Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Energy & Fuels

Gel fuels can become an alternative energy resource within the framework of the implementation of the program for developments in rocket and space technology. These propellants combine the advantages of solid and liquid rocket propellants, of which the main ones are related to safety aspects, energy efficiency and storage. The components range and gel fuels compositions are diverse, so the method of their preparation in each specific case can be quite different, especially when using thickeners of various origins.

- gel fuel

- thickener

- dispersion

- ignition

- combustion

1. Introduction

At present, three main types of fuels are widely used in practice: liquid [1,2], solid [3,4] and gaseous [5,6]. Liquid fuels (gasoline, diesel fuel, kerosene, hydrazine, heptyl, alcohols, naphtha, benzene-gasoline mixtures, fuel oil, kerosene and methoxydiethylborane/tetrahydrofuran and others), as a rule, are used in internal combustion engines (motor transport, shipbuilding) [7], jet engines (aviation) [8], liquid-propellant rocket engines [9] and technological installations in thermal power engineering [10]. Solid fuels (coals, combustible shale, metallized composite solid fuels and others) are used as energy resources in coal-fired steam and water-heating boilers [11], blast furnaces [12] and solid rocket engines [13]. Gaseous fuels (methane, propane, dimethyl ether, coke oven gas and others) are widely used in various applications, but the most efficient energy potential of these fuels is used in gas turbines [14].

Along with the aforementioned fuels, in recent years, in transport technology and in the energy sector, a promising direction of development is the design of effective compositions and methods for obtaining various types of composite fuels: synthesis gas [15], coal-water slurries [16], coal-water slurries with petrochemicals [17], suspension fuels [18], gel fuels [19,20] and fuel briquettes [21]. This is mainly attributable to the tasks of improving the environmental, energy, economic and operational characteristics of both technological systems of devices in transport and energy, and the processes of storage, transportation and combustion of new fuels types.

In recent years, the prospects for space exploration have been the main incentives for developments in the rocket and space industry. The solution for this problem requires an integrated approach to conducting fundamental research and using their results in practice to make rational, technical decisions when conducting development work. One of the main problems is the need to develop new fuels, study their properties, as well as study the physicochemical processes that occur during their ignition and combustion.

Solid and liquid propellants were widely used in rocket and space technology at the end of the XX and the beginning of the XXI century. Each of them has its own advantages and disadvantages compared to one other. To date, the potential of such fuels is almost completely exhausted, according to many experts [22,23,24]. Gel fuels can become an alternative energy resource within the framework of the implementation of the program for developments in rocket and space technology. These propellants combine the advantages of solid and liquid rocket propellants [24], of which the main ones are related to safety aspects (a small amount of vapor is released during leaks compared to liquid fuels; indifference to shock, friction and electrostatic discharge; minimal risk of accidental ignition, because the combustion process is sufficiently well controlled and can be stopped; the elastic-deformable or viscous-plastic state prevents the formation of cracks in the fuel charge, so their development does not affect the increase in the combustion area, uncontrolled combustion or explosion), energy efficiency (relatively high specific thrust impulse compared to composite solid propellants) and storage (long-term storage without maintaining special conditions; flexible packaging; relatively low proportion of solid fine particle settling in high-viscosity formulations compared to liquid fuels). Gel fuels have higher energy characteristics than composite solid propellants; in particular, a specific thrust impulse is about 3000–3500 m/s [25]. Replacing a composite solid propellant with a gel fuel will make it relatively easy to implement dynamic control of engine thrust during the time in practice [24]. Furthermore, gel fuels, compared to liquid fuels, have lower fire hazard rates because of the minimization of evaporation losses and leakage during storage. Gel fuel components and their combustion products tend to have a lower environmental impact than typical liquid propellants [26].

The aggregate state of gel fuel can differ significantly depending on its purpose and environmental characteristics—from liquid (with high viscosity) to solid (elastically deformable). Within the framework of ignition theories of solid and liquid condensed substances [27,28,29,30,31], the properties of composite solid propellants and liquid fuels have been studied in full, and mathematical models have been developed to predict the characteristics of physicochemical transformations that occur when they are heated. The results of experimental studies [22,23] indicate a fairly significant difference in the regularities and characteristics of the physicochemical processes occurring during the ignition and combustion of gel fuels, compared with typical solid and liquid fuels.

2. Fuel Preparation

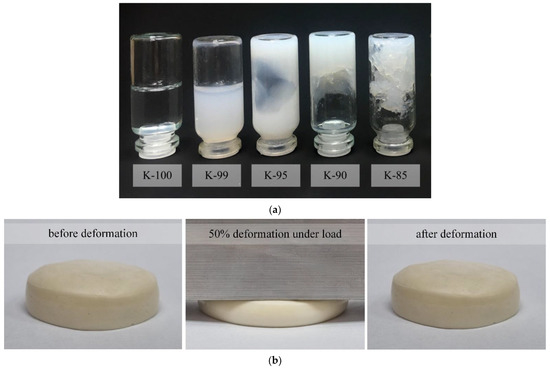

Physically, gel fuels are rheologically modified liquids, the properties of which are changed by adding various thickeners (gelling agents) [24,54,55,56]. Depending on the type of thickeners, it is currently conventionally accepted [24,54,55] in the scientific periodical literature as the distinguishing of two fundamentally different (in terms of rheological properties and physical and mechanical characteristics) types of gel fuels. On the one hand, these are “soft substances” (Figure 1a) that exhibit the physical and mechanical characteristics of both a solid and a liquid, depending on the level of shear stress [24,54]. On the other hand, these are materials with a three-dimensional elastically deformable solid framework (Figure 1b) containing finely dispersed liquid drops in the matrix cells [55].

Figure 1. Appearance of gel fuels: (a) Liquid and plastically deformable fuel compositions based on kerosene: K-100—100 % kerosene, K-99—99 wt% kerosene, 1 wt% silicon dioxide, K-95—95 wt% kerosene, 5 wt% silicon dioxide, K-90—90 wt% kerosene, 10 wt% silicon dioxide, K-85—85 wt% kerosene, 15 wt% silicon dioxide; (b) Elastically deformable: 50 vol% oil + 48 vol% aqueous solution of PVA (10 wt%) + 2 vol% emulsifier.

The first type of fuel is obtained, as a rule, by adding organic and inorganic thickeners to combustible liquids, and the second is obtained by adding polymeric thickeners. Rheological properties, physico-mechanical and physico-chemical characteristics of combustible liquids change quite significantly after thickening. After obtaining the gel fuels and for a certain period of time during storage, their viscosity increases by several times compared to combustible liquids in the initial state, and the density increases significantly, especially if finely dispersed metal particles are added to the fuel composition [56]. These components also contribute to the growth of the thermal effect of the combustion process [57] and the specific energy density [24]. Thus, the production and practical application of gel fuels can provide a high level of control over operational characteristics, uniformity and reproducibility of fuel compositions, as well as energy characteristics.

Mainly potential technologies for the use of gel fuels, for example, in rocket and ramjet engines, afterburners, involve the implementation of the processes of their transportation through pipelines, supply to the combustion chamber and organization of direct combustion, similar to the processes characteristic of typical liquid fuels in the initial state [24,54,55,56,57]. It is worth noting that in addition to thickening flammable liquids, gel oxidizers are also used in practice to solve some problems [58,59]. In the early stages of development of gel fuels in the middle of the XX century, they were considered solely as a replacement for mixed solid fuels [58,59,60,61,62,63]. Accordingly, the corresponding formulations of the first gel fuels and oxidizers were developed [58,59,60,61,62,63].

However, later, it was proposed to use gel propellants instead of liquid propellants [54,64], since the thickening of the latter made it possible to minimize their main operational disadvantages, as well as to improve the energy characteristics mainly by adding metal powders, the particles of which can be fairly evenly distributed in the volume of the thickened combustible liquid. This has led to gel fuels being predominantly characterized as non-Newtonian fluids. The compositions most widely used in experimental studies are given in references Table 1.

Table 1. Compositions of typical gel fuels.

| Rocket Fuel | Thickener a | Additives a,b,c | Notes | Ref. |

|---|---|---|---|---|

| Water (98.5%) | Carbopol 941 (0.5%) (2–7 µm) |

NaOH (1%) | Mechanical mixing | [23] |

| JP-5 JP-8 IRFNA HP |

AO (2–5%) SiO2 (4–8%) SiO2 (3–5%) SiO2 (5–7%) |

– | Mechanical mixing | [65] |

| Jet A1 (85%) | Thixatrol 289 (7.5%) | MIAK (7.5%) | Mechanical mixing | [66] |

| Jet A1 (NA) | Thixcin R (4–7%) | NA | Mixing at 40–60 °C for 2.5 h at 1000 rpm. | [67] |

| MMH | HPC (3%) Aerosil (6%) Hybrid Gel (2–3%) |

– | Mechanical/acoustic mixing at 60 °C | [68] |

| Jet A1 (85%) | Thixatrol ST (7.5%) (23 µm) |

Xylene (7.5%) | Mixing at 63 °C for 1 h at 1200 rpm. | [34] |

| ISROsene (85–65%) | Thixatrol ST (7.5%) (23 µm) | Xylene (7.5%) Nano aluminum oxide (50–150 nm) Oleic acid (10%) |

Mixing at 63 °C for 1 h at 1200 rpm. | [69,70] |

| RP-1 | Carbosil (5%) (44 µm) | 0–55% Alex (100 nm) Tween 85 (0–1.3%) |

– | [71] |

Notes. a—relative ratios of components in %wt. b—weight percent surfactant dependent on metal content. c—liquid additives are used as solvents for thickeners.

As a rule, the main component of these fuel compositions are flammable liquids used as fuels in aerospace technology, such as liquefied hydrogen [72,73,74]; hypergolic fuels, including hydrazine [36,75,76,77], monomethylhydrazine (MMH) [36,63,64,75,77,78,79], unsymmetrical dimethylhydrazine (UDMH) [22,36,63], tetramethylethylenediamine (TMEDA) [80]; various grades of kerosene-based jet fuel JP (JP-1, JP-5, JP-8 and JP-10) [63,75,76,77] and Jet A1 [23,34,50,81,82], RP-1 [54,71]; and alcohol-containing fuels based on methanol [58] and ethanol [58,83,84]. Other common liquid components of gel fuels are isopropanol [58], oils of petroleum origin [61], spent organic solvents (benzene, acetone and chlorinated solvents) [61], nitromethane [85], ethanolamine [86], aniline [63], nitropropane [63], isooctane [87], hexane [73,74], propane [74], ethane [74], paraffin [50], glycerol [88] and ammonium ethyl acetate [89].

Oxidizers used in gel form are mainly used in conjunction with hypergolic fuels. Among such oxidants, red fuming nitric acid (RFNA) [62,87] inhibited red fuming nitric acid (IRFNA) [62,64,75,77] and hydrogen peroxide [75,76,77,87,89], as well as cryogenic substances such as substituted bromine trifluoride [62], bromine pentafluoride-chlorine trifluoride [62], liquefied oxygen [89] and oxygen difluoride; a large number of nitroalkanes and nitrogen tetroxide [59] can be noted as well.

A significant amount of research related to the development of fuel formulations is aimed at identifying suitable types of thickeners for specific combustible liquids and oxidizers [24,77]. As a rule, most thickeners are commercially available manufactured compounds. Both inorganic [90] and organic thickeners are used, many of which are polymeric [91]. For thickeners, typical selection criteria apply [90,91,92]: they must be compounds that are applicable at low concentrations; they must be combustible, provide a reversible system; and thickeners should be non-aggressive, environmentally friendly and economically affordable.

Inorganic thickeners, such as silica, work well with fuels and oxidizers [91]. However, they are inert and, therefore, their use obviously leads to losses and a decrease in the energy efficiency of the fuel during combustion. In addition, their tendency to form covalent bonds reduces the reversibility of the gel fuel and negatively affects its flow characteristics.

Polymeric thickeners such as Carbopol, cellulose compounds, Xanthan and others are used as aqueous solutions to thicken combustible liquids. These compounds are straight or branched chain polymers and form a strong entangled or cross-linked network through hydrogen bonds when dissolved in water [91]. Cellulosic compounds and agar-agar can only thicken fuels. Although the rheology of these polymer gels exhibits shear thinning characteristics, the molecular bonding of the polymer chains to water prevents liquid breakdown and subsequent aerosol formation, which impairs atomization. However, atomization can be achieved for fuels containing agar-agar as a thickener, which absorbs water and forms a network around the liquid rather than binding to its molecules [92]. These examples illustrate the importance of the thickener–liquid interaction in fuel atomization and highlight the need for proper thickener selection.

Unlike polymer gels, low molecular weight thickeners are used to obtain some organic gels based on organic liquids [93]. Organogels resemble polymer gels in the structure of molecular bonds that form a matrix, in the cells of which finely dispersed liquid drops are located. They are easier to spray compared to polymer gels because of a component with reduced tensile viscosity. Moreover, they burn together with liquid fuel and oxidizers. For example, the castor oil derivative Thixcin R is used to thicken a suspension of coal and oil [61], as well as Jet A1 [94]. Other castor oil derivatives are widely used as a non-polymeric organic thickener—Thixatrol [23,34,50,69,70,82,94], Thixatrol ST [23,34,50,82,91,95], MPA 60 [96], Thixatrol 289 [97,98], Thixcin R [61,94], Thixatrol Plus [99].

Among inorganic thickeners, and most likely among all types of thickeners used for the preparation of gel fuels, various forms of silicon dioxide are most widely used [72,75,79,86,87,99]; for example Cabosil and Aerosil. It is worth noting that the results of numerous studies indicate the need for caution when choosing these commercially available silica gel thickeners for the preparation of gel fuels, since the latter do not always satisfy the basic typical requirements for rheological properties and physical and mechanical characteristics. To date, a large number of combinations have been proposed between widely used liquid fuels and thickeners, but only a small part of these fuel compositions has ever been used in experimental studies of the gel fuels spraying and combustion.

Equally important components of gel fuels are energy additives, for example, metal powders. The concentration of the metal is the determining factor if it is used as an energy additive. The typical range of metal content in fuel by mass is 5–60% [91,98,100]. The justification for the advantage of metallized fuel compositions is to obtain suspensions that have a greater value of thrust per kilogram of oxidizer (or air). Preference is given to metals with the highest volume and mass values of combustion heat [101,102,103,104]. It is known that Mg is characterized by the highest thrust per kilogram of air at stoichiometric mixture ratios, followed by Al [101]. In practice, Al2O3 is sticky and melts at the flame temperature of a typical gel fuel [100,101], whereas boron combustion is difficult to initiate [102]. Magnesium oxides do not melt and, therefore, Mg is a promising component for metallized gel fuels. The efficient use of boron requires the organization of a more complex fuel combustion mode [103,104].

The components range and gel fuels compositions are diverse, so the method of their preparation in each specific case can be quite different, especially when using thickeners of various origins (polymeric, organic, and inorganic). However, most techniques for preparing gel fuels rely on the mixing of thickener, solvent (optional), metal particles, catalysts, stabilizing surfactants (if metals are added) and liquid fuel at room conditions or elevated temperatures using mechanical or acoustic methods. The order of adding the listed components to the mixture, their concentrations and mixing times are quite significantly different in each specific case [34,75,94,105,106,107,108]. The main stages and conditions for the preparation of gel fuels are four possible combinations of combustible liquid component/oxidizers and thickeners: fuel–organic (polymeric) thickener, oxidizer–inorganic thickener, fuel–inorganic thickener and fuel–organic (non-polymeric) dispersed thickener. It should be noted that compositions based on organic thickeners and oxidizing agents are of no practical interest, since the vast majority of oxidizing agents are highly reactive with organic thickeners [105].

In [19,109,110], methods for the preparation of gel fuels are presented by thickening waste oils of petroleum origin with a polymeric thickener (without additional components and with the addition of finely dispersed solid combustible particles), as well as by thickening kerosene with an inorganic thickener (silicon dioxide).

Based on the analysis of references [19,34,75,94,105,106,107,108,109,110], it was concluded that the component composition of gel fuels is very diverse and, in each specific case, is determined by the availability of components, such as a thickener (organic, inorganic or polymeric) and the necessary rheological properties or physical and mechanical characteristics of the final product, as a rule. The latter, in turn, have a direct impact on all subsequent stages of the gel fuel life cycle, in particular, the processes of its storage, transportation through fuel lines, spraying in combustion chambers and direct combustion.

This entry is adapted from the peer-reviewed paper 10.3390/en16010298

This entry is offline, you can click here to edit this entry!