Ants are excellent architects in the animal kingdom. The activities of “design”, “material selection” and “construction” of their nests are full of magical secrets. After hundreds of millions of years of survival of the fittest, the nests of each species of ant are generally characterised by reasonable structure and good mechanical performance, and also reflect the law of “obtaining large and solid living space with the least amount of material”. The complex underground ant colony nest system is large in scale, stable in internal environmental characteristics, has excellent ventilation, appropriate humidity and temperature, and makes use of natural barriers, such as thin grasses, trees, sand and stone, around entrances and exits, as well as having good physical structure, resistant to pressure, water, heat and moisture. Ants have very strict requirements on the size, weight, lustre and colour of the building materials for the nest, such as soil particles. As social insects, ants are responsible for the site selection and materials selection of their nests, the design of the whole nest, organising and coordinating the grand construction process, and managing the nest.

1. Characteristics of Underground Ant Nest Structures

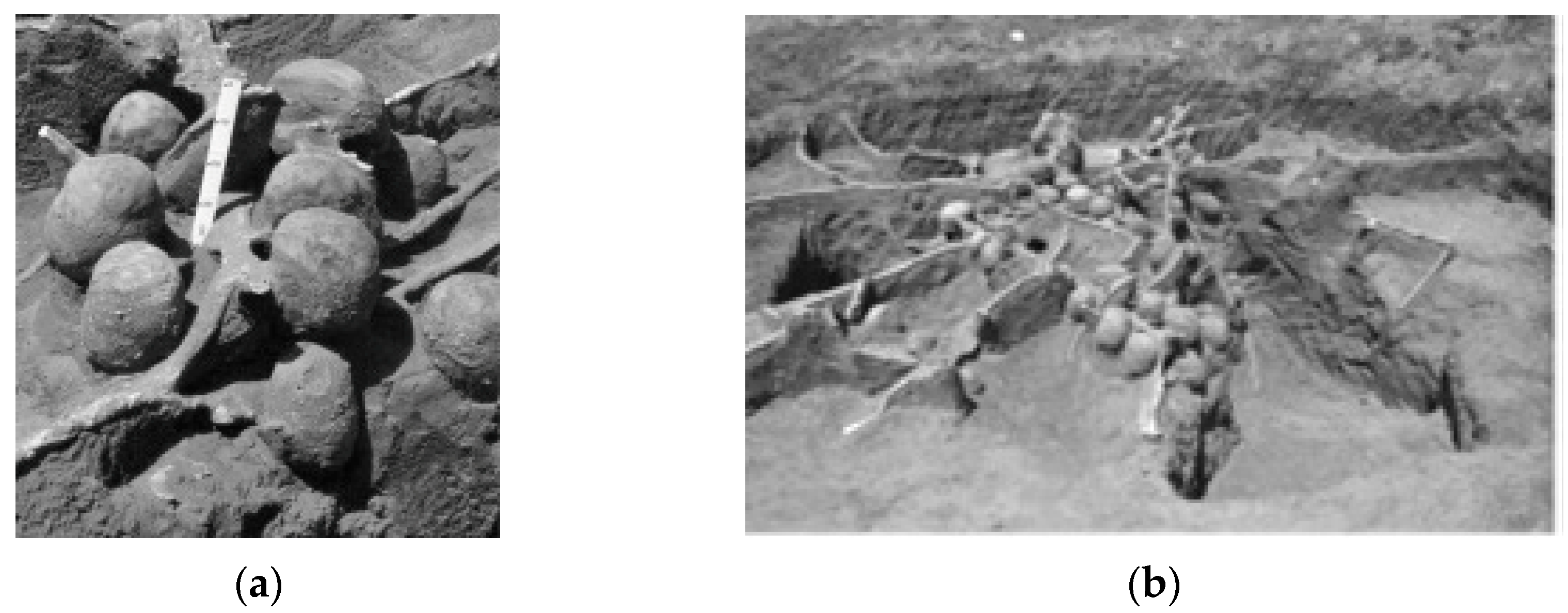

Moreira et al.

[1] studied the internal and external structure of Atta bisphaerica nests by casting them in cement at Santana Farm, Brazil, as shown in

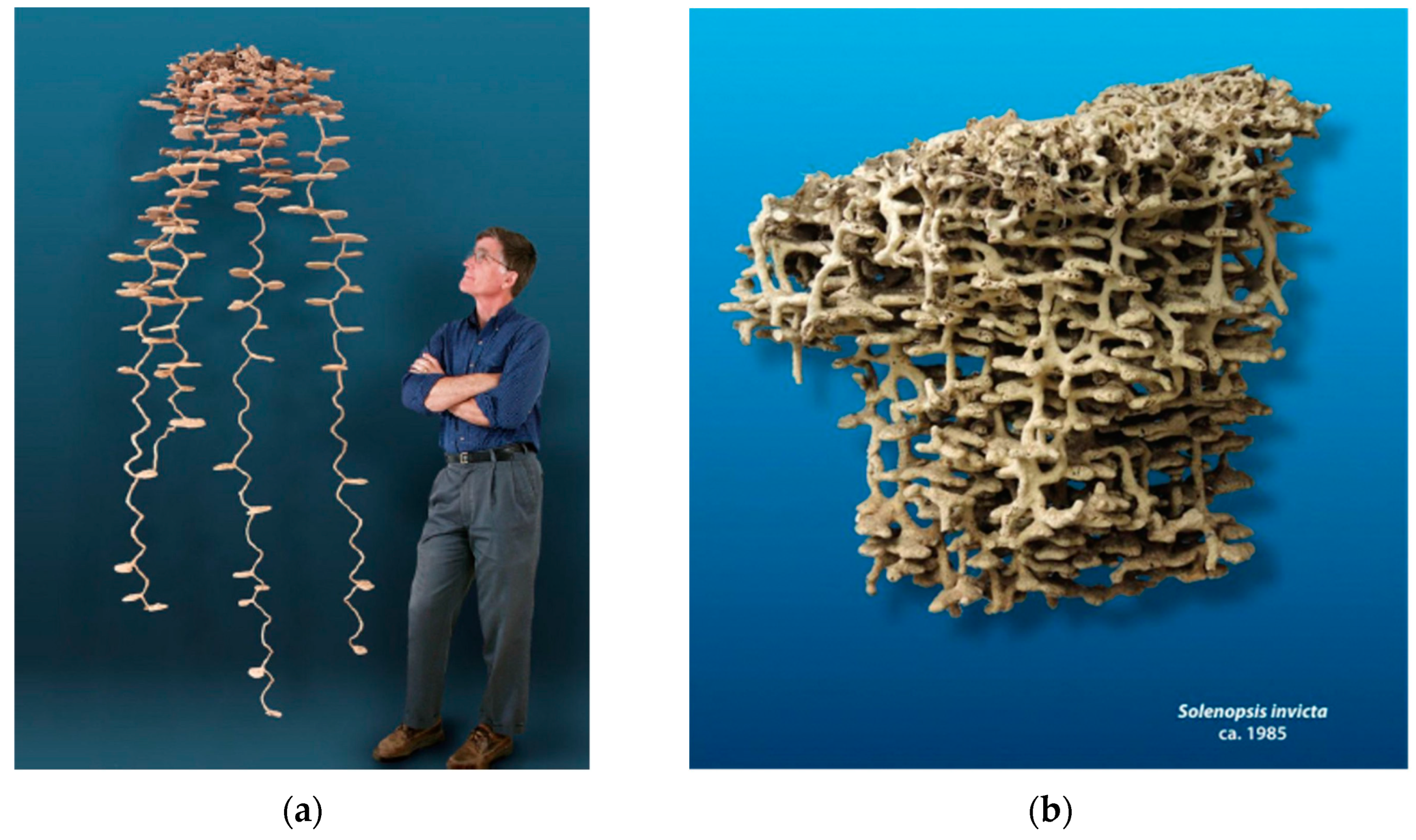

Figure 1. Based on multiple castings and/or excavations conducted by Tschinkel and Moreira et al., the generality of the nest structure was confirmed, but the total size of the nest varied greatly from one population to another, ranging from a depth of 20–30 cm to a huge underground fort extending to a depth of nearly 3.5 m (

Figure 2a). Although each species builds a nest typical of its species, some elements are identical. The most visible features are the vertical tunnels that connect greater or lesser horizontal chambers. However, the tunnels are varied; for example,

Figure 2a, shows a helical tunnel. Variations in the shape, size, quantity and positioning of the fundamental parts result in the species-typical construction of numerous nests. The majority of this variance is due to changes in elemental properties. The consequence is that the diameter of the tunnel, the horizontal perimeter, area and shape of the chambers, the distance between chambers, and so on, may all change. As shown in

Figure 2, the sum of this variation produces unique, species-typical architectures. For example, the nest of Solenopsis invicta (

Figure 2b) is more complex compared to the nest of Pogonomyrmex badius (

Figure 2a) as it consists of many units of chambers and tunnels, which are closely packed together. In addition, Rabeling et al.

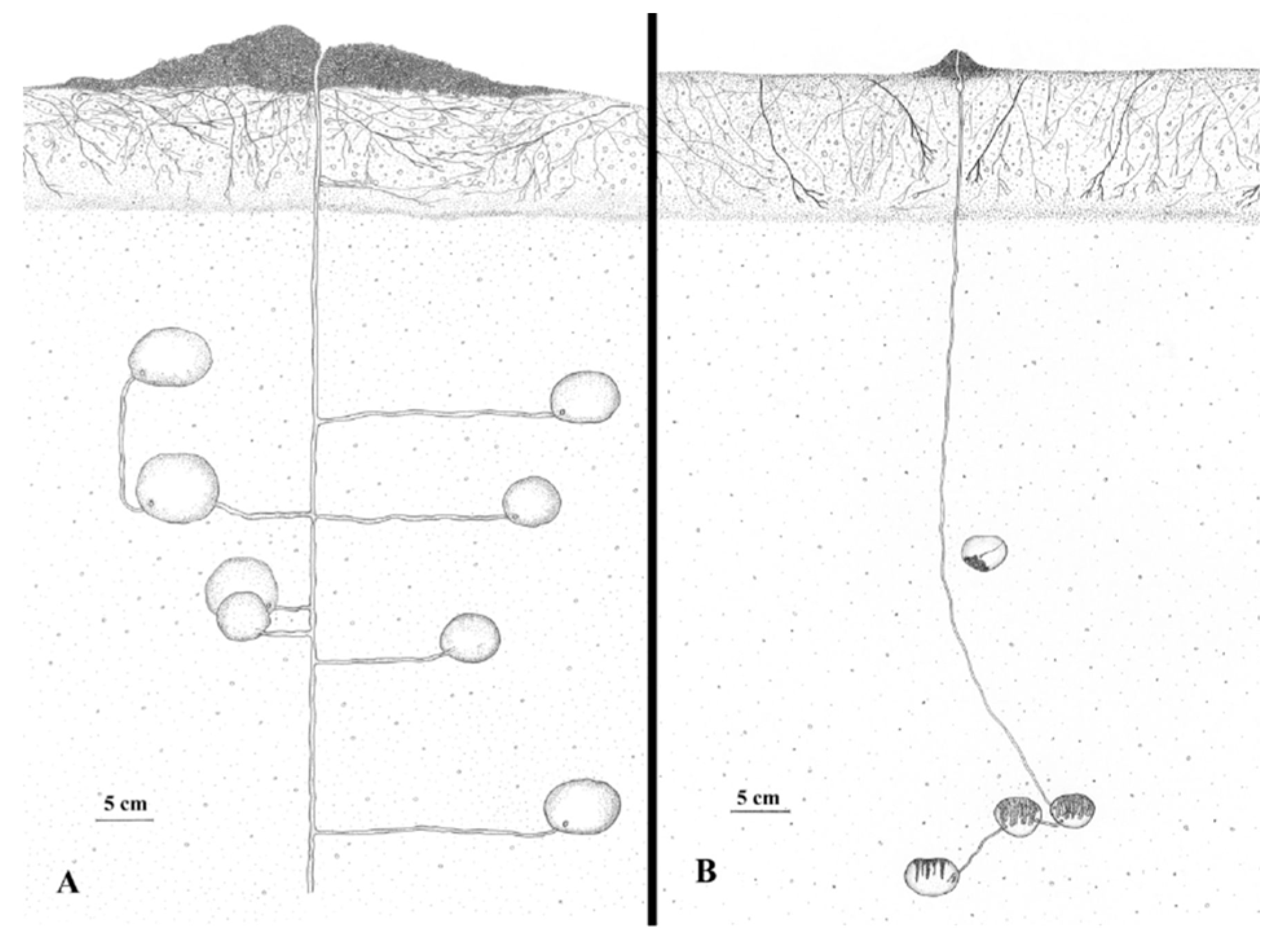

[2] studied the nest structure of the ant species Mycocepurus goeldii and Mycocepurus smithii in an agroforestry habitat near Manaus, Brazil. The two species were found to construct their nests in two distinct ways, as shown in

Figure 3. The nests of the former possessed a ‘tree-like’ structure and those of the latter displayed a ‘necklace-like’ structure. The nest systems of M. goeldii and M. smithii consisted of 1–21 or 1–15 chambers, respectively, and the nest chambers constructed by workers of M. smithii were noticeably smaller than those of M. goeldii.

Figure 1. Atta bisphaerica nest: (a) chamber and tunnel details and (b) radial distribution of foraging tunnels.

Figure 2. A plaster cast of (a) Pogonomyrmex badius nest and (b) Solenopsis invicta nest.

Figure 3. Two nest architectures found in Mycocepurus nests. (A) A Mycocepurus goeldii nest; (B) A Mycocepurus smithii nest.

An ant’s nest is built in a complex structure that contains irregular descent axes, horizontal chambers, and tunnels

[3][4]. These elongated voids contain cross sections that are round, oval, or flat oval, and their long axis is normally inclined from perpendicular by 20° to 70° (rarely 90°). They are modular structures from which new axes may extend an already existing structure

[5]. These distinctive topological traits of ant nests are also influenced by the life cycle and development of the colony. With growth of the community, nest excavation rates and final nest size rise. Ant nests are known to be built underground so that they can withstand loads accidentally imposed by other organisms on the surface or forces caused by natural events. The majority of current study on ant nest construction has concentrated on the nest’s intricacy, namely basements, shaft nodes, and tunnels

[6][7]. However, little attention has been paid to the role of structural morphology in improving the mechanical robustness of ant nest constructions. With the introduction of 3D printing (3DP) technology, academics are increasingly using it to mimic nature-inspired buildings

[8][9]. Researchers can complete the complicated building of an ant nest with great precision using 3DP technology, making it easily accessible, inexpensive, and ecologically beneficial

[10]. Since 3DP technology allows for flexibility in design, complicated structures may be easily manufactured. Topological optimisation methods, which produce the greatest results by optimising the design in the appropriate constraint space, can be used to enhance the design of complicated structures

[11]. In 2022, Kushwaha et al.

[12] investigated the mechanical robustness of 3D-printed anthill constructions, which is currently unique in the literature. The team extracted four distinct nest types using cement casting. Three-dimensional micro-computed tomography (CT) scans were used to digitise the cement structures. A finite element method (FEM) was used to simulate the digitised structures under different loading conditions. The digital architecture was 3D printed and evaluated under uniaxial loading conditions. Following that, an innovative biomimetic solution was demonstrated using a blending of computational and experimental analysis to define the structural topology and material contributions to the strength and deformation resistance of the ant nest structure. The results showed that the abnormal mechanical robustness of ant scaffolds was caused by two distinct architectural components, namely, the main spine (core) and the secondary arms, that grew for long periods of time. The primary spines of ant nests seemed to develop in a funnel-like structure from the top to the bottom, and afterwards expanded as the surface area increases. This provided the base with the typical hourglass shape. These constructions were capable of withstanding high stress levels without suffering considerable deformation and retained their original shape. The mound branches and branch structure could endure increasing stress and deformation due to volume pressure as the surface area increased, making it a sacrificial unit for major calamities like floods and earthquakes. A robust design was demonstrated by 3DP technology and FEM simulations, and, as a result, tree-trunk geometry may be used to create civil structures.

2. Internal Environmental Characteristics of Underground Ant Nest

Numerous social insect species also control the microclimate within their nests to ensure constant living circumstances that are unaffected by changes in the outside environment

[13]. Some leafcutter ant nests exhibit a similar phenomenon, controlling the oxygen/carbon dioxide balance by passive air movement. Kleineidam et al.

[14] studied the mechanisms driving nest ventilation in a nest of Atta vollenweideri. Their research found that wind-induced nest ventilation, which drew air from central entrances, was extremely effective during the summer. However, in the fall, A. vollenweideri colonies shut the majority (approximately 90%) of the nest openings, reducing wind-induced nest ventilation. Bollazzi et al. demonstrated that leafcutter ant colonies, of several Acromyrmex species, built thatch nests at temperatures that were more stable than ambient temperatures, just like many other ants that lived in temperate climates. By changing thatch structures, such as by lowering thatch thickness or penetrating the thatch with apertures to enable heat exchange with the external world, workers could balance temporary variations in nest microclimate

[15]. In addition, Bollazzi indicated that workers of Acromyrmex Heyeri created more openings in the thatch of the nest at higher temperatures in the range of 20–30 °C. When the air around the nest was dried at a constant temperature during the experiment, worker ants were observed to open holes. This suggested that A. Heyeri’s workers exchanged responses related to thermoregulation in order to maintain humidity in the internal nest

[16]. To keep the nest close to its ideal developmental temperature, worker ants of many ant species that dig their nests into the earth periodically shifted the nests away from, or toward, the surface when the surface warmed up or cooled down

[17][18].

3. Ventilation Analysis of the Ant Nest

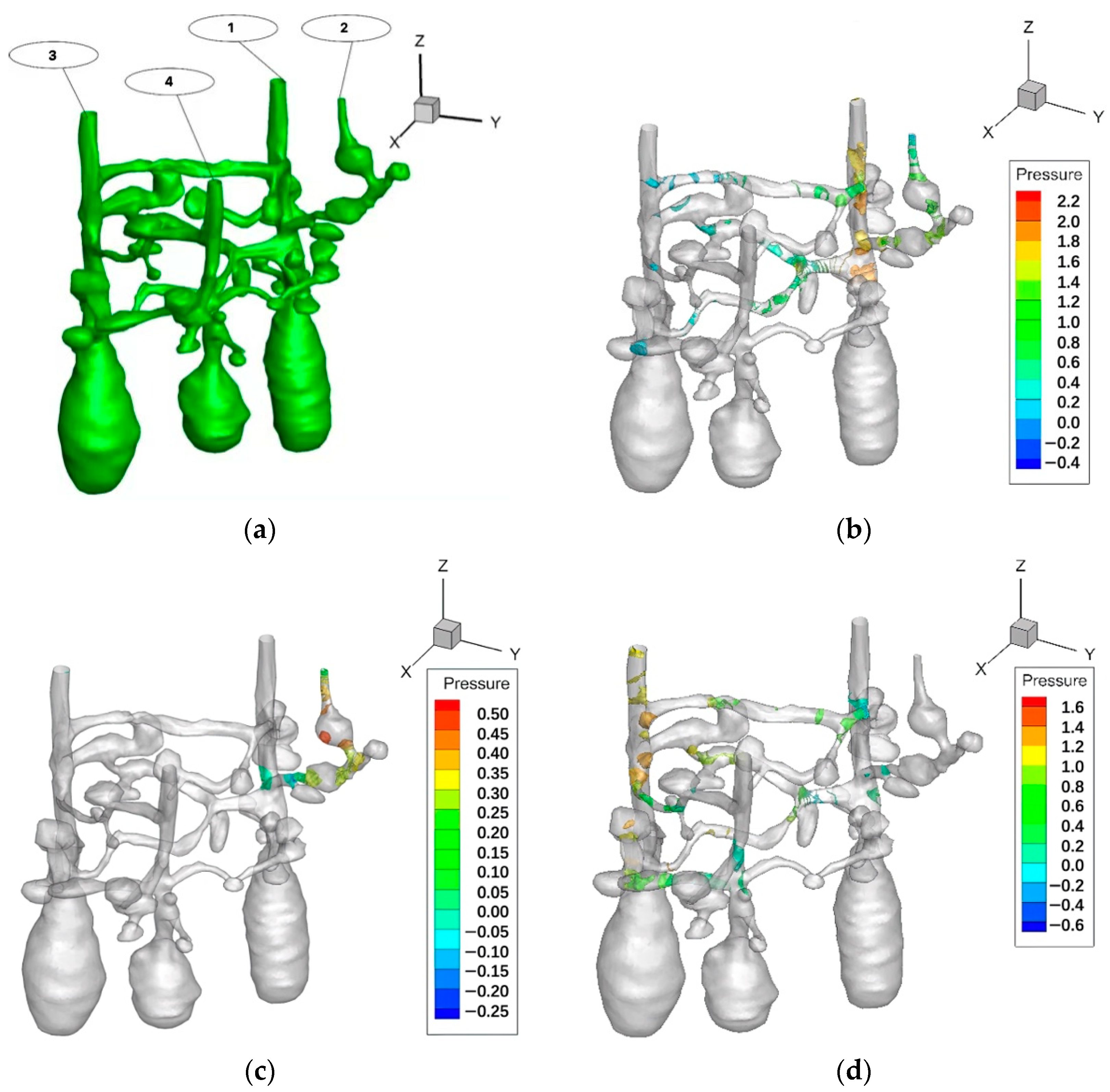

Subterranean nests of Iridomyrmex anceps were collected from different collection sites, manually cut and exposed to frozen computer numerical control (CNC) milling of the nests in the laboratory, and, then, 2D and 3D digital structural models of the nests of Iridomyrmex anceps were established (Figure 4a). Ventilation simulations of the underground nest structure were carried out using finite element analysis software (FLUENT) and the ventilation characteristics of the nest were discussed. The results revealed that the ventilation environment inside the underground nest was stable and the airflow from outside had little effect on the life of ants inside the nest. The simulation assumed that the air inside the nest was not exchanged with the surrounding soil and that air could only be circulated within the nest, with air entering through one entrance and exiting through other exits.

Figure 4. (a) 3D model of ant nest structure with inlets 1, 2, 3 and 4; pressure distribution inside the underground ant nest using (b) inlet 1, (c) inlet 2 and (d) inlet 3 as a fluid inlet, respectively.

When inlet 1 was used as the fluid inlet, the pressure distribution inside the underground nest is shown in Figure 4b. It can be seen that after the air entered inlet 1, it mainly flowed out through inlet 2 and inlet 3, which were adjacent to inlet 1. Inlet 4 was arranged diagonally with inlet 1 and was far away, and the air basically did not flow out from inlet 4. After entering the interior of the nest through inlet 1, the air flowed mainly in the first and second layers of the nest structure and did not go deeper into the third layer of the queen chamber, and the air flowed out through the upper channels.

When inlet 2 was used as the fluid inlet, the pressure distribution inside the underground nest is shown in Figure 4c. It can be seen that, due to the small geometry of inlet 2, the air entering through inlet 2 flowed mainly to inlet 1, which was closer, and out of inlet 1, without flowing to inlets 3 and 4, which were farther away. The air flow was mainly concentrated in the first nest chamber and channel connected to inlet 1 and inlet 2, and the air did not flow to the second and third nest chambers and channels, which were farther away from the surface.

When inlet 3 was used as the fluid inlet, the pressure distribution inside the subterranean nest is shown in Figure 4d. It can be seen that the gas flowing through inlet 3 mainly flowed out of inlet 1 and inlet 4 and not out of inlet 2, as inlet 1 and inlet 4 were adjacent to inlet 3. The gas flow was mainly concentrated in the nest chambers and channels of the first and second layers, which were closer to the ground, and the gas did not flow to the deeper third layer of the structure.

The above analysis showed that when gas entered the underground colony nest from any entrance or exit, the internal gas flow mainly concentrated in the first and the second layer of nest chambers and channels which were closer to the ground, and the gas did not flow to the deeper third layer of the structure. Gases flowing in from one of the entrances and exits of the nest would preferentially flow out through the entrance and exit closer to it. When there was no exchange of air between the interior of the nest and the surrounding soil, natural winds and other gases generally did not reach the third level of the structure, the queen’s chamber.

4. Morphological Bionics of Underground Ant Nest Structures

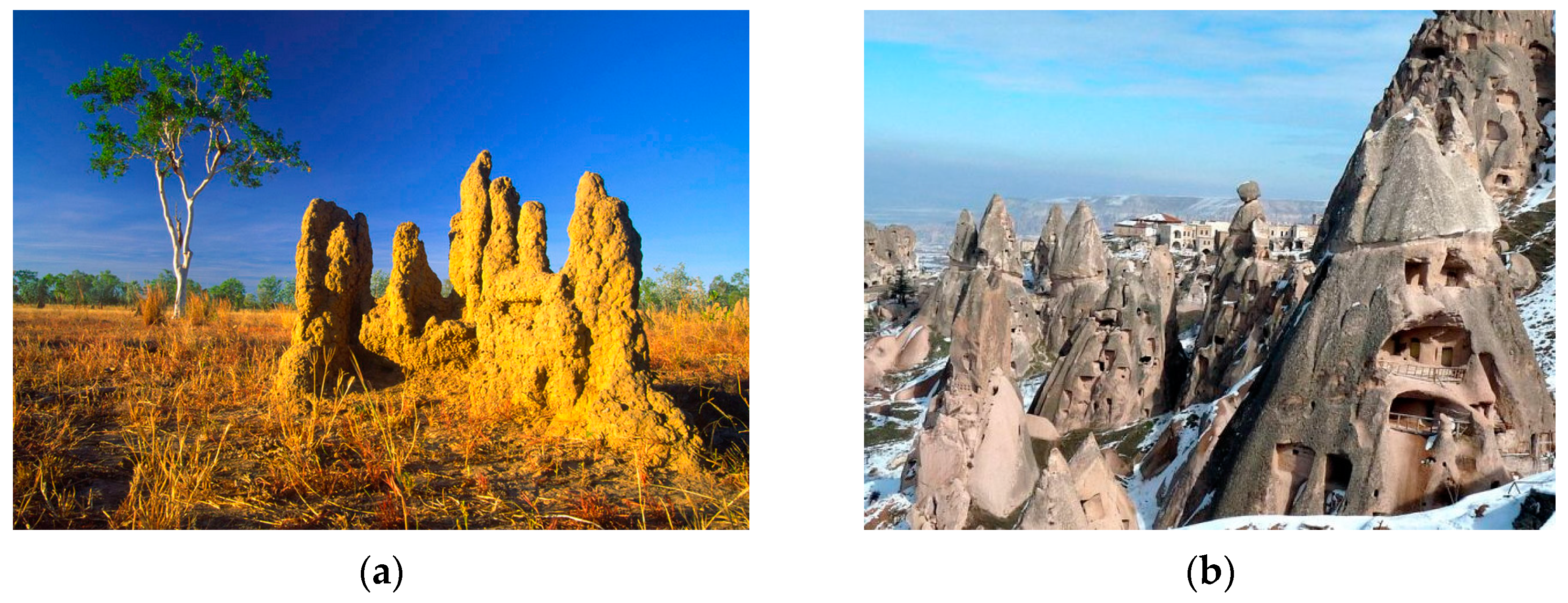

In terms of morphological bionics, the underground city of Cappadocia in Turkey is a masterpiece of ant nest bionics. With churches, schools, warehouses, breweries, kitchens, wells, toilets and other amenities, each Cappadocian underground city is like an underground network of anthills that could house and provide for thousands or even tens of thousands of people for long periods of time. Two of the largest underground cities are found in Cappadocia, the Derinkuyu and the Kaymakli, which is a much smaller city than the Derinkuyu. There were eight levels of underground caves, with bedrooms, kitchens, dining rooms, wineries, stables, churches, schools and a water reservoir at the bottom of each level. From the ground level to the bottom, many ventilation holes were excavated so that the air could circulate smoothly through the underground city, even when descending to the lowest level, without any auxiliary air supply. There were not only stone staircases, but also shafts and secret passages between the various levels, and the surface exits were covered by houses and mountains, and there was even a secret passage dug between the underground city of Kaymakli and the Derinkuyu, which is ten kilometres away (Figure 5).

Figure 5. Comparison of the morphology of (a) the anthill and (b) the rock house in Cappadocia, Turkey.

5. Functional Bionics of Underground Ant Nest Structures

Through an in-depth study of underground ant nests, it was found that ant nests have obvious characteristics and advantages in terms of environmental functions, such as constant temperature, moisture retention and ventilation, which are worth studying and exploring in depth.

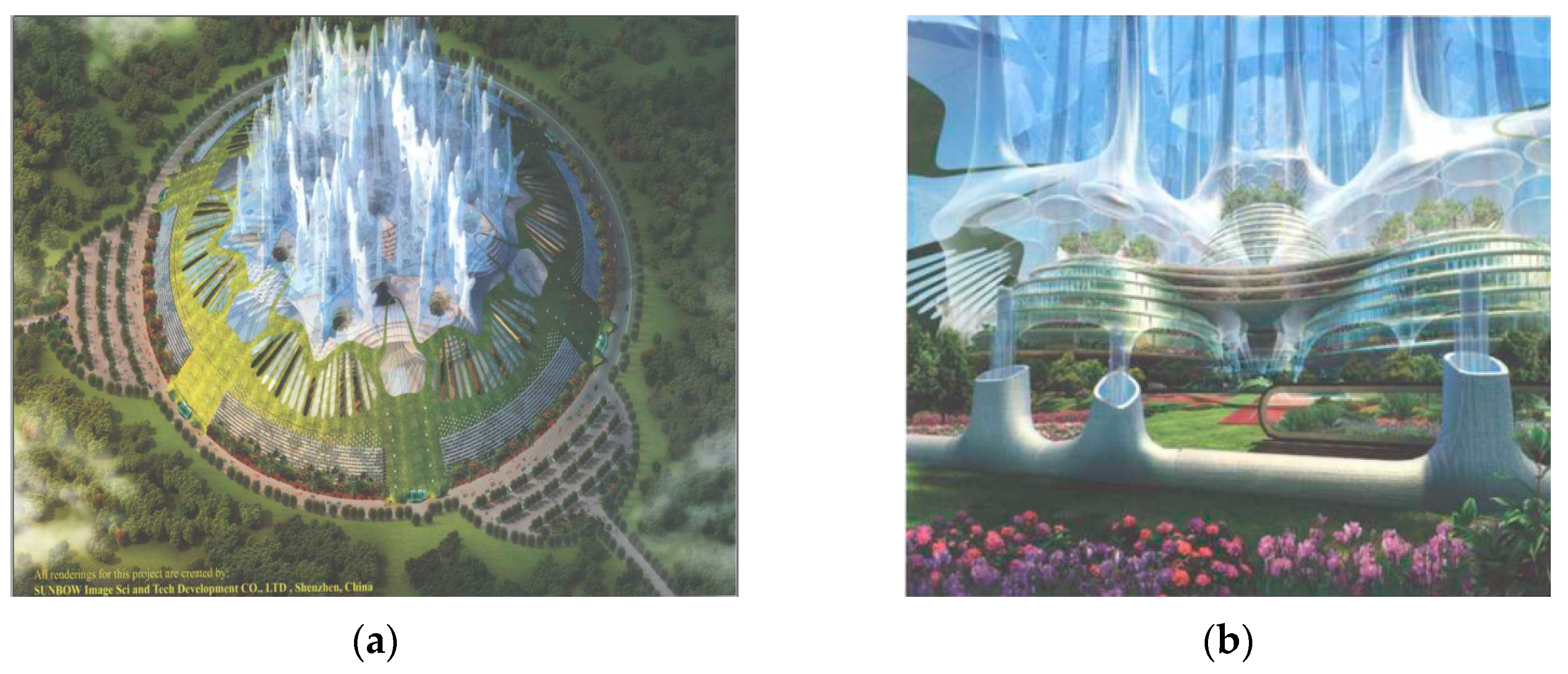

The concept of the Global Health Centre (as shown in

Figure 6), developed by the State Key Laboratory of Subtropical Building Science at the South China University of Technology in Guangzhou, China, aimed to mimic an underground ant colony nest in building a cave environment that is well insulated, hydrated and ventilated. With a diameter of 500 metres and a height of 120 metres, the cave is an apartment complex for 2000 people. The building’s temperature is maintained at 18 to 22 °C all year round, based on the principle of the passive water-cooling design of an ant nest. Ants dig deeper into the underground, creating linear shafts that become the water table at the source of the underground, often forming an aquifer where the pressure of the groundwater from the aquifer collects water in the burrows dug by the ants. These water-storage burrows then become a source of cooling for the whole nest, with cool air rising when it encounters the warm bodies of the ants and other warmer nests. A series of concentric circular walls suspended from the ceiling inside the room act as cooling heat sinks, able to collect moist air and concentrate it into cooler air. In this way, the heat generated inside is allowed to rise and escape through the ventilation chimney at the top of the nest

[19].

Figure 6. (a,b) Global Health Centre in Guangzhou.

This entry is adapted from the peer-reviewed paper 10.3390/buildings12122225