1. Introduction

Construction is an important and labor-intensive industry with a complex working environment. In order to handle the challenges of COVID-19, an aging population, and the accelerating pace of life, it is urgent to develop advanced technology used in the construction industry [

1]. In construction, next to water, reinforced concrete is the most commonly used material worldwide and has a profound impact on construction quality [

2,

3]. As an effective tool to increase efficiency in the building process and reduce casualties among construction workers, various concrete construction robot has been proposed and applied in the field, which provides encouraging capabilities.

The early research and practice of concrete construction robots in the construction industry can be traced back to the 1970s and 1980s, and the development of new technologies to improve productivity in the construction industry has been envisaged since the late 1980s [

4]. With the development of artificial intelligence technology, sensor technology, and BIM technology [

5], the construction robot technology for site construction has gradually matured [

6,

7], and a large number of single-task construction robots and integrated robots are emerging at construction sites, making construction tasks more efficient, accurate and safe [

8,

9]. With the maturity of autonomous driving technology and laser detection technology [

10], more concrete construction robots have applied the technology of autonomous driving detection and sensor detection. These make the building robots more intelligent and construction more precise.

Although considerable research has been carried out and various types of structures and technologies have been developed [

11,

12], the field is far from mature, and the use of concrete construction robots is still limited [

13]. With the popularization and application of concrete construction robots [

14,

15], a series of problems, such as the adaptation of robots to complex building environments [

16], the management and maintenance of robots at concrete construction sites, and the training of new industrial workers, are worth in-depth discussion. Meanwhile, technical research on concrete construction robots is scattered and lacks unified technical systems and standards. Therefore, this paper sorts out and introduces the research cases of concrete construction robots at home and abroad and puts forward corresponding development suggestions according to the use of concrete construction robots. This could broaden the research ideas for related enterprises and institutions and provide a reference for the development of concrete construction robots.

According to the application situation, existing concrete construction robots can be categorized as concrete distribution robots [

17,

18,

19], concrete leveling and compaction robots [

20,

21,

22], concrete floor finishing robots [

23,

24,

25], concrete surface painting robots [

26,

27], 3D printing construction robots for additive manufacturing [

28,

29,

30], and construction-used surveillance robots [

31,

32,

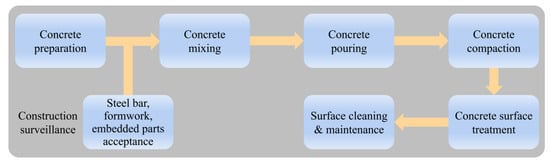

33]. The common concrete construction process is shown in

Figure 1. A large variety of autonomous vehicle driving and monitoring techniques [

34,

35,

36] has been widely used in concrete construction robots; however, they lack clear relevance to the key functions in the building process. Based on this point, we attempt to explain the basic functions of concrete construction with the related autonomous robots. Due to the complexity and diversity of the building concrete construction environment, the current workload that can be handled by concrete construction robots is far from meeting actual engineering needs, indicating that the global concrete construction robot application market is still in the incubation period.

Figure 1. Common concrete construction process, all of which require appropriate surveillance.

2. Development Status of Concrete Construction Robots

2.1. Concrete Distribution Robots

According to the concrete distribution mode, construction robots can be categorized as pouring concrete robots and shotcrete construction robots. Concrete pouring refers to the process of pouring concrete into formworks or planes until they are plasticized [

37]. The distribution of concrete is important with regard to concrete pouring. The traditional manual distribution of concrete has problems such as a high working intensity, slow working speed, and uneven distribution of concrete. However, a concrete distribution robot can achieve the uniform distribution of mixed concrete on a large surface or template system [

38]. Shotcrete is a raw material that behaves the same as conventional concrete, but the construction process is special [

39]. This process sprays concrete mixed with a certain amount of accelerant into a tunnel rock layer or the surface of initial support by means of a jet mechanical arm, which can protect the rock or structure part.

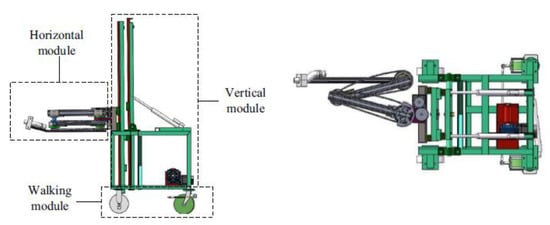

2.1.1. Concrete Pouring Construction Robot

The commonly used concrete pouring construction robots include concrete pumping pouring robots and concrete tower crane pouring robots. Concrete pumping pouring robots require relatively high quality for a slump of concrete and need to move the conveying pipe in time. The concrete distribution height is limited, but it saves time and manpower.

The stationary concrete distribution robot developed by InaraMART consists of three parts: a base part that can be fixed to the ground, a middle part that consists of four motion joints and links, and an end concrete pouring actuator [

40]. Its towering crane structure can lift materials or equipment to appropriate positions and manually control the swing of joints and connecting rods to open the end concrete pouring actuator at the appropriate positions. Because of the large swing range of the connecting rod, it requires a large working space. However, due to its high structure, it is not suitable for construction in buildings.

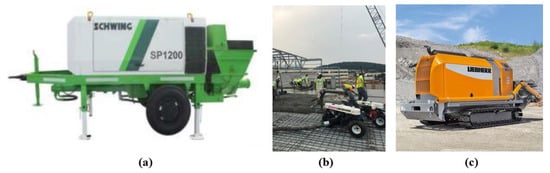

Shyam et al. introduced and analyzed the SP 1200D concrete pumping pouring robots (

Figure 2a) [

41], which can be mounted on a truck or placed on a trailer. This robot normally pumps concrete at lower volumes than boom pumps, which can be widely used for smaller-volume concrete placing applications such as swimming pools, sidewalks, single-family home concrete slabs, and most ground slabs. The Intelligent Steering mobile concrete pumping pouring robot (

Figure 2b) developed by SOMERO [

42] consists of several four-wheel mobile robot vehicles equipped with concrete pumping hoses, several of which are used for guidance and positioning. Moreover, an end vehicle is used for concrete pouring execution. The motion path of the robot vehicle can be controlled manually, and the concrete can be transported and distributed with the hose. It is suitable for the ground concrete pouring of large buildings with large areas. Developed by LIEBHERR [

43], the Crawler concrete pumping pouring robot 140 D-K (

Figure 2c) can be flexibly maneuvered with its sturdy construction and has been specially developed for concrete pile foundations in combination with a drilling rig.

Figure 2. Mobile concrete pumping pouring robots. (

a) SP 1200D concrete pumping pouring robots [

41], reproduced with permission from Shyam et.al., Improving the efficiency of stationary concrete pumps using whitworth quick return mechanism; published by IOP Publishing, 2021; (

b) Intelligent Steering mobile concrete pumping pouring robots [

42], reproduced with permission from SOMERO; 2022; (

c) Crawler concrete pumping pouring robots [

43], reproduced with permission from LIEBHERR; 2022.

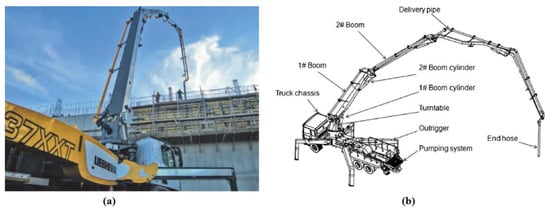

Cantilever concrete pouring robots are used on most larger construction projects because they are capable of pumping at very high volumes and because of the labor-saving nature of the placing boom. A cantilevered concrete pouring robot [

44,

45] uses a remote-controlled articulating robotic arm (called a boom) to place concrete accurately when attached to a truck, and longer units are attached to semi-trailers, as shown in

Figure 3. The robotic arm has complex redundant motion joints. In order to achieve intelligent construction, Kang et al. [

46] used a hybrid genetic algorithm for the optimal trajectory planning of redundant mechanisms. A thorough overview of the dynamic modeling of the manipulator was also introduced [

47,

48].

Figure 3. Cantilever concrete pouring robot. (

a) Mobile cantilever concrete pouring robot [

44], reproduced with permission from Wanner et al., Tool-center-point control of a flexible link concrete pump with hydraulic limitations using quadratic programming; published by IEEE, 2019; (

b) Cantilever concrete pouring robot components [

45], reproduced with permission from Wu et al., Fatigue life prediction for boom structure of concrete pump truck; published by Elsevier, 2016.

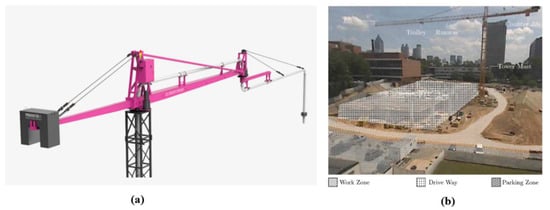

The intelligent follow-up concrete distribution robot (

Figure 4a) developed by Bright Dream Robotics [

49] is composed of a large arm and a small arm driven by a motor, a platform with an adjustable building height, and a hose for pumping concrete. By controlling the combined movement of the upper and lower arms, workers can easily change the position of the end hose to quickly carry out construction and concrete distribution. Additionally, it is suitable for pouring concrete on the flat floor of a building without a roof.

Figure 4. Concrete tower crane pouring robots. (

a) The intelligent follow-up concrete distribution robot [

49], reproduced with permission from Bright Dream Robotics; 2022; (

b) Traditional concrete tower crane pouring robots with site layout [

50], reproduced with permission from Yang et al., Vision-Based Tower Crane Tracking for Understanding Construction Activity; published by American Society of Civil Engineers, 2014.

Concrete tower crane pouring robots have low requirements on the collapse degree of concrete, and the quality of concrete is well controlled in the distribution process. The height of distribution is not restricted, and there is generally no need for handling. Yang et al. [

50] exploited a model-based visual pose estimation algorithm to track the jib angle versus time that determines the crane process model and site layout. In order to improve the construction time and precision of concrete distribution, Shapira et al. [

51] designed a tower crane-mounted live video system to enhance the visibility of the operator for both daytime and night-time operations.

2.1.2. Shotcrete Construction Robot

Shotcrete is used to spray concrete mixed with a certain amount of accelerant into a tunnel rock layer or onto the surface as initial support by means of the mechanical arm of a jet machine to protect the rock or the structure. This construction process is simple and fast, which improves the construction speed and reduces the disassembly process of formwork construction. The concrete density is high with good impermeability, and economic benefits are significantly improved. Shotcrete is widely used in the construction of both conventional railway and highway tunnels that play a supporting role in special hydraulic tunnel projects. In contrast to concrete pouring construction robots, this placement method enables shotcrete to be placed in vertical or overhead positions with irregular geometry and little or no formwork [

52].

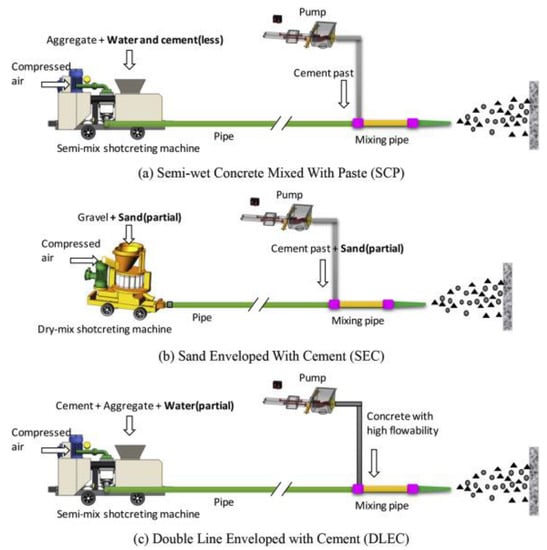

For instance, Zhu et al. introduced the evolution of the shotcrete construction robot (

Figure 5) construction process [

53]. According to the construction method, shotcrete can be applied with a dry method or a wet method [

54]. Wet construction mixes the concrete with good workability and accelerator and sprays it onto the surface of the structure with the help of a jet [

55]. Dry construction can introduce dust and other serious pollution, causing great harm to the human body and increasing the rebound rate. Compared with dry spraying, wet spraying produces less rebound and dust and can achieve higher coating quality [

56]. Therefore, engineers have been focusing on the development of wet-spraying robots.

Figure 5. Schematic of evolved processes for shotcrete construction robot [

53], reproduced with permission from Zhu et al., Effect of Doped Glass Fibers on Tensile and Shear Strengths and Microstructure of the Modified Shotcrete Material: An Experimental Study and a Simplified 2D Model; published by MDPI, 2021.

2.2. Concrete Leveling and Compaction Robots

Because the concrete pouring process will inevitably lead to the existence of internal voids and uneven pouring surfaces, it is necessary to determine the leveling and compaction before concrete solidification. Manual leveling and compaction usually involve pouring concrete. Then, workers with spades that are preliminarily lying flat perform slurry beating so that sand and stone are evenly distributed, concrete bubbles are released, and the overall concrete is compacted [

57]. These steps require workers with excellent experience, which is difficult to obtain. The final concrete leveling effect and structural strength are related to the technology of the workers [

58]. Concrete leveling and compaction robots can improve the flatness of the building plane, optimize the uniform distribution of coarse and fine materials in the concrete, and improve the durability of the concrete [

59]. A concrete compacting robot can optimize the uniform distribution of coarse and fine materials in concrete and improve the durability of concrete [

60]. This process partially or fully automates a highly repetitive and labor-intensive task.

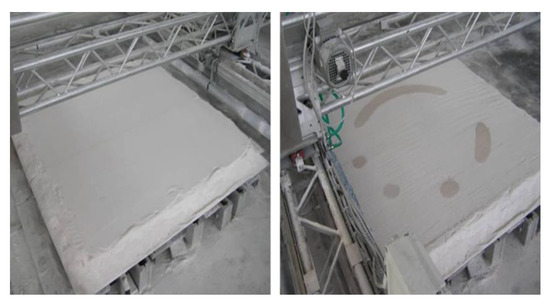

With the progress of laser calibration and control technology, autonomous concrete floor treatment equipment (laser leveling machines) has appeared on the market, which is used to replace traditional manual work [

24]. Laser flat heads are divided into scrapers, cloth screws, vibrators, and leveling beam modules. According to traditional methods of construction, after pouring concrete, it is necessary to scrape the excess concrete, roll it with a roller, spray a cement slurry, rub it with wood, and finally wipe it. These comprise multiple construction procedures. The use of laser leveling machine construction integrates these multiple procedures together, with one machine significantly improving construction progress and quality.

In the 1950s, an engineer with the Kansas State Highway Commission invented the first autonomous concrete floor screeds. By changing the indicator, the operator can adjust the height of the leveling mechanism by adjusting the screw in order to obtain a relatively smooth concrete pavement. The maximum span of the equipment in the ground leveling operation can reach 7.4 m [

61]. Caterpillar is one of the most representative screen-leveling equipment and production enterprises in the world, and the most representative product is the M series screeds [

62]. The screeds are characterized by a number of operation gears, such as high speed and low torque or high torque and low speed, according to the consistency of the concrete.

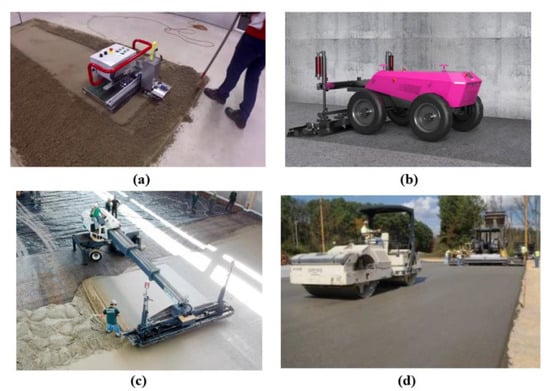

The leveling equipment and leveling devices (

Figure 6a) developed by Floor master corporation are designed as a crawler car, with a leveling mechanism and a compacting mechanism in front of the car [

63]. The spiral device of the flattening mechanism is controlled by the motor and is used for dispersing the excess concrete materials accumulated in front of the vehicle to form a primary mortar surface. The motor drives the ball screw to rotate, which further drives the compacting plate of the compacting mechanism to vertically beat the concrete surface. In addition, the laser receiver and the photoelectric sensor can accurately control the concrete compacting height and the self-running position. Workers are only needed to control the machine, which reduces the labor intensity. Moreover, this equipment is suitable for leveling and compacting the ground.

Figure 6. Concrete leveling and compaction robots. (

a) Micro-concrete leveling robots [

63], reproduced with permission from Floormaster; 2021; (

b) Medium-scale concrete leveling robots [

64], reproduced with permission from Ifdesign; 2021; (

c) Large-scale concrete leveling robots [

65], reproduced with permission from Fortepiso; 2018; (

d) Concrete compaction robots [

66], reproduced with permission from Mehta et al., Advancements in concrete technology; published by American Concrete Institute, 1999.

The ground leveling robot (

Figure 6b) developed by Guangdong Bojiatuo Construction Technology Co., Ltd. (Foshan, China) is designed as a four-wheeled trolley [

64]. The actuator in front of the robot includes a scraper for pre-leveling the concrete surface and a whole plate for releveling. It has a unique two-degree-of-freedom (2-DoF) adaptive system, high-precision laser identification and measurement system, and a real-time control system. This system can dynamically adjust and accurately control the end of the actuator so that it can always maintain a millimeter-level accuracy. Based on the self-developed GNSS navigation system, the ground leveling robot can automatically set the planning path of concrete leveling and achieve the autonomous leveling construction of concrete ground. It could be used for smaller industrial projects, commercial work, and residential slab-on-grade.

Large-scale concrete leveling robots (

Figure 6c) have been developed by the Fortepiso Corporation [

65]. The robot travels over an area to be paved, similar to a train on a track. This operation requires the placement of concrete and the speed of the pavers. A special paving system provides the appropriate vibration and consolidation for each layer, resulting in a smooth surface. Patented molds incorporate double paving into a single mold design. The system avoids not only the need to use more equipment for the job but also the need to extend the pavers to a great length between the front and back for a second layer of paving. Though the large laser leveling machine technology only needs reference point control, it can ensure the ground smoothness of a large area of work. Laser technology reduces the errors caused by human factors and solves the conventional contradiction of a large area and short period, poor smoothness, low construction process molding, and no construction joints. With a high degree of mechanization, laser technology can effectively liberate productivity and greatly reduce construction costs. Abhishek et al. introduced a concrete compaction robot [

66] with two rolling barrels (

Figure 6d). The two barrels at the rear side are compacted twice, and the last rolling barrel is driven by a motor. This can only control its forwards or backward movement and needs to be carried by workers to change direction. It is suitable for the compaction of ground concrete.

2.3. Concrete Floor Finishing Robots

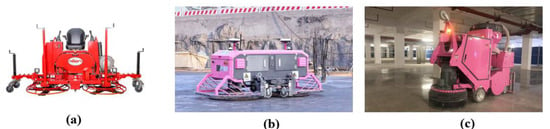

2.3.1. Semi-Autonomous Concrete Floor Finishing Robot

The Polishing Rider (

Figure 7a), developed by the Allen Engineering Corporation, is driven by workers for a concrete polishing process [

69]. Under the car, there are two sets of mud blades that can rotate at high speed and high torque. Each blade forms a small angle with the ground, which presses the concrete surface under high-speed rotation, extrudes water, and fills the surface gap. In addition, it is equipped with standard features of power steering control and jacks to ensure that workers can easily drive indoors and complete the steering. The operator riding the machine needs the skill to drive it and must endure the violent vibrations of its engine and trowel.

Figure 7. Concrete surface treatment robots. (

a) The polishing rider [

69], reproduced with permission from Allen Engineering; 2020; (

b) The basement glazing robot [

49], reproduced with permission from Bright Dream Robotics; 2022; (

c) The floor grinding robot [

70], reproduced with permission from Bright Dream Robotics; 2022.

The basement glazing robot (

Figure 7b) developed by Guangdong Bojiatuo Construction Technology Co., Ltd. achieves the autonomous construction of concrete floor glazing through an intelligent motion control algorithm and integrated navigation technology [

49]. It is also actuated by two sets of blades that rotate at high speed. The robot moves according to a pre-programmed path for polishing, but at the edge of the wall, the robot spatula cannot move. Thus, it needs to be handled manually.

A floor grinding robot (

Figure 7c) developed by Guangdong Bojiatuo Construction Technology Co., Ltd. is used to remove floating slurry on the surface of the concrete after solidification to carry out subsequent floor surface construction work [

70]. The main purpose is to replace the grinding mill. The body also carries a water tank. Motor control for high-speed spinning mills that remove the floating pulp in the process can reduce dust pollution and helps to prolong the service life of grinding. This robot is not easy to scratch and can improve the quality of grinding, perform a relatively dumb light effect, and provide the daily maintenance of the ground. Only one person is required to control the construction of the grinding robot. It is applied to the construction of epoxy floors, solidified floors, and emery floors of underground garages and indoor workshops.

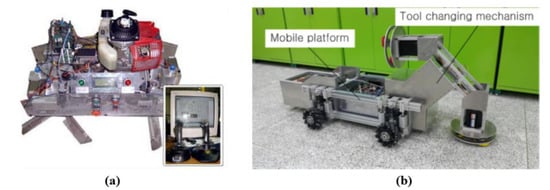

2.3.2. Autonomous Concrete Floor Finishing Robot

Woo et al. designed a small concrete floor finishing trowel robot (

Figure 8a) consisting of a mobile platform central unit with electric motors [

71]. The units are located on the front and back of the central unit, and the measuring and control units are located on the top of the mobile platform central unit. The end-effector mounted at the bottom of the work unit performs floor finishing. The end-effector uses an ultrasonic vibration unit connected to a spatula, which squeezes the concrete surface to achieve a polishing effect. The robot can be operated remotely by a worker or by a pre-programmed movement path.

Figure 8. Concrete surface treatment robots. (

a) Small concrete floor finishing trowel robot [

71], reproduced with permission from Woo et al., Experiment of Concrete Floor Finishing Robot; published by Institute of Control, Robotics and Systems, 2004; (

b) Concrete polishing robot system [

72], reproduced with permission from Cho et al., Performance Evaluation of Concrete Polishing Robot with Omnidirectional Mobile Mechanism; published by The Korean Society of Manufacturing Technology Engineers, 2016.

Cho et al. designed a concrete polishing robot system (

Figure 8b) as a mobile trolley driven by four Macanum wheels [

72]. There are two wheels on each side that can move forward/backward and rotate according to the direction of rotation of the left and right wheels. A scraper is installed on the front side of the trolley to make the concrete surface smoother. It works through a preset motion trajectory without manual operation. This robot is suitable for residential floors, warehouses, basements, factories, airports, shopping malls, and other areas that need high-precision concrete ground constructions.

2.4. Concrete Surface Painting Robots

When the concrete is solidified, according to the environmental requirements, it may be necessary to spray paint on the surface of the solidified concrete to achieve a better visual perception [

73]. The painting color can be adjusted according to the environmental needs, and the compatible color can be sprayed to produce color patterns. After spraying, a protective film is added to the surface of the concrete, which can increase the wear resistance of the concrete surface. This film is conducive to surface cleaning and maintenance. Furthermore, rich colors can be used to coordinate with the surrounding scenery. At present, existing concrete surface painting is mainly performed through manual scraping or rolling [

74]. This method is laborious, costly, and inefficient, and the construction effect is too dependent on the technology of construction personnel to ensure the uniformity of the coating. If the external wall is sprayed, the construction personnel need to be hoisted at a high altitude with a crane, which has a potential safety hazard [

75]. The use of robots for this type of work is stable, safe, and reliable, resulting in high efficiency and lower construction costs. Spraying construction is a common process in decoration engineering, including indoor spraying, exterior spraying, floor coating, and other processes [

76]. The common moving modes are guide rail, climbing wall, and mobile [

77].

Warszawsky et al. [

78] developed a robot for interior finishing tasks named “TAMIR”, composed of six-degree-of-freedom robotic arms and a removable chassis. Kahane et al. [

79] adopted human–computer interaction to optimize the working efficiency of the robot and set three working scenes, which can realize the switching and movement of different working scenes. In 2018, Asadi et al. [

80] developed a man–machine collaborative indoor spraying robot called Pictobot based on this classic structure, as shown in

Figure 9a. Pictobot consists of six components: a mobile chassis, an airless spraying system, a self-lifting structure (maximum lifting height of 10 m), a mechanical arm, and a sprinkler head device. Operator perception and judgment are responsible for setting spraying parameters (pressure, thickness, etc.) through remote operation control of the changing robot work site to cope with the changing working environment. The robot is responsible not only for the low wall and corner painting operations but also for spraying at the height of the wall to reduce the heavy work of the workers, such as climbing and bending. With the help of the sensor device, the scene is reconstructed, the 3D characteristics of the wall are analyzed, the height of the lifting mechanism is then automatically controlled, and the movement of the arm of the spraying gun is finally planned. In construction sites without manual participation, an APP remote control robot can be used for manual operations and autonomous spraying operations.

Figure 9. Concrete surface painting robots. (

a) The indoor spraying robot [

80], reproduced with permission from Asadi et al., Pictobot: A cooperative painting robot for interior finishing of industrial developments; published by IEEE, 2018; (

b) the OutoBot robot [

81], reproduced with permission from Cho et al., Wind resistance performance analysis of automated exterior wall painting robot for apartment buildings; published by Korean Society of Civil Engineers, 2015.

Cho et al. [

81] developed the suspended structure OutoBot robot (

Figure 9b), which is hoisted outdoors with a rope during operation. The hydraulic cylinder is supported by four legs to maintain the main body away from the wall. The main body is designed with a manipulator equipped with a camera and a nozzle that can clean the surface or spray with high-pressure water. The working process requires only one worker to remotely control it on the ground. Deploying multiple systems to work together can speed up the process and shorten the construction period. Wang et al. [

82] developed an intelligent spraying robot with an autonomous motion function, as shown in

Figure 10. A face-to-face parallel adjustment algorithm based on laser ranging is used to keep the robot parallel to the wall during the spraying process. The polar coordinate transformation method based on LiDAR data enables the robot to automatically identify the areas that do not need spraying. No manual control or handling is required during the entire spraying process.

Figure 10. Overall structure of the 2G robot [

82], reproduced with permission from Wang et al., Intelligent spraying robot for building walls with mobility and perception; published by Elsevier, 2022.

In order to study how spraying can be more flexible in space construction, the statics [

83,

84], kinematics [

85,

86], and dynamics [

87,

88] of deployable structures are studied in depth. Wei et al. [

89] used the collapsible structure of spiral algebra for flexibility in changing their workspace. Lu et al. built deployable components using Myard linkages [

90] and designed a series and parallel manipulator [

91]. Agrawal et al. [

92] and Chen et al. [

93] analyzed and discussed the application of polyhedron geometry to the foldable structure in this respect.

Small-scale indoor spraying robots have also become a focus, as they claim to work at full scale without a reduction in performance [

94,

95,

96]. The 6-DOF manipulator was mounted on a 2-DOF hexapod robot in the horizontal direction, but there was no actual spraying experiment. Compared with an indoor spraying sequence, outer wall spraying is more dangerous. In a special scenario of working at high altitudes outside, an exterior wall painting robot has higher performance requirements in terms of stability, safety, and reliability. In order to achieve efficient and stable operation, an exterior wall spraying robot needs to have the functions of adsorption and free movement of the exterior wall. The common structures are absorption-type structures and suspended structures.

As for the adsorption structure robot, the world’s first wall-climbing robot using vacuum adsorption was developed in 1966 [

97]. Developed by Auto Craw LLC [

98], Auto Crawler adopts the crawler adsorption mode, and a sucker is installed on the outside of the crawler. The crawler and the external wall remain relatively static when walking. During movement, it can adapt to the concave and convex changes of the wall, but the omnidirectional movement ability is poor, and sharp turns will cause damage to the belt. Moreover, the Harbin Institute of Technology has successfully developed a tracked magnetic adsorption robot [

99] and a wall-climbing robot [

100].

2.5. Three-Dimensional Printing Construction Robots for Additive Manufacturing

Recently, advancements in the application of 3D printing in building construction have developed rapidly in the past decade [

101]. Contrary to the traditional cutting material construction method, only the necessary materials are provided, which greatly reduces waste. Using the concept of 3D printing to superimpose and pour concrete layer by layer after slicing, the building structure can achieve the primary molding of the building body [

102]. However, the current 3D printing process is expensive and is not suitable for large-scale products and traditional design methods. The range of materials that can be used is very limited. Thus, the construction cost of 3D printing is high.

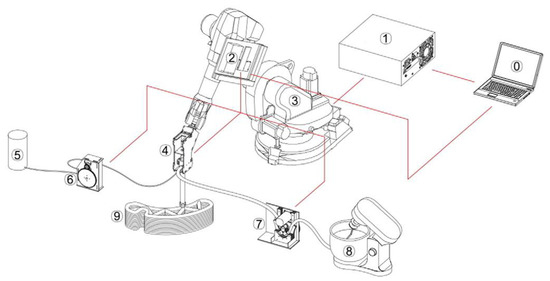

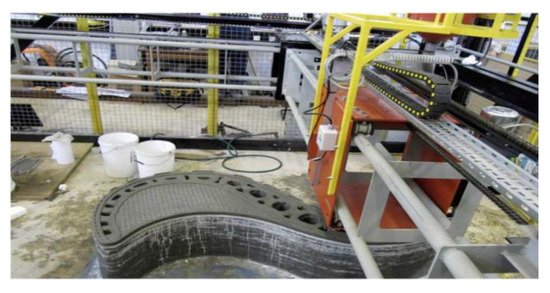

A typical 3D printer and its delivery system are shown in

Figure 11. In order to ensure the implementation of 3D printing technology, the first step is to design a construction path through 3D to 2D slicing software. It starts by cutting the 3D shape of an object into thin, flat layers of a certain thickness and then designs the path of each layer. All of these paths consist of contours and fill patterns [

103]. At present, the three 3D printing methods that are used in construction generally include contour crafting (CC), concrete printing, and D-shape 3D printing [

104]. Meanwhile, a number of new printing methods are being investigated, such as rock printing [

105], inkjet powder printing [

106,

107], multi-story apartment printing, and complete office printing.

Figure 11. Schematic of the 3D printing setup: 0. System command; 1. Robot controller; 2. Printing controller; 3. Robotic arm; 4. Printhead; 5. Accelerating agent; 6. Peristaltic pump for accelerating agent; 7. Peristaltic pump for premix; 8. Premix mixer; 9. Three-dimensional-printed object [

103], reproduced with permission from Gosselin et al., Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders; published by Elsevier, 2016.

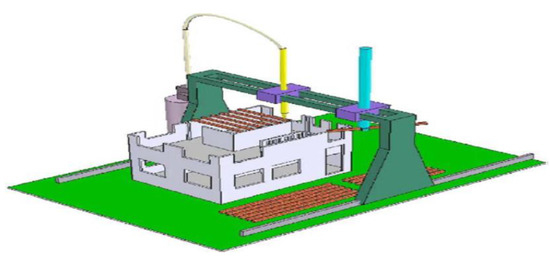

The basic principle of CC technology is the same as that of other ordinary 3D printers. The material is stacked layer by layer in the specified position using extrusion equipment [

108]. The difference is that the printing material of CC is high-density and high-performance concrete. The CC machine (

Figure 12) developed by the University of Southern California consists of an XYZ gantry system, a nozzle assembly with three motion control components (

Figure 13) (extrusion, rotation, and scraper deflection), and a six-axis coordinated motion control system [

109]. The cylinder piston extrudes the concrete material from the nozzle. By controlling the angle of the scraper, the required building shape can be obtained during rotation, and the concrete surface treated by the scraper is relatively smooth and flat. Its rapid, efficient, and economical construction materials have advantages in building low-income housing and emergency shelters. The ability to build complex curves and other geometric shapes can also be applied to building unique buildings.

Figure 12. Construction of conventional buildings using CC [

109], reproduced with permission from Khoshnevis et al., Toward Total Automation of On-Site Construction—An Integrated Approach Based on Contour Crafting; published by Technische Universiteit Eindhoven, 2003.

Figure 13. A nozzle assembly with three motion control components [

109], reproduced with permission from Khoshnevis et al., Toward Total Automation of On-Site Construction—An Integrated Approach Based on Contour Crafting; published by Technische Universiteit Eindhoven, 2003.

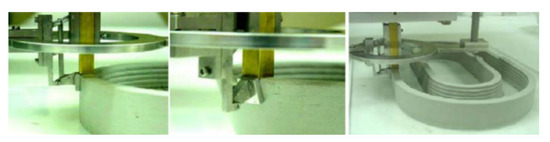

The large-scale 3D printing of ultra-high performance concrete (

Figure 14) developed by XtreeE SAS [

110] consists of a system command, robot controller, printing controller, robotic ARM, printhead, accelerating agent, and peristaltic pumps for the accelerating agent and for the premix mixer. Because it does not have a scraper for contour machining, a smaller nozzle is used to obtain a better surface. Printed product surfaces will produce a unique rib finish, and many industrial arts printed with concrete use this feature to show artistic effects. However, if a smooth surface is needed, the wet material is wiped during construction, or the printed surface is ground to a smooth surface. Since there is no other external force applied to the concrete extruded from the nozzle to the print, there will be small gaps between the layers in the printing process, which will affect the strength of the print. High-strength concrete is developed to compensate for the strong influence caused by the existence of this pore structure.

Figure 14. Large-scale 3D printing of ultra-high-performance concrete [

110], reproduced with permission from Lim et al., Fabricating construction components using layered manufacturing technology; published by Loughborough University, 2009.

The D-shape printing machine (

Figure 15) developed by Monolite Ltd. includes an XYZ gantry system [

111], an adhesive distribution system, and a series of nozzles arranged on the gantry. The principle is that a layer of material with the required thickness is laid in the largest printing area and compacted. Then, the nozzle installed at the specified position on the gantry releases the deposition adhesive to make the structure of the desired part solid. Thus, the next layer of material is added to continue the operation, the unbonded material is removed, and the printed part is presented. Since this process is solidified layer by layer, it is not necessary to consider the problem of adding supporting parts to the suspended position.

Figure 15. D-shape printing machine [

111], reproduced with permission from Cesaretti et al., Building components for an outpost on the lunar soil by means of a novel 3D printing technology; published by Elsevier, 2014.

Whether it is a gantry-type or manipulator-type concrete 3D printing machine, its motion range is limited. So, the final printed architectural structure size cannot fully meet the demand. Furthermore, different buildings need different structures and materials because of the particularity of buildings, which makes it difficult to standardize the products or easy to computerize. Thus, production on a large scale is not easy.

2.6. Construction-Used Surveillance Robots

Using autonomous robotic systems to virtually monitor the work-in-progress during the whole construction process is a flexible approach to improving safety, quality, and productivity in construction engineering and management [

112]. The rapid advances in sensing, 3D reconstruction, and artificial intelligence, along with autonomous navigation algorithms and low-cost cameras, have made autonomous robots more affordable, reliable, and easy to operate for construction-used surveillance [

113]. Generally, these robots include two categories: (1) unmanned aerial vehicles (UAVs), namely, drones; (2) unmanned ground vehicles. By capturing very large collections of images and videos and processing these visual data into 3D models by computer methods, construction-used surveillance robots can frequently serve in the different phases of the whole construction process, such as land surveying, logistics, onsite construction, maintenance, and demolition.

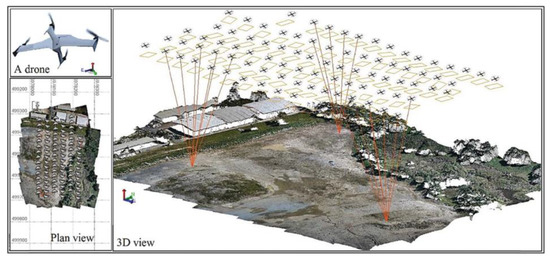

As a key procedure at the beginning of the construction process, land surveying is a fundamental part of the construction industry. Conventional land surveying methods need bulky tools, such as tripods, GSP waypoints, and total stations, to provide navigation and data collection capabilities. Drone-based surveillance robots equipped with cameras, autopilots, and image-processing software can be applied to provide faster and less costly land surveying and mapping in constructions [

114,

115]. One study compared these two measurements, a manual ground-based survey and a photogrammetric survey, by using a drone-based surveillance robot [

114]. A camera mounted on the drone is pointed down towards the ground to measure 3D dimensional coordinates, and 3D models can be then created by aerial photogrammetry (

Figure 16). Compared with a traditional GPS survey, the drone-based surveillance robot can reduce the time to one-third and greatly increase the point density by more than 3000 times through the process of autonomously collecting color-coded points. In addition, Fleming et al. [

115] used a smartphone-controlled drone to measure the geometry of the support system during the excavation stage of a construction project. Two-dimensional images were converted into three-dimensional construction models to guide different types of construction activities, e.g., site geometry change, geotechnical engineering evaluation, and responses of adjacent structures. Using this method, the construction activities of the project can be adjusted in time.

Figure 16. A photogrammetric survey procedure using drone-based surveillance robot [

9], reproduced with permission from Choi et al., Safe breakwater-following control of an autonomous underwater vehicle with non-zero forward velocity; published by Elsevier, 2007.

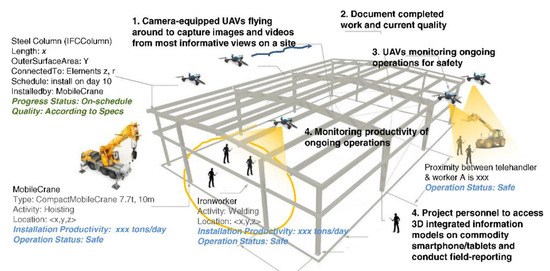

Autonomous surveillance robots are also effective tools in onsite constructions (

Figure 17) [

112]. The visual performance monitoring procedure using this method is to first collect onsite images or videos from the most informative views; secondly, analyze them about performance deviations, especially for progress and quality during construction; thirdly, monitor ongoing operations for productivity and safety; then characterize the as-is conditions of existing construction sites; finally, visualize and communicate the most updated state of work-in-progress. Most of the studies use GPS-based drones and predetermined flight paths to achieve autonomous navigation and data collection [

116,

117,

118]. However, these drones for onsite construction surveillance are negatively affected by poor GPS signals in indoor environments or by shadows caused by nearby buildings or other structures. They can also be subject to navigational hazards due to the loss of calibration on magnetometer sensors close to steel components. Therefore, recent efforts have been devoted to Simultaneous Localization and Mapping (SLAM) techniques [

119] for both drones and unmanned ground robots. Kim et al. [

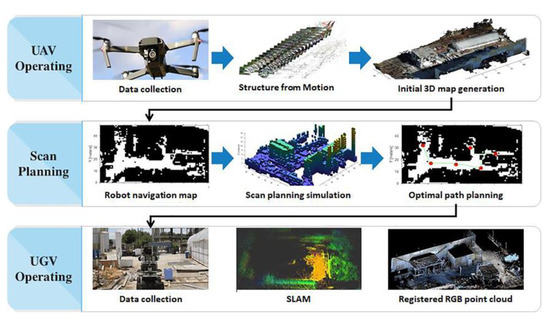

120] developed a drone-assisted automated framework for autonomous ground robots equipped with laser scanning systems outdoors with the aid of drones. They use a coarse 3D point cloud generated by a drone as an initial map of the target site to determine the scan location and path (

Figure 18). A mobile ground robot can collect data at stationary laser scan positions with less occluded views while capturing crucial geometric information as much as it can. Optimal paths for the autonomous robot to navigate among the estimated scan positions are finally generated.

Figure 17. The next generation onsite construction where surveillance robots autonomously monitor work-in-progress [

112], reproduced with permission from Ham et. al., Visual Monitoring of Civil Infrastructure Systems via Camera-Equipped Unmanned Aerial Vehicles (UAVs): A Review of Related Works; produced by Springer, 2016.

Figure 18. Drone-assisted surveillance of autonomous mobile robot in onsite construction [

120], reproduce with permission from Kim et. al., UAV-Assisted Autonomous Mobile Robot Navigation for as-Is 3D Data Collection and Registration in Cluttered Environments; produced by Elsevier, 2019.

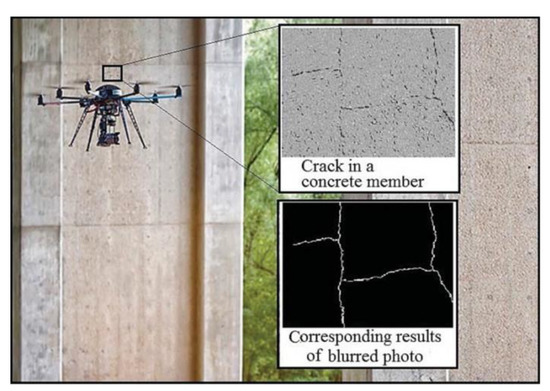

With a hugely increased amount of aging buildings, inspection and monitoring are of great importance to the existing civil structures. Their lifespans can be extended by evaluating their structural states. Conventional methods normally require special equipment and specially trained personnel involved in the inspection process, which can lead to high costs. However, drone-based autonomous robots only require an operator on the ground to control the flight path and camera monitoring the drone. Therefore, they have been exploited in visual inspection and damage detection of construction structures, e.g., building damage [

121]. With a remote sensing system mounted on drones, high-resolution images can be obtained from decimeters to centimeter scale (

Figure 19) [

122]. Capturing images at appropriate scales allows us to autonomously perform comprehensive damage assessment by determining different levels of damage evidence from complete collapse to cracks in buildings. Drone-assisted surveillance robots have also demonstrated the potential to identify and report defects on tunnel lining surfaces (e.g., water leakage, spalling, and cracks) [

123].

Figure 19. Crack detection using a drone [

122], reproduced with permission from Yang et. al., A Real-Time Tunnel Surface Inspection System Using Edge-AI on Drone; published by IEEE, 2022.

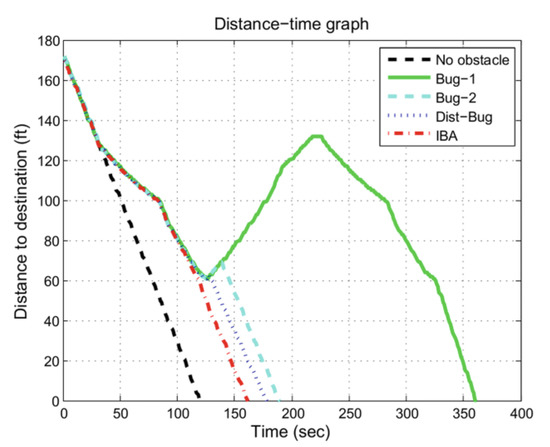

Among the above applications, autonomous driving technology has revolutionized the more tractable use of concrete construction robots, namely autonomous mobile robots [

124,

125,

126,

127]. Unlike cars functioning on city streets, autonomous mobile robots in construction are at a point where they can be safely integrated by utilizing the same equipment as self-driving cars. However, robot navigation to achieve autonomy is a very challenging problem, especially in construction sites. The unknown environment requires the ability of safe path planning in construction robots, particularly for obstacle avoidance of autonomous control. Therefore, Zohaib et al. [

128] developed an intelligent obstacle avoidance algorithm, called Intelligent Bug Algorithm (IBA), to navigate an autonomous mobile robot. This algorithm can well accomplish the goal in relatively less time compared with other algorithms (

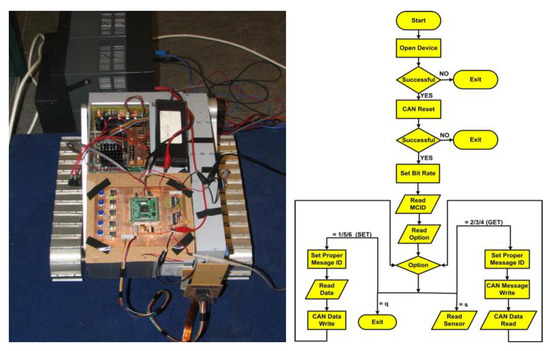

Figure 20). Iqbal et al. [

129] presented a specialized tracking system for a tethered-based robotic vehicle, RObot for Scientific Applications (ROSA), which could also be also used in other tethered robots for construction after minor modifications (

Figure 21). The proposed system is capable of tracking the tether within a resolution of ±6 cm for the rover’s 40 m. After solving the above problem, autonomous mobile robots can be applied to various construction processes. For instance, an autonomous mobile robot named Romu was developed for working with small-scale sheet piles (

Figure 22) [

130]. Sheet piles can be carried into a target setting and driven into the ground sequentially, creating a sturdy wall that could serve as a check dam to assist in reducing flash floods in the arid environment. When inserting sheet piles into the soil, Romu uses a vibratory hammer and relies on its own weight to drive piles deeper without carrying excessive additional mass.

Figure 20. Performance comparison of Intelligent Bug Algorithm (IBA) [

128], reproduced with permission from Zohaib et. al., IBA: Intelligent Bug Algorithm—A Novel Strategy to Navigate Mobile Robots Autonomously; published by Springer, 2014.

Figure 21. Tether tracking and control of ROSA [

129] that can be used in construction robots, reproduced with permission from Iqbal et. al., Tether Tracking and Control of ROSA Robotic Rover; published by IEEE, 2008.

Figure 22. Romu, an autonomous robot capable of carrying sheet piles and driving them [

130], reproduced with permission from Melenbrink et. al., Autonomous Sheet Pile Driving Robots for Soil Stabilization; published by IEEE, 2019.

3. Discussion

The study of concrete construction robots is a new field that combines construction and the research of robots. Its wide application range can cover the whole duration of construction. Challenges and opportunities in concrete construction robots for long-term development and improvement, together with that of autonomous robots in concrete construction, will be discussed in the following directions.

3.1. Challenges and Opportunities

3.1.1. Increased Automation

Researchers and engineers have made significant progress in robotics and automation for construction over the last decade. Driverless construction equipment, robotics, and electric vehicles (aerial or ground) are considered ideal solutions to environmental construction problems and labor shortages. However, the main difficulty of them is teaching the machines to deal with the complexities of construction sites. Generally, construction robots can be categorized into three types: remote-controlled, semi-autonomous, and fully autonomous. Existing concrete construction robots need more workers or technicians to participate in the construction process, and workers need to deal with technical problems encountered during operation. Most of them belong to the first two types, and high-level automation has not yet been fully achieved. The future concrete construction robot should be equipped with multiple types of sensors, combined with large data technology, independent analysis, and processing of construction problems encountered so that a fully autonomous level can be achieved.

3.1.2. Miniaturization

Most of the existing concrete construction robots are large and require very large construction space. Some details, such as corners, cannot be handled well and are not convenient for assembly, disassembly, and transportation. The future trend in construction robots is they are designed to be miniaturized, light, and efficient. This can be achieved by improving battery capacity and innovating navigation technologies and devices, such as the transforming Tesla drone concept. An advanced lithium-ion battery allows the drone to extend flight time by up to one hour on a single charge. In addition, construction robots equipped with cameras can be controlled by tracking the head movements of virtual reality (VR) headsets. The combination of VR and wearable devices can fully visualize the construction sites and building components, which further reduces some physical equipment or sensors on the robots. After the concrete construction robot is miniaturized, the movement is subsequently more flexible. Thus, narrow spaces can be handled, and transportation at the end of the project can be facilitated.

3.1.3. High Precision

Digitization in construction concentrates on the centralized building information model, which reforms the construction industry by embracing mature technologies. The traditional concrete construction robot sensor accuracy is low, there will be a small deviation, and the robot will not be able to accurately locate and provide correct feedback due largely to the limitation of GPS, resulting in a poor construction effect. However, the use of high-precision sensors will increase the design costs, contrary to the original intention of reducing costs. Recent studies have been exploring innovative navigation systems and algorithms for robotics, meaning that future construction robots will be able to dispatch from the reliance on GPS satellites. Until then, the construction robots can autonomously move inside the structures, infrastructures, and buildings under construction, such as that underground, in deep canyons, and in other places with poor or unavailable GPS signals. Combining the sensor data with the advanced navigation systems and algorithms, the high-precision construction effect can be obtained by optimizing the motion trajectory and posture. The new technology will achieve more comprehensive construction quality inspections and time management.

3.1.4. Development of the Inter-Robot Coordination System

Even for extremely simple residential construction, plenty of skilled workers are required for repetitive tasks, which need to be not only successfully completed but also effectively coordinated with each other. Task coordination has been demonstrated in industrial fields with homogeneously distributed robots, heterogeneous robots, and multi-system integration of drones and ground vehicles. For instance, by simply following pre-planned paths without communicating with each other, autonomous excavators and haulage trucks can still be operated simultaneously. This level of task coordination is years ahead of the level that can be achieved in construction sites. Existing concrete construction robots are independent, and the connection between their constructions is not smooth, resulting in a waste of time. If the cooperative construction system among concrete construction robots can be established, multiple concrete construction robots can participate in the construction together, completing different work without interfering with each other. It can be monitored in real time, achieve partial overlap of each process, and shorten the construction period. For full autonomy in construction, advanced autonomous systems should be developed to achieve inter-robot coordination among robots performing various tasks.

3.2. Autonomous Robots in Concrete Construction

Autonomous driving and monitoring technologies have been gradually proposed and applied in concrete construction in terms of leveling and compaction robots, floor finishing robots, surface painting robots, 3D printed construction robots and construction-used surveillance robots. However, some shortcomings or challenges of using autonomous robots should be addressed in the construction process. First, the use of these robots, especially drones, can be limited by local regulations, which vary from region to region. Second, using autonomous robots in concrete construction requires professional operators, as controlling these devices can be challenging. Third, autonomous robots on construction sites face a critical issue of moving reliability since rain and strong winds can negatively affect moving paths. To ensure reliability and enhance applicability, more reliable algorithms that can cope with a variety of conditions must be developed. Fourth, there is still a lack of electricity and payload capacities with the robots, which limits their operating time. Fifth, equipping more devices on the robots requires a better power-generation module. Last, the automated level of these technologies needs to be improved because many of them need to be accompanied by manual detection by construction workers.

In the modern construction industry, autonomous robots are one of the most innovative technologies which have the promising potential to facilitate various construction activities. These activities can involve not only concrete construction but also different phases of tasks over the whole construction process, such as construction sites survey, onsite constructions, work-in-progress monitoring, document records for progress and safety, constructed structures inspection, leading to savings in time, costs and injuries while improving construction quality.

Companies and institutional researchers have observed the valuable benefits of using autonomous robots in construction work. First, injury and fatality can be greatly reduced or avoided through the effective use of robots. Having a mapping solution based on autonomous robots yields automated movements or flights to reduce risks associated with surveying construction sites, such as heavy equipment and hazard-related injuries. Autonomous-robot-based technologies can also resolve the difficulties of dangerous and hard-to-reach structural inspections, including but not limited to steep-sloped roofs, walls, and facades on the exterior, towers, and bridges, damage from complete collapse to cracks in buildings. Second, autonomous robotic approaches are relatively cost-effective and can improve production efficiency. Rather than using human resources, heavy equipment, and expensive tools, drones can achieve rapid data collection and automatic analysis with impressive accuracy in construction site surveying, monitoring, and inspection, significantly reducing project costs. Autonomous robots can also avoid the high personnel costs that repetitive works of onsite constructions require, such as concrete distribution, leveling, compaction, floor finishing, and surface painting, while leading to a higher level of productivity at the same time. Last, unmanned aerial and ground vehicles in construction using autonomous robotic technologies have been determined as ideal solutions to environmental construction problems and labor shortages. In the future construction industry, drones could be used to guide autonomous robots on the ground in safe and efficient patterns. Consequently, autonomous robots collaborating with drones on construction sites will be able to reduce fuel consumption, shorten construction schedules, and improve the safety of construction processes. In conclusion, we believe that developing autonomous robots in construction will be a trend.

4. Conclusions

As an emerging technology with great development potential, concrete construction robots are expected to realize “safer, more efficient, greener and more intelligent” construction, and the whole construction industry must take this opportunity to complete this leapfrog in development. In this paper, the technical progress of concrete construction robots and autonomous robots in concrete construction are described systematically. Meanwhile, some development suggestions are put forward from several perspectives.

This review provides a new perspective based on the basic functions during the concrete construction process, and the mechatronic system of autonomous construction robots can be developed accordingly. This new insight builds a close connection between the basic demands of highly repetitive or dangerous construction tasks and the functional structures of autonomous construction robots. We divide the existing concrete construction robots both on the market and under study into six categories: distribution robots, leveling and compaction robots, floor finishing robots, surface painting robots, 3D printing robots for additive manufacturing, and construction-used surveillance robots. The general characteristics, functions, and applications of the robots are described and compared systematically, which could guide developers to better design robots that closely match real construction needs. The mechatronic system of an intelligent construction robot is supposed to be achieved by integrating functional mechanical parts, autonomous control systems, and highly precise sensors. It is hoped that this paper will provide inspiration for future researchers to grasp the future trends of robotic research in concrete construction.

This entry is adapted from the peer-reviewed paper 10.3390/drones6120424