Mining sector is an economic foundation and the main source of national wealth for many countries. Modern mining operations are ever more reliant on efficient usage of costly large-scale mining equipment (e.g., trucks, shovels/excavators/loaders, conveyors and crushers). Thus, mining equipment management is becoming crucial for the mining industry. To be viable and sustainable, mining enterprises need to operate different types of mining equipment units at various stages with the objective of minimizing the total cost or maximizing the whole productivity.

- open-pit mining

- mining equipment management

- shovel–truck

1. Introduction

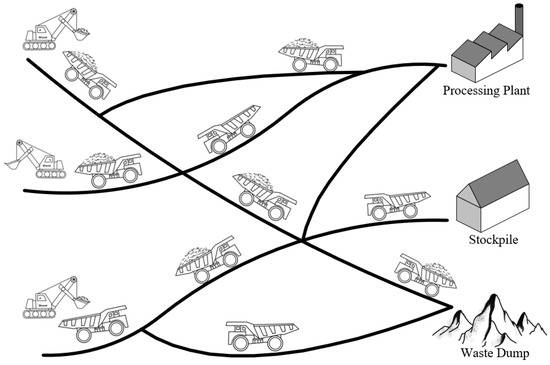

2. Shovel–Truck (ST) System

| Authors | Year | Country | Problem Types | Solution Techniques |

|---|---|---|---|---|

| Young and Rogers | 2022 | USA | Mine haul truck dumping process simulation | A high-fidelity modelling method |

| Liu et al. | 2022 | China | Mine excavators timetabling | Mixed integer programming and metaheuristics |

| de Carvalho and Dimitrakopoulos | 2021 | Canada | Integrated truck-dispatching and production | Reinforcement learning |

| Upadhyay et al. | 2021 | Canada | Production scheduling with shovel allocation | Mixed integer programming |

| Aguayo et al. | 2021 | Chile | Productivity and safety of shovel–truck system | Interaction analysis |

| Elijah et al. | 2021 | Kenya | Shovel–truck haulage optimisation | Queuing theory |

| Wang et al. | 2021 | China | Mine truck fuel consumption analysis | Regression analysis |

| Bakhtavar and Mahmoudi | 2020 | Iran | Shovel–truck allocation | Scenario-based robust optimisation |

| Basiri et al. | 2020 | Iran | Reliability assessment of shovel–truck system | Statistical methods |

| Zhang et al. | 2020 | China | Multi-objective unmanned truck scheduling | Improved genetic algorithms (NSGA-II) |

| Kansake and Frimpong | 2020 | USA | Estimate tire dynamic forces on haul roads | An analytical model |

| Shah and Rehman | 2020 | Pakistan | Shovel–truck allocation problem | Mixed integer programming |

| Ozdemir and Kumral | 2019 | Canada | A two-stage shove-truck dispatching system | A simulation-based optimisation approach |

| Dabbagh and Bagherpour | 2019 | Iran | Matching factor of shovel–truck system | Ant colony optimisation |

| Liu and Chai | 2019 | China | Routing optimisation of open-pit trucks | Mixed integer programming |

| Moniri-Morad et al. | 2019 | Iran | Capacity analysis of shovel–truck system | Discrete event simulation |

| Sun et al. | 2018 | China | Prediction of travel times of trucks | Machine learning techniques |

| Baek and Choi | 2017 | Korea | Design of a haul road for an open-pit mine | Douglas–Peucker algorithm |

| Dindarloo and Siami-Irdemoosa | 2017 | USA | Classification and clustering of shovels failures | Data mining techniques |

| Patterson, Kozan and Hyland | 2017 | Australia | Energy efficient shovel–truck scheduling | Mixed integer programming and metaheuristics |

| Bajany et al. | 2017 | South Africa | Shove-truck dispatching | Mixed integer programming |

| Burt et al. | 2016 | Australia | Mining equipment selection | Mixed integer programming |

| Chang et al. | 2015 | China | Open-pit truck scheduling | Mixed integer programming |

| Dindarloo et al. | 2015 | USA | Truck and shovel selection and sizing | Stochastic simulation |

| Rodrigo et al. | 2013 | France | Dynamic open-pit mine truck allocation | Simulation-and-optimisation framework |

| Choi and Nieto | 2011 | Korea | Haulage routing optimisation of mining trucks | Least-cost path algorithm with Google Earth |

| Souza et al. | 2010 | Brazil | Dynamic truck allocation in open-pit mining | Hybrid metaheuristic algorithms |

| Topal and Ramazan | 2010 | Australia | Mine equipment maintenance scheduling | Mixed integer programming |

| Choi et al. | 2009 | Korea | Haulage routing optimisation of mining trucks | Multi-criteria least-cost path analysis |

| Ercelebi and Bascetin | 2009 | Türkiye | Shovel–truck dispatching | Linear programming and queuing theory |

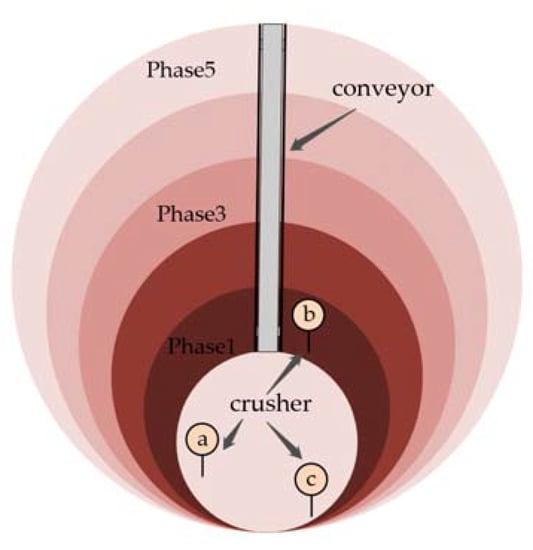

3. In-Pit Crushing–Conveying (IPCC) System

| Authors | Year | Country | Problem Types | Solution Techniques |

|---|---|---|---|---|

| Gu et al. | 2021 | China | Layout optimisation of IPCC | Particle swarm optimisation algorithms |

| Liu and Pourrahimian | 2021 | Canada | IPCC production scheduling | Mixed integer programming |

| Shamsi and Nehring | 2021 | Australia | Optimal transition point between IPCC and ST | Analysis of cumulative discounted costs |

| Wachira et al. | 2021 | Kenya | Performance analysis of SMIPCC | Mine productivity index |

| Paricheh and Osanloo | 2020 | Iran | IPCC planning with OPMPS | Mixed integer programming |

| Samavati et al. | 2020 | Australia | IPCC production planning and scheduling | Integer non-linear programming |

| Hay et al. | 2020 | Australia | Ultimate pit limit determination for SMIPCC | Block model and network flow algorithm |

| Yakovlev et al. | 2020 | Russia | Flow diagrams of IPCC | Cyclical-and-continuous method |

| Abbaspour et al. | 2019 | Germany | Optimum location and relocation of SMIPCC | Transportation problem and scenarios analysis |

| Paricheh et al. | 2018 | Iran | IPCC location and timing problem | A heuristic approach |

| Paricheh et al. | 2017 | Iran | IPCC location problem | Mixed integer programming |

| Yarmuch et al. | 2017 | Chile | IPCC location evaluation | Markov chains |

| Schools | 2015 | USA | Condition monitoring of IPCC | Condition monitoring technology analysis |

| Roumpos et al. | 2014 | Greece | Optimal location and distribution point of IPCC | Simulation modelling |

4. Hybrid IPCC-ST System

Despite the rising trends in using the IPCC system, some mining companies are still hesitating to use IPCC in their mining operations due to reliability and flexibility concerns. To improve mining reliability and reduce unexpected risks, a more flexible framework is needed to make proper transition decisions between IPCC and ST systems to satisfy the location and relocation of the semi-mobile crusher.

Table 3 concludes the main characteristics of papers on the hybrid IPCC-ST system, which contains various mining equipment types such as trucks, shovels/excavators/loaders, conveyors, and crushers. As shown in Table 3, some insightful findings are presented. First, from the perspective of problem types, evaluation factors involved on the hybrid IPCC-ST system focused on the evaluation criteria with the consideration of environmental, social, economic, reliability and safety factors. Environmental factors include greenhouse gas, harmful gas, particular substance, and waste dumps. Efficiency factors mainly concern fuel consumption of each equipment and energy efficiency of the whole mining system. Social factors contain employment rates and salary levels. Economic factors are generally related to purchasing, renting, operating and maintenance costs. Safety issues refer to the reliability, failure rates of equipment and security of personnel. As the emphasis was placed on the performance evaluation, most papers tended to evaluate the economic value, production efficiency and environmental protection of the hybrid IPCC-ST system; but occasionally consider the system robustness, safety issues, economic factors and social indicators. Second, the majority of solution techniques for system performance evaluation are based on the multi-criteria decision-making methods. Third, due to its intrinsic complexity, the planning and scheduling optimisation methodology for the hybrid IPCC-ST system is scarce in the current literature.

| Authors | Year | Country | Problem Types | Solution Techniques |

|---|---|---|---|---|

| Patyk and Bodziony | 2022 | Poland | Equipment selection in a surface mine | Multi-criteria decision-making methods |

| Chinnasamy et al. | 2022 | India | Introduction of ELECTRE for MCDM | fuzzy DS-ELECTRE |

| Shamsi et al. | 2022 | Canada | Production scheduling optimisation of hybrid IPCC-ST | Mixed integer programming |

| Krysa, Bodziony and Patyk | 2021 | Poland | Raw materials transportation | Discrete simulation |

| Kaźmierczak and Górniak-Zimr | 2021 | Poland | Accessibility of non-metallic mineral deposits | Evaluation and classification |

| Purhamadani et al. | 2021 | Iran | Energy consumption of IPCC-ST | Data analysis |

| Bernardi et al. | 2020 | Canada | Comparison of fixed and mobile IPCCs and ST | Discrete event simulation |

| Kawalec et al. | 2020 | Poland | Transition and replacement between IPCC and ST | Data analysis |

| Almeida et al. | 2019 | Brazil | ST system versus IPCC system | Environmental and economic comparison |

| Ghasvareh et al. | 2019 | Iran | Haulage system selection in open-pit mining | Multi-criteria decision-making methods |

| Nunes et al. | 2019 | Canada | Comparison analysis of SMIPCC and ST | Multi-criteria decision-making methods |

| Abbaspour et al. | 2018 | Germany | Selection analysis of ST and IPCC | Evaluation of safety and social indexes |

| Nehring et al. | 2018 | Australia | Strategic mine planning for ST and IPCC | Mine planning and evaluation |

| Özfirat et al. | 2018 | Türkiye | Selection of coal transportation mode | Fuzzy analytic hierarchy process |

| Rahimdel and Bagherpour | 2018 | Iran | Selection analysis of ST and IPCC | Multi-criteria decision-making methods |

| de Werk et al. | 2018 | Canada | Cost analysis of material handling systems | A Monte Carlo simulation |

| Braun et al. | 2017 | Germany | Sustainable technology diffusion of ST and IPCC | Data analysis |

| Patterson, Kozan and Hyland | 2016 | Australia | Integrated open-pit coal mining system | Mixed integer programming |

| Yakovlev et al. | 2016 | Russia | Conveyor-and-truck haulage system evaluation | A cyclical-and-continuous method |

| Liu et al. | 2015 | China | Energy consumption and carbon emissions of IPCC-ST | Power consumption calculation model |

| Rahmanpour et al. | 2014 | Iran | Comparison analysis of IPCC and ST | Analytic hierarchy process |

| Norgate and Haque | 2013 | Australia | Greenhouse gas impact of IPCC and ore-sorting | A life-cycle assessment method |

| Vujić et al. | 2013 | Serbia | Equipment Selection of Excavator–Conveyors–Spreader | Multi-criteria decision-making methods |

| Abedi et al. | 2012 | Iran | Analysis of mineral prospectivity mapping | ELECTRE III method |

| Bazzazi et al. | 2011 | Iran | Equipment selection of IPCC-ST | Fuzzy multiple-attribute decision making |

| Owusu-Mensah and Musingwini | 2011 | Ghana | Evaluation of ore transport options | Multi-criteria decision-making methods |

This entry is adapted from the peer-reviewed paper 10.3390/mining2040043