Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Wheat harvesting is one of the most important links in the whole wheat production process. In China, the wheat planting areas are wide, and the patterns are diversified. In addition, the problem of harvest losses caused by the numerous brands and low performance of domestic combine harvesters has always existed. Any losses during harvesting will result in less income for the farmers.

- wheat

- mechanical losses

- sensor monitoring

- intelligent control

1. Introduction

China is listed as the largest grain producer [1]. In 2021, the wheat planting areas were 23.568 million ha, with a total output of 136.946 million tons [2]. Wheat harvesting is one of the most important operations in the whole production process. Harvest loss refers to a decrease in the total grain output and quality during grain harvesting, and it also represents a direct loss of farmers’ income [3][4]. Mechanized wheat harvesting losses mainly include header losses, threshing and separation losses, and cleaning losses [5]. At different harvest stages, the overall loss rate of wheat production is about 6.58%. The maximum loss of grain occurred in the process of the mechanical harvest of the crops (2.18%), followed by the loss caused by bird feeding, rodents, insect pests, natural grain falling, etc. (1.92%), and nearly 0.38% of grain loss was caused in the process of transportation [6]. In recent years, more and more relevant studies and reports have confirmed that the loss of wheat during harvest is becoming more and more serious, which needs to be solved urgently [7][8][9].

2. Major Losses in Wheat Combine Harvester Operation

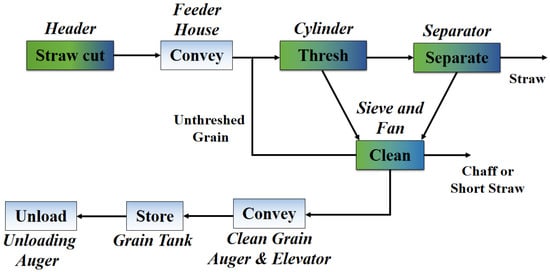

A combine harvester can complete multiple processes such as cutting, threshing, cleaning, and separation all at one time, which greatly improves grain harvesting efficiency. Before making any changes or adjustments in order to reduce losses, it is helpful to understand the working principle of a combine harvester. The operation of a combine harvester is highlighted in Figure 1 and begins at the header unit, where the cutting and gathering of the grains takes place. Then, the material is fed to the threshing cylinder through the inclined conveyor for threshing and separation, and then the straw is discharged from the end of the cylinder. The mixture of the remaining grains, short stalks, and impurities fall into the shaking plate through the concave screen and then enter the cleaning system for cleaning. The clean grains are transported to a storage tank through the grain conveying device, and the grain is unloaded when the grain tank is filled.

Figure 1. Working principle of a combine harvester, highlighting where losses typically occur.

The losses caused by the combine harvester during field operation can be divided into header losses (losses at the front of a harvester) and comprehensive losses (losses during threshing, separation, and cleaning). The following are the different types of losses that occur during harvesting operations.

2.1. Header Losses

A study of harvest loss at North Dakota State University showed that most of the harvest losses occur before the grains entered the machine; the grain loss caused by the combine header accounts for more than 50% of the total harvest losses [10], which is mainly caused by low manual mechanical adjustment accuracy and header vibration. When the machine is harvesting, the height of the reel should be such that the reel plate acts at two-thirds of the height of the wheat plants; if the reel is too high, it easily hits the wheat ears, causing the grains to fall off. When the reel position is too low, the wheat grain is easily deflected to the forward direction of the machine. When wheat plants are cut, the wheat ears fall to the front of the header; when the speed of the reel is too high, it can easily break the wheat ears from the root, resulting in serious wheat ear losses. When wheat is harvested by a machine after it is fully mature, the vibration of the header will also cause some grains to fall down due to less adhesion between the grains and the wheat ears [11]. When harvesting to the end of a field, if the header is raised slowly, the wheat plants left on the header floor will be thrown out due to inertia [12]. The low intelligence level of the header and poor accuracy of manual mechanical adjustment are important reasons for wheat loss and provide a starting point for improving intelligence to reduce harvest loss. Domestic combine harvesters are usually purchased by farmers themselves, the operators generally start harvesting without formal training and understanding the functions of combine. Incorrect operation is also the cause of serious harvest losses. The position of reel action is shown in Figure 2.

Figure 2. Schematic diagram of the position of reel action.

2.2. Losses Due to Threshing and Separation

The threshing and separation system is one of the core working areas of a wheat combine harvester, which play a key role in grain loss and crushing during harvesting operation, directly affecting the operating performance of the whole machine [13][14]. In the process of grain threshing and separation, it is inevitable that there will be unclean threshing, broken grains, and incomplete separation, resulting in grain loss, which is closely related to the structure form of the threshing cylinder, concave clearance, the amount of material feeding, and other parameters.

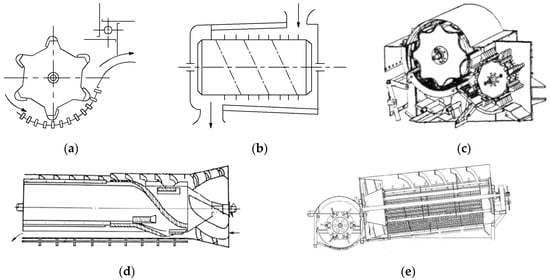

According to the flow direction of the materials, the structures of the threshing cylinders on a combine harvester can be roughly divided into tangential flow type, transverse axial flow type, tangential flow + transverse axial flow type, longitudinal axial flow type, and tangential flow + longitudinal axial flow type. Figure 3 shows the five structural forms of the threshing cylinder. For the tangential flow threshing cylinder, the grain tangentially enters the concave (concave ‘wrap’ angle α was between 105° and 120°) part and is then discharged along the tangential direction of the cylinder, which leads to the unclean threshing of the grain ears due to the extremely short time taken. For the axial flow threshing cylinder, the grain tangentially enters the threshing chamber, spirals forward in the axial direction (while moving circularly with cylinder) and is then finally thrown out in the axial direction, which leads to unclean threshing due to the short length of time and low effectiveness of threshing. For the longitudinal axial flow cylinder, the grain axially enters and axially discharges, and the grain crushing rate is higher due to the long movement path of the materials along the cylinder axial direction, with a long threshing time [15]. For the tangential + longitudinal axial flow cylinder, the grain tangentially enters and axially discharges, which takes a long time to thresh, with straw crushing seriously increasing the difficulty of the separation, and there are certain grain-crushing and entrainment losses. The existing threshing cylinders have some degree of grain loss, so it is necessary to use intelligent sensor technology, such as a grain entrainment loss monitoring sensor and a speed sensor, to achieve grain loss monitoring and the real-time adjustment of the cylinder parameters to reduce threshing and separation losses. At the same time, when the concave clearance is too large, the material flow is better, but the amount of unthreshed material is high; if the clearance is too small, it is easy for blockages to affect the operational efficiency of the whole machine.

Figure 3. Structure diagrams of the threshing cylinder: (a) tangential flow type; (b) transverse axial flow type; (c) tangential flow + transverse axial flow type; (d) longitudinal axial flow type; (e) tangential flow + longitudinal axial flow type.

2.3. Cleaning Losses

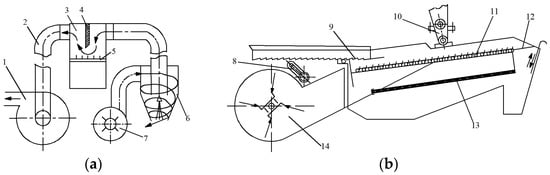

When the combine harvester is operating in the field, the cleaning system can inevitably produce grain loss; cleaning loss is an important parameter for measuring the operational performance of a combine harvester, and it is also one of the important links for causing harvest grain losses [16][17]. The cleaning loss rate is affected by the cleaning mode, feeding amount, the working parameters of the mechanism, etc. At present, the cleaning devices mainly include the airflow type and the air and screen type [18][19]. The airflow cleaning device is generally used on micro and small-sized harvesters in mountainous and hilly areas; it is difficult for the airflow-only system to remove long stalks and high humidity impurities due to the limitation of its structure and power, resulting in high impurity content. The air and screen cleaning device is widely used, with strong applicability; the impurity content is smaller after cleaning, and the cleaning loss is greatly affected by the feeding amount. When the feeding amount is too large, the broken straw stacked on the screen surface is too thick, and the cleaning burden becomes too heavy, resulting in grain loss [20]. Secondly, when the speed of the cleaning fan is too high, the wheat grains (after cleaning) are relatively clean, but most of the grains are blown out of the machine due to the higher fan speed; if the speed of the fan is too low, the impurities cannot be completely separated from the grain, resulting in high impurity content. If the vibration frequency of the vibrating screen is too high or the inclination angle is too small, some grains will be excluded from the machine before falling through the screen hole. In short, in order to achieve the best cleaning result, it is necessary to monitor cleaning loss with the help of sensor technology in real time, and then automatically adjust the relevant working parameters. Figure 4 shows two cleaning devices.

Figure 4. Structure diagrams of the cleaning device: (a) air flow type; (b) windscreen type. 1—suction fan; 2—conveyor pipe; 3—sedimentation interceptor; 4—barrier plate; 5—windshield; 6—cleaning drum; 7—thrower; 8—strut; 9—jitter plate; 10—boom; 11—upper screen; 12—rear screen; 13—lower screen; 14—fan.

References

- Ren, J.; Yang, J.; Zhou, J.; Liu, L.; Li, X. Co-production of ethanol, xylo-oligosaccharides and magnesium lignosulfonate from wheat straw by a controlled magnesium bisulfite pretreatment (MBSP). Ind. Crops Prod. 2018, 113, 128–134.

- Liang, Z.; Li, Y.; Ma, P.; Wei, C.; Wang, J. Structural optimization and experiment on cleaning system in longitudinal-axial combine harvester. J. Agric. Mech. Res. 2018, 40, 170–174.

- Song, H.; Zhang, H.; Li, J.; Wu, Z. Loss of harvest of China’s grain—A case study of wheat in Henan Province. J. Huazhong Agric. Univ. Soc. Sci Ed. 2015, 4, 1–6.

- Wu, L.; Hu, Q.; Zhu, D.; Wang, J. Empirical analysis of main influencing harvest rice losses—Based on the ordered multinomial Logistic model. China Rural Surv. 2015, 6, 22–33+95.

- Zhao, X.; Cao, B.; Zhao, L. Study on the evaluation index system of grain loss and waste after delivery. Grain Sci. Technol. Econ. 2015, 40, 6–9.

- Sharma, S.; Singh, R.; Raghuwanshi, J. Economic Analysis of Losses at Different Stages of Harvest and Post-Harvest Operation in Wheat Production in Gwalior District of Madhya Pradesh. J. Com. Mobil. Sustain. Dev. 2022, 16, 971–975.

- Cao, F.; Zhu, J.; Guo, Y.; Liu, J.; Wu, L. How high is the loss of wheat harvest in China—Based on experimental investigation in 4 provinces and 5 places. J. Arid. Land Resour. Environ. 2018, 32, 7–14.

- Huang, D.; Yao, L.; Wu, L.; Zhu, X. Measuring rice loss during harvest in China: Based on experiment and survey in five provinces. J. Nat. Resour. 2018, 33, 1427–1438.

- Li, X.; Huang, D.; Wu, L. Study on grain harvest losses of different scales of farms—Empirical Analysis Based on 3251 farmers in China. China Soft Sci. 2019, 8, 184–192.

- Zareei, S.; Pour, S.; Moghaddam, M.; Sahrayan, H. Optimum setting of combine header for wheat harvesting using Taguchi method. Res. Crops 2012, 13, 1142–1146.

- Sun, Y. Causes and Solutions to Grain Loss of Wheat Combine Harvester. Agric. Mach. Maint. 2014, 4, 30.

- Zhang, S.; Ding, C. Analysis of wheat and corn machine harvesting loss reduction technology. Agric. Mach. Technol. Ext. 2021, 11, 43–44.

- Xie, F.; Luo, X.; Lu, X.; Sun, S.; Ren, S. Threshing principle of flexible pole-teeth roller for paddy rice. Trans. Chin. Soc. Agric. Eng. 2009, 25, 110–114.

- Tang, Z.; Li, Y.; Liang, Z. Optimal parameters prediction and control of rice threshing for longitudinal axial threshing apparatus. Trans. Chin. Soc. Agric. Eng. 2016, 32, 70–76.

- Wang, X.; Shi, Q.; Ni, C.; Liu, S. Application status and analysis of axial flow roller threshing device. Farm Mach. 2009, 15, 73–75.

- Zhang, G.; Jin, C.; Yang, T.; Liu, Z.; Chen, M.; Zhou, D. Design and implementation of monitoring system for cleaning loss rate of combined harvester. J. Chin. Agric. Mech. 2019, 40, 146–150.

- Wei, C.; Li, M.; Yu, L.; Zhu, L. Research on loss monitoring of grain cleaning in combined harvester based on Kalman filter. J. Agric. Mech. Res. 2016, 38, 23–27.

- Ning, X.; Jin, C.; Yin, X.; Liu, P.; Li, Q. Research status and development trend of air-and-screen cleaning device for cereal combine harvesters. J. Chin. Agric. Mech. 2018, 39, 5–10.

- Li, B. Agricultural Machines; China Agricultural Press: Beijing, China, 1999.

- Ni, J. Exploration and Research on the loss of wheat harvester cleaning. Farm Mach. 2021, 5, 91–93.

This entry is offline, you can click here to edit this entry!