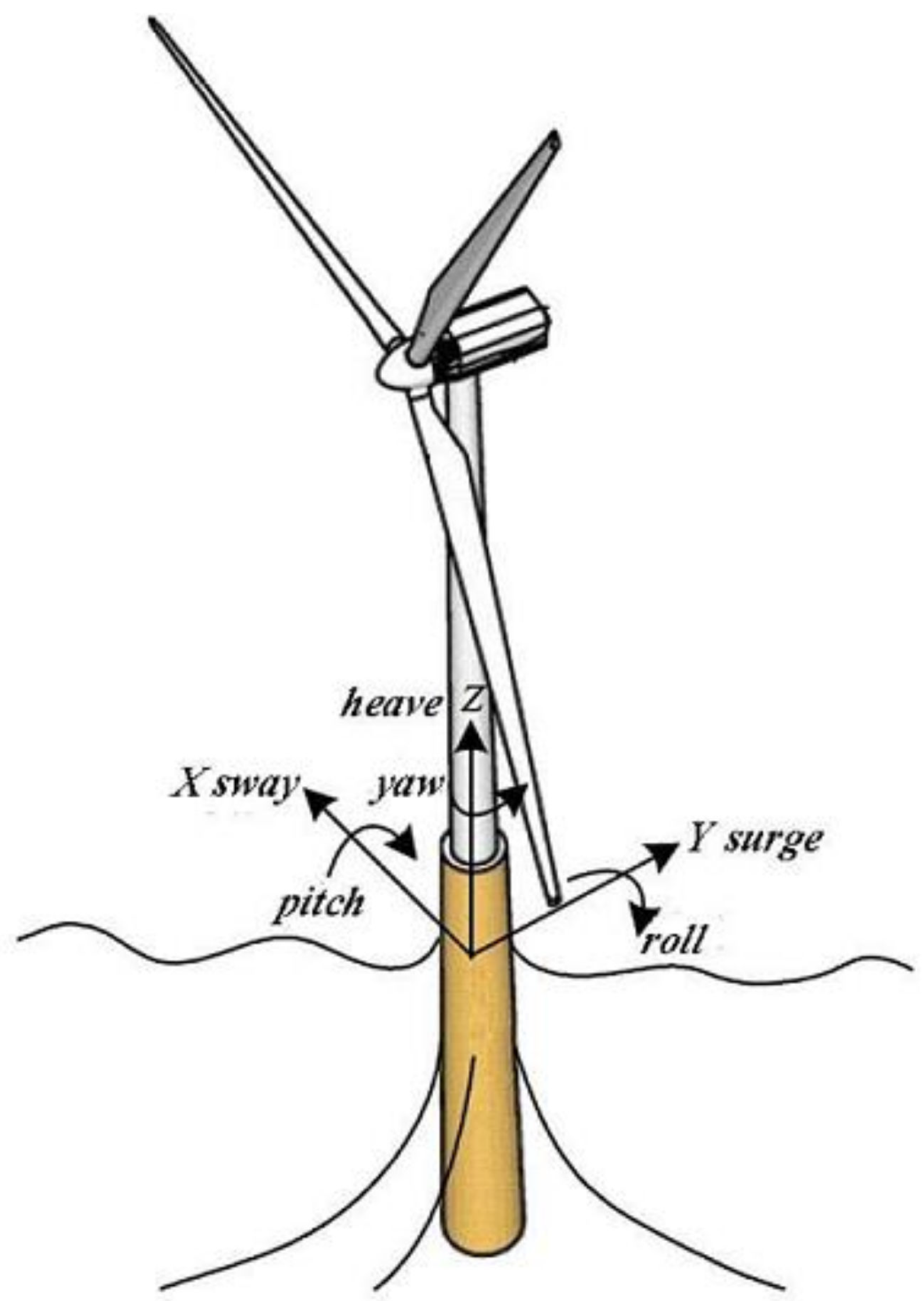

The performance of FOWTs is affected by the displacement in six degrees of freedom (6DOF), which consists of three translational (surge X, sway Y, and heave Z) and three rotational (roll, pitch, and yaw) modes of movement, as can be seen in Figure 2. The motions in 6DOF are caused by the combined influence of the environmental and system restoring loads that act on a floating wind turbine [5].

Figure 2. The degrees of freedom of an offshore floating wind turbine platform [6].

The following section reviews some well-known and cutting-edge ideas for floating offshore wind turbine platforms and mooring methods for upcoming offshore wind farms in relatively deep waters.

2. Spar-Type Platform

Floating spar-buoy offshore wind turbines (FSOWTs) are one of the best design concepts that have the potential to effectively harvest energy in deep waters [7][8]. It might be claimed that FSOWTs are unlikely to be the best solution for FOWTs due to the complexity of their installation at deep drafts; nevertheless, they are the only viable option for mass production owing to their ease of construction [9]. In combination with the mass-dominated dynamic behavior, the deep draft of the spar and the comparatively small water plane area reduce the heave excitation forces, which results in great hydrodynamic stability and a very strong performance in the heave mode of motion.

A typical configuration of a spar-buoy consists of a cylindrical floating spar-buoy that is fastened to the ground by cables. The spar-type platform with either a catenary or taut mooring system maintains its stability by lowering the center of mass with regard to the center of buoyancy using the substantial ballast at the lower level of the structure, significantly contributing to the roll, pitch and displacement. Mooring lines are utilized to prevent drifting and limit the surge and sway motions. For spar-type platforms, it is also possible to eliminate the wind-induced yaw motion by using delta mooring lines [10].

3. Semi-Submersible Platform

The semi-submersible concept was originally developed for use in the offshore oil and gas industry where a large drill deck was needed [11]. Semi-submersible FOWTs typically consist of a number of vertical columns joined by cross braces or pontoons [12][13][14]. Heave plates or skirts are usually attached to the bottom of the columns in order to increase the added mass and damping. However, an additional lift force on heave plates or skirts may appear due to vortex shedding [15].

Thanks to the small draft, the deployment of semisubmersible FOWTs can be made in the regions with a water depth of ranging from 40 m to 50 m. They can be assembled on dry docks, where the platforms are then towed offshore using standard tug boats providing significant logistical and financial savings. Limited sensitivity to water depth, quayside integration, large payload capacity and the possibility to reposition the platform following field abandonment are just a few advantages of semisubmersible platforms. Furthermore, especially for the systems where the turbine is located on the side of the floater, the operation and maintenance are relatively easier [16]. The ballasts inside the chamber provide a better stability in harsh environments, even though obtaining an active ballast in the system may produce additional needs for maintenance.

4. Barge Platform

Barges achieve stability using their distributed buoyancy, taking advantage of the large water plane area. One of the most common types of barge platforms used in offshore wind industry is Ideol. This type of floating structure is usually distinguished by a rectangular annulated-shaped floating substructure with a pool at its center (a.k.a., the moon pool), which diminishes the floater motion by absorbing the wave loads [17].

For barge platforms, a catenary mooring system is typically utilized to prevent drifting [18]. It is also possible to use abandoned vessels as a floating platform for wind turbines; however, the applicability of both barges and ship-shaped structures is constrained by several problems that include, depending on the system size, high tower-base bending moments, pitch dynamic motions induced by the waves, and associated accelerations at the nacelle and wave loading [19]. However, it may be feasible to employ such a notion in calm bays and seas.

5. Tension Leg Platform

The stability of the tension leg platform (TLP) is utilized by its excess buoyancy as well as the vertical tendons that are anchored to the seabed. The key benefit of employing TLPs over spar and semisubmersible platform technologies is the smaller and lighter substructure [20]. TLPs have a considerably smaller footprint due to the taut mooring lines and the resulting vertical tension at the anchorage.

To support large vertical loads, different types of anchoring systems, such as suction anchors, gravity anchors, or anchor piles, are used depending on the geology and seabed conditions [21]. The biggest problem with TLPs is that they rely on pretensioned tendons to maintain stability. In this regard, a possible failure in the mooring or anchoring system may result in capsizing since the mooring system restores the stability of the platform [22].

6. Catamaran Platform

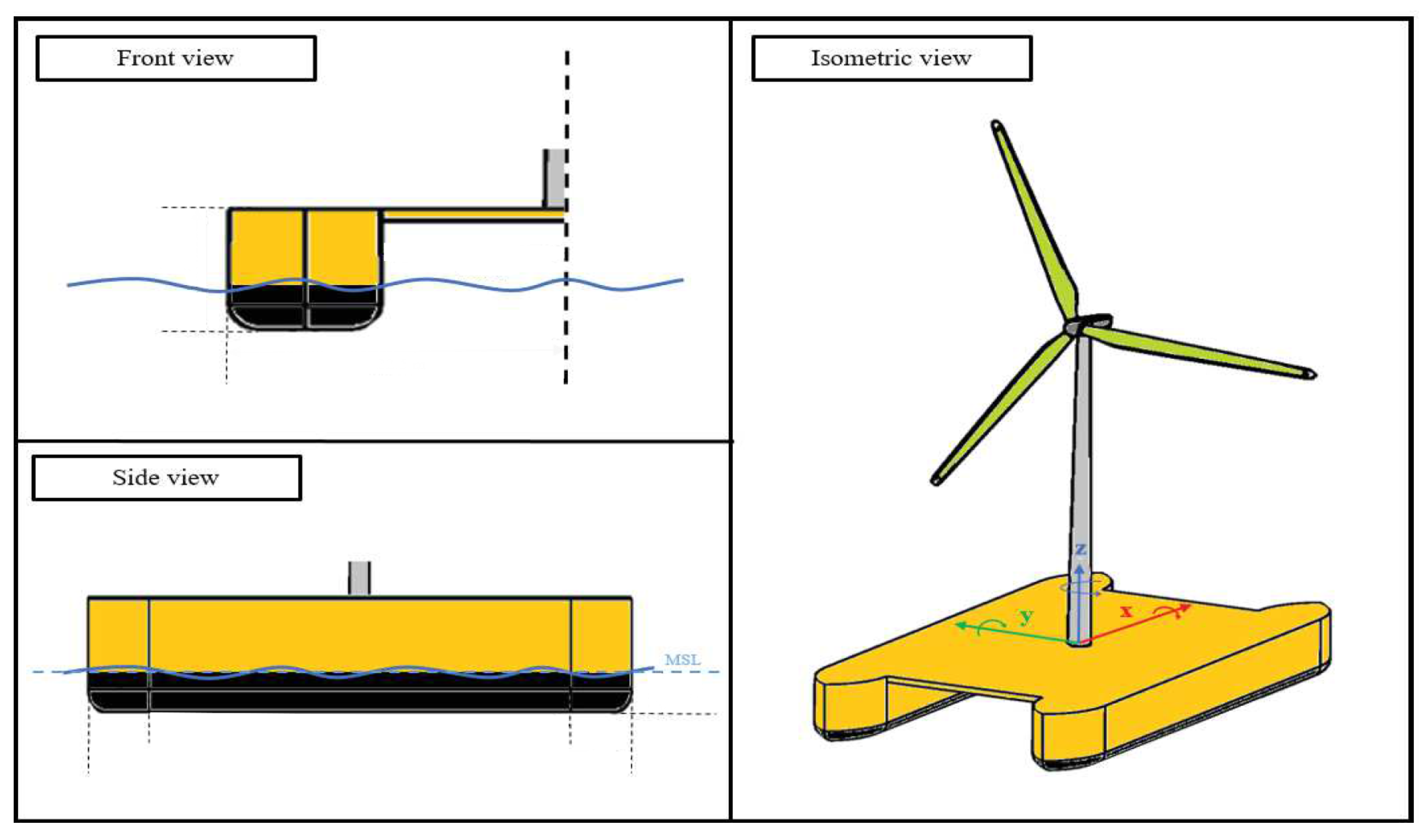

The largest construction vessel in the world, a.k.a. Pioneering Spirit, and several environmentally friendly power boats were built using catamarans, which are frequently utilized in the maritime transportation and leisure industries [23]. Catamarans are well known for their high levels of stability and vast usable deck space, both of which are advantageous for offshore renewable energy systems. For heeling stability, a catamaran primarily relies on its beam (width) and demi-hull buoyancy. This implies that the stability increases with increasing beam width and length. An essential design factor for a FOWT is its longitudinal stability (pitch), which has a direct impact on the amount of power generated [24]. As a result of their renowned transverse stability, there is a significant chance that converting a catamaran into a FOWT support platform is worthwhile. A standard catamaran can be transformed into a platform for tidal energy according to various studies [25][26][27]. There is not much literature that emphasizes converting a catamaran into a useful support platform for operating wind turbines. This is a new technology for FOWTs, tested only at small scales and subject to continuous research. In this regard, single-point mooring catamarans were designed and tested for some special offshore operations [28]. The results showed that the side-to-side movement could only be avoided with external control methods. In a work, an equally spaced semi-hull catamaran platform was proposed, where a wind turbine is placed in the middle of the platform with a mooring system of eight slack [29] (Figure 3). According to the numerical analyses, the proposed design had considerably reduced responses (7% and 22% reduction in rotor thrust and fore-aft tower-base bending moment, respectively) and boosted stability (up to 50% pitch response reduction in comparison with the barge platform) [29].

Figure 3. Preliminary catamaran FOWT concept schematic [29].

7. Novel Platform Designs

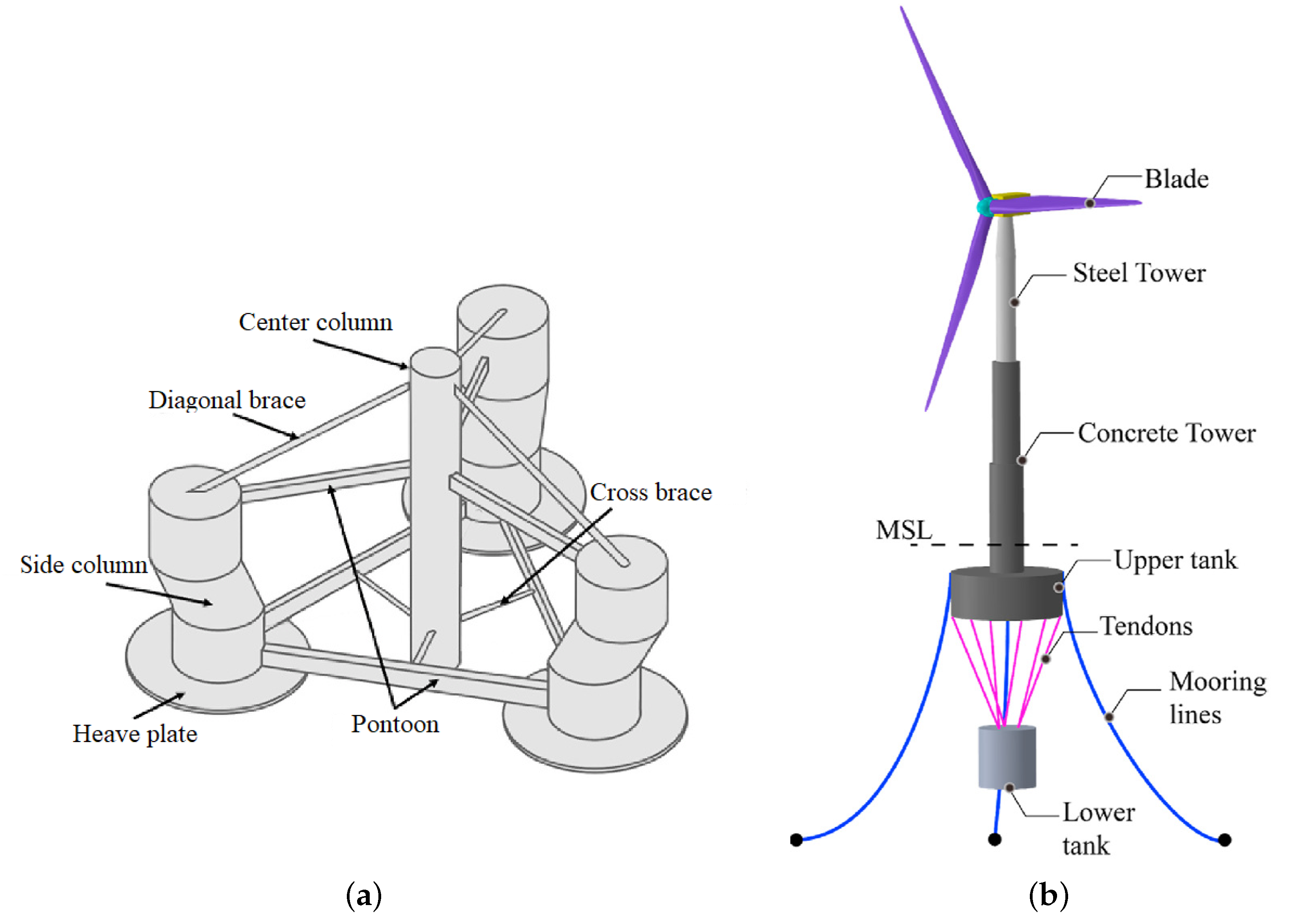

In recent years, researchers have proposed novel floating platforms that take advantage of the strengths of existing concepts and combine them to achieve more cost-effective designs. Fully submersible platforms, for example, combine the advantages of semi-submersible and spar platforms (Figure 4a). This concept employs inclined side columns that are used to increase the water plane and thus the moment of inertia while minimizing the draft and stress on the support structure [30]. A fully submersible floating platform is similar to a semi-submersible one, but the middle parts of the columns are inclined outwards, while the upper and lower parts remain upright to connect to the center column via a set of cross braces and pontoons. This alteration lowers the platform’s center of gravity, which is the primary source of stability in spar platforms, while simultaneously increasing the moment of inertia from which semi-submersible platforms achieve stability [31]. The dynamic response analysis of fully submersible platforms indicates that this type of floating platform has a relatively better overall dynamic performance, and the cost is 12.8% lower than that of a semi-submersible platform [30].

TELWIND is a novel multi-body floating platform developed by ESTEYCO S.A.P. with a wide cylindrical platform and a cylindrical ballast body suspended by six tendons [33]. The spar of TELWIND is composed of a telescopic tower and two independent concrete bodies connected by suspension tendons (Figure 4b). The upper concrete body maintains buoyancy, while the lower concrete body serves as the ballasting body. The telescopic tower allows for wet towing of the pre-assembled system, as folding in the tower provides a more stable configuration for the structure. This floating platform is designed to withstand harsh metocean conditions. In this regard, TELWIND’s dynamic performance was tested both experimentally and numerically under various wind and wave load cases [32]. For this multi-body floating platform, the dynamic behavior is found to be highly sensitive to the state of tendons’ health.

This entry is adapted from the peer-reviewed paper 10.3390/en16010002

References

- Castro-Santos, L.; Filgueira-Vizoso, A.; Carral-Couce, L.; Formoso, J.Á.F. Economic feasibility of floating offshore wind farms. Energy 2016, 112, 868–882.

- Schwanitz, V.J.; Wierling, A. Offshore wind investments–realism about cost developments is necessary. Energy 2016, 106, 170–181.

- Mei, X.; Xiong, M. Effects of second-order hydrodynamics on the dynamic responses and fatigue damage of a 15 MW floating offshore wind turbine. J. Mar. Sci. Eng. 2021, 9, 1232.

- Roddier, D.; Cermelli, C.; Weinstein, A. WINDFLOAT: A Floating Foundation for Offshore Wind Turbine Part I: Design Basis and Qualification Process. Paper No. OMAE2009-79229. In Proceedings of the 28th International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; p. V010T09A073.

- Cottura, L.; Caradonna, R.; Novo, R.; Ghigo, A.; Bracco, G.; Mattiazzo, G. Effect of pitching motion on production in a OFWT. J. Ocean. Eng. Mar. Energy 2022, 8, 319–330.

- Hu, D.; Deng, L.; Zeng, L. Study on the Aerodynamic Performance of Floating Offshore Wind Turbine Considering the Tower Shadow Effect. Processes 2021, 9, 1047.

- Ashuri, T.; Zaayer, M. Review of design concepts, methods and considerations of offshore wind turbines. In Proceedings of the 2007 European Offshore Wind Conference and Exhibition, Berlin, Germany, 4–6 December 2007; European Wind Energy Association EWEA: Brussels, Belgium, 2007.

- Maienza, C.; Avossa, A.; Ricciardelli, F.; Coiro, D.; Troise, G.; Georgakis, C.T. A life cycle cost model for floating offshore wind farms. Appl. Energy 2020, 266, 114716.

- Zheng, Z.; Chen, J.; Liang, H.; Zhao, Y.; Shao, Y. Hydrodynamic responses of a 6 MW spar-type floating offshore wind turbine in regular waves and uniform current. Fluids 2020, 5, 187.

- Nielsen, F.G.; Hanson, T.D.; Skaare, B. Integrated dynamic analysis of floating offshore wind turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006; Volume 47462, pp. 671–679.

- Lefebvre, S.; Collu, M. Preliminary design of a floating support structure for a 5 MW offshore wind turbine. Ocean. Eng. 2012, 40, 15–26.

- Johannessen, M. Concept Study and Design of Floating Offshore Wind Turbine Support Structure. Master’s Thesis, KTH, School of Engineering Sciences (SCI), Aeronautical and Vehicle Engineering, Naval Systems, Stockholm, Sweden, 2018.

- Liu, Y.; Hu, C.; Sueyoshi, M.; Yoshida, S.; Iwashita, H.; Kashiwagi, M. Motion response characteristics of a Kyushu-University semi-submersible Floating Wind Turbine with trussed slender structures: Experiment vs. numerical simulation. Ocean. Eng. 2021, 232, 109078.

- Ahn, H.; Ha, Y.J.; Cho, S.g.; Lim, C.H.; Kim, K.H. A Numerical Study on the Performance Evaluation of a Semi-Type Floating Offshore Wind Turbine System According to the Direction of the Incoming Waves. Energies 2022, 15, 5485.

- Benitz, M.A.; Schmidt, D.P.; Lackner, M.A.; Stewart, G.M.; Jonkman, J.; Robertson, A. Comparison of hydrodynamic load predictions between reduced order engineering models and computational fluid dynamics for the oc4-deepcwind semi-submersible. In Proceedings of the 2014 International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 45547, p. V09BT09A006.

- James, R.; Weng, W.Y.; Spradbery, C.; Jones, J.; Matha, D.; Mitzlaff, A.; Ahilan, R.; Frampton, M.; Lopes, M. Floating Wind Joint Industry Project—Phase I Summary Report. Carbon Trust Tech. Rep. 2018, 19, 2–20.

- Van Kessel, J.L.F. Aircushion Supported Mega-Floaters. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010.

- Jonkman, J.; Buhl, M. Loads Analysis of a Floating Offshore Wind Turbine Using Fully Coupled Simulation; No. NREL/CP-500-41714, Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2007.

- Jonkman, J.M. Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine; University of Colorado at Boulder: Boulder, CO, USA, 2007.

- Adam, F.; Myland, T.; Dahlhaus, F.; Großmann, J. Gicon®-TLP for wind turbines—the path of development. In Proceedings of the The 1st International Conference on Renewable Energies Offshore (RENEW), Lisbon, Portugal, 24–26 November 2014; pp. 24–26.

- Chuang, T.C.; Yang, W.H.; Yang, R.Y. Experimental and numerical study of a barge-type FOWT platform under wind and wave load. Ocean. Eng. 2021, 230, 109015.

- Atcheson, M.; Garrad, A.; Cradden, L.; Henderson, A.; Matha, D.; Nichols, J.; Roddier, D.; Sandberg, J. Floating Offshore Wind Energy; Springer: Berlin/Heidelberg, Germany, 2016.

- Fang, C.; Chan, H.; Incecik, A. Investigation of motions of catamarans in regular waves—II. Ocean. Eng. 1997, 24, 949–966.

- Johlas, H.M.; Martínez-Tossas, L.A.; Churchfield, M.J.; Lackner, M.A.; Schmidt, D.P. Floating platform effects on power generation in spar and semisubmersible wind turbines. Wind Energy 2021, 24, 901–916.

- Qasim, I.; Gao, L.; Peng, D.; Liu, B. Catamaran or semi-submersible for floating platform–selection of a better design. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 121, p. 052041.

- Junianto, S.; Prastianto, R.W.; Wardhana, W. Motion Responses Analysis for Tidal Current Energy Platform: Quad-Spar and Catamaran Types. China Ocean. Eng. 2020, 34, 677–687.

- Brown, S.; Ransley, E.; Xie, N.; Monk, K.; De Angelis, G.; Nicholls-Lee, R.; Guerrini, E.; Greaves, D. On the impact of motion-thrust coupling in floating tidal energy applications. Appl. Energy 2021, 282, 116246.

- Xue, K.; Wang, W.B.; Wang, W.Y. A Dynamic Positioning Method for Single Point Mooring System of a Catamaran. In Key Engineering Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2011; Volume 450, pp. 47–50.

- Cutler, J.; Bashir, M.; Yang, Y.; Wang, J.; Loughney, S. Preliminary development of a novel catamaran floating offshore wind turbine platform and assessment of dynamic behaviours for intermediate water depth application. Ocean. Eng. 2022, 258, 111769.

- Zhang, H.; Wang, H.; Cai, X.; Xie, J.; Wang, Y.; Zhang, N. Novel method for designing and optimising the floating platforms of offshore wind turbines. Ocean. Eng. 2022, 266, 112781.

- Zhang, H.; Wang, H.; Cai, X.; Xie, J.; Wang, Y.; Zhang, N. Research on the Dynamic Performance of a Novel Floating Offshore Wind Turbine Considering the Fully-Coupled-Effect of the System. J. Mar. Sci. Eng. 2022, 10, 341.

- Yang, Y.; Bashir, M.; Michailides, C.; Mei, X.; Wang, J.; Li, C. Coupled analysis of a 10 MW multi-body floating offshore wind turbine subjected to tendon failures. Renew. Energy 2021, 176, 89–105.

- Armesto, J.A.; Jurado, A.; Guanche, R.; Couñago, B.; Urbano, J.; Serna, J. Telwind: Numerical analysis of a floating wind turbine supported by a two bodies platform. In International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51319, p. V010T09A073.

This entry is offline, you can click here to edit this entry!