Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Hybrid manufacturing is defined as a process based on the combination of more than one process. There are several types of hybrid manufacturing, although the most common is the type that combines laser additive manufacturing and 5-axis machining processes.

- hybrid manufacturing

- CNC machining

- additive manufacturing

1. Introduction

Nowadays, with the advances in materials for several industrial sectors, such as the aerospace, biomedical and automotive sectors, new methods/processes are needed to fulfil the production demand and required quality [1]. Standard methods of manufacturing have thus started to be put aside, whilst more advanced methods of manufacturing raised, so that customer needs are met without affecting the profitability of the companies [2].

It is in this way that the concept of hybrid manufacturing arises. The idea behind hybrid manufacturing is joining different processes on the same setup in order to achieve the effect known as “1 + 1 = 3” [3,4]. The term “hybrid manufacturing” is directly linked to the integration of different processes, and its development is related to the requirements and complexity of new parts [5].

Thus, the objective of hybrid manufacturing is the joining of two or more distinct processes in a single piece of equipment, observing the unique advantages of each one, while minimizing the limitations of the process [6]. It is observed that there are several types of hybrid manufacturing, although the most common is the type that combines laser additive manufacturing and 5-axis machining processes [7].

Additive manufacturing allows the production of 3D geometric parts through layer overlay [8,9], being a suitable method for efficient production of parts; however, the cost is high and requires a high financial capital, which makes the technique not yet widely used [10]. 5-axis machining is a process more and more used in the industry [11], allowing a single configuration to machine five sides of the part [12] and providing high accuracy and surface quality [13].

2. Additive Manufacturing

Additive manufacturing is the process of manufacturing parts layer by layer, enabling the production of parts with more robust and complex geometries [14]. This technology is of great relevance and represents a real challenge for today’s industries, given its flexibility and ability to provide differentiated products and parts [15,16,17,18]. Additive manufacturing is popularly known as “3D printing”, and it is a process which takes place under digital control. In this process, the raw material is placed in the equipment in the form of wire or powder, and the part produced according to the geometry contained in a CAD project (computer-aided design) [19].

The classification of additive manufacturing processes, in the past, was based on the criterion of separating materials into a liquid basis, solid basis or powder basis [21]. However, in 2010, the American Society for Testing and Materials (ASTM) published the standard “ASTM F42—Additive Manufacturing”, which considers additive manufacturing in seven categories [22]:

- (i)

-

Binder blasting;

- (ii)

-

Directed energy deposition—DED (comprised of processes such as direct deposition of metal), such as wire arc additive manufacturing (WAAM);

- (iii)

-

Material extrusion (which includes fuse deposition modeling (FDM));

- (iv)

-

Material jetting;

- (v)

-

Powder bed fusion (which includes processes such as direct metal laser sintering (DMLS) and selective laser sintering (SLS));

- (vi)

-

Sheet laminating (ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM));

- (vii)

-

Vat polymerization.

In binder blasting, an ink jet is selectively deposited onto bond powder materials, typically plaster or starch, and creates three-dimensional objects, consisting of placing thin layers of this powder, with the print head ejecting and depositing drops of binder [23]. In the study carried out by Chen et al. [24], alumina powder was used as a material processed in different ways to obtain granules with different properties, and aiming at the final quality of the part in terms of compressive strength and density. With this, it was verified that the alumina samples were produced properly and with density and compressive strength within the expected ranges.

The directed energy deposition (DED) process uses thermal energy to build the 3D product, layer by layer, with very good properties. The volumetric density of the product can be practically 100%, and its use with hybrid systems is very frequent, given the ability to deposit heterogeneous materials on the substrate with adequate characteristics [25,26,27].

In the work by Chen et al. [28], it was observed that changes in temperature directly influence the melting and cooling of the material, and consequently also influence the final microstructure and the resulting hardness. Thus, it was possible to predict the hardness distribution of a part by monitoring the temperature changes that occurred. For this purpose, some key temperature features (KTFs) were defined, according to the temperature field present in the DED process, and the resulting hardness predictions were made, showing that predictions were consistent with the real hardness trends.

Tekumalla et al. [29] studied high-vanadium high-speed steels (HVHSSs), which are considered difficult to machine materials due to their high hardness. Thus, the DED method was used, with two alloy compositions: Fe-10V-4.5Cr-2.5C and Fe-15V-13Cr-4.5C, which are highly wear-resistant alloys due to their vanadium and carbon content, and after processing, high hardness of the products was confirmed through a comparison performed regarding these materials after conventional heat treatment. In the work by Radhakrishnan et al. [30], the laser-directed energy deposition method was used to deposit titanium/titanium carbide (Ti/TiC) with 20%, 40% and 60% TiC. The formation of the non-stoichiometric compound TiC0.55 was observed, and hardness increased with TiC content increasing.

Still regarding the DED process, wire feeding processes are divided into three types: (i) wire and arc additive manufacturing (WAAM) processes, which combine an arc, working as a thermal energy source, and a wire, which is the raw material, providing energy efficiency less than 90%; (ii) additive manufacturing of wire and laser (WLAM), which in turn uses the concept of laser cladding and welding in order to produce metal parts that do not have porosity; and finally, (iii) additive manufacturing of wire and electron beam (WEAM), which, as the name implies, uses a beam of electrons as a source of energy [27].

Grossi et al. [31] analyzed the dynamic behavior of a NACA 9403 airfoil produced using the WAAM technique, exploring by finite element analysis (FE) the subsequent machining process in order to predict the dynamics of the part during that machining process. Thus, the system was able to simulate the material removal process and the dynamic behavior of the part previously generated by WAAM, updating its variable geometry.

On the other hand, using another technology known as PAW (plasma arc welding), and in order to analyze the deposition process based on process characteristics and mechanical and microstructural properties, Artaza et al. [32] produced two Ti6Al4V walls with a high deposition rate (2 kg/h) and in an inert argon atmosphere, with no significant differences in microstructural or mechanical properties after thermal heat treatments. Still in relation to PAW technology and Ti6Al4V alloy, Veiga et al. [33] analyzed the production, as well as the quality, of the alloy produced using this technology with subsequent milling, and observed that there were no large deviations in the mechanical properties of the samples in different positions and orientations, and the up-milling showed torque values that were slightly larger. However, the quality of the final surface was superior.

The principle of material extrusion is a technique widely used popularly in domestic environments. This process uses a wire which is extruded and gradually forms the product. A layer of material is deposited horizontally through a nozzle, and then with increments in the vertical direction, until the desired shape is reached [20,34]. There are several technologies for this process, for example the FDM (fused deposition modeling) process, the most common being associated with the extrusion of thermoplastics. However, there are research and investigation opportunities for other processes, including the development of new materials and new technologies, within this same process [35].

Awasthi et al. [36] addressed the challenges faced by the FDM technique, given the wide variety of new materials emerging, emphasizing thermoplastic elastomers (TPE) that are compatible with the process. However, the process is limited due to the difficulty of printing, as well as the generation of defects in the produced parts. In the work by Jin et al. [37], a mathematical model was made and analyzed to verify the surface of the product manufactured through the FDM technique, indicating that the precision of the upper surface is determined through the ratio between the flow of the molten material and the feed rate of the nozzle, whilst the lateral surface is related to the thickness of the process layer and the bedding angle. Thus, it is suggested that the aforementioned ratio be properly used and the thickness of the layer is kept as thin as possible.

Thus, in that work, the process parameters were split into two groups: the first being the pre-processing parameters and the second the manufacturing parameters. Seven different proportions between Q (filament flowrate) and f (feed rate) were selected. It was observed that with increasing the ratio between Q and f, the surface quality became more consistent, but worsened when the ratio reached a value greater than the reference value of 0.585.

Yap et al. [38] used the additive manufacturing technique of material jetting to create a methodology that analyzes the capability of this process regarding the ideal quality and the dimensional accuracy of the manufactured part, utilizing three specific benchmarks. On the other hand, Tyagi et al. [39] made a thorough analysis of the material jetting technique, investigating the fundamentals of the process, as well as the characteristics and properties of the produced parts, especially the influences on mechanical properties, emphasizing that the orientation used is crucial to obtain better mechanical properties.

In relation to the powder bed fusion (PBF) technique, a heat source is used to melt the material in powder form, and thus giving rise to three-dimensional objects layer by layer, and with highly complex geometries [40,41,42]. This technology is often used to produce parts for the aerospace industry [43]. The selective laser sintering (SLS) process is the main technique behind this process [20], and the most suitable when it is desired to produce on a large scale [44]. Based on this, Nar et al. [45] characterized the surface topography of the LS PA12 specimens. Compared to the injection molding technique, SLS produces surfaces with high roughness, due to the nature of the powder used, and this can affect their performance in its various features.

Another technique of additive manufacturing is called sheet laminating, and as the name implies, metal sheets are joined to form the product. UAM (ultrasonic additive manufacturing), a hybrid technique, is included in this class [46].

Hehr et al. [48], in their work, thoroughly analyzed the entire history of the UAM process, in the case of the technological developments achieved and the areas in which it is most used. Knowing that the technique uses ultrasonic energy with the function of bonding the metal layers, the authors explained in a chronological way all the advances of the technique, as well as the characterization methods and how they influence the mechanical properties obtained.

Still in relation to additive manufacturing, another technique used is called vat polymerization. In this technique, UV or laser light is used in the photopolymerization of a liquid photopolymer, which solidifies, layer by layer, forming the product in 3D [49,50]. Revilla-León et al. [51], analyzed the influence of the design (solid, alveolar, and hollow) of the mold base with two different thicknesses (1 and 2 mm), in order to evaluate the accuracy of the obtained mold. For this, a digital mold of each design was made, and the honeycomb and hollow designs were further subdivided into the two thicknesses mentioned above. Additionally, a comparison of the mold obtained via printing with the digital mold was made. It was observed that the vat polymerization process can provide a good complement to the extrusion material process, being used for the manufacture of surgical instruments and in the dental field as well [52].

Based on this, it is known that nowadays, additive manufacturing is an industrial area with a last-generation of metal or composite printing machinery, used in an under-development sector that often uses cheap plastic filament printers to reduce production costs [14]. However, the continuous growth and studies around additive manufacturing demonstrate that it may have a significant place in the future of the industry, given the possibility of manufacturing lightweight and resistant materials and products, thus being able to be widely used in the aerospace as well as in the automotive industries, which requires high dimensional accuracy. In addition, in medicine, there has been a great advance when using this technology due to the possibility of producing bone prototypes and tailor-made protheses. Furthermore, in 2012, at least four additional significant technologies were observed in the additive manufacturing sector, which confirms its great growth and development [53].

As examples of recent advances, there is, according to the work of Khondoker et al. [54], an extruder that can carry out the deposition of mechanically interlocked extrudates composed of two immiscible polymers, which prints two filaments through a single nozzle, and with this, a reduction in adhesion failures between the filaments is observed. Furthermore, Cresswell-Boyes et al. [55] developed three-dimensional (3D) precise artificial teeth with two different materials (polylactic acid and thermoplastic elastomer) through tomography files generated from scans obtained by X-ray microtomography (XMT), using several open-source programs. The next approach will be to replicate the properties of natural teeth. In turn, Park et al. [56] demonstrated for the first time the multifunctional integration of various semiconductor devices produced through additive manufacturing, with the production of high-performance polymeric photodetectors and integrated multifunctional devices. Figure 4 illustrates this work.

Figure 4. Structure of photodetector. Reproduced from [56], 2018, Wiley.

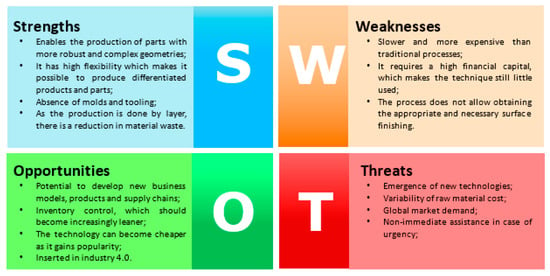

Therefore, additive manufacturing, according to Tofail et al. [57], is at a crossroads between a promising but unproven process for producing functional parts. Therefore, as observed by Pragana et al. [58], new applications have been developed in the field of additive manufacturing to overcoming the limitations of the several developed processes. Based on the factors that permeate this technology in development and growth, a brief diagnosis of this context was carried out through a SWOT analysis/diagram, as shown in Figure 5.

Figure 5. SWOT analysis regarding additive manufacturing.

This entry is adapted from the peer-reviewed paper 10.3390/met12111874

This entry is offline, you can click here to edit this entry!