Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Green & Sustainable Science & Technology

The fique plant (Furcraea Vent.) forms part of a group of xerophytic monocotyledonous species. It belongs to the Asparagaceae family, the Agavoidea subfamily, and is native to the Andean region of South America.

- fique plant

- natural fiber

- cellulose

- Furcraea Andina

- composites

1. Introduction

The growing world population is driving the intensification of agricultural production. The arable lands dominate 38% of the world’s land area, and almost 30% of the world’s net primary production is for human sustenance [1].

Another type of agricultural production is industrial crops with non-food uses, such as fibers, other industrial products such as cotton, tobacco, jatropha, and fique, and raw material for bioenergy, among others [2].

The fique plant does not compete with food uses and is tolerant to severe water stress due to its ability to recycle carbon dioxide through CAM metabolism (crassulacean acid metabolism) [3]. The fique fibers are extracted from the plant leaves by mechanical methods. The extraction does not include solvents, which provide production without traces of fique contaminants, concentrated mainly in long fibers and fibrous residue with more than 85% humidity [4,5].

Fique is a native plant from the Andes region, and it spreads to other South American countries because of its adaptability to many environmental conditions [6]. Colombia is the first fique grower in the world, with an estimated 15,000 hectares planted by 2019 and a production of 30,000 tons of fique fiber, known as cabuya, which begins the cultivation of the plant by extracting the fiber, its uses and commercialization [7].

The cultivation of fique in Colombia represents the main economic activity of around 70,000 peasant economy families. Fique is grown in 10 departments of the country, where the Nariño department is the first producer, with 37.92% of the national total, followed by Cauca with 36.82%, Santander with 11.55%, Antioquia 11.04%, and Guajira 2.67% [3,8].

The fique fiber consumption by the industry in Colombia is around 25,000 tons of fiber/year. The national companies can increase its demand from 9000 tons/year to 13,000 tons/year due to the increase in the packaging uses for the coffee and cocoa export sector, as well as the fiber demand for the production of textile products and handicrafts, mainly [9,10]. According to the industrial consumption, around 70% of the fiber is used in packaging manufacture. The production of agromantles and geotextiles employs nearly 15%, 10% in cords and ropes, and 5% in mattresses manufacture [11].

At the global level, there is a deficit of jute and sisal fiber with characteristics similar to fique fibers, which become an opportunity for growth and competitiveness in the fique sector [12]. The more demand for fiber, the higher volumes of the fique residues in the field will generate because the fiber represents only 4–5% of the total leaf harvested. The remaining 95–96% corresponds to residues from the fiber extraction process and is made up of the liquid contained in the leaf, called juice and some leaf and fiber fragments, known as bagasse [7,9,10].

The residues of the fiber extraction process, called by-products, are usually abandoned by farmers on the land without any use. Every year nearly 93,400 tons of fique bagasse and approximately the same amount of juice are generated and left on the farms [13,14]. The liquid residues spontaneously filter into soils or migrate to water sources, constituting an environmental impact factor due to their COD, BOD5, saponins, steroids, and minerals contents [9,14].

In addition, the waste of 96% of the fique leaf, together with the few existing functionalities of the fiber during most of the 20th century, has led the fique producers to be characterized as producers of a peasant economy with little income, low level of schooling and with official poverty indicators located at the lowest levels [15].

The generation of new functionalities for the different by-products becomes an option to offer higher income and better quality of life to the fique communities. At the same time, it can reduce the residue impact caused on their environment and offer a source of raw material of natural origin for the industry.

In recent decades, new fique applications have been developed both for fiber [4,16,17,18,19], as well as for juice [20,21,22], and bagasse [13,23,24], in a way that promotes sustainable growth based on the transformation of renewable and low-cost resources [25].

Studies carried out by Guancha-Chalapud et al., based on a circular economy model, propose a feasible option to revalue up to 7500 tons of waste per year from the Colombian fique agribusiness [7].

2. The Fique Plant

The fique plant (Furcraea Vent.) forms part of a group of xerophytic monocotyledonous species. It belongs to the Asparagaceae family, the Agavoidea subfamily, and is native to the Andean region of South America [9,26]. The genus Furcraea includes more than 400 species located in Colombia, Ecuador, Venezuela, Mexico, Costa Rica, India, Sri Lanka, Algeria, and Madagascar [27].

The fique plant has a thick stem of about 30 cm in diameter and can reach a height between 2 and 7 m. From the stem emerge several linear-lanceolate leaves in the form of rosettes. The leaves have dimensions between 1 and 2 m in length and 10–20 cm in width [15,27,28]. Figure 1 shows the fique plant.

Figure 1. Fique Plants.

The most cultivated species in Colombia are F. macrophylla Baker, F. cabuya Trelease and F. castilla [26,29]. F. macrophylla is known as Uña de Águila, with spines on the margin of its leaves, being the most cultivated in Nariño and Cauca departments [26]. F. cabuya, known as Ceniza, is characterized by having light and strong fibers, widely used in handicrafts, and F. castilla, also called Bordo de Oro, with a yellow coloration on the margin of the leaf [29].

There are three alternatives for the propagation of the fique plant. Sexual propagation is by seed, and is very rare due to different maturation times of stigmas and stamens [14]. Asexually, the fique plant reproduces through “hijuelos” and “bulbillos”. The “hijuelos” are small seedlings with three or four true leaves that grow at the base of the main stem. The “bulbillos” are structures that develop from meristematic buds located in the plant inflorescence [30].

The fique is considered a rustic plant that adapts to different ecological zones. However, the number and size of the leaves and the quantity and quality of the fiber depend directly on the soil type, the amount of daily light, temperature, and rainfall [14]. The plant develops adequately at 19–23 °C temperatures, a height above sea level between 1300 and 2000 m.a.s.l., 1000–1600 mm per year of rainfall, relative humidity between 50 and 70%, and sun exposure of approximately six hours a day [31]. The best soils have medium texture, present good porosity, and good natural drainage. This way, the excess water is eliminated, and the tissues prevents rotting. In addition, it is recommended to manage the crop in silica-clay soils with a pH between 5.5 and 7.0 [32].

3. Fique Production System in Colombia

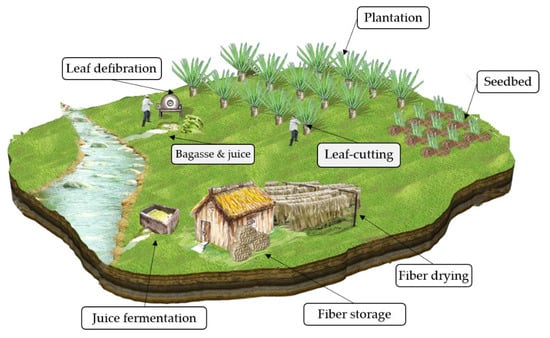

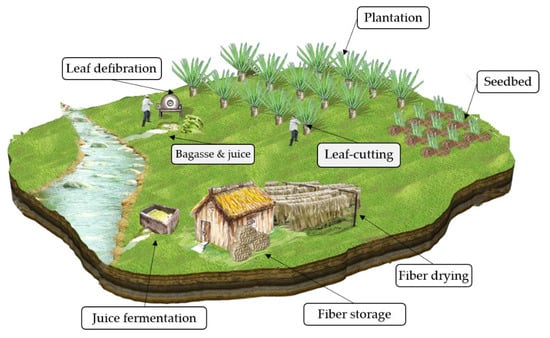

The fique production system in Colombia comprises an initial seedbed stage, where the seeds germinate, and the seedlings develop until they are ready for planting in the definitive site. Subsequently, the plantation follows, which requires a period of at least 4–5 years to reach sufficient maturity for post-harvest. In this stage, the leaves are cut and defibrated to obtain the fique fiber, called “cabuya”. Figure 2 illustrates the different stages of the fique production system in Colombia.

Figure 2. Representation of the fique production system in Colombia.

In the fique production system, a plot of land separated from the plantation is managed and occupied for a period not exceeding eight months for the growth of “hijuelos” (Figure 3a) and 16–18 months for the “bulbillos” (Figure 3b) before transplanting to the final growing area. These plots are usually located in parts of the farm close to the farmer’s house to carry out a more frequent intervention in the care of the seedlings. A seedbed aims to provide the plants with the necessary conditions and care for their full development, especially concerning weed elimination because the faster weed growth prevents receiving sunlight to the seedling [33].

Figure 3. Fique seedlings for cultivation. (a) “hijuelos”, (b) “bulbillos”, (c) Seedlings planted in soil beds, (d) Seedlings planted in black plastic bags.

In this way, the seedbed helps getting fique plants of approximately 50–70 cm in height, with a vigorous development in their root and foliar systems to be transplanted.

There are two seedbed systems for fique cultivation in Colombia. The first consists of directly sowing the seedling in soil beds approximately 1.2 m wide, previously prepared with organic matter (Figure 3c). There, the “Hijuelos” or “bulbillos” are planted at a distance of 15–20 cm for the adequate growth of the seedlings. The seedbed is located in an open-air area on land with good runoff to avoid the water accumulation. This system has a cost per unit of around 10 ¢.

The second fique seedbed system consists in sowing the seedlings in black plastic bags, with dimensions of 12 × 20 cm (Figure 3d). The bags are previously filled with soil fertilized with organic matter. This system allows locating the seedlings near the farmer’s property, regardless of the land topography. The bags used to be placed on a table to separate the plants from the ground. This system has a cost per unit of around 15 ¢.

3.1. Fique Crop

Once the seedlings reach a height between 50 and 70 cm, they are transplanted from the seedbed to the definitive site. Traditionally, farmers sow fique plants on the perimeter of other crops or on the property boundaries. As a peasant economy crop, fique farmers allocate the best land on their farms to species considered by them to be more profitable, such as coffee or “pancoger” plantations, as those species for self-consumption are called, destined for satisfying part of the food needs of the producers [34]. In perimeter crops, fique plants are usually planted in individual sowing furrows with distances of 1.5 m between plants to make enclosures that function as living barriers.

In recent decades, the establishment of fique in monoculture or compact cultivation has been increasing. In this system, the land is used exclusively for fique production. The establishment includes a double intercalated furrow, with distances of 1.5 m between furrows and 2 m between plants, with a space of 3–4 m in the streets. This distribution allows a planting density of 2000–2500 plants per hectare [8].

During the first year of cultivation, different maintenance activities are carried out, such as weed control, fertilization, and preventive pests and diseases management. Weed control is carried out frequently during the first months due to the low height of the plant. When the plant grows, the weeds height does not exceed the fique plant one, and the control is done every three months.

The employment of synthetic fertilizers has not been a common practice in traditional production systems. The fique plant is considered a rustic species and can develop in soils classified as “poor” due to its low content of macro/micronutrients and lack of organic matter. However, with the development of intensive production systems, organic matter and specific fertilizers are beginning to be incorporated into integrated management practices.

For its part, the pest and disease control is related to the presence of the “Macana” or “Rayadilla” disease, caused by the Fique Necrotic Streak Virus, belonging to the Dianthovirus genus of the Tombusviridae family [35]. Macana is the most common and limiting disease with the highest impact on the crop in Colombia and consists of progressive and necrotic deterioration in the leaves, significantly affecting the fiber quality [35].

3.2. Fique Postharvest

After 4–5 years of cultivation, the fique plant reaches the necessary maturity to carry out the post-harvest for obtaining fiber. This process is usually done once a year, especially in the months with less rainfall, although some producers prefer to divide it into two times throughout the year, using half of the leaves on each occasion. The fique post-harvest comprises the stages of leaf cutting, mechanical defibration, and fiber drying.

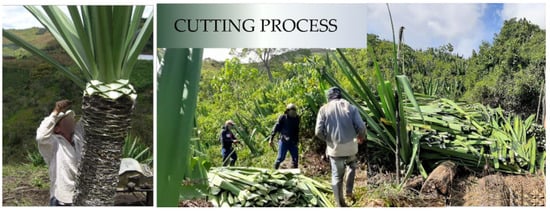

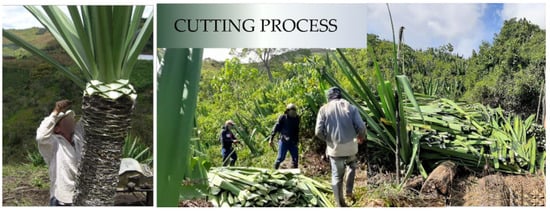

3.2.1. Leaf-Cutting

The farmers cut the leaves manually, using knives or machetes. Only the most mature leaves are cut, i.e., those leaves with an angle of 0–30° to the horizontal, as shown in Figure 4. They usually cut 15–20 leaves per plant in a single annual harvest. The cutter leaves approximately 5 cm from the base of the leaf, taking care not injure the leaves that remain standing due to the plant health can be affected [36]. Farmers select the groups of leaves in the best conditions in terms of size, color, and maturity to ensure fiber quality.

Figure 4. Leaf cutting.

In physiological terms, the plant must have a minimum of 20 leaves for its biological process to continue. In fique crops with biotypes that have prickles on the leaves, an additional step called “desespinado” is carried out to remove the prickles on the leaf margin with a knife. Once cut, the leaves are deposited on the ground, forming piles and then transferred to the defibration area (Figure 4).

3.2.2. Leaf Defibration

After the cutting process, the leaf defibration is carried out, which consists of mechanically extracting the fiber. It corresponds to the sclerenchyma tissue, separating it from the mesophyll of the leaf. There is a machine with a series of metal rotors to remove the mesophyll from the leaf, exposing the fibers.

In the defibration process, the leaves are stripped to reduce entanglements and facilitate fiber extraction, as shown in Figure 5. The process begins by introducing the leaf into the machine (Figure 5a), first by the base, the thickest part, extracting approximately ¾ of the leaf (Figure 5b). Then, the leaf is inverted and entered through the tip until it is totally defibrated (Figure 5c).

Figure 5. Fique leaves defibration. (a) Machine for fiber extraction, (b) Leaf positioning on the machine, (c) Fiber defibration, (d) Fiber handling in the machine, (e) Fiber shaking step, (f) Extracted fiber organized in bundles.

The defibration should be carried out in a period not exceeding 12–15 h after cutting. The aim is to prevent a physiological deterioration in the leaf called “palisade leaf” that complicates the extraction and affects fiber quality. After defibration, the fiber is shaken and put together in bundles corresponding to twelve leaves (Figure 5d–f) [36].

The personnel required to perform the cutting and defibration will depend on the capacity of the fiber extraction machine. For machines of 250–300 kg fiber/day and 400–500 kg fiber/day, the personnel required is presented in Table 1.

Table 1. Personnel required to perform the defibration process.

| Machine | 250–300 kg Fiber/Day | 400–500 kg Fiber/Day |

|---|---|---|

| Cutters | 1 | 2 |

| Porters | 2 | 4–5 |

| Machine Operators | 2 | 3 |

After the leaf defibration, a process is carried out to eliminate the greenish color of the fiber. In previous years, the color removal used to be done through liquid fermentation (Figure 6) in 1–2 m3 cement tanks built by the farmers. According to [36], fermentation was considered necessary to obtain quality fiber since the action of microorganisms increases the temperature and organically decomposes the matter that accompanies the fiber. Likewise, the chemical compounds of the fique detach the cellulose fragments present in the fibers, as shown in Figure 6.

Figure 6. Liquid fermentation process for the fique juice.

However, fermentation implies the employment of high amounts of water, approximately 200 L per day. It represents high loads of saponins, sugars, proteins, alkaloids, and elements such as nitrogen, phosphorus, calcium, and potassium coming from the juice attached to the fiber [9,21]. This liquid waste is usually dumped on site, going to nearby water sources.

In recent years, the dry process has been carried out, shaking immediately after the extraction to drying later in sheds. There, periods of light and darkness alternate so that the fiber acquires the characteristic light yellow coloration.

3.2.3. Fiber Drying

After desfibration, the fiber is still impregnated with leaf juice. For that reason it is deposited in piles for 12 h, where it undergoes dry fermentation, as shown in Figure 7a. Then, a manual shaking of the fiber bundles is carried out to remove fragments of fiber and bagasse that remain attached after extraction.

Figure 7. Fique fiber drying. (a) Piles of fique fiber, (b) Aspect of the fique piles on the soil, (c) Fiber disposition during the drying, (d) Dried fiber and color change, (e) Dried fiber aspect, (f) Bundles of fique fibers before the storage, (g) Detail of the fique fiber storage.

After shaking, the fiber is spread out in the “secadero”, which is a structure similar to a clothesline (Figure 7c,d). In a period of 1–3 days, depending on weather conditions, the fiber color changes from green to yellow (Figure 7e). Once the fiber is dry, the bundles are assembled again (Figure 7f). The bundles form packages of approximately 40–50 Kg (Figure 7g). The last part of the process consists of controlling the humidity to ensure values close to 12% and storing it. The fiber can last 2 to 3 years in storage.

This entry is adapted from the peer-reviewed paper 10.3390/su15010695

This entry is offline, you can click here to edit this entry!