Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Sandwich structures are a class of multifunctional high-performance structural composites that have the advantages of being lightweight, of a high strength-to-weight ratio, and of high specific energy absorption capabilities.

- multifunctional composites

- sandwich structures

- mechanical properties

1. Introduction

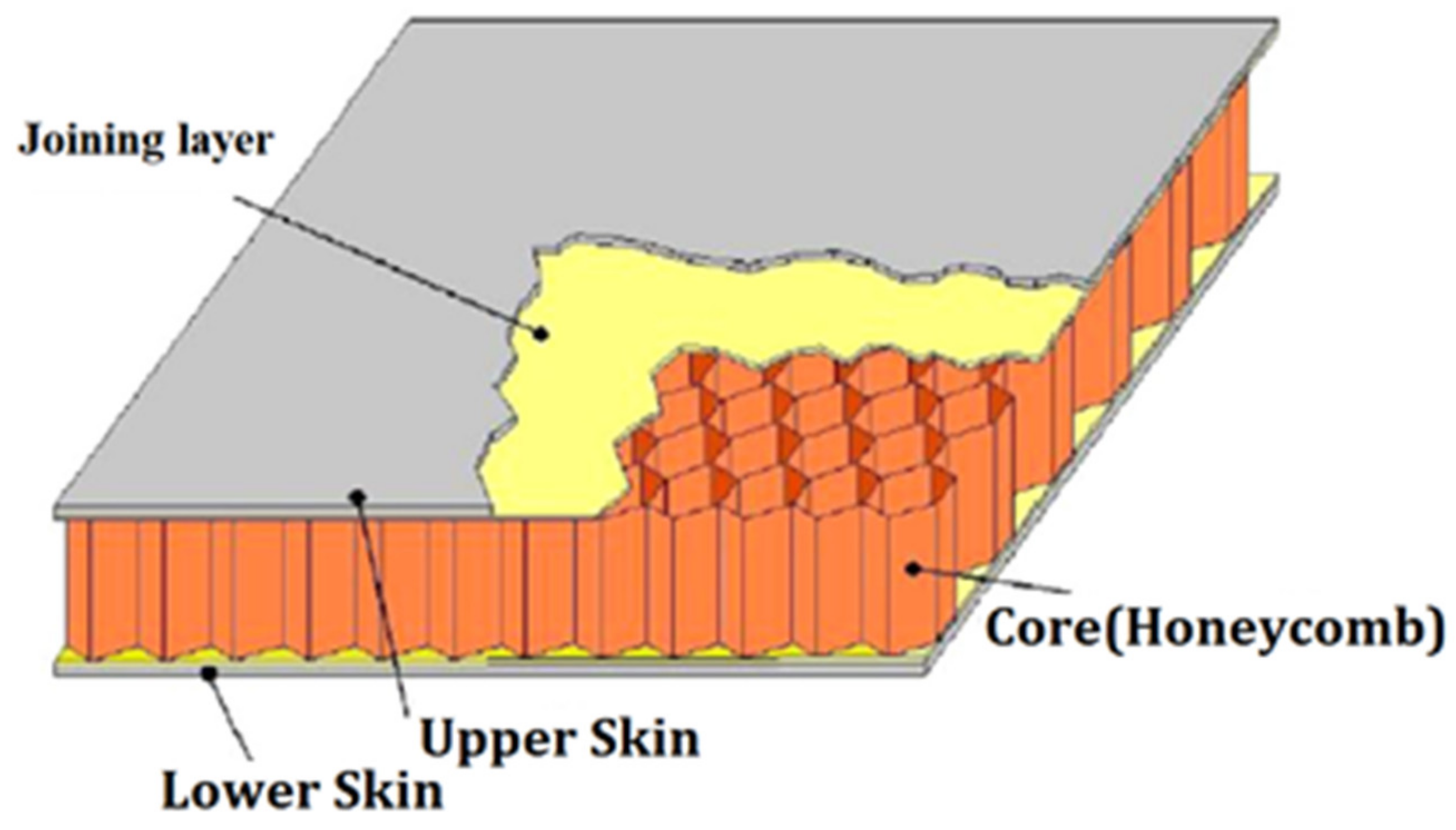

Composites have many advantages over conventional virgin materials, such as steel and aluminum, as these provide weight reduction, fuel saving, high specific strength and stiffness, increased stability, and corrosion resistance. Due to these advantages, the use of composites is growing in areas such as aircrafts, high speed trains, space crafts, as well as the automotive, marine, and building industries [1][2]. Although various types of composites are available, sandwich structures have attracted much interest in recent years due to their unique properties, i.e., high bending resistance, high stiffness, light weight, and shock absorption capability [3]. Sandwich structure is a special form of a laminated composite formed by two stiff facings at the top and bottom (e.g., alloys of aluminum, fiber-reinforced polymer (FRP) composites and epoxy/carbon composites, etc.) along with a lightweight core (e.g., honeycomb, truss, and foam, etc.). Both the face sheet and the core were bonded by a suitable joining technique. The schematic representation of a typical sandwich beam is shown in Figure 1 [4]:

Figure 1. Typical sandwich structure [4].

The unique advantages of sandwich structures are that they have an improved energy absorption ability, excellent ballistic resistance, and extraordinary thermal and noise isolation properties. These advantages of sandwich structures led to a wide scope of engineering applications, such as in the marine, automotive, aeronautical, and aviation industries. The first use of a sandwich composite was reported during World War II on a “Mosquito” and a “Vampire” aircraft, wherein end-grain balsa was used as the core and plywood as the skin [5]. The Korean Tilting Train eXpress body is made by sandwich structure elements consisting of carbon fabric/epoxy prepreg face sheets and an aluminum honeycomb core, which reduces the weight of the car’s upper body by 39%, while also reducing external sound, lowering wheel–rail forces, reducing ground vibrations, and enhancing weight reduction [6]. For their space shuttle orbiter, NASA uses graphite/epoxy honeycomb sandwich composites due to their low density, their minimum thermal expansion, and their higher modulus of elasticity [7]. Modern swift racing boats use honeycomb core sandwich structures in places such as decks and sax boards, aiming to furnish extra stiffness and reduce the overall weight [8]. The loudspeakers diaphragms consist of a honeycomb sandwich disk to provide a wider frequency range [9]. The smart slab technique adopted the honeycomb sandwich pixel LED so that displays can be integrated into the architecture [10]. For its car body chassis, Ferrari F50 has used carbon/epoxy face sheets (skin) embedded on Nomex honeycomb core sandwich constructions [11]. Al-Bahar Towers, Abu Dhabi, uses honeycomb structures, which open and close relative to the sun’s movement, which helps to reduce the gain by about 50% without compromising the effective transfer of natural light inside the tower [12]. It is observed that composite sandwich structures are adopted in multifarious areas.

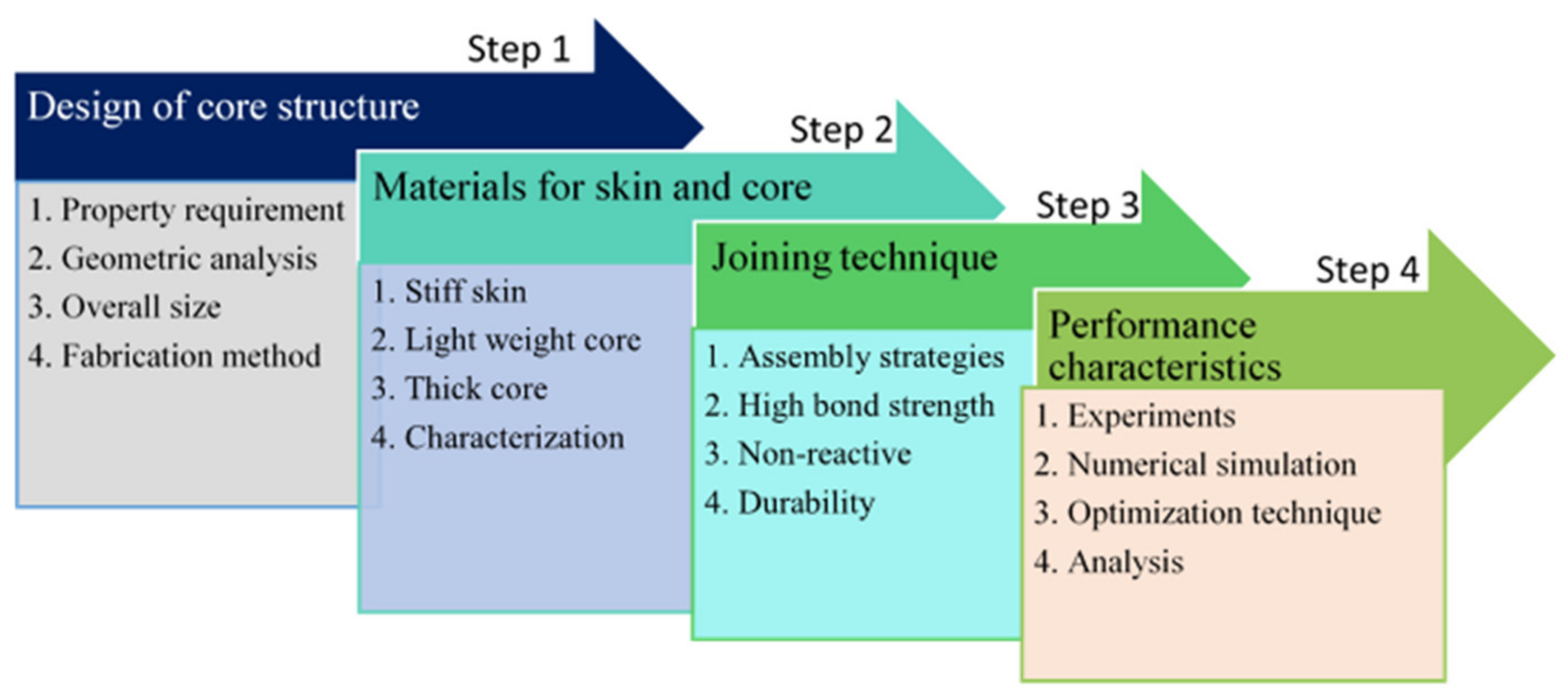

The performance sandwich structures were first influenced by the topological design. Secondly, by the choice material and its processing method. Thirdly, by the technique that the joining method adopted to fabricate the sandwich beam. Figure 2 shows insight into the detailed procedure for the development of an advanced composite sandwich structure. The novelty of the present work lies in the thorough research on the different creative core structures, their material, their composite skin (face sheet) materials, and their joining techniques. Researchers also focused on different testing techniques and methods to assess the performance of the advanced sandwich composite structures and the challenges thereof. The advancement in the development of new designs, materials, and fabrication techniques upgraded the sandwich structure by executing cell topology planning and optimization techniques. Considering the exhaustive picture of sandwich structure for various applications, an extensive review was carried out in the current investigation.

Figure 2. Steps to achieve advanced sandwich structure with extraordinary performance.

2. Design of Core Structure

The core is the centrally positioned layer of a sandwich structure. The prime requirement of the core layer is to augment the thickness of the sandwich structure without up surging the overall weight. The core provides compressive and shear strength in the sandwich structure [13]. The core design is the initial step for the creation of the sandwich structure. There are several types of cores which are broadly classified into traditional and innovative cores. Examples of traditional cores are honeycomb, foam, corrugated, and truss cores, etc. The innovative cores are derivate, hybrid, hollow, hierarchical, graded, folded, and smart cores, etc. [14]. Figure 3 shows the summarized view of different types of sandwich structures based on the types of cores. Moreover, the different types of cores are discussed in detail in the subsequent sections.

Figure 3. Types of cores.

2.1. Traditional Core Structure

The traditional core can be broadly divided into two categories: homogeneous and non-homogeneous support of the skin. The homogeneous support cores are foam/cellular cores, whereas the non-homogeneous support cores are textile/pin/truss/pyramidal, corrugated, and honeycomb cores.

2.2. Innovative Core Structure

The innovative cores can be broadly categorized into derivate, hybrid, hollow, hierarchical, graded, folded, and smart core.

3. Composite Skin Material

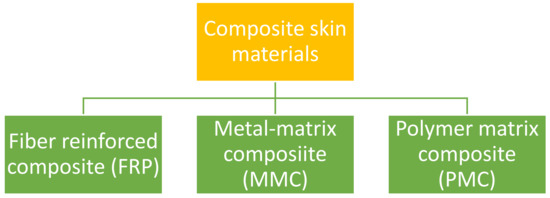

The indispensable property of skin used in the sandwich structure is to resist in-plane shearing and out-of-plane compressive load and to prevent itself from bending and fracturing. Nearly all structural materials which are accessible in the form of thin sheets may be used to form the faces of the sandwich panel. The material for the face sheet should have good toughness, hardness, and impact resistance ability. The composite skin in this particular case can be well suited compared to virgin material that satisfies the above requirement [15]. The composite skin has recently shown applications in various industries. For instance, the panels in aircraft structures make use of composite steel, aluminum, or other metals, even though reinforced plastics are very often adopted in remarkable applications to reduce weight. The skin material is broadly classified into fiber reinforced composites, metal-matrix composites, and polymer matrix composites as shown in Figure 4.

Figure 4. Classification of composite skin material.

4. Joining Technique

The performance of load bearing, lightweight sandwich structures requires a novel joining technique to accomplish the prime requirement of firm amalgamation skin with the core.

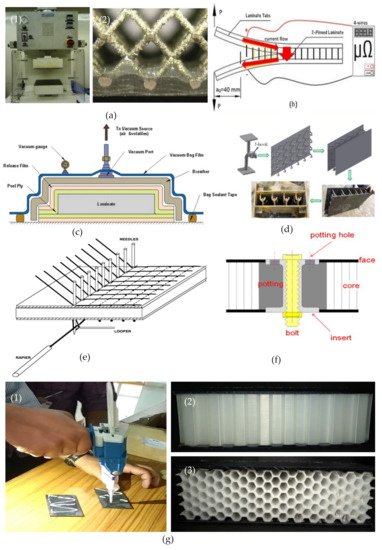

The joining techniques play a vital role in the fabrication of a sandwich structure, which can act as a potential energy transforming unit from the skin to the core. The joining procedures adopted by the researchers are wide and diverse depending on their material properties, such as place of application and overall strength requirement. Among the joining technology, one can find heated press [16], vacuum bagging [17], Z-pinning [18], J-hooking [19], stitching [20], bolting [21], and adhesives [15] are usually adopted in the fabrication of sandwich structures, which is illustrated in Figure 5. The following is the brief literature survey in the context of joining techniques.

Figure 5. (a) Heated press (1) manufacture setup (2) skin–core bond details of SS316L lattice core and CFRP skins [16], (b) Z-pinning technique [17], (c) Vacuum beg setup [18], (d) J-hooking technique [19], (e) Stitching technique [20], (f) Bolting technique [21], (g) Adhesive technique; (1) Adhesive gun; (2) Sandwich construction in out-of-plane; and (3) In-plane direction [15].

Feng et al. [22] investigated Kenaf/glass reinforced hybrid composites on the shearing failure strength test with bolted joint. The test was conducted in a heated chamber with a temperature sweep from 25 to 60 °C. It was observed that an increase in the preload moment of the bolted joint improves the load carrying capacity. Wei et al. [23] performed single lap joint testing on CFRP steel with two types of adhesives, i.e., 7779 and MA830. It was noted that the joint strength is mostly dependent on overlap length and type of adhesive, and the joint with the 7779 adhesive showed a 3 kN higher failure load than the MA830 adhesive. Chen et al. [24] adopted the resin transfer molding method to fabricate sandwich structures with PVC foam core and glass aramid fiber face sheet. The material used for resin was epoxy and curing agent at 10:3 ratios. It was observed that the sandwich panels made with chopped fiber toughening provided a strength about 0.06% higher than that of the virgin sample.

This entry is adapted from the peer-reviewed paper 10.3390/polym14204267

References

- Rajak, D.K.; Pagar, D.D.; Menezes, L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667.

- Naresh, K.; Cantwell, W.J.; Khan, K.A.; Umer, R. Single and multi-layer core designs for Pseudo-Ductile failure in honeycomb sandwich structures. Compos. Struct. 2021, 256, 113059.

- Krzyzak, A.; Mazur, M.; Gajewski, M.; Drozd, K.; Komorek, A.; Przybyłek, P. Sandwich structured composites for aeronautics: Methods of manufacturing affecting some mechanical properties. Int. J. Aerosp. Eng. 2016, 2016, 7816912.

- Castanie, B.; Bouvet, C.; Ginot, M. Review of composite sandwich structure in aeronautic applications. Compos. Part C Open Access 2020, 1, 100004.

- Jones, B.O.; Dixon, M.V. (Eds.) The Macmillan Dictionary of Biography; Springer: Berlin/Heidelberg, Germany, 1981.

- Mistry, J.; Johnson, M.S.; Galappaththi, U.I.K. Selection and ranking of rail vehicle components for optimal lightweighting using composite materials. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 390–402.

- Le, V.T.; San Ha, N.; Goo, N.S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: A review. Compos. Part B Eng. 2021, 226, 109301.

- Available online: http://www.swiftinternational.biz/ROWING/rw_01_aboutOurBoats.php (accessed on 15 November 2021).

- Available online: http://www.aes.org/e-lib/browse.cfm?elib=3882 (accessed on 15 November 2021).

- Available online: http://en.academic.ru/dic.nsf/enwiki/4465505 (accessed on 15 November 2021).

- F50—The Ultimate Ferrari. Available online: http://www.F50.com (accessed on 15 November 2021).

- Available online: http://www.e-architect.co.uk/dubai/al-bahar-towers-abu-dhabi (accessed on 15 November 2021).

- Wei, X.; Li, D.; Xiong, J. Fabrication and mechanical behaviors of an all-composite sandwich structure with a hexagon honeycomb core based on the tailor-folding approach. Compos. Sci. Technol. 2019, 184, 107878.

- Feng, Y.; Qiu, H.; Gao, Y.; Zheng, H.; Tan, J. Creative design for sandwich structures: A review. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420921327.

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Rama Sreekanth, S. Evaluation of Cell Parameter Variation on Energy Absorption Characteristic of Thermoplastic Honeycomb Sandwich Structure. Arab. J. Sci. Eng. 2021, 46, 12487–12507.

- Mines, R.A.W.; Tsopanos, S.; Shen, Y.; Hasan, R.; McKown, S.T. Drop weight impact behaviour of sandwich panels with metallic micro lattice cores. Int. J. Impact Eng. 2013, 60, 120–132.

- Mouritz, A. Review of z-pinned laminates and sandwich composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106128.

- Mostafa, A.; Shankar, K.; Morozov, E.V. Insight into the shear behaviour of composite sandwich panels with foam core. Mater. Des. 2013, 50, 92–101.

- Huang, Z.; Liew, J.R. Compressive resistance of steel-concrete-steel sandwich composite walls with J-hook connectors. J. Constr. Steel Res. 2016, 124, 142–162.

- Potluri, A.; Kusak, E.; Reddy, T.Y. Novel stitch-bonded sandwich composite structures. Compos. Struct. 2003, 59, 251–259.

- Song, K.I.; Choi, J.Y.; Kweon, J.H.; Choi, J.H.; Kim, K.S. An experimental study of the insert joint strength of composite sandwich structures. Compos. Struct. 2008, 86, 107–113.

- Feng, N.L.; Malingam, S.D.; Irulappasamy, S. Bolted joint behavior of hybrid composites. In Failure Analysis in Biocomposites, Fiber-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2019; Volume 1, pp. 79–95.

- Wei, K.; Chen, Y.; Li, M.; Yang, X. Strength and failure mechanism of composite-steel adhesive bond single lap joints. Adv. Mater. Sci. Eng. 2018, 2018, 5810180.

- Chen, Q.; Linghu, T.; Gao, Y.; Wang, Z.; Liu, Y.; Du, R.; Zhao, G. Mechanical properties in glass fiber PVC-foam sandwich structures from different chopped fiber interfacial reinforcement through vacuum-assisted resin transfer molding (VARTM) processing. Compos. Sci. Technol. 2017, 144, 202–207.

This entry is offline, you can click here to edit this entry!