Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The field of high-pressure materials research has grown steadily, with many remarkable discoveries having been made. Recent progress in laser material processing within diamond anvil cells (L-DACs); researchers focus on the practice of laser-driven dynamic compression within diamond anvil cells (i.e., LDC–DAC experimentation).

- laser dynamic compression

- diamond anvil cell

- isentropic compression

1. Introduction

Since the 1930′s, investigators have developed increasingly capable pressure generating devices, such as lever-arm presses [1], piston-driven presses [2], and opposed anvil presses [3][4]; this has enabled materials to be studied at successively higher static pressures over time [5]. In the mid-20th century, Charlie Weir et al. invented the first diamond anvil cell (DAC), in which samples were observed directly through diamond anvils at pressures of over 3 GPa [6]; this revolutionised high pressure materials research, making it possible to monitor phase changes and chemical reactions as pressure was applied [6]. Soon thereafter, laser beams were introduced into DACs for the first time (to process materials) by Takahashi and Bassetta [1].

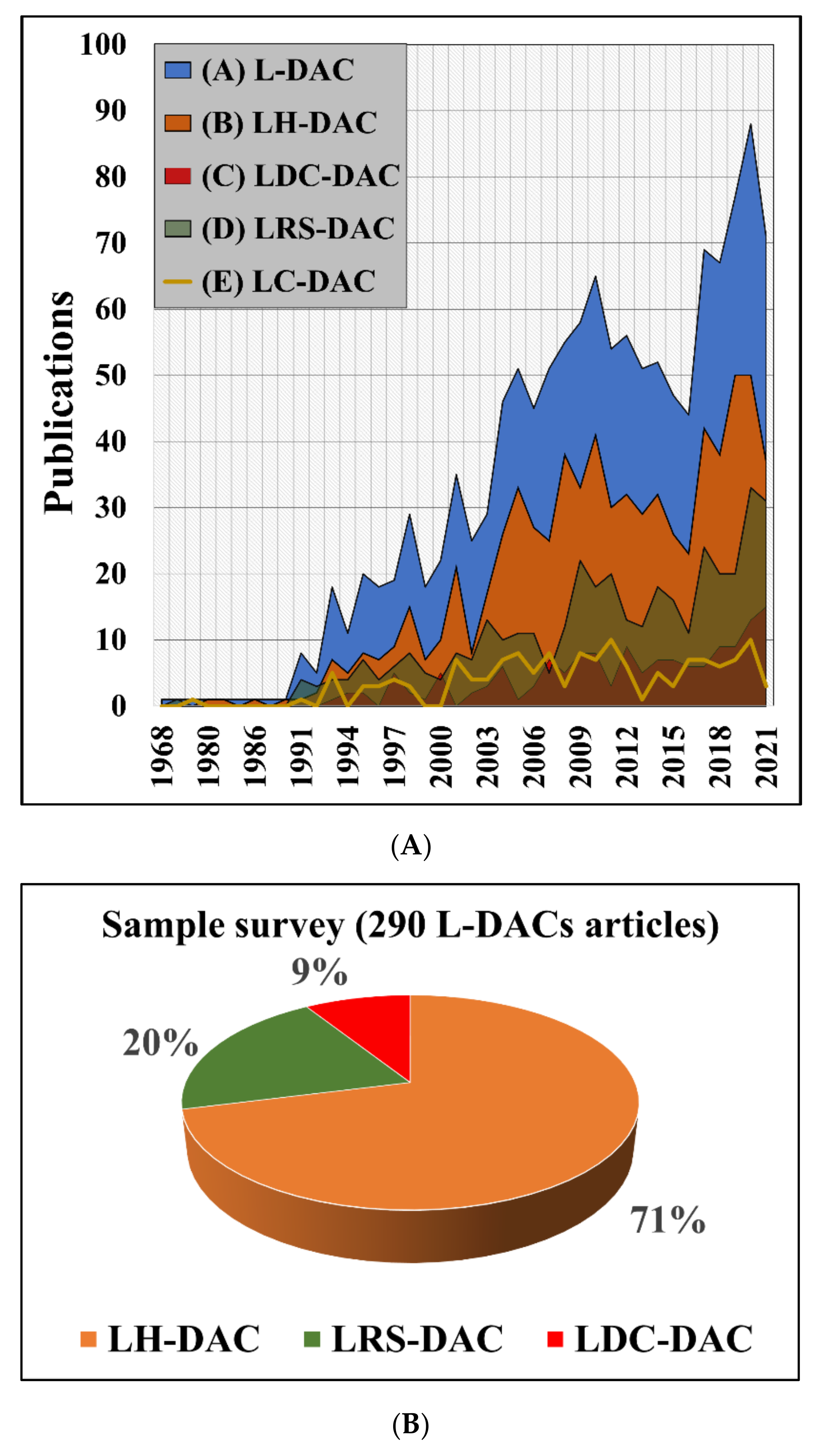

An apparatus that focuses a laser beam between diamond anvils to heat, shock, or induce chemical reactions within a sample, is known as a laser diamond anvil cell (L-DAC) [7]. L–DAC systems have opened a door to entirely new research fields, such as the measurement of material properties at high pressures and high temperatures (HPHT) [8][9][10][11][12][13][14] or the study of extremophile biological organisms at pressures similar to those extant at hydrothermal vents [3][15]. Figure 1A illustrates how the number of journal articles involving L–DAC experiments has risen steadily since the early 1990′s—and is now approaching 60–70 articles per year (blue curve).

Figure 1. (A) Total annual scientific production for all L–DAC studies [Blue] compared with laser heated DAC (LH–DAC) [Orange], laser reactive synthesis DAC (LRS-DAC) [Green], and laser-driven dynamic compression DAC (LDC–DAC) [Red] studies [7]. (B) Comparison of the total number of articles produced in each.

The three parts are based on the primary modes of material modification presented in Figure 1A,B. Part I of this series summarises the more common laser-heated diamond anvil cell (LH–DAC) mode of experimentation (71% of papers) [7]. Part II focuses on dynamic material compression within DACs using intense pulsed lasers, rather than laser heating samples. Researchers refer to this as laser-driven dynamic-compression diamond anvil cell (LDC–DAC) experimentation (9% of papers). The LDC–DAC mode is distinguished from other L–DAC modes through the presence of a pressure-wave or shockwave that considerably modifies a sample material’s structure/composition, and where heating is a secondary contributor, if present at all. Part III reviews the application of lasers to induce chemical reactions within diamond anvil cells (20% of papers); this latter method is dubbed laser reactive synthesis diamond anvil cell (LRS-DAC) experimentation. Although noteworthy reviews have previously outlined the development of DACs and high pressure research methods [1][5][6][14][16][17][18], speaks to laser materials processing—where all three modes of material modification/synthesis are described [19][20]. While the LH–DAC mode has been a principal driver throughout early L–DAC research [1], applications have now diversified, and interest is shifting toward the LDC–DAC and LRS-DAC modes—as evidenced by the Red/Green plots of Figure 1A.

Part II, provides the key physics, historical events, and recent developments of LDC–DAC experimentation. Tables of materials modified/synthesised via LDC–DAC systems are given along with their corresponding process conditions of static pressure, shock pressures, temperature rises, and laser source wavelengths/energies (where available). The intent is to act as a field guide for others in setting-up and conducting their own high-pressure LDC–DAC research endeavours. Note that only laser-induced dynamic compression within DACs is considered here; neither light-gas gun experiments (without driving lasers) nor laser-induced shock compression (without transparent anvils).

LDC–DAC experimentation provides researchers with a singular route to attaining extreme pressures across a large cross-sectional area (with pressures up to 1 TPa, thus far); the method is especially interesting as a multiplicative effect between the DAC pre-compression and the laser dynamic compression (LDC) has been documented [21]. This is well beyond the pressures attainable with single-stage hydrostatic or gas-membrane-driven diamond anvil cells [20][22] where otherwise multiple stages and/or nano-scale surface areas are required to attain such pressures [23].

LDC–DAC experimentation has enabled condensed matter physicists to determine material densities, melting curves, Hugoniot curves, equations of state (EOS), and transport properties for many common elements and compounds over a wide variety of conditions [19][20][24][25][26][27]. Furthermore, LDC–DAC methods have enabled geophysicists and planetary physicists to determine the properties of dense matter at conditions akin to those deep within planetary interiors, providing insight into the structure and dynamics present within the terrestrial planets [19][28]. The technique has allowed researchers to better understand how lasers interact with matter—and how shock-/pressure-waves travel through materials at high pressures [27][29]. Although multi-stage DACs can achieve pressures greater than 380 GPa, when sample sizes greater than 20 μm across are to be compressed, the LDC–DAC mode is presently the primary means to achieve pressures >> 380 GPa [19][30][31][32].

Alternative methods similar to, but distinguished from LDC–DAC processing are confined laser shock compression (e.g., explosive compression inside crystals) [33][34], open-atmosphere laser-driven dynamic compression (OA–LDC) [32][35], and high-power, multi-beam, laser-driven dynamic compression (HP–MB–LDC) [36][37]; all of these methods are generally conducted without the use of pre-compression within a diamond anvil cell. However, it is important to note that materials processing has indeed been carried out using these methods. For example, in the latter case (HP–MB–DC), the world’s highest-ever recorded pressures while synthesising novel materials was achieved (≈1.5 and 5 TPa) and high-pressure forms of Si–C and diamond were realised [37][38]. Even greater pressures have been achieved by HP–MB–DC methods (to 100 TPa) during plasma fusion experiments, but without synthesising any intended material [39][40]. However, OA–LDC and HP–MB–LDC methods typically require large facilities with multiple laser sources, e.g., the National Ignition Facility (NIF) or OMEGA Laser Facility [30], which have traditionally been outside the scope of many researchers. That said, the availability of high-peak-power lasers is growing rapidly, with new capabilities in short-laser pulse lasers becoming widely accessible at a reasonable cost [41][42][43][44].

2. Overview of Laser Dynamic Compression in Diamond Anvil Cells (LDC–DACs)

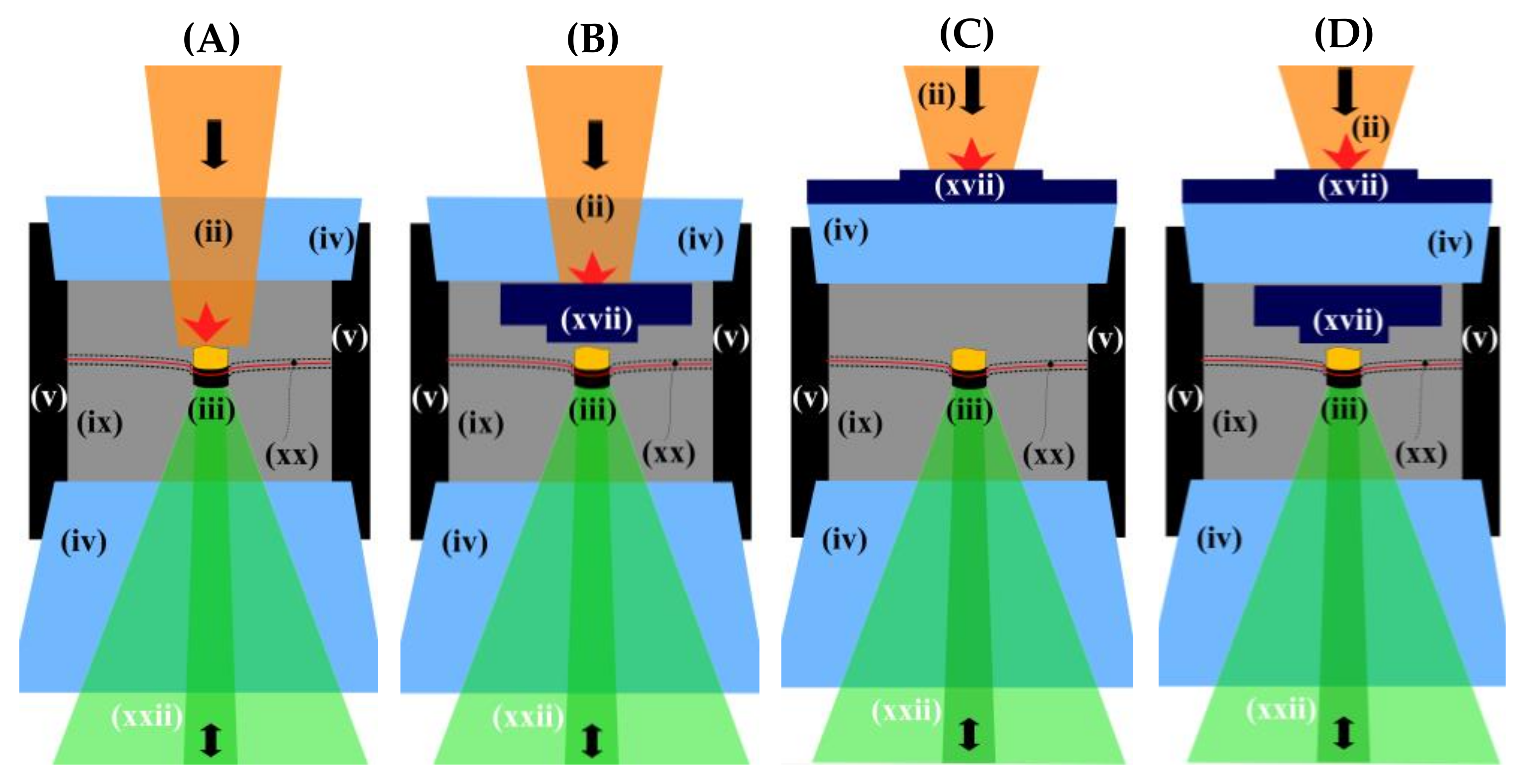

A typical laser-driven dynamic compression diamond anvil cell (LDC–DAC) experiment is illustrated in Figure 2A–D. LDC–DAC systems include a pulsed laser system ((i), not shown), a focused laser beam (ii), a material sample to be compressed (iii), at least one diamond anvil (iv), a chamber gasket (v), and an optional laser target (xvii) placed at the laser focus. Diamond is commonly used for the transparent anvils (iv) in LDC–DAC experiments due to its high shock impedance, wide transmission bandwidth, and dielectric constant [22], although other materials, such as sapphire (Al2O3) and quartz (SiO2), have been utilised [32][45][46][47].

Figure 2. Illustrations of laser-driven dynamic compression diamond anvil cell (LDC–DAC) experiments. (A) The sample of interest is the target, (B) a separate target inside the anvil, (C) a target outside the anvil, and (D), a target outside and driver inside the anvil.

In some experimental setups, the sample itself is the laser target, as displayed in Figure 2A [22][30][48]. In most configurations, however, a target comes before the sample to be compressed (See Figure 2B–D). The laser target’s purpose is to absorb the laser light before it arrives at the sample; this target can be placed in several locations, such as at the inside surface of the incident anvil (Figure 2B) [24][25][49][50][51][52], or on the exterior surface of the same anvil (Figure 2C) [53][54][55]—or on both surfaces of the incident anvil (Figure 2D) [29][45][46][56][57][58][59][60]. Note that in the references for Figure 2C, the examples provided are not strictly L-DACs but are arranged similarly to that of an L–DAC (with a fully enclosed pressurised cell). Many variations on these configurations have been attempted in the past [45][61][62][63].

In LDC–DACs, the laser system typically includes a high-peak-power laser, with pulse widths ranging from nanoseconds down to picoseconds. As each focused laser pulse arrives, a portion of the target is ablated, a plasma plume emerges, and a shock- or pressure-wave (xx) results which passes through the sample (iii); these pressure waves or shockwaves momentarily act as a “second stage” DAC to locally compress the sample to higher pressures, while maintaining the DAC’s background pre-compression pressure [20]. Often rarefaction waves follow the shock- or pressure-waves [64], and all of these waves reflect (somewhat) at interfaces between materials, e.g., where the target contacts the sample [60]. These waves can subsequently interfere with each other, which often degrades (or enhances) the compression [57].

Pressure waves are broadly defined as a disturbance that propagates through a medium at sonic velocities [65][66][67]. Shockwaves typically propagate faster than the speed of sound and there is an abrupt change in pressure as the wave arrives (approaching that of a step function) [67]. In LDC–DAC systems, pressure waves and shockwaves are generated from a combination of the instant (thermal) pressure induced by the expanding plasma and momentum transferred to the target as material is ablated away [56]. As the applied driving energy increases, i.e., the intensity of the laser, the velocity and amplitude of the wave typically increases proportionally [59][65][67][68].

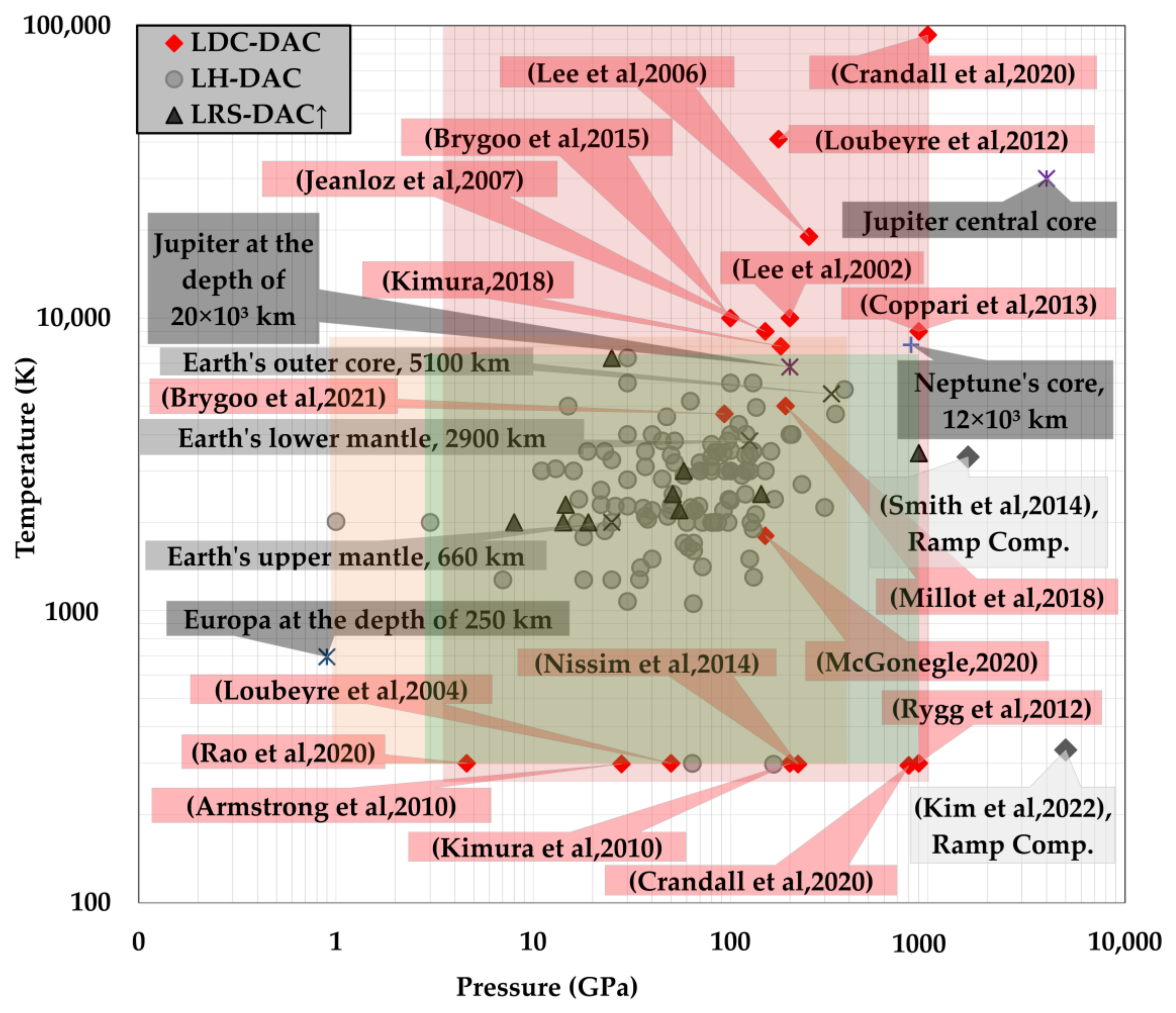

Using nanosecond and shorter laser pulse widths, researchers can drive samples without a significant temperature rise during compression. This is beneficial for several reasons: first, it permits materials to be compressed in an isentropic manner, so that their density/structure can be more easily determined [31]. Second, large-scale diffusion is delayed or prevented—which otherwise leads to contamination—as is known to occur during LH–DAC experiments [69]. Third, samples may be retained in a solid phase rather than melting immediately, so that potential new solid phases can be identified [31]. Fourth, thermal stresses on the anvil’s materials are often reduced, extending the pressure range of the devices [25]. And finally, short-pulse widths provide access to extreme pressures, but at low-to-moderate temperature ranges, which are not otherwise readily accessible (refer to the lower portion of the red boxed region in Figure 3) [22][24][32][46][48]. For instance, samples possessing cryogenic boiling points, such as H, He, Ar, etc. are much easier to compress from cooled samples when laser heating does not occur [70].

Figure 3. P–T diagram of L–DAC experimentation, showing region investigated by LDC–DAC systems (Red) [21][28][30][56][57][58][59][71][72], LH–DAC systems (Orange) [8][20][73][74][75][76][77][78][79][80][81][82][83][84][85][86][87][88][89][90][91][92][93][94][95][96][97][98][99][100][101][102][103][104][105][106][107][108][109][110][111][112][113][114][115][116][117][118][119][120][121][122][123][124][125][126][127][128][129][130][131][132][133][134][135][136][137][138][139][140][141][142][143][144][145][146][147][148][149][150][151][152][153][154][155][156][157][158][159][160][161][162][163][164][165][166][167][168][169][170][171][172][173][174][175][176][177][178][179][180][181][182][183][184][185][186][187][188], and LRS–DAC systems (Green) [189][190][191][192][193][194][195][196]. For reference, P–T markers are also provided for several geophysical locations, including the P–T at a depth of 250 km of Europa’s oceans [197], 60–5100 km underneath the Earth’s surface [59][103][159], 12 × 103 km-deep in Neptune’s core [198], (20 to 71.5) × 103 km-deep in Jupiter’s core [199][200] and two LDC experiments with ramp -compression [37][38].

Note that the low-temperature, high-pressure region (<500 K, 100–600 GPa) is also similar to conditions anticipated within many ice moons or gas giant planets [22], (for reference, estimated P–T conditions within several planetary bodies are provided in Figure 3). Many investigators attempting to clarify the internal structure of planetary bodies are conducting LDC–DAC experiments. For example Kimura et al. studied many of the primary constituents in the solar system, including the low-Z compounds: H2, He, H2O, NH3, and CH4, and determined their EOS to better model planetary dynamics [22]. Another study by Eggert et al. attained Hugoniot data of fluid He at moderate temperatures and within the hundred GPa regime using LDC–DAC [46]. From this, Eggert et al. measured material properties that had previously been predicted by Path-Integral Monte Carlo (PIMC) and Activity Expansion (ACTEX) calculations [46]. Similarly, Rygg et al. measured the crystal structures of C, MgO, Fe, Cu, Zr, Sn, Ta, and Pb samples at up to 900 GPa and close to 300 K [48].

LDC–DAC experimentation has also been used to examine materials within high-pressure, high-temperature (HPHT) regimes that are difficult to access otherwise (>5000 K, >250 GPa) [22]. For instance, hydrogen’s phase diagram was explored at conditions at a depth of ~7000 km within Jupiter’s atmosphere (~5000 K and ~50 GPa) [21][201], and researchers were able to investigate the potential for metallisation of water at up to ≈19,000 K and 250 GPa with 4 ns laser pulses [30]. Similarly, Coppari et al. obtained phase transition data and the EOS of magnesium oxide over the range of 4000–9000 K and 600–900 GPa utilising ≈4.5 ns laser pulses [30]. And finally, Loubeyre et al. extended the known properties of hydrogen and deuterium over the range of 297–40,900 K and 0.3–175 GPa using 1-ns laser pulses [28]. In all these cases, high fluences and extended pulse widths (≥1 ns) were employed to ensure both strong shock loading and heating of the samples [26].

A primary advantage of the LDC–DAC experimental mode is the ability to control initial-, peak-, and final-conditions (ρ-P-T) of the sample material. For example, initial densities of a sample are controlled via (isothermal) compression within a DAC prior to delivering a laser shock, while the maximum (peak) compression is obtained through the laser fluence, pulse width, pulse shape, and target/sample geometries. By conducting the experiment within a DAC, the material arrives at a final, elevated pressure, making it possible to preserve metastable states that would otherwise deteriorate at lower pressures (which sometimes happens when using LDC alone) [22].

Nevertheless, LDC–DACs do have some limitations, and as shown in Figure 1B, comprise only a minor fraction of all L–DAC publications. This may in part be due to the complexity of the experiments and/or lack of access to the necessary high-energy laser sources [19]. In addition, there is a limited selection of material characterisation probes that can be used during LDC–DAC experiments, where real-time, ultrafast characterisation is required. One important complication is the requirement for custom anvil shapes—often thick on the opposing (diagnostic) anvil (iv), and thinned on the incident (drive beam) anvil (iv)—and specialty shapes are often needed along the laser beam path [25]. The opposing anvil material must also be designed to have high impedance matching with the sample [31].

Of course, a significant limitation is the strength of the anvil materials in their required geometries. Diamond is the most commonly-used anvil material, yet it is often thinned to <400 micron thicknesses on the incident anvil [56]. Diamond anvils are subject to failure during compression experiments, which raises the experimental cost, and requires significant effort to reset the LDC–DAC system for subsequent runs. Although sapphire has lower compressive strength (~2 GPa static, ~21 GPa dynamic) than diamond (~35 static, ~98 GPa dynamic), it has also been used as an anvil material during LDC–DAC experiments [32][45][202][203][204]. Similarly, quartz has also been used as an anvil or window (~1 GPa static, ~9 GPa dynamic) [205][206]. Further research is required to maximise the peak pressures attained during shock loading and minimise the cost/effort of LDC–DAC experimental runs [48].

This entry is adapted from the peer-reviewed paper 10.3390/jmmp6060142

References

- Bassett, W.A. The birth and development of laser heating in diamond anvil cells. Rev. Sci. Instrum. 2001, 72, 1270–1272.

- Bridgman, P.W. Polymorphism, Principally of the Elements, up to 50,000 kg/cm2. Phys. Rev. 1935, 48, 893–906.

- Hemley, R.J.; Percy, W. Bridgman’s second century. High Pressure Res. 2010, 30, 581–619.

- Sahu, P.C.; Chandra Shekar, N.V. High pressure research on materials. Resonance 2007, 12, 49–64.

- Ren, D.; Li, H. A Review of High-Temperature and High-Pressure Experimental Apparatus Capable of Generating Differential Stress. Front. Earth Sci. 2022, 10, 852403.

- Bassett, W.A. Diamond anvil cell, 50th birthday. High Pressure Res. 2009, 29, 163–186.

- Alabdulkarim, M.E.; Maxwell, W.D.; Thapliyal, V.; Maxwell, J.L. A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part I: Laser-Heated Diamond Anvil Cells. J. Manuf. Mater. Process. 2022, 6, 111.

- Saxena, S.K.; Dubrovinsky, L.S.; Häggkvist, P.; Cerenius, Y.; Shen, G.; Mao, H.K. Synchrotron X-Ray Study of Iron at High Pressure and Temperature. Science 1995, 269, 1703–1704.

- Andrault, D.; Fiquet, G. Synchrotron radiation and laser heating in a diamond anvil cell. Rev. Sci. Instrum. 2001, 72, 1283–1288.

- Hemley, R.J.; Mao, H.-K.; Struzhkin, V.V. Synchrotron radiation and high pressure: New light on materials under extreme conditions. J. Synchrotron Radiat. 2005, 12, 135–154.

- Kavner, A.; Panero, W.R. Temperature gradients and evaluation of thermoelastic properties in the synchrotron-based laser-heated diamond cell. Phys. Earth Planet. Inter. 2004, 143–144, 527–539.

- Duffy, T.S. Synchrotron facilities and the study of the Earth’s deep interior. Rep. Prog. Phys. 2005, 68, 1811–1859.

- Boehler, R.; Musshoff, H.G.; Ditz, R.; Aquilanti, G.; Trapananti, A. Portable laser-heating stand for synchrotron applications. Rev. Sci. Instrum. 2009, 80, 045103.

- Piermarini, G.J. High pressure X-ray crystallography with the diamond cell at NIST/NBS. J. Res. Nat. Inst. Stand. Technol. 2001, 106, 889.

- Zimmerman, A.M. High-Pressure Studies in Cell Biology. In International Review of Cytology; Bourne, G.H., Danielli, J.F., Jeon, K.W., Eds.; Academic Press: Cambridge, MA, USA, 1971; Volume 30, pp. 1–47.

- O’Bannon, E.F.; Jenei, Z.; Cynn, H.; Lipp, M.J.; Jeffries, J.R. Contributed Review: Culet diameter and the achievable pressure of a diamond anvil cell: Implications for the upper pressure limit of a diamond anvil cell. Rev. Sci. Instrum. 2018, 89, 111501.

- Zhao, D.; Wang, M.; Xiao, G.; Zou, B. Thinking about the Development of High-Pressure Experimental Chemistry. J. Phys. Chem. Lett. 2020, 11, 7297–7306.

- Akimoto, S.-i. High-Pressure Research in Geophysics: Past, Present and Future. In High-Pressure Research in Mineral Physics: A Volume in Honor of Syun-iti Akimoto; Terra Scientific Publishing Company: Tokyo, Japan, 1987; pp. 1–13.

- Falk, K. Experimental methods for warm dense matter research. High Power Laser Sci. Eng. 2018, 6, e59.

- Duffy, T.S.; Smith, R.F. Ultra-High Pressure Dynamic Compression of Geological Materials. Front. Earth Sci. 2019, 7, 23.

- Loubeyre, P.; Celliers, P.M.; Hicks, D.G.; Henry, E.; Dewaele, A.; Pasley, J.; Eggert, J.; Koenig, M.; Occelli, F.; Lee, K.M.; et al. Coupling static and dynamic compressions: First measurements in dense hydrogen. High Pressure Res. 2004, 24, 25–31.

- Kimura, T.; Ozaki, N.; Okuchi, T.; Terai, T.; Sano, T.; Shimizu, K.; Sano, T.; Koenig, M.; Hirose, A.; Kakeshita, T.; et al. Significant static pressure increase in a precompression cell target for laser-driven advanced dynamic compression experiments. Phys. Plasma 2010, 17, 054502.

- Dubrovinskaia, N.; Dubrovinsky, L.; Solopova Natalia, A.; Abakumov, A.; Turner, S.; Hanfland, M.; Bykova, E.; Bykov, M.; Prescher, C.; Prakapenka Vitali, B.; et al. Terapascal static pressure generation with ultrahigh yield strength nanodiamond. Sci. Adv. 2016, 2, e1600341.

- Armstrong, M.R.; Crowhurst, J.C.; Bastea, S.; Zaug, J.M. Ultrafast observation of shocked states in a precompressed material. J. Appl. Phys. 2010, 108, 023511.

- Moon, S.J.; Cauble, R.; Collins, G.W.; Celliers, P.M.; Hicks, D.; Da Silva, L.B.; Mackinon, A.; Wallace, R.; Hammel, B.; Hsing, W.; et al. Experimental Design for Laser Produced Shocks in Diamond Anvil Cells; US Department of Energy (US): Atlanta, GA, USA, 2001. Available online: https://www.osti.gov/biblio/15002090 (accessed on 9 October 2022).

- Lee, K.K.M.; Benedetti, L.R.; Jeanloz, R.; Celliers, P.M.; Eggert, J.H.; Hicks, D.G.; Moon, S.J.; Mackinnon, A.; Da Silva, L.B.; Bradley, D.K.; et al. Laser-driven shock experiments on precompressed water: Implications for “icy” giant planets. J. Chem. Phys. 2006, 125, 014701.

- Crandall, L.E.; Rygg, J.R.; Spaulding, D.K.; Boehly, T.R.; Brygoo, S.; Celliers, P.M.; Eggert, J.H.; Fratanduono, D.E.; Henderson, B.J.; Huff, M.F.; et al. Equation of State of CO2 Shock Compressed to 1 TPa. Phys. Rev. Lett. 2020, 125, 165701.

- Loubeyre, P.; Brygoo, S.; Eggert, J.; Celliers, P.M.; Spaulding, D.K.; Rygg, J.R.; Boehly, T.R.; Collins, G.W.; Jeanloz, R. Extended data set for the equation of state of warm dense hydrogen isotopes. Phys. Rev. B: Condens. Matter 2012, 86, 144115.

- Shu, H.; Li, J.; Tu, Y.; Ye, J.; Wang, J.; Zhang, Q.; Tian, H.; Jia, G.; He, Z.; Zhang, F.; et al. Measurement of the sound velocity of shock compressed water. Sci. Rep. 2021, 11, 6116.

- Coppari, F.; Smith, R.F.; Eggert, J.H.; Wang, J.; Rygg, J.R.; Lazicki, A.; Hawreliak, J.A.; Collins, G.W.; Duffy, T.S. Experimental evidence for a phase transition in magnesium oxide at exoplanet pressures. Nat. Geosci. 2013, 6, 926–929.

- McGonegle, D.; Heighway, P.G.; Sliwa, M.; Bolme, C.A.; Comley, A.J.; Dresselhaus-Marais, L.E.; Higginbotham, A.; Poole, A.J.; McBride, E.E.; Nagler, B.; et al. Investigating off-Hugoniot states using multi-layer ring-up targets. Sci. Rep. 2020, 10, 13172.

- Rao, U.; Chaurasia, S.; Mishra, A.K.; Pasley, J. Phase transitions in benzene under dynamic and static compression. J. Raman Spectrosc. 2021, 52, 770–781.

- Rapp, L.; Haberl, B.; Pickard, C.J.; Bradby, J.E.; Gamaly, E.G.; Williams, J.S.; Rode, A.V. Experimental evidence of new tetragonal polymorphs of silicon formed through ultrafast laser-induced confined microexplosion. Nat. Commun. 2015, 6, 7555.

- Juodkazis, S.; Kohara, S.; Ohishi, Y.; Hirao, N.; Vailionis, A.; Mizeikis, V.; Saito, A.; Rode, A. Structural changes in femtosecond laser modified regions inside fused silica. J. Opt. 2010, 12, 124007.

- Spaulding, D.K. Laser-Driven Shock Compression Studies of Planetary Compositions; ProQuest Dissertations Publishing: Ann Arbor, MI, USA, 2010.

- Lazicki, A.; McGonegle, D.; Rygg, J.R.; Braun, D.G.; Swift, D.C.; Gorman, M.G.; Smith, R.F.; Heighway, P.G.; Higginbotham, A.; Suggit, M.J.; et al. Metastability of diamond ramp-compressed to 2 terapascals. Nature 2021, 589, 532–535.

- Smith, R.F.; Eggert, J.H.; Jeanloz, R.; Duffy, T.S.; Braun, D.G.; Patterson, J.R.; Rudd, R.E.; Biener, J.; Lazicki, A.E.; Hamza, A.V.; et al. Ramp compression of diamond to five terapascals. Nature 2014, 511, 330–333.

- Kim, D.; Smith, R.F.; Ocampo, I.K.; Coppari, F.; Marshall, M.C.; Ginnane, M.K.; Wicks, J.K.; Tracy, S.J.; Millot, M.; Lazicki, A.; et al. Structure and density of silicon carbide to 1.5 TPa and implications for extrasolar planets. Nat. Commun. 2022, 13, 2260.

- Bachmann, B.; Kritcher, A.L.; Benedetti, L.R.; Falcone, R.W.; Glenn, S.; Hawreliak, J.; Izumi, N.; Kraus, D.; Landen, O.L.; Le Pape, S.; et al. Using penumbral imaging to measure micrometer size plasma hot spots in Gbar equation of state experiments on the National Ignition Facility. Rev. Sci. Instrum. 2014, 85, 11D614.

- Kritcher, A.L.; Döppner, T.; Swift, D.; Hawreliak, J.; Collins, G.; Nilsen, J.; Bachmann, B.; Dewald, E.; Strozzi, D.; Felker, S.; et al. Probing matter at Gbar pressures at the NIF. High Energy Density Phys. 2014, 10, 27–34.

- Sistrunk, E.; Alessi, D.; Bayramian, A.J.; Chesnut, K.D.; Erlandson, A.C.; Galvin, T.C.; Gibson, D.; Nguyen, H.T.; Reagan, B.A.; Schaffers, K.I.; et al. Laser Technology Development for High Peak Power Lasers Achieving Kilowatt Average Power and Beyond. Proc. SPIE 2019, 11034, 1103407.

- Crawford, D.; Thiagarajan, P.; Goings, J.; Caliva, B.; Smith, S.; Walker, R. Advancements of ultra-high peak power laser diode arrays. Proc. SPIE 2018, 10514, 105140H.

- Xia, J.; Dong, X.; Yuan, H. Generation of High Peak Power Pulses With Controllable Repetition Rate in Doubly Q-Switched Laser With AOM/SnSe2. Front. Phys. 2022, 10, 213.

- Chvykov, V. New Generation of Ultra-High Peak and Average Power Laser Systems; IntechOpen: London, UK, 2018.

- Crandall, L.E.; Rygg, J.R.; Spaulding, D.K.; Huff, M.F.; Marshall, M.C.; Polsin, D.N.; Jeanloz, R.; Boehly, T.R.; Zaghoo, M.; Henderson, B.J.; et al. Equation-of-state, sound speed, and reshock of shock-compressed fluid carbon dioxide. Phys. Plasma 2021, 28, 022708.

- Eggert, J.; Brygoo, S.; Loubeyre, P.; McWilliams, R.S.; Celliers, P.M.; Hicks, D.G.; Boehly, T.R.; Jeanloz, R.; Collins, G.W. Hugoniot Data for Helium in the Ionization Regime. Phys. Rev. Lett. 2008, 100, 124503.

- Boehly, T.R.; Hicks, D.G.; Celliers, P.M.; Collins, T.J.B.; Earley, R.; Eggert, J.H.; Jacobs-Perkins, D.; Moon, S.J.; Vianello, E.; Meyerhofer, D.D.; et al. Properties of fluid deuterium under double-shock compression to several Mbar. Phys. Plasma 2004, 11, L49–L52.

- Rygg, J.R.; Eggert, J.H.; Lazicki, A.E.; Coppari, F.; Hawreliak, J.A.; Hicks, D.G.; Smith, R.F.; Sorce, C.M.; Uphaus, T.M.; Yaakobi, B.; et al. Powder diffraction from solids in the terapascal regime. Rev. Sci. Instrum. 2012, 83, 113904.

- Lee, K.K.M.; Benedetti, L.R.; Mackinnon, A.; Hicks, D.; Moon, S.J.; Loubeyre, P.; Occelli, F.; Dewaele, A.; Collins, G.W.; Jeanloz, R. Taking Thin Diamonds to Their Limit: Coupling Static-Compression and Laser-Shock Techniques to Generate Dense Water. AIP Conf. Proc. 2002, 620, 1363–1366.

- Henry, E.; Brygoo, S.; Loubeyre, P.; Koenig, M.; Benuzzi-Mounaix, A.; Ravasio, A.; Vinci, T. Laser-driven shocks in precompressed water samples. J. Phys. IV France 2006, 133, 1093–1095.

- Eggert, J.H.; Celliers, P.M.; Hicks, D.G.; Rygg, J.R.; Collins, G.W.; Brygoo, S.; Loubeyre, P.; McWilliams, R.S.; Spaulding, D.; Jeanloz, R.; et al. Shock Experiments on Pre-Compressed Fluid Helium. AIP Conf. Proc. 2009, 1161, 26–31.

- LLNL; Bastea; Zaug, J. Shocking Results from Diamond Anvil Cell Experiments. Available online: https://www.llnl.gov/news/shocking-results-diamond-anvil-cell-experiments (accessed on 1 November 2022).

- Benuzzi-Mounaix, A.; Koenig, M.; Huser, G.; Faral, B.; Grandjouan, N.; Batani, D.; Henry, E.; Tomasini, M.; Hall, T.A.; Guyot, F. Generation of a double shock driven by laser. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 2004, 70, 045401.

- Guarguaglini, M.; Hernandez, J.A.; Benuzzi-Mounaix, A.; Bolis, R.; Brambrink, E.; Vinci, T.; Ravasio, A. Characterizing equation of state and optical properties of dynamically pre-compressed materials. Phys. Plasma 2019, 26, 042704.

- Sollier, A.; Auroux, E.; Vauthier, J.S.; Boustie, M.; He, H.; de Rességuier, T.; Berterretche, P.; Desbiens, N.; Bourasseau, E.; Maillet, J.B. A New Experimental Design for Laser-Driven Shocks On Precompressed And Preheated Water Samples. AIP Conf. Proc. 2007, 955, 1192–1195.

- Jeanloz, R.; Celliers, P.M.; Collins, G.W.; Eggert, J.H.; Lee, K.K.M.; McWilliams, R.S.; Brygoo, S.; Loubeyre, P. Achieving high-density states through shock-wave loading of precompressed samples. Proc. Natl. Acad. Sci. USA 2007, 104, 9172–9177.

- Nissim, N.; Eliezer, S.; Werdiger, M.; Perelmutter, L. Approaching the “cold curve” in laser-driven shock wave experiment of a matter precompressed by a partially perforated diamond anvil. Laser Part. Beams 2013, 31, 73–79.

- Brygoo, S.; Millot, M.; Loubeyre, P.; Lazicki, A.E.; Hamel, S.; Qi, T.; Celliers, P.M.; Coppari, F.; Eggert, J.H.; Fratanduono, D.E.; et al. Analysis of laser shock experiments on precompressed samples using a quartz reference and application to warm dense hydrogen and helium. J. Appl. Phys. 2015, 118, 195901.

- Brygoo, S.; Loubeyre, P.; Millot, M.; Rygg, J.R.; Celliers, P.M.; Eggert, J.H.; Jeanloz, R.; Collins, G.W. Evidence of hydrogen–helium immiscibility at Jupiter-interior conditions. Nature 2021, 593, 517–521.

- Kimura, T. Application of Laser Technology for Static and Dynamic Compression Experiments. Rev. High Press. Sci. Technol. 2018, 28, 131–138.

- Neff, S.; Martinez, D.; Plechaty, C.; Stein, S.; Presura, R. Developing flyer plate impact experiments for shockwave interaction studies. In Proceedings of the 2010 Abstracts IEEE International Conference on Plasma Science, IEEE, Norfolk, VA, USA, 20–24 June 2010.

- Neff, S.; Presura, R. Simulation of shock waves in flyer plate impact experiments. Laser Part. Beams 2010, 28, 539–545.

- Schram, D.C.; Mazouffre, S.; Engeln, R.; van de Sanden, M.C.M. The Physics of Plasma Expansion. In Atomic and Molecular Beams: The State of the Art 2000; Campargue, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2001; pp. 209–235.

- Eliezer, S. The Interaction of High-Power Lasers with Plasmas; Institute of Physics Publishing: Bristol, UK, 2002.

- Itoh, S. CHAPTER 3.2—Shock Waves in Liquids. In Handbook of Shock Waves; Ben-Dor, G., Igra, O., Elperin, T.O.V., Eds.; Academic Press: Burlington, NJ, USA, 2001; pp. 263–314.

- Sakakura, M.; Terazima, M.; Shimotsuma, Y.; Miura, K.; Hirao, K. Observation of pressure wave generated by focusing a femtosecond laser pulse inside a glass. Opt. Express 2007, 15, 5674–5686.

- Henderson, L.R.F. CHAPTER 2—General Laws for Propagation of Shock Waves Through Matter. In Handbook of Shock Waves; Ben-Dor, G., Igra, O., Elperin, T.O.V., Eds.; Academic Press: Burlington, NJ, USA, 2001; pp. 143–183.

- Hamilton, B.W.; Sakano, M.N.; Li, C.; Strachan, A. Chemistry Under Shock Conditions. Annu. Rev. Mater. Res. 2021, 51, 101–130.

- Williams, Q.; Knittle, E.; Jeanloz, R. The high-pressure melting curve of iron: A technical discussion. J. Geophys. Res. Solid Earth 1991, 96, 2171–2184.

- Woollam, J.A.; Chu, C.W. High-Pressure and Low-Temperature Physics; Springer: New York, NY, USA, 2012.

- Nissim, N.; Eliezer, S.; Werdiger, M. The sound velocity throughout the P-ρ phase-space with application to laser induced shock wave in matter precompressed by a diamond anvil cell. J. Appl. Phys. 2014, 115, 213503.

- Millot, M.; Hamel, S.; Rygg, J.R.; Celliers, P.M.; Collins, G.W.; Coppari, F.; Fratanduono, D.E.; Jeanloz, R.; Swift, D.C.; Eggert, J.H. Experimental evidence for superionic water ice using shock compression. Nature Physics 2018, 14, 297–302.

- Yoo, C.-S.; Wei, H.; Dias, R.; Shen, G.; Smith, J.; Chen, J.-Y.; Evans, W. Time-Resolved Synchrotron X-ray Diffraction on Pulse Laser Heated Iron in Diamond Anvil Cell. J. Phys. Conf. Ser. 2012, 377, 012108.

- Dewaele, A.; Mezouar, M.; Guignot, N.; Loubeyre, P. High melting points of tantalum in a laser-heated diamond anvil cell. Phys. Rev. Lett. 2010, 104, 255701.

- Andrault, D.; Fiquet, G.; Kunz, M.; Visocekas, F.; Häusermann, D. The Orthorhombic Structure of Iron: An in Situ Study at High-Temperature and High-Pressure. Science 1997, 278, 831–834.

- Armstrong, L.S.; Walter, M.J. Tetragonal almandine pyrope phase (TAPP): Retrograde Mg-perovskite from subducted oceanic crust? Eur. J. Mineral. 2012, 24, 587–597.

- Armstrong, L.S.; Walter, M.J.; Tuff, J.R.; Lord, O.T.; Lennie, A.R.; Kleppe, A.K.; Clark, S.M. Perovskite Phase Relations in the System CaO–MgO–TiO2–SiO2 and Implications for Deep Mantle Lithologies. J. Petrol. 2012, 53, 611–635.

- Benedetti, L.R.; Loubeyre, P. Temperature gradients, wavelength-dependent emissivity, and accuracy of high and very-high temperatures measured in the laser-heated diamond cell. High Pressure Res. 2004, 24, 423–445.

- Boehler, R. Melting of the FeFeO and the FeFeS systems at high pressure: Constraints on core temperatures. Earth Planet. Sci. Lett. 1992, 111, 217–227.

- Boehler, R. Temperatures in the Earth’s core from melting-point measurements of iron at high static pressures. Nature 1993, 363, 534–536.

- Boehler, R.; Ross, M.; Boercker, D.B. High-pressure melting curves of alkali halides. Phys. Rev. B Condens. Matter 1996, 53, 556–563.

- Boehler, R.; Chopelas, A. A new approach to laser heating in high pressure mineral physics. Geophys. Res. Lett. 1991, 18, 1147–1150.

- Boehler, R.; Ross, M.; Boercker, D.B. Melting of LiF and NaCl to 1 Mbar: Systematics of Ionic Solids at Extreme Conditions. Phys. Rev. Lett. 1997, 78, 4589–4592.

- Bolfan-Casanova, N.; Andrault, D.; Amiguet, E.; Guignot, N. Equation of state and post-stishovite transformation of Al-bearing silica up to 100GPa and 3000K. Phys. Earth Planet. Inter. 2009, 174, 70–77.

- Meade, C.; Mao, H.K.; Hu, J. High-Temperature Phase Transition and Dissociation of (Mg, Fe)SiO3 Perovskite at Lower Mantle Pressures. Science 1995, 268, 1743–1745.

- Dewaele, A.; Mezouar, M.; Guignot, N.; Loubeyre, P. Melting of lead under high pressure studied using second-scale time-resolved x-ray diffraction. Phys. Rev. B Condens. Matter 2007, 76, 144106.

- Dewaele, A.; Belonoshko, A.B.; Garbarino, G.; Occelli, F.; Bouvier, P.; Hanfland, M.; Mezouar, M. High-pressure—High-temperature equation of state of KCl and KBr. Phys. Rev. B Condens. Matter 2012, 85, 214105.

- Dobson, D.P.; Hunt, S.A.; Ahmed, J.; Lord, O.T.; Wann, E.T.H.; Santangeli, J.; Wood, I.G.; Vočadlo, L.; Walker, A.M.; Thomson, A.R.; et al. The phase diagram of NiSi under the conditions of small planetary interiors. Phys. Earth Planet. Inter. 2016, 261, 196–206.

- Dubrovinsky, L.S.; Saxena, S.K.; Lazor, P.; Ahuja, R.; Eriksson, O.; Wills, J.M.; Johansson, B. Experimental and theoretical identification of a new high-pressure phase of silica. Nature 1997, 388, 362–365.

- Errandonea, D.; Schwager, B.; Ditz, R.; Gessmann, C.; Boehler, R.; Ross, M. Systematics of transition-metal melting. Phys. Rev. B Condens. Matter 2001, 63, 132104.

- Errandonea, D.; Somayazulu, M.; Häusermann, D.; Mao, H.K. Melting of tantalum at high pressure determined by angle dispersive x-ray diffraction in a double-sided laser-heated diamond-anvil cell. J. Phys. Condens. Matter 2003, 15, 7635–7649.

- Errandonea, D.; Boehler, R.; Japel, S.; Mezouar, M.; Benedetti, L.R. Structural transformation of compressed solid Ar: An x-ray diffraction study to 114 GPa. Phys. Rev. B Condens. Matter 2006, 73, 092106.

- Errandonea, D.; MacLeod, S.G.; Burakovsky, L.; Santamaria-Perez, D.; Proctor, J.E.; Cynn, H.; Mezouar, M. Melting curve and phase diagram of vanadium under high-pressure and high-temperature conditions. Phys. Rev. B Condens. Matter 2019, 100, 094111.

- Fedotenko, T.; Dubrovinsky, L.; Aprilis, G.; Koemets, E.; Snigirev, A.; Snigireva, I.; Barannikov, A.; Ershov, P.; Cova, F.; Hanfland, M.; et al. Laser heating setup for diamond anvil cells for in situ synchrotron and in house high and ultra-high pressure studies. Rev. Sci. Instrum. 2019, 90, 104501–104511.

- Fiquet, G.; Andrault, D. Powder X-ray diffraction under extreme conditions of pressure and temperature. J. Synchrotron Radiat. 1999, 6, 81–86.

- Fiquet, G.; Andrault, D.; Itié, J.P.; Gillet, P.; Richet, P. X-ray diffraction of periclase in a laser-heated diamond-anvil cell. Phys. Earth Planet. Inter. 1996, 95, 1–17.

- Fiquet, G.; Dewaele, A.; Andrault, D.; Kunz, M.; Le Bihan, T. Thermoelastic properties and crystal structure of MgSiO3 perovskite at lower mantle pressure and temperature conditions. Geophys. Res. Lett. 2000, 27, 21–24.

- Friedrich, A.; Morgenroth, W.; Bayarjargal, L.; Juarez-Arellano, E.A.; Winkler, B.; Konôpková, Z. In situ study of the high pressure high-temperature stability field of TaN and of the compressibilities of ϑ-TaN and TaON. High Pressure Res. 2013, 33, 633–641.

- Golberg, D.; Bando, Y.; Eremets, M.; Takemura, K.; Kurashima, K.; Yusa, H. Nanotubes in boron nitride laser heated at high pressure. Appl. Phys. Lett. 1996, 69, 2045–2047.

- Heinz, D.L.; Sweeney, J.S.; Miller, P. A laser heating system that stabilizes and controls the temperature: Diamond anvil cell applications. Rev. Sci. Instrum. 1991, 62, 1568–1575.

- Hrubiak, R.; Meng, Y.; Shen, G. Microstructures define melting of molybdenum at high pressures. Nat. Commun. 2017, 8, 14562.

- Huang, X.; Li, F.; Zhou, Q.; Meng, Y.; Litasov, K.D.; Wang, X.; Liu, B.; Cui, T. Thermal equation of state of Molybdenum determined from in situ synchrotron X-ray diffraction with laser-heated diamond anvil cells. Sci. Rep. 2016, 6, 19923.

- Japel, S.; Schwager, B.; Boehler, R.; Ross, M. Melting of copper and nickel at high pressure: The role of d electrons. Phys. Rev. Lett. 2005, 95, 167801.

- Kavner, A.; Duffy, T.S. Pressure–volume–temperature paths in the laser-heated diamond anvil cell. J. Appl. Phys. 2001, 89, 1907–1914.

- Kesson, S.E.; Fitz Gerald, J.D. Partitioning of MgO, FeO, NiO, MnO and Cr2O3 between magnesian silicate perovskite and magnesiowüstite: Implications for the origin of inclusions in diamond and the composition of the lower mantle. Earth Planet. Sci. Lett. 1992, 111, 229–240.

- Kesson, S.E.; Fitz Gerald, J.D.; Shelley, J.M.G. Mineral chemistry and density of subducted basaltic crust at lower-mantle pressures. Nature 1994, 372, 767–769.

- Kiefer, B.; Duffy, T.S. Finite element simulations of the laser-heated diamond-anvil cell. J. Appl. Phys. 2005, 97, 114902.

- Kim, Y.-H.; Ming, L.C.; Manghnani, M.H. High-pressure phase transformations in a natural crystalline diopside and a synthetic CaMgSi2O6 glass. Phys. Earth Planet. Inter. 1994, 83, 67–79.

- Kimura, T.; Kuwayama, Y.; Yagi, T. Melting temperatures of H2O up to 72 GPa measured in a diamond anvil cell using CO2 laser heating technique. J. Chem. Phys. 2014, 140, 074501.

- Young-Ho, K.O.; Kyoung Hun, O.H.; Kwang Joo, K.I.M. Installation and Operation of a Double-Sided Laser Heating System for the Synthesis of Novel Materials Under Extreme Conditions. New Phys. Sae Mulli NPSM 2019, 69, 1107–1114.

- Knittle, E.; Jeanloz, R. Synthesis and Equation of State of (Mg,Fe) SiO3 Perovskite to Over 100 Gigapascals. Science 1987, 235, 668–670.

- Kumar, N.R.; Shekar, N.V.; Sekar, M.; Subramanian, N.; Mohan, P.C.; Srinivasan, M.P.; Parameswaran, P.; Sahu, P.C. Diamond and diamond-like carbon in laser heated diamond anvil cell at 16.5 GPa and above 2000 K from pyrolitic graphite. Indian J. Pure Appl. Phys. 2008, 46, 783–787.

- Kupenko, I.; Strohm, C.; McCammon, C.; Cerantola, V.; Glazyrin, K.; Petitgirard, S.; Vasiukov, D.; Aprilis, G.; Chumakov, A.I.; Rüffer, R.; et al. Time differentiated nuclear resonance spectroscopy coupled with pulsed laser heating in diamond anvil cells. Rev. Sci. Instrum. 2015, 86, 114501.

- Lavina, B.; Dera, P.; Kim, E.; Meng, Y.; Downs Robert, T.; Weck Philippe, F.; Sutton Stephen, R.; Zhao, Y. Discovery of the recoverable high-pressure iron oxide Fe4O5. Proc. Natl. Acad. Sci. USA 2011, 108, 17281–17285.

- Lazicki, A.; Dewaele, A.; Loubeyre, P.; Mezouar, M. High-pressure—Temperature phase diagram and the equation of state of beryllium. Phys. Rev. B Condens. Matter 2012, 86, 174118.

- Lin, J.-F.; Santoro, M.; Struzhkin, V.V.; Mao, H.-k.; Hemley, R.J. In situ high pressure-temperature Raman spectroscopy technique with laser-heated diamond anvil cells. Rev. Sci. Instrum. 2004, 75, 3302–3306.

- Lin, J.-F.; Sturhahn, W.; Zhao, J.; Shen, G.; Mao, H.-k.; Hemley, R.J. Absolute temperature measurement in a laser-heated diamond anvil cell. Geophys. Res. Lett. 2004, 31, L14611.

- Lin, Y.; Hu, Q.; Zhu, L.; Meng, Y. Structure and Stability of Iron Fluoride at High Pressure–Temperature and Implication for a New Reservoir of Fluorine in the Deep Earth. Minerals 2020, 10, 783.

- Liu, L.-G. A new high-pressure phase of spinel. Earth Planet. Sci. Lett. 1978, 41, 398–404.

- Liu, L.-g. High pressure NaAlSiO4: The first silicate calcium ferrite isotype. Geophys. Res. Lett. 1977, 4, 183–186.

- Liu, J.; Wang, C.; Lv, C.; Su, X.; Liu, Y.; Tang, R.; Chen, J.; Hu, Q.; Mao, H.-K.; Mao, W.L. Evidence for oxygenation of Fe-Mg oxides at mid-mantle conditions and the rise of deep oxygen. Natl. Sci. Rev. 2020, 8, 1–6.

- Lord, O.T.; Wann, E.T.H.; Hunt, S.A.; Walker, A.M.; Santangeli, J.; Walter, M.J.; Dobson, D.P.; Wood, I.G.; Vočadlo, L.; Morard, G.; et al. The NiSi melting curve to 70GPa. Phys. Earth Planet. Inter. 2014, 233, 13–23.

- Lord, O.T.; Wood, I.G.; Dobson, D.P.; Vočadlo, L.; Wang, W.; Thomson, A.R.; Wann, E.T.H.; Morard, G.; Mezouar, M.; Walter, M.J. The melting curve of Ni to 1 Mbar. Earth Planet. Sci. Lett. 2014, 408, 226–236.

- Meng, Y.; Shen, G.; Mao, H.K. Double-sided laser heating system at HPCAT for in situ x-ray diffraction at high pressures and high temperatures. J. Phys. Condens. Matter 2006, 18, S1097–S1103.

- Ming, L.c.; Bassett, W.A. Laser heating in the diamond anvil press up to 2000°C sustained and 3000°C pulsed at pressures up to 260 kilobars. Rev. Sci. Instrum. 1974, 45, 1115–1118.

- Miyagi, L.; Kanitpanyacharoen, W.; Raju, S.V.; Kaercher, P.; Knight, J.; MacDowell, A.; Wenk, H.-R.; Williams, Q.; Alarcon, E.Z. Combined resistive and laser heating technique for in situ radial X-ray diffraction in the diamond anvil cell at high pressure and temperature. Rev. Sci. Instrum. 2013, 84, 025118.

- Nabiei, F.; Badro, J.; Boukaré, C.; Hébert, C.; Cantoni, M.; Borensztajn, S.; Wehr, N.; Gillet, P. Investigating Magma Ocean Solidification on Earth Through Laser-Heated Diamond Anvil Cell Experiments. Geophys. Res. Lett. 2021, 48, e2021GL092446.

- Ohfuji, H.; Irifune, T.; Okada, T.; Yagi, T.; Sumiya, H. Laser heating in nano-polycrystalline diamond anvil cell. J. Phys. Conf. Ser. 2010, 215, 5.

- Ohtaka, O.; Andrault, D.; Bouvier, P.; Schultz, E.; Mezouar, M. Phase relations and equation of state of ZrO2 to 100 GPa. J. Appl. Crystallogr. 2005, 38, 727–733.

- Panero, W.R.; Jeanloz, R. Temperature gradients in the laser-heated diamond anvil cell. J. Geophys. Res. Solid Earth 2001, 106, 6493–6498.

- Santamaría-Pérez, D.; Boehler, R. FeSi melting curve up to 70 GPa. Earth Planet. Sci. Lett. 2008, 265, 743–747.

- Pigott, J.S.; Reaman, D.M.; Panero, W.R. Microfabrication of controlled-geometry samples for the laser-heated diamond-anvil cell using focused ion beam technology. Rev. Sci. Instrum. 2011, 82, 115106.

- Pigott, J.S.; Velisavljevic, N.; Moss, E.K.; Draganic, N.; Jacobsen, M.K.; Meng, Y.; Hrubiak, R.; Sturtevant, B.T. Experimental melting curve of zirconium metal to 37 GPa. J. Phys. Condens. Matter 2020, 32, 355402.

- Polvani, D.A.; Meng, J.F.; Hasegawa, M.; Badding, J.V. Measurement of the thermoelectric power of very small samples at ambient and high pressures. Rev. Sci. Instrum. 1999, 70, 3586–3589.

- Prakapenka, V.B.; Kubo, A.; Kuznetsov, A.; Laskin, A.; Shkurikhin, O.; Dera, P.; Rivers, M.L.; Sutton, S.R. Advanced flat top laser heating system for high pressure research at GSECARS: Application to the melting behavior of germanium. High Pressure Res. 2008, 28, 225–235.

- Prakapenka, V.B.; Shen, G.; Dubrovinsky, L.S. Carbon transport in diamond anvil cells. High Temp. High Press. 2003, 35/36, 237–249.

- Raju, S.V.; Hrubiak, R.; Drozd, V.; Saxena, S. Laser-assisted processing of Ni-Al-Co-Ti under high pressure. Mater. Manuf. Processes 2017, 32, 1606–1611.

- Ross, M.; Boehler, R.; Söderlind, P. Xenon Melting Curve to 80 GPa and 5p-d Hybridization. Phys. Rev. Lett. 2005, 95, 257801.

- Runge, C.E.; Kubo, A.; Kiefer, B.; Meng, Y.; Prakapenka, V.B.; Shen, G.; Cava, R.J.; Duffy, T.S. Equation of state of MgGeO3 perovskite to 65 GPa: Comparison with the post-perovskite phase. Phys. Chem. Miner. 2006, 33, 699–709.

- Sadovyi, B.; Wierzbowska, M.; Stelmakh, S.; Boccato, S.; Gierlotka, S.; Irifune, T.; Porowski, S.; Grzegory, I. Experimental and theoretical evidence of the temperature-induced wurtzite to rocksalt phase transition in GaN under high pressure. Phys. Rev. B Condens. Matter 2020, 102, 235109.

- Saha, P.; Mukherjee, G.D. Temperature measurement in double-sided laser-heated diamond anvil cell and reaction of carbon. Indian J. Phys. 2021, 95, 621–628.

- Saha, P.; Mazumder, A.; Mukherjee, G.D. Thermal conductivity of dense hcp iron: Direct measurements using laser heated diamond anvil cell. Geosci. Front. 2020, 11, 1755–1761.

- Salem, R.; Matityahu, S.; Melchior, A.; Nikolaevsky, M.; Noked, O.; Sterer, E. Image analysis of speckle patterns as a probe of melting transitions in laser-heated diamond anvil cell experiments. Rev. Sci. Instrum. 2015, 86, 093907.

- Santamaría-Pérez, D.; Ross, M.; Errandonea, D.; Mukherjee, G.D.; Mezouar, M.; Boehler, R. X-ray diffraction measurements of Mo melting to 119 GPa and the high pressure phase diagram. J. Chem. Phys. 2009, 130, 124509.

- Schultz, E.; Mezouar, M.; Crichton, W.; Bauchau, S.; Blattmann, G.; Andrault, D.; Fiquet, G.; Boehler, R.; Rambert, N.; Sitaud, B.; et al. Double-sided laser heating system for in situ high pressure–high temperature monochromatic x-ray diffraction at the esrf. High Pressure Res. 2005, 25, 71–83.

- Shen, G.; Mao, H.-k.; Hemley, R.J.; Duffy, T.S.; Rivers, M.L. Melting and crystal structure of iron at high pressures and temperatures. Geophys. Res. Lett. 1998, 25, 373–376.

- Shen, G.; Rivers, M.L.; Wang, Y.; Sutton, S.R. Laser heated diamond cell system at the Advanced Photon Source for in situ x-ray measurements at high pressure and temperature. Rev. Sci. Instrum. 2001, 72, 1273–1282.

- Shen, G.; Prakapenka, V.B.; Rivers, M.L.; Sutton, S.R. Structure of Liquid Iron at Pressures up to 58 GPa. Phys. Rev. Lett. 2004, 92, 185701.

- Shen, G.; Mao, H.-k.; Hemley, R. Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating with Multimode Nd:YAG Laser. In Advanced Materials ’96 New Trends in High Pressure Research; Akaishi, M., Ed.; The Institute: Tsukuba, Japan, 1996.

- Shieh, S.R.; Duffy, T.S.; Shen, G. X-ray diffraction study of phase stability in SiO2 at deep mantle conditions. Earth Planet. Sci. Lett. 2005, 235, 273–282.

- Shim, S.H.; Duffy, T.S.; Jeanloz, R.; Shen, G. Stability and crystal structure of MgSiO3 perovskite to the core-mantle boundary. Geophys. Res. Lett. 2004, 31.

- Shukla, B.; Shekar, N.V.C.; Kumar, N.R.S.; Ravindran, T.R.; Sahoo, P.; Dhara, S.; Sahu, P.C. Twin chamber sample assembly in DAC and HPHT studies on GaN nano-particles. J. Phys. Conf. Ser. 2012, 377, 012014.

- Singh, A.K.; Andrault, D.; Bouvier, P. X-ray diffraction from stishovite under nonhydrostatic compression to 70GPa: Strength and elasticity across the tetragonal→orthorhombic transition. Phys. Earth Planet. Inter. 2012, 208–209, 1–10.

- Sinmyo, R.; Hirose, K. The Soret diffusion in laser-heated diamond-anvil cell. Phys. Earth Planet. Inter. 2010, 180, 172–178.

- Sinmyo, R.; Pesce, G.; Greenberg, E.; McCammon, C.; Dubrovinsky, L. Lower mantle electrical conductivity based on measurements of Al, Fe-bearing perovskite under lower mantle conditions. Earth Planet. Sci. Lett. 2014, 393, 165–172.

- Spiekermann, G.; Kupenko, I.; Petitgirard, S.; Harder, M.; Nyrow, A.; Weis, C.; Albers, C.; Biedermann, N.; Libon, L.; Sahle, C.J.; et al. A portable on-axis laser-heating system for near-90degrees X-ray spectroscopy: Application to ferropericlase and iron silicide. J. Synchrotron Radiat. 2020, 27, 414–424.

- Stutzmann, V.; Dewaele, A.; Bouchet, J.; Bottin, F.; Mezouar, M. High-pressure melting curve of titanium. Phys. Rev. B Condens. Matter 2015, 92, 224110.

- Auzende, A.-L.; Gillot, J.; Coquet, A.; Hennet, L.; Ona-Nguema, G.; Bonnin, D.; Esteve, I.; Roskosz, M.; Fiquet, G. Synthesis of amorphous MgO-rich peridotitic starting material for laser-heated diamond anvil cell experiments—Application to iron partitioning in the mantle. High Pressure Res. 2011, 31, 199–213.

- Tateno, S.; Hirose, K.; Ohishi, Y.; Tatsumi, Y. The Structure of Iron in Earth’s Inner Core. Science 2010, 330, 359–361.

- Watanuki, T.; Shimomura, O.; Yagi, T.; Kondo, T.; Isshiki, M. Construction of laser-heated diamond anvil cell system for in situ x-ray diffraction study at SPring-8. Rev. Sci. Instrum. 2001, 72, 1289–1292.

- Weck, G.; Recoules, V.; Queyroux, J.-A.; Datchi, F.; Bouchet, J.; Ninet, S.; Garbarino, G.; Mezouar, M.; Loubeyre, P. Determination of the melting curve of gold up to 110 GPa. Phys. Rev. B Condens. Matter 2020, 101, 014106.

- Yagi, T.; Susaki, J.-I. A Laser Heating System for Diamond Anvil Using CO2 Laser. In High-Pressure Research: Application to Earth and Planetary Sciences; Terra Scientific Publishing Company: Tokyo, Japan, 1992; pp. 51–54.

- Yang, L.; Karandikar, A.; Boehler, R. Flash heating in the diamond cell: Melting curve of rhenium. Rev. Sci. Instrum. 2012, 83, 063905.

- Yoo, C.S.; Akella, J.; Moriarty, J.A. High-pressure melting temperatures of uranium: Laser-heating experiments and theoretical calculations. Phys. Rev. B Condens. Matter 1993, 48, 15529–15534.

- Yoo, C.S.; Akella, J.; Campbell, A.J.; Mao, H.K.; Hemley, R.J. Phase Diagram of Iron by in Situ X-ray Diffraction: Implications for Earth’s Core. Science 1995, 270, 1473–1475.

- Yoo, C.S.; Söderlind, P.; Moriarty, J.A.; Cambell, A.J. dhcp as a possible new ϵ′ phase of iron at high pressures and temperatures. Phys. Lett. A 1996, 214, 65–70.

- Yusa, H.; Takemura, K.; Matsui, Y.; Morishima, H.; Watanabe, K.; Yamawaki, H.; Aoki, K. Direct transformation of graphite to cubic diamond observed in a laser-heated diamond anvil cell. Appl. Phys. Lett. 1998, 72, 1843–1845.

- Zerr, A.; Boehier, R. Melting of (Mg, Fe)SiO3-Perovskite to 625 Kilobars: Indication of a High Melting Temperature in the Lower Mantle. Science 1993, 262, 553–555.

- Zerr, A.; Miehe, G.; Serghiou, G.; Schwarz, M.; Kroke, E.; Riedel, R.; Fueß, H.; Kroll, P.; Boehler, R. Synthesis of cubic silicon nitride. Nature 1999, 400, 340–342.

- Zhang, L.; Meng, Y.; Mao, H.-k. Unit cell determination of coexisting post-perovskite and H-phase in (Mg,Fe)SiO3 using multigrain XRD: Compositional variation across a laser heating spot at 119 GPa. Prog. Earth Planet. Sci. 2016, 3, 13.

- Zhang, D.; Jackson, J.M.; Zhao, J.; Sturhahn, W.; Alp, E.E.; Hu, M.Y.; Toellner, T.S.; Murphy, C.A.; Prakapenka, V.B. Temperature of Earth’s core constrained from melting of Fe and Fe0.9Ni0.1 at high pressures. Earth Planet. Sci. Lett. 2016, 447, 72–83.

- Zinin, P.V.; Prakapenka, V.B.; Burgess, K.; Odake, S.; Chigarev, N.; Sharma, S.K. Combined laser ultrasonics, laser heating, and Raman scattering in diamond anvil cell system. Rev. Sci. Instrum. 2016, 87, 123908.

- Zou, G.; Ma, Y.; Mao, H.-k.; Hemley, R.J.; Gramsch, S.A. A diamond gasket for the laser-heated diamond anvil cell. Rev. Sci. Instrum. 2001, 72, 1298–1301.

- Weathers, M.S.; Bassett, W.A. Melting of carbon at 50 to 300 kbar. Phys. Chem. Miner. 1987, 15, 105–112.

- Huang, D.; Siebert, J.; Badro, J. High pressure partitioning behavior of Mo and W and late sulfur delivery during Earth’s core formation. Geochim. Cosmochim. Acta 2021, 310, 19–31.

- Kurnosov, A.; Marquardt, H.; Dubrovinsky, L.; Potapkin, V. A waveguide-based flexible CO2-laser heating system for diamond-anvil cell applications. C.R. Geosci. 2019, 351, 280–285.

- Chidester, B.A.; Thompson, E.C.; Fischer, R.A.; Heinz, D.L.; Prakapenka, V.B.; Meng, Y.; Campbell, A.J. Experimental thermal equation of state of B2− KCl. Phys. Rev. B Condens. Matter 2021, 104, 094107.

- Zhang, Y.; Tan, Y.; Geng, H.Y.; Salke, N.P.; Gao, Z.; Li, J.; Sekine, T.; Wang, Q.; Greenberg, E.; Prakapenka, V.B.; et al. Melting curve of vanadium up to 256 GPa: Consistency between experiments and theory. Phys. Rev. B Condens. Matter 2020, 102, 214104.

- Gaida, N.A.; Niwa, K.; Sasaki, T.; Hasegawa, M. Phase relations and thermoelasticity of magnesium silicide at high pressure and temperature. J. Chem. Phys. 2021, 154, 144701.

- Anzellini, S.; Burakovsky, L.; Turnbull, R.; Bandiello, E.; Errandonea, D. P–V–T Equation of State of Iridium Up to 80 GPa and 3100 K. Crystals 2021, 11, 452.

- Liu, L.-g. Silicate perovskite from phase transformations of pyrope-garnet at high pressure and temperature. Geophys. Res. Lett. 1974, 1, 277–280.

- Nishiyama, N.; Langer, J.; Sakai, T.; Kojima, Y.; Holzheid, A.; Gaida, N.A.; Kulik, E.; Hirao, N.; Kawaguchi, S.I.; Irifune, T.; et al. Phase relations in silicon and germanium nitrides up to 98 GPa and 2400°C. J. Am. Ceram. Soc. 2019, 102, 2195–2202.

- Bassett, W.A.; Li-Chung, M. Disproportionation of Fe2SiO4 to 2FeO + SiO2 at pressures up to 250kbar and temperatures up to 3000 °C. Phys. Earth Planet. Inter. 1972, 6, 154–160.

- Kavner, A.; Jeanloz, R. The high-pressure melting curve of Allende meteorite. Geophys. Res. Lett. 1998, 25, 4161–4164.

- Boehler, R.; von Bargen, N.; Chopelas, A. Melting, thermal expansion, and phase transitions of iron at high pressures. J. Geophys. Res. Solid Earth 1990, 95, 21731–21736.

- Wakamatsu, T.; Ohta, K.; Yagi, T.; Hirose, K.; Ohishi, Y. Measurements of sound velocity in iron–nickel alloys by femtosecond laser pulses in a diamond anvil cell. Phys. Chem. Miner. 2018, 45, 589–595.

- Deemyad, S.; Sterer, E.; Barthel, C.; Rekhi, S.; Tempere, J.; Silvera, I.F. Pulsed laser heating and temperature determination in a diamond anvil cell. Rev. Sci. Instrum. 2005, 76, 125104.

- Deemyad, S.; Silvera, I.F. Melting Line of Hydrogen at High Pressures. Phys. Rev. Lett. 2008, 100, 155701.

- Yoo, C.S.; Akella, J.; Cynn, H.; Nicol, M. Direct elementary reactions of boron and nitrogen at high pressures and temperatures. Phys. Rev. B Condens. Matter 1997, 56, 140–146.

- Serghiou, G.; Miehe, G.; Tschauner, O.; Zerr, A.; Boehler, R. Synthesis of a cubic Ge3N4 phase at high pressures and temperatures. J. Chem. Phys. 1999, 111, 4659–4662.

- Sahu, P.C.; Takemura, K.; Yusa, H. Synthesis experiments on B-Sb, Ge-Sb, and Xe-Pd systems using a laser heated diamond anvil cell. High Pressure Res. 2001, 21, 41–50.

- Sorb, Y.A.; Subramanian, N.; Ravindran, T.R.; Sahu, P.C. High Pressure in situ Micro-Raman Spectroscopy of Ge-Sn System Synthesized in a Laser Heated Diamond Anvil Cell. AIP Conf. Proc. 2011, 1349, 1305–1306.

- Sanjay Kumar, N.R.; Chandra Shekar, N.V.; Chandra, S.; Basu, J.; Divakar, R.; Sahu, P.C. Synthesis of novel Ru2C under high pressure–high temperature conditions. J. Phys. Condens. Matter 2012, 24, 362202.

- Fedotenko, T.; Dubrovinsky, L.; Khandarkhaeva, S.; Chariton, S.; Koemets, E.; Koemets, I.; Hanfland, M.; Dubrovinskaia, N. Synthesis of palladium carbides and palladium hydride in laser heated diamond anvil cells. J. Alloys Compd. 2020, 844, 156179.

- Gréaux, S.; Andrault, D.; Gautron, L.; Bolfan-Casanova, N.; Mezouar, M. Compressibility of Ca3Al2Si3O12 perovskite up to 55 GPa. Phys. Chem. Miner. 2014, 41, 419–429.

- Zerr, A.; Serghiou, G.; Boehler, R.; Ross, M. Decomposition of alkanes at high pressures and temperatures. High Pressure Res. 2006, 26, 23–32.

- Vance, S.; Harnmeijer, J.; Kimura, J.; Hussmann, H.; deMartin, B.; Brown, J.M. Hydrothermal Systems in Small Ocean Planets. Astrobiology 2007, 7, 987–1005.

- Helled, R.; Anderson, J.D.; Podolak, M.; Schubert, G. Interior Models of Uranus and Neptune. Astrophys. J. 2010, 726, 15.

- Guillot, T.; Gautier, D. 10.13—Giant Planets. In Treatise on Geophysics; Schubert, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 439–464.

- Fossati, L.; Shulyak, D.; Sreejith, A.G.; Koskinen, T.; Young, M.E.; Cubillos, P.E.; Lara, L.M.; France, K.; Rengel, M.; Cauley, P.W.; et al. A data-driven approach to constraining the atmospheric temperature structure of the ultra-hot Jupiter KELT-9b. Astron. Astrophys. 2020, 643, A131.

- French, M.; Becker, A.; Lorenzen, W.; Nettelmann, N.; Bethkenhagen, M.; Wicht, J.; Redmer, R. Ab Initio Simulations for Material Properties Along the Jupiter Adiabat. Astrophys. J. Suppl. ApJS 2012, 202, 5.

- Banerjee, A.; Bernoulli, D.; Zhang, H.; Yuen, M.-F.; Liu, J.; Dong, J.; Ding, F.; Lu, J.; Dao, M.; Zhang, W.; et al. Ultralarge elastic deformation of nanoscale diamond. Science 2018, 360, 300–302.

- Ruoff, A.L. On the yield strength of diamond. J. Appl. Phys. 1979, 50, 3354–3356.

- Reinhart, W.D.; Chhabildas, L.C.; Vogler, T.J. Investigating phase transitions and strength in single-crystal sapphire using shock–reshock loading techniques. Int. J. Impact Eng. 2006, 33, 655–669.

- Bisschop, J.; den Brok, B.; Miletich, R. Brittle deformation of quartz in a diamond anvil cell. J. Struct. Geol. 2005, 27, 943–947.

- Borg, J.P.; Vogler, T.J. Mesoscale simulations of a dart penetrating sand. Int. J. Impact Eng. 2008, 35, 1435–1440.

This entry is offline, you can click here to edit this entry!