Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The concept of an eco-industrial park (EIP) that promotes resource sharing, reutilization of waste, and exchange of materials among industries and communities brings significant benefits in terms of environmental, social, and economic aspects.

- blockchain

- Industry 4.0

- eco-industrial park

1. Introduction

Over the years, industrial growth and urbanization have resulted in increased greenhouse gas (GHG) emissions, as seen from the efforts for emission reduction [1][2] and a dedicated study of the impact on China [2], resource consumption, and solid waste traced through studies on solid waste metabolism [3][4][5], resource consumption [4] and waste management in the European Union [5]. Industrialization can bring positive impacts through long-term economic growth [6]. Therefore, it is crucial to find strategies that can reduce the negative impacts while promoting economic growth [7]. The concept of an eco-industrial park has emerged as a solution to promote resource efficiency and integration. The term “eco-industrial park” (EIP) refers to controlled industrial regions encouraging cross-industry and community collaboration to minimize environmental impacts, reduce waste and pollution, and effectively share resources [8].

The emergence of Industry 4.0 technologies could potentially become a technological driver for the EIP concept. Industry 4.0 technologies comprise Internet of Things, cyber-physical systems, artificial intelligence, machine learning, blockchain, cloud computing, and many more. Besides the Internet of Things (IoT), blockchain is among the technologies that have received much attention recently. Blockchain technology originates from the world’s first cryptocurrency, Bitcoin, which was established in 2009 by Nakamoto [9], whose real identity remains unknown. As Bitcoin became acceptable to the public in 2017, its underlying technology suggests building trust between two unknown and unrelated parties to the point that sensitive and secure transactions can be carried out across an open network, like the internet, with complete assurance [10] has gained much interest.

The architecture of blockchain technology seems to be a potential solution to the EIP issues, as the collaboration among the communities, industrial partners, policymakers, and service provision bodies needs to be built beforehand. For the resource sharing to come afterward, the lack of trust and privacy-related issues could hinder this process. Blockchain technology promises immutability, transparency, and tamper-proof distributed ledger data recorded afterward. On the other hand, Industry 4.0 provides digitization, data exchange, and seamless communication between machines and automation technology with the utilization of the internet. The integration of these technologies can help make EIP development viable.

2. Eco-Industrial Park

This section presents the international framework of an EIP [8] together with its practitioners’ guide [11] in the development steps from a national level to an industrial level. These would serve as the main guideline for all stakeholders to develop new or convert their existing industrial park into an EIP.

2.1. Eco-Industrial Park Framework

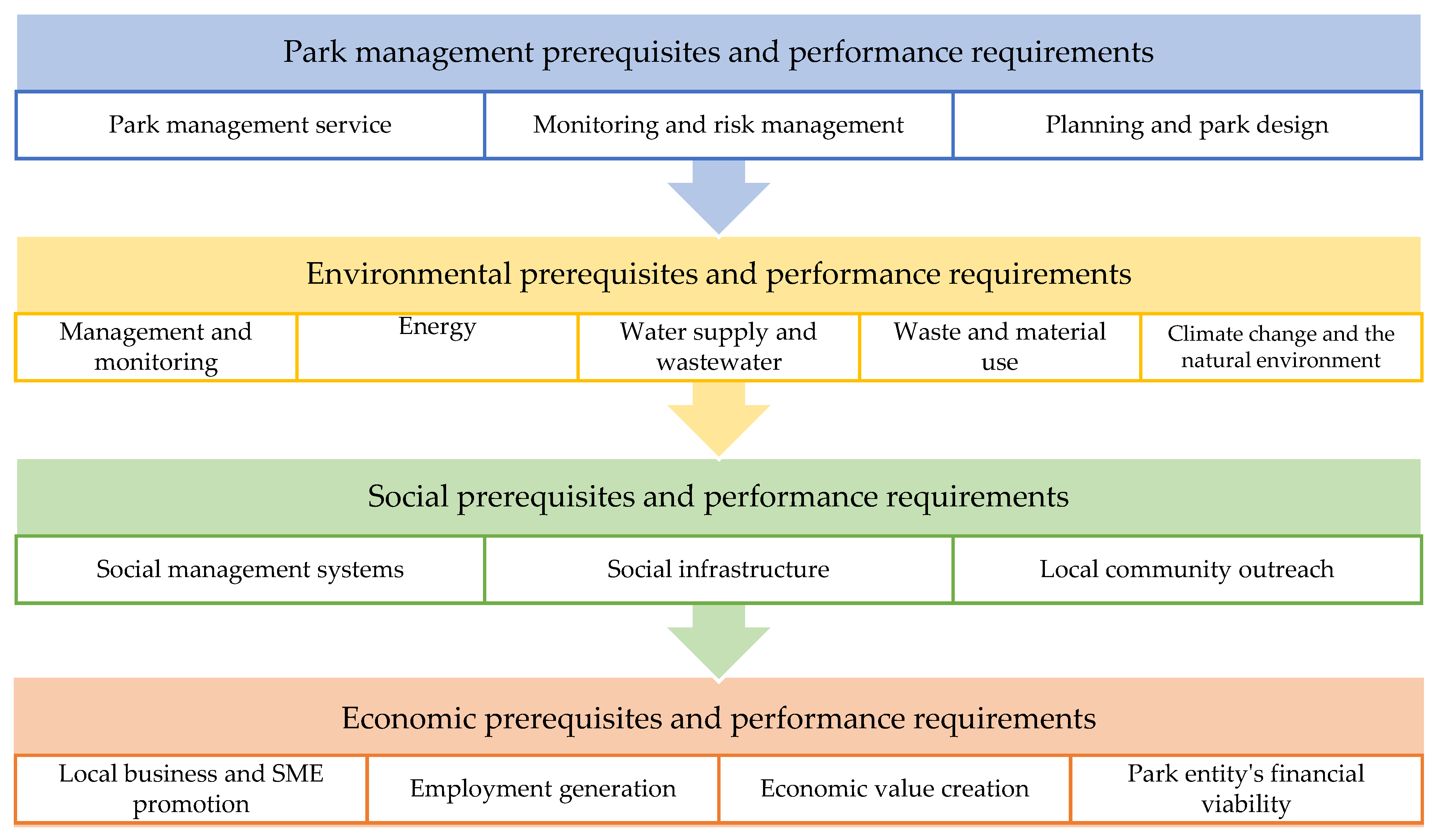

The UNIDO, in partnership with the World Bank Group and GIZ, published the first edition of the worldwide framework for EIPs in 2017, while a revised edition was published in 2021 [8]. The goal of the framework is to standardize, on a global scale, the criteria and performance levels that must be met by industrial parks for them to be designated EIPs. In addition, the organization aims to assist stakeholders in developing and transitioning to EIPs—engaging, encouraging, and consistently recognizing EIPs—and providing benchmarks to enhance the performance, sustainability, and inclusivity of the industrial sector. The framework takes an inclusive approach and creates a mutual understanding of EIPs in four key categories of prerequisite and performance requirements, as depicted in Figure 1. These categories include park management, environmental, social, and economic. The first section of the framework presents the concept, benefits, drivers of EIP implementation, and the barriers that hinder its development process. The second and third sections discuss the approach to defining performance requirements for EIPs that covers the categories mentioned previously, followed by the future prospects of the EIP.

Figure 1. Prerequisites and performance requirements of eco-industrial park.

An EIP is a managed industrial area that encourages cooperation between different sectors and communities to improve economic, social, and environmental performance. In addition, this concept has been developed to address other interrelated issues, including resource-efficient and cleaner production, industrial symbiosis, climate change, pollution, social norms, shared infrastructure, improved risk management, and shared resources like land and ecosystem services. The primary motivations of EIPs are to reduce environmental impacts, promote efficiency gains and cost-effectiveness, facilitate community cohesiveness, build resilience to many threats, increase access to financing and technical assistance, and boost competitiveness. International industry practice and experience have shown that various economic, environmental, and social benefits have emerged from the EIP. These advantages may extend beyond what is typically expected in a business case. The advantages of the EIP extend beyond monetary considerations. They also help mitigate risks associated with obtaining necessary resources and proper authorization. In addition, they boost competitiveness, advance business growth, and enhance credibility. The EIP case studies conducted by the UNIDO also highlighted several advantages, such as improved access to financing and technical assistance, as well as policy, economic, and societal benefits.

Moreover, establishing an EIP framework and strategic planning may help mitigate some of the challenges associated with its implementation. Many industrial parks have made progress toward sustainability, but only a few mature EIPs exist. As a result, park owners, operators, and businesses face various internal and external challenges, from technological limitations to poor management. An overview of some of the significant challenges for eco-industrial development, including the legislative, technological, and socioeconomic barriers and also institutional and organizational capability. These barriers urge different levels of parties to find solutions to foster the successful development of EIPs.

2.2. Development of Eco-Industrial Parks

The terms “industrial symbiosis” and “EIP” are sometimes used interchangeably when considering their advantages from an environmental, social, and economic standpoint. Industrial symbiosis is a collaborative strategy in which numerous independently operating businesses collaborate to exchange waste or by-products, energy, and water in addition to sharing resources and infrastructure, which is advantageous to all parties in terms of the environment and economy [12][13][14]. Industrial symbiosis is said to be a component of EIPs [15]. Therefore, it is not surprising that many of the current EIPs feature it. As a result, they have identical goals and encounter similar obstacles to achieving environmental, social, and economic gains.

To support the framework [8], the same organizations published a practitioner’s guide [11] and practitioner’s guide toolbox [16] that indicates step-by-step explanations and a toolbox for EIP development at different levels. The development of EIPs begins with the adoption of the international framework at the national level. It is then followed by the implementation of the framework at the industrial park level. Finally, the most crucial step is the implementation of industrial symbiosis. There is a wealth of literature that highlights the significant efforts made in the search for the finest tools, methodologies, and approaches to support the step of identifying opportunities for an industrial symbiosis network, including the review of industrial symbiosis tools [17][18][19], EIP optimization [20][21][22][23][24][25], and studies of industrial symbiosis fostering steps [26][27].

However, considering these huge efforts in developing EIPs, they demand a significant amount of collaboration and contributions from parties at all levels in such research institutions, industrial partners, policymakers, service providers, and others involved with high commitment. All the involved parties must give sufficient data. The most effective methods, technologies, and tools to find opportunities for an industrial symbiosis network need to be explored. Sufficient data should include access to a considerable quantity of supporting material. The information must include facts and specific information about the EIP members. As the EIP is home to a sizable number of organizations and businesses that collaborate closely, the data could have characteristics such as large volume, distributed storage, syntax heterogeneity, semantic heterogeneity, and privacy [15]. Lack of trust, unclear advantages, unfamiliarity with the concept of industrial symbiosis, and inadequate information exchange are some of the main issues that have been highlighted as impeding the development of the EIP [28][29][30]. Therefore, a technological approach to eliminate this constraint is urgently needed.

This entry is adapted from the peer-reviewed paper 10.3390/su15010052

References

- Dong, H.; Ohnishi, S.; Fujita, T.; Geng, Y.; Fujii, M.; Dong, L. Achieving Carbon Emission Reduction through Industrial & Urban Symbiosis: A Case of Kawasaki. Energy 2014, 64, 277–286.

- Liu, X.; Bae, J. Urbanization and Industrialization Impact of CO2 Emissions in China. J. Clean Prod. 2018, 172, 178–186.

- Guan, Y.; Huang, G.; Liu, L.; Zhai, M.; Zheng, B. Dynamic Analysis of Industrial Solid Waste Metabolism at Aggregated and Disaggregated Levels. J. Clean Prod. 2019, 221, 817–827.

- Luzi, A.; Marilungo, E.; Germani, M. Development of a Methodology to Analyze Energy and Resources Consumption along the Product Value Chain. In Proceedings of the Procedia CIRP; Elsevier: Cambridge, UK, 2015; Volume 33, pp. 145–150.

- Minelgaitė, A.; Liobikienė, G. Waste Problem in European Union and Its Influence on Waste Management Behaviours. Sci. Total Environ. 2019, 667, 86–93.

- Haraguchi, N.; Martorano, B.; Sanfilippo, M. What Factors Drive Successful Industrialization? Evidence and Implications for Developing Countries. Struct. Change Econ. Dyn. 2019, 49, 266–276.

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A Comprehensive Review of Industrial Symbiosis. J. Clean Prod. 2020, 247.

- United Nations Industrial Development Organization UNIDO; Work Bank Group. GIZ—An International Framework for Eco-Industrial Parks. Available online: https://openknowledge.worldbank.org/handle/10986/35110 (accessed on 21 October 2022).

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 30 October 2022).

- Muftic, S.; Sanchez, I. Overview and Analysis of the Concept and Applications of Virtual Currencies. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC105207 (accessed on 30 October 2022).

- United Nations Industrial Development Organization UNIDO; World Bank Group; GIZ; Ministry of Trade, Industry and Energy. A Practitioner’s Handbook for Eco-Industrial Parks. Available online: https://openknowledge.worldbank.org/handle/10986/30458 (accessed on 22 October 2022).

- Lowe, E.A.; Evans, L.K. Industrial Ecology and Industrial Ecosystems. J. Clean Prod. 1995, 3, 47–53.

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy, Annual Review of Energy and Environmen. Annu. Rev. Energy Environ. 2000, 25, 313–337.

- Schwarz, E.J.; Steininger, K.W. Implementing Nature’s Lesson: The Industrial Recycling Network Enhancing Regional Development. J. Clean Prod. 1997, 5, 47–56.

- Zhou, L.; Zhang, C.; Karimi, I.A.; Kraft, M. An Ontology Framework towards Decentralized Information Management for Eco-Industrial Parks. Comput. Chem. Eng. 2018, 118, 49–63.

- United Nations Industrial Development Organization UNIDO; World Bank Group; GIZ; Ministry of Trade, Industry and Energy. A Practitioner’s Handbook for Eco-Industrial Parks: Toolbox. Available online: https://openknowledge.worldbank.org/handle/10986/31456 (accessed on 22 October 2022).

- Kastner, C.A.; Lau, R.; Kraft, M. Quantitative Tools for Cultivating Symbiosis in Industrial Parks; a Literature Review. Appl. Energy 2015, 155, 599–612.

- Azevedo, J.; Ferreira, I.; Dias, R.; Ascenço, C.; Magalhães, B.; Henriques, J.; Iten, M.; Cunha, F. Industrial Symbiosis Implementation Potential—An Applied Assessment Tool for Companies. Sustainability 2021, 13, 1420.

- Lawal, M.; Wan Alwi, S.R.; Manan, Z.A.; Ho, W.S. Industrial Symbiosis Tools—A Review. J. Clean Prod. 2021, 280, 124327.

- Boix, M.; Montastruc, L.; Azzaro-Pantel, C.; Domenech, S. Optimization Methods Applied to the Design of Eco-Industrial Parks: A Literature Review. J. Clean Prod. 2015, 87, 303–317.

- Kuznetsova, E.; Zio, E.; Farel, R. A Methodological Framework for Eco-Industrial Park Design and Optimization. J. Clean Prod. 2016, 126, 308–324.

- Valenzuela-Venegas, G.; Vera-Hofmann, G.; Díaz-Alvarado, F.A. Design of Sustainable and Resilient Eco-Industrial Parks: Planning the Flows Integration Network through Multi-Objective Optimization. J. Clean Prod. 2020, 243, 118610.

- Misrol, M.A.; Alwi, S.R.W.; Lim, J.S.; Manan, Z.A. Multi-Objective Optimization of an Integrated Energy-Water-Waste Nexus for Eco-Industrial Park. Chem. Eng. Trans. 2021, 89, 349–354.

- Ramos, M.A.; Rocafull, M.; Boix, M.; Aussel, D.; Montastruc, L.; Domenech, S. Utility Network Optimization in Eco-Industrial Parks by a Multi-Leader Follower Game Methodology. Comput. Chem. Eng. 2018, 112, 132–153.

- Leong, Y.T.; Lee, J.Y.; Tan, R.R.; Foo, J.J.; Chew, I.M.L. Multi-Objective Optimization for Resource Network Synthesis in Eco-Industrial Parks Using an Integrated Analytic Hierarchy Process. J. Clean Prod. 2017, 143, 1268–1283.

- Jayakrishna, K.; Vibha, M.; Jain, S.; Kulatunga, A.K. Fostering Systematic Eco-Innovation in an Industrial Symbiosis Environment Using DEMATEL. Int. J. Ind. Syst. Engineering 2020, 34, 20–42.

- Jato-Espino, D.; Ruiz-Puente, C. Bringing Facilitated Industrial Symbiosis and Game Theory Together to Strengthen Waste Exchange in Industrial Parks. Sci. Total Environ. 2021, 771, 145400.

- Park, J.; Duque-Hernández, J.; Díaz-Posada, N. Facilitating Business Collaborations for Industrial Symbiosis: The Pilot Experience of the Sustainable Industrial Network Program in Colombia. Sustainability 2018, 10, 3637.

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid. J. Ind. Ecol. 2015, 19, 141–153.

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ Env. 2015, 28, 32–53.

This entry is offline, you can click here to edit this entry!