Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Energy harvesters serve as continuous and long-lasting sources of energy that can be integrated into wearable and implantable sensors and biomedical devices. Biomechanical energy is one of the largest categories and one of the most utilized among all other energy sources.

- bioelectronics

- energy harvesting

- wearables

- implantable electronics

1. Introduction

Continuous monitoring plays a vital role in a timely medical diagnosis and prevents a large spectrum of diseases [1]. In modern medical practice this approach is implemented via wearable biosensors that register any anomalous biomarker deviations [2]. A core problem, however, is that continuous monitoring via wearable biosensors cannot be developed without a sufficient energy source. Typically, energy is provided by either a battery, by an energy harvester, or a combination of both [3][4].

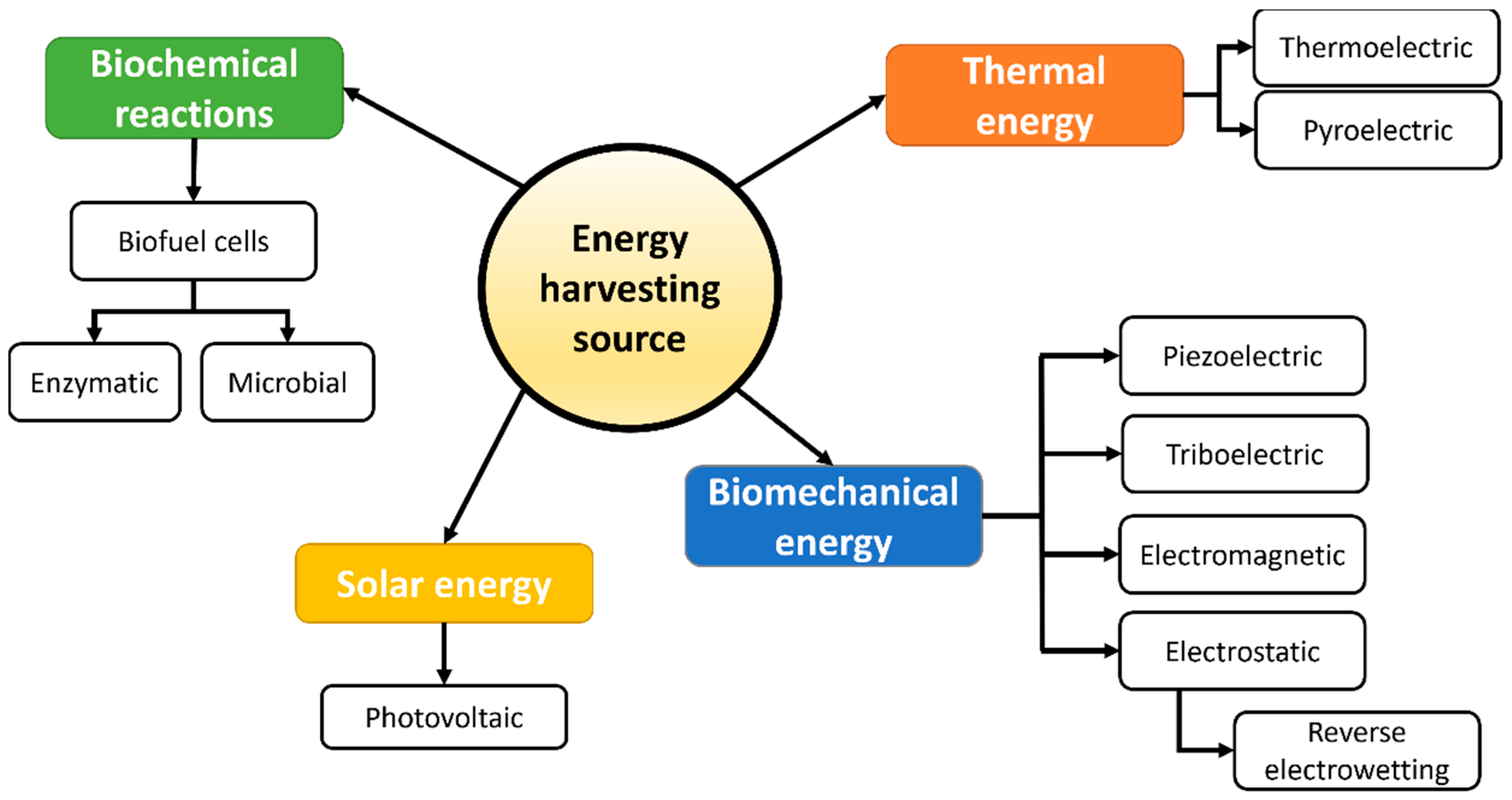

Energy harvesting is a process of collecting, converting and providing ready-to-use energy for an arbitrary device. The circuitry for such a device consists of nanogenerators (NGs) and a power management unit that conditions the scavenged energy into a usable form [5]. Research into energy harvesting requires a multi-disciplinary approach which considers both electrical and biological factors to achieve optimum conversion results. Thermal, biomechanical, biochemical and solar energy (Figure 1) can be scavenged from the ambient environment or the human body [3][6][7][8][9]. In addition, the same external stimuli that are converted to energy can effectively be monitored by energy harvesters [10].

Figure 1. Energy conversion methods based on applied physical principles.

The history of energy harvesters can be traced back to 2006 when Zhong Lin Wang published a report on piezoelectric nanogenerator that was comprised of ZnO nanowire arrays [11]. This fundamental article became an instant classic among the scientific community for its breakthrough novelty at that time. The microminiaturization trend goes back to 1959 when Richard Feynman professed a famous lecture with a title “There’s Plenty of Room at the Bottom” [12] where he discussed the possibility of manipulating atoms to severely reduce sizes of mechanical and electronic devices. The alluring capabilities of micro-sized world echoed within the research and medical communities [1][13][14] and since then a surge of interest in this area has been developed.

Batteries are quite often used in glucose biosensors, for example, because they represent a reliable and long-lasting source of energy. Typical power values of biosensing electronics are less than 10 μW [15] but due to the sole nature of continuous monitoring, batteries become the bottleneck of the power design. For instance, glucose biosensors have a needle that penetrates the skin in order to collect data (Figure 2) and any time the battery needs to be replaced, the patient must go through a painful procedure of taking the biosensor in and out which involves puncturing the skin. Low battery capacity necessitates regular replacements, every week or two; each time the entire glucose biosensor is replaced, not just the battery. The 1.55 V coin-cell battery, which is mounted inside the Abbot’s biosensor, tends to drive higher the end price of the continuous glucose monitoring. Therefore, it is desirable to identify means and methods that allow biosensors to realize continuous monitoring at full potential without the requirement to depend on batteries.

Figure 2. Abbott’s continuous glucose monitoring biosensor; https://diatribe.org (accessed on 9 October 2022).

2. Biomechanical Energy Harvesting

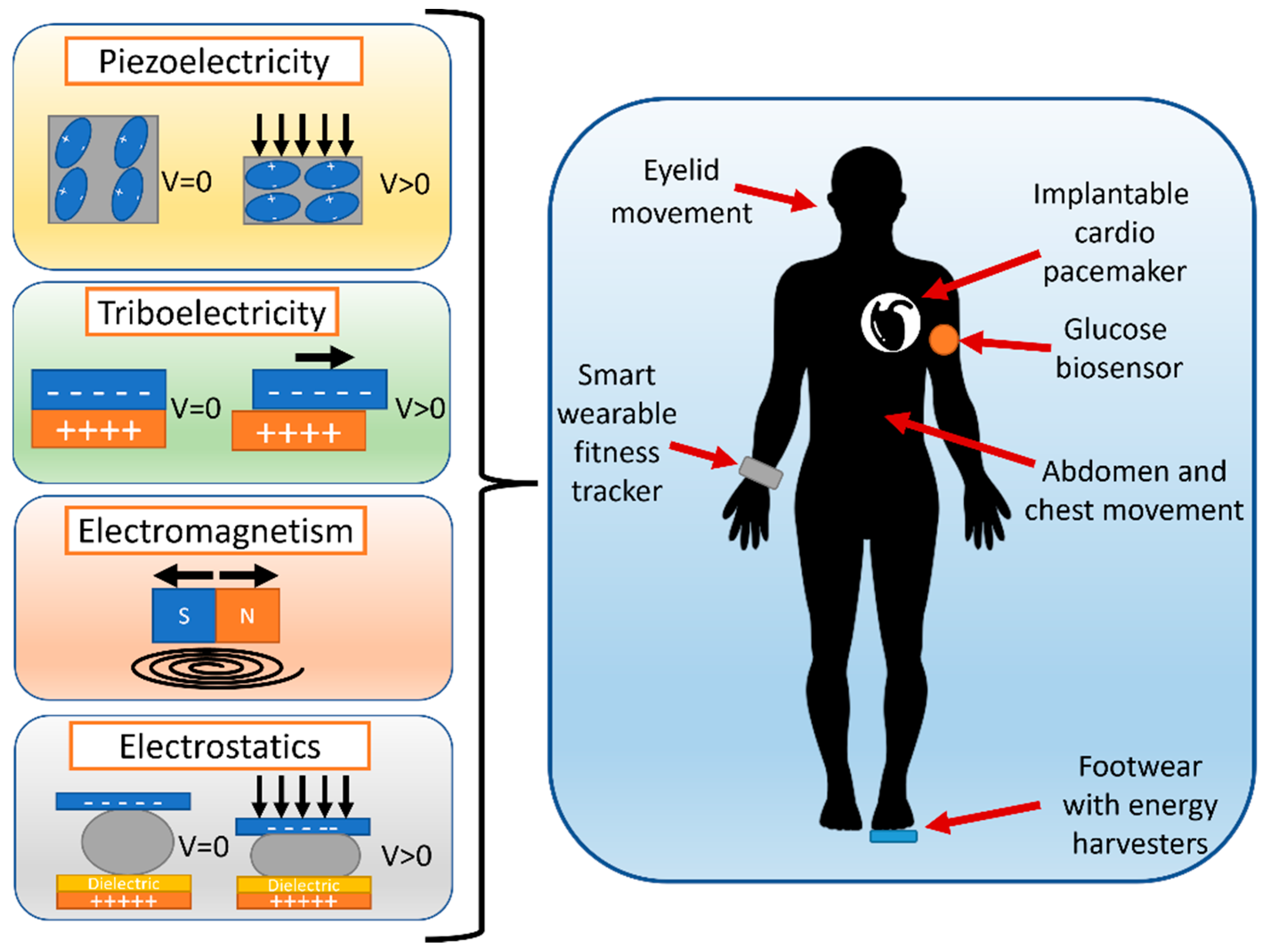

Biomechanical energy is one of the largest categories and one of the most utilized among all other energy sources [3][7][8][9][16][17]. The human body is full of flexible joints and points of concentrated pressure (Figure 3) that could be used for energy harvesting from limb movement, respiration, chest and abdomen displacement, eyelid movement, body pressure onto soil while walking, etc [18][19][20][21].

Figure 3. Biomechanical energy in the human body [22].

2.1. Piezoelectric Nanogenerators

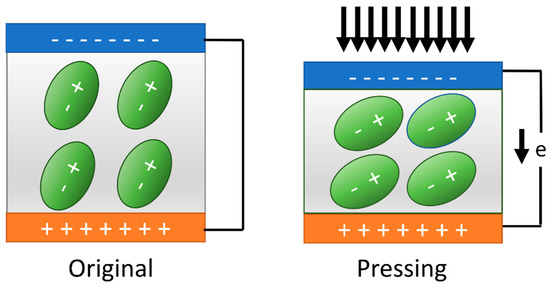

Piezoelectric nanogenerators (PENGs) are used in many applications such as sensors and actuators [23][24][25][26], energy harvesters, micro-electromechanical systems (MEMS) [27] and microfluidics [28]. Energy generation is possible because piezoelectric materials lack central symmetry in their structure. An applied mechanical load induces spontaneous polarization in PENGs and thus electricity is generated (Figure 4). Their popularity is based on their scalability potential, high output power, simplicity of integration [25][29] and availability of “of-the-shelf” energy harvesting solutions (Würth Elektronik, Physik Instrumente, TE connectivity, etc). The downside of PENGs is that their output depends on frequency and optimum actuation values lie in a high-frequency range.

Figure 4. Physical principle of piezoelectric generator [9].

Piezoelectric materials are classified into four main groups: inorganic, organic, composites and biocomposites. Inorganic materials, such as lead zirconate titanate (PZT), barium titanate (BT) and quartz have high values for their electric parameters (piezoelectric strain constant, electromechanical coupling factor and dielectric constant) but they are rigid, brittle and require polling process to function [30]. Organic materials, represented mainly by polyvinylidene difluoride (PVDF) and its copolymer trifluoroethylene (PVDF-TrFE), are on the opposite side of the spectrum and have high elasticity, while having less electrical efficiency. Polymer composites are intended to be the best of both worlds, combining the high piezoelectric parameters of the inorganic materials while staying flexible and biocompatible like the organic materials. Mostly, this is performed by depositing ceramic element, such as BT, on a polymer matrix, such as PVDF [31][32]. Biocomposites are biological tissues that possess inherent piezoelectricity, such as hair, bone, fish bladder, etc. [32].

The most commonly used materials are ZnO, polyvinylidene difluoride (PVDF) and lead zirconate titanate (PZT) [25], all of which have inherent pyroelectric properties [33][34].

The recent advances in the field of piezoelectric energy harvesting build on developments in additive manufacturing capabilities [35]. Montero et al. [36] used inkjet printing to deposit an interdigitated electrode which is subsequently coated with PVDF film. The resulted power density was 0.5 µW·cm−3 with a maximum value of 2.4 nW for the device. Potential applications are varied, for example, a backpack is a quite common form of an attire and thus it is relevant to investigate how much energy can be harvested from it. Zhang et al. [37] used force amplification via a double-bridge frame, studied effects of this method via numerical simulations and experiments and presented a backpack with the maximum output power of 4.13 μW. This power output was reached when the harvester was integrated into a backpack and the person wearing it was jogging. Ruiz et al. [21] demonstrated a respiratory piezoelectric based sensor which, not only provided data for health monitoring, but also could act as an energy harvester. Beyaz [23] described a blood pressure sensing technique which exploits PENGs. Three piezoelectric transducers were used to exhibit and receive acoustic signals to detect geometrical changes in artery tissue. In terms of biodegradable materials, Kumar et al. [38] used reinforced polycarbonate which resulted in a flexible platform that provided high power density up to 2556 μW·cm−3 at maximum. An unorthodox approach was taken by Sun et al. [39] who reported a PENG made out of a wood sponge. Balsa wood was processed to remove lignin and hemicellulose which resulted in a crystal structure that possessed a high piezoelectric coefficient. Not only does this NG used a biodegradable material, but wood is also present in an abundance thus making this PENG a prominent candidate for wearable harvesters. The scalability potential of the PENG suggests that it can be used for application for wearable electronics and for powering LED lights and LCD screens. The peak power density reached was 0.6 nW·cm−2. Due to the way the internal electrostatic field propagates inside the piezoelectric material, it is usually synonymous with relatively low current density and thus lower power density output, especially compared to triboelectric materials. Gu et al. [40] proposed a variant of PENG with high output current density. In order to achieve this, a high piezoelectric coefficient material Sm-PMN-PT was selected, and an intercalation electrode structure was utilized. Essentially, the way to increase piezoelectric energy lies in increasing electrode surface area. The authors of this work proposed a way to enhance PENG by integrating multiple electrodes inside the piezoelectric film and sandwiching them together resulting in a PENG which had as high as 12 units of this structure stacked together. As a result, a maximum peak short-circuit current of 320 μA was obtained by the harvester. Xu et al. [41] designed a PENG that can be attached to one of the leads of a pacemaker. The main material used was microporous P(VDF-TrFE) thin film that was deposited onto Kapton film and sandwiched between Au electrodes. From the engineering point of view, the authors decided to implement a multibeam design. The harvester had a cylindric form and its inner space was filled with piezoelectric films which play role of beams. Then, the harvester was placed onto a lead. A pacemaker lead was fixed by these films and when the lead was subject to movement, its energy was transferred to the PENG. The output energy was 6.5 μJ that was stored in a 120 uF capacitor. It can be deduced that, despite being relatively simple and long-studied subject, PENGs are in a high demand and present a very prominent foundation for energy harvesting. Yet, their cost and dependence on actuation frequency need to be taken into account during the design phase [42].

2.2. Triboelectric Nanogenerators

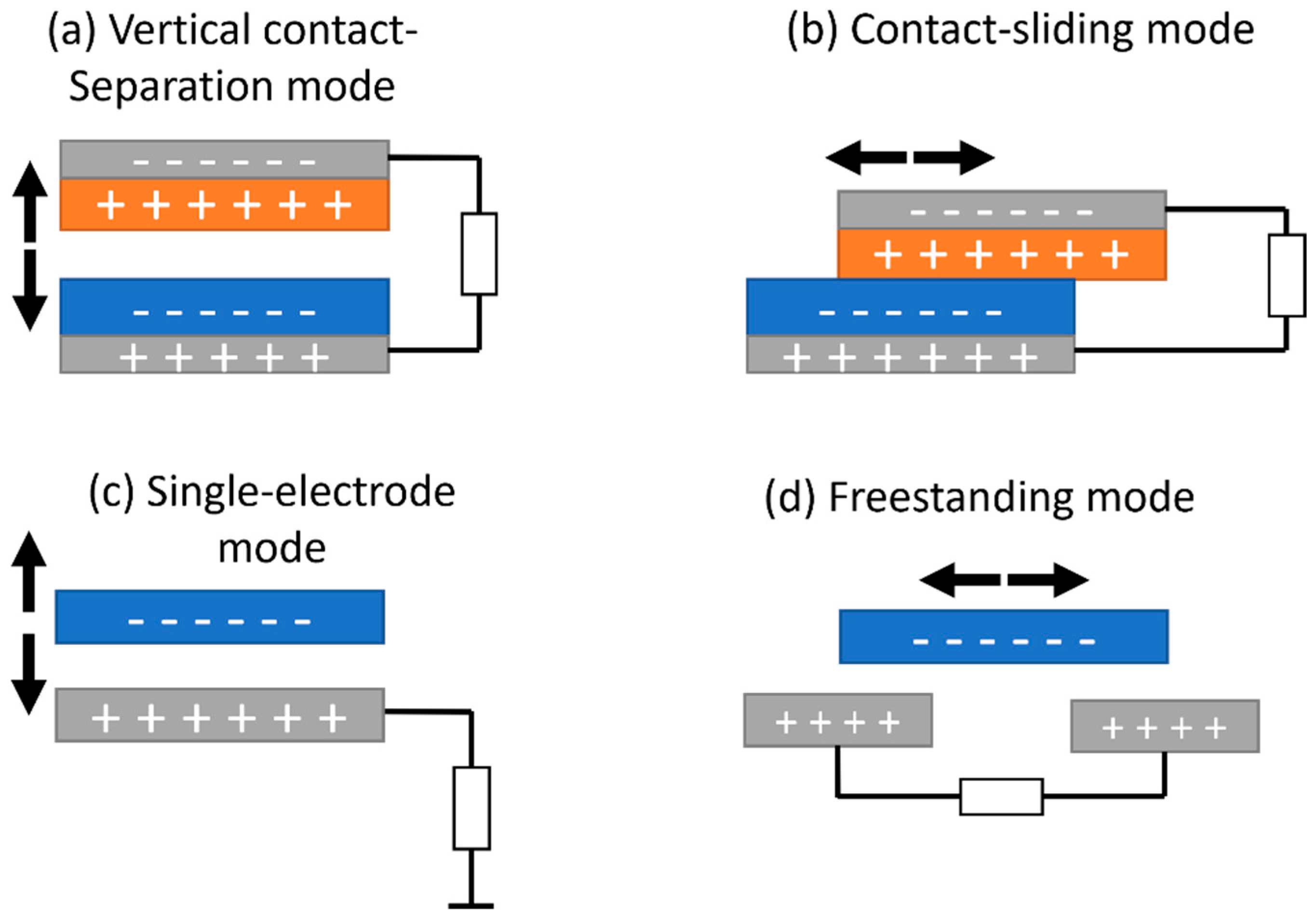

Triboelectric nanogenerators (TENGs) are used to power many sensors and energy harvesters of different designs [20][43][44]. TENGs harvest kinetic energy of the human body akin to PENGs and exploit the same points of mechanical pressure. The underlying physical principle is the fact that materials have different tribopolarities and when paired properly, spatial manipulation causes triboelectrification and electrostatic induction. Surface porosity plays a vital role in the process of designing TENGs [45]. There are four fundamental operational modes of TENGs as displayed in Figure 5, each utilized under different circumstances [44]. In the vertical contact separation mode (Figure 5a) which features two electrodes and a dielectric film, when the mechanical force is applied, triboelectrification charges the electrodes, and when the force is released and there is a small gap between the electrodes, electrostatic induction causes current to flow. Contact-sliding or lateral-sliding mode (Figure 5b) works similarly to the first mode, yet electrodes move to the sides. In the single-electrode mode (Figure 5c), only one grounded electrode is present which is spatially separated from a dielectric film. While approaching to and departing from the electrode, electrical field changes due to the triboelectrification. The potential difference between the materials cause electrons to flow. In the freestanding triboelectric-layer mode (Figure 5d) the dielectric layer moves, while the electrodes remain still. The major advantage of using TENGs is their low cost per Watt at low frequencies [46], their high output power and that the output voltage is independent of frequency. However, the issue of the overvoltage influences the energy conditioning circuitry and TENGs tend to have small currents.

Figure 5. Fundamental operational modes of TENG: (a) vertical contact-separation mode, (b) contact-sliding mode, (c) single-electrode mode, (d) freestanding triboelectric-layer mode [9].

Triboelectrification occurs between two materials, one of which has a higher electron affinity (acceptor), while the other material has lower electron affinity (donor). According to the results of material selection summary [47], Polytetrafluoroethylene (PTFE), polydimethyl-siloxane (PDMS), fluorinated ethylene propylene (FEP) and Kapton are widely used as electron acceptors. As electron donors, materials such as aluminum, cuprum, skin and Nylon are mostly used. In addition, triboelectric generators can be represented as four (4) layers which are the charge-generating, charge trapping, charge-collecting and charge-storage layers whereas the materials for such complex structure are described elsewhere [48].

In terms of practical application, Zhang et al. [49] presented a paper-based TENG capable of producing up to 171 mW·m−2. A highlight of this work is that a single-electrode TENG can be produced relatively economically and fast from waste paper, which serves as a triboelectric layer. Jiang et al. [50] described a TENG with self-healing capabilities. The synthesized elastomer proved to be both extremely elastic (10000%) and could completely repair itself while reaching an output of 450 mW·m−2. Another single-electrode mode TENG for tactile sensors was designed by Wu et al. [51] where the surface porosity was optimized in order to provide the best results possible and a power density of 33.75 W·m−2 was achieved. Guan et al. [52] reported a TENG based on a two-electrodes contact-separate mode that had a negative Poisson-ratio fiber inserted into positive Poisson-ratio hallow cylinder. This synergistic structure could provide up to 52.36 mW·m−2. Liao et al. [53] proposed an ion-gel based TENG that could heal itself, could effectively work in a wide range of temperatures (−70 to 250 °C) and was transparent. The approach of using ion-gel instead of regular electrodes allows to reach outstanding stretchability parameters (1012%). The self-healing capability was tested by cutting the gel in half and sticking it back together. The demonstrated TENG reached power density of 2.17 W·m−2. Another unusual application of gel in TENG was suggested by Sheng et al. [54] who investigated the application of highly stretchable (>10,000%) TENG as an arm training sensor or for helping patients with self-rehabilitation. This harvester reached a power density of 30 mW·m−2. Yang et al. [55] indicated that there are still ways to improve the design layout of TENG instead of trying to improve harvesters on molecular level with a report on a honey combed TENG. The outer layer which forms a carcass of the harvester is a 3D printed TPU material, the top three honeycomb walls are coated with conductive fabric and PBAT film while the bottom three walls are coated with Al film. In this case, PBAT and Al work as triboelectric layers when being pressed against each other. Additionally, this design was very easily manufactured making it extremely useful for prototyping and massive production. This design solution reached a power output of 10.79 W·m−2 and a high voltage of 1500 V. Ryu et al. [56] described a TENG producing 4.9 μW·cm−3 which is suitable for use with IMDs and pacemakers. In this work, the TENG consisted of multiple stacked units, it works in free-standing mode and harvests vertical displacement of the chest. The harvested energy was subsequently conditioned and put into a Li-ion battery. This work also featured an in vivo experiment involving an adult mongrel. Over a span of 24 h, 144 mW of power was harvested considering both periods of low and high activity. Biocompatibility was examined by the inflammation response of the animal which proved to be within limits and no signs of infections or fever were observed. Overall, TENGs are a prominent method of energy harvesting that has a considerable amount of output power that is achieved through various intricate design choices. However, the conditioning circuit plays a huge role in this type of harvesters due to the overvoltage [42].

2.3. Electromagnetic Generators

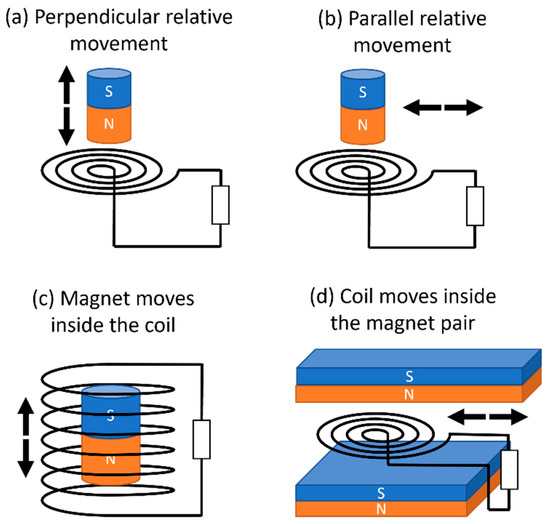

Electromagnetic generators (EMGs) follow a variety of constructive implementations that revolve around moving a coil relative to magnets thus exploiting Faraday’s law of induction [9][10] which implies that a change in magnetic flux results in an induction of electromotive force. It can be achieved through four main mechanisms: moving the magnet perpendicularly relative to the coil (Figure 6a), moving the magnet in parallel to the coil (Figure 6b), moving the magnet inside the coil (Figure 6c); and moving the coil in-between magnets (Figure 6d). The current trend in EMGs lies in the hybridization of EMGs and TENGs, which proves to have fruitful results. The main advantage of EMGs is that they have low matching resistance values [57] and can be effectively used at low frequencies [58]. On the other hand, they have inherently rigid nature and might have reliability issues [59].

Figure 6. Physical principle of electromagnetic generator: (a) perpendicular relative movement, (b) lateral or parallel relative movement, (c) magnet movement inside the coil, (d) coil relative movement in-between magnets [9].

Jiang et al. [60] presented a hybrid harvester where human body pressure from movement is transformed via transmission into radial movement of a generator. The generator consisted of rotating triboelectric blades which worked in the freestanding triboelectric-layer mode, magnets and coils that were placed in the rotor and the stator respectively. In terms of output power, the harvester provided 14.68 mJ when integrated into a shoe. Li et al. [61] developed a magnetized microscale needle array which also possessed triboelectric properties. The device used microneedles that induced triboelectrification when rubbed against the substrate, which also acted as a magnet moving up and down relatively to the coil. This combination of energy harvesting generators achieved up to 16.19 μW·m−2 for a load of 106 Ω. Practical application involved putting the harvester into a shoe and the values of collected voltage for walking and jogging were very different for the TENG (2.8 V and 6 V respectively), whereas the collected current for the EMG indicated less difference (4.5 µA vs. 5.3 µA). Iqbal et al. [57] described PENG mixed with EMG that could be inserted into a shoe insole. As a result, the overall output was better than using PENG or EMG separately and a power of 4.05 µW·cm−3 was achieved. On the other hand, Lai et al. [62] reported on a hybrid harvester that scavenges electromagnetic energy from the ambient environment such as a mobile phone, laptop or any other electronic device. The mechanical energy was harvested via TENG that worked in the single-electrode mode. The peak power was 360 µW·m−1. Li et al. [58] designed a hybrid PENG and EMG, where PENG was connected to the EMG via a spring-loaded mechanism. In this harvester, two generators harvested energy separately, but they were combined through the mechanical transmission. A power output of 36.21 mW·cm−3 was reached. Electromagnetic energy is an underutilized and unconventional source for biomechanical energy harvesting, but it may prove to be useful in combination with other NGs.

2.4. Electrostatic Nanogenerators

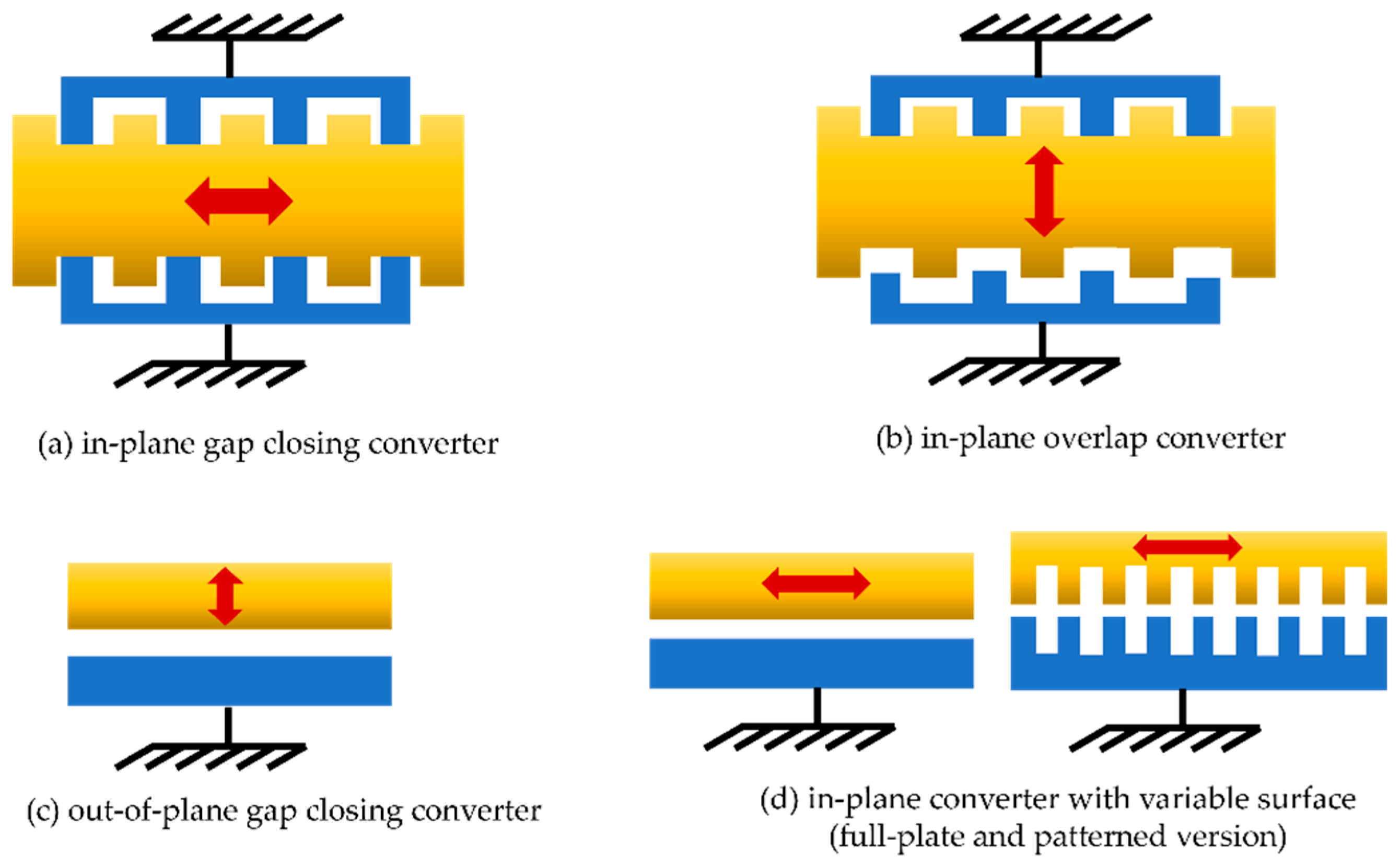

Electrostatic generators (ESGs) are a type of a varying capacitor and their working principle is described by electrostatic induction [8]. The capacitance of such a device changes as a result of changes in the overlap area or in the gap between two electrodes, caused by some external stimuli (Figure 7). The induced electrical charge will result in electric current. There are four main shapes of ESGs: an in-plane gap closing ESG where the electrode moves sideways (Figure 7a), an in-plane overlap ESG where the counter-electrode moves in plane thus changing the overlap (Figure 7b), out-of-plane gap closing converter where the gap between electrodes changes (Figure 7c), in-plane ESG where the overlap varies by moving across one axis (Figure 7d). The application of such varying capacitors ranges from biosensors, textile wearable electronics, biomechanical energy harvesting to solar energy storage. The main advantage of using ESGs is their simple structure and high output at high frequencies however they frequently need bias voltage to function properly and most methods of increasing frequency of a harvester (or self-oscillation feature) includes MEMS [63][64].

Figure 7. Main shapes of electrostatic generators: (a) in-plane gap closing converter, (b) in-plane overlap converter, (c) out-of-plane gap closing converter, (d) in-plane converter with variable surface [65].

Wu et al. [64] continued the trend of hybridization that is so prominent in other NGs and described a rotatory disc-based EMG and ESG. The modus operandi of the EMG followed the principles discussed in the previous section, while ESG consists of an electret film and the respective electrode. The rotatory movement of the electret film relative to the electrode causes a change in the overlap area. The maximum output density is 2.5 W·m−3 for EMG and 107.8 W·m−3 for ESG. Pourshaban et al. [66] designed an electrostatic generator which is integrated into a contact lens where a tear droplet plays the role of the electret. The average obtained power is 0.265 µW. Erturun et al. [67] proposed a hybrid of PENG and ESG. In this structure, a piezoelectric film is sandwiched between Au and Al electrodes. The Al electrode is coated with Teflon on the opposite side to the PENG and is isolated from the bottom Cu electrode via an air gap confined by two Styrofoam pads. When the harvester is subjected to stress, the electron flow is directed to the Al electrode and outwards, when pressure is released. The maximum attained power density was ∼8.8 μW·cm−3. Cao et al. [68] proposed a hybrid of PENG and EMG where vibrations of a piezoelectric cantilever were also used to harvest electrostatic energy. This is due to fluctuations of a beam that has ESG electrode on it which changes the gap distance and induces change in capacitance. Capacitive harvesters represent a stable source of energy and have been thoroughly investigated for a long period of time thus making them a very suitable choice for a hybridization.

2.5. Reverse Electrowetting on Dielectric Phenomenon (REWOD)

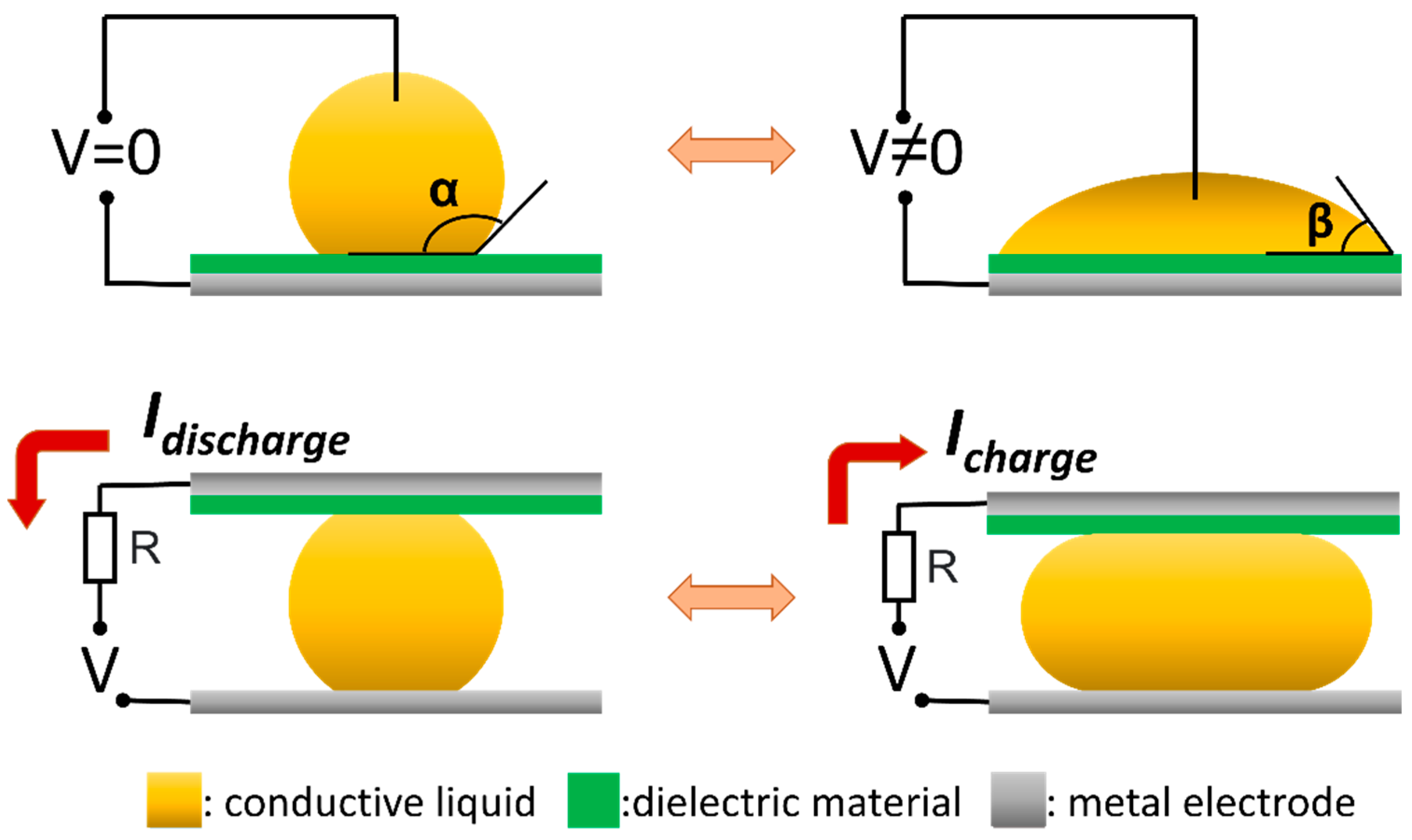

Recently, a lot of attention has been drawn to the reverse electrowetting on dielectric phenomenon (REWOD) [69][70][71]. This is a prominent subclass of ESGs which is based on the direct electrowetting on dielectric (EWOD) phenomenon. EWOD exploits the fact that the liquid-solid (droplet-electrode) interfacial energy can be manipulated by the application of an electric field. This leads to a change in the apparent contact angle between the droplet and the electrode which increases the overlap area (Figure 8). A droplet could potentially be a physiological fluid [72] thus a biomolecular absorption should be taken into account [73]. REWOD works in the opposite manner and when a bubble of conductive liquid is pressed in-between electrodes, the overlap area changes thus significantly increasing the capacitance of the system. Adhikari et al. [71] studied REWOD phenomenon via changing different parameters of the system such as dielectric thickness, electrolyte and dielectric concentrations. When two dissimilar dielectrics are introduced, the system can work without the external bias voltage. A total power density of 53.3 nW·cm−2 was obtained. Tasneem et al. [74] proposed a wearable motion tracking sensor powered by a REWOD principle. A significant focus of the work was oriented towards the conditioning circuit. In this case, the authors used a rectifier based on a Schottky diode followed up by a booster circuitry and the resulted power density of the harvester was 58 nW·cm−2. Hsu et al. [63] described a REWOD harvester that could produce as much as 100 W·m−2 with a 4.5 V of bias voltage and it instantly became one of the most prominent works in the field. The described harvester heavily relies on multiplication of the number of REWOD units and the frequency of their oscillations. Thus, the REWOD method of harvesting biomechanical energy holds a significant potential in what it can practically be achieved.

Figure 8. EWOD and REWOD processes [63].

This entry is adapted from the peer-reviewed paper 10.3390/en15217959

References

- Gambhir Sanjiv, S.; Ge, T.J.; Vermesh, O.; Spitler, R.; Gold Garry, E. Continuous health monitoring: An opportunity for precision health. Sci. Transl. Med. 2021, 13, eabe5383.

- Leenen, J.P.L.; Leerentveld, C.; van Dijk, J.D.; van Westreenen, H.L.; Schoonhoven, L.; Patijn, G.A. Current Evidence for Continuous Vital Signs Monitoring by Wearable Wireless Devices in Hospitalized Adults: Systematic Review. J. Med. Internet Res. 2020, 22, e18636.

- Song, Y.; Mukasa, D.; Zhang, H.; Gao, W. Self-Powered Wearable Biosensors. Acc. Mater. Res. 2021, 2, 184–197.

- Tan, P.; Zou, Y.; Fan, Y.; Li, Z. Self-powered wearable electronics. Wearable Technol. 2020, 1, e5.

- Molina Arias, L.; Iwaniec, J.; Iwaniec, M. Modeling and Analysis of the Power Conditioning Circuit for an Electromagnetic Human Walking-Induced Energy Harvester. Energies 2021, 14, 3367.

- Guo, X.; Liu, L.; Zhang, Z.; Gao, S.; He, T.; Shi, Q.; Lee, C. Technology evolution from micro-scale energy harvesters to nanogenerators. J. Micromech. Microeng. 2021, 31, 093002.

- He, T.; Guo, X.; Lee, C. Flourishing energy harvesters for future body sensor network: From single to multiple energy sources. iScience 2021, 24, 101934.

- Rong, G.; Zheng, Y.; Sawan, M. Energy Solutions for Wearable Sensors: A Review. Sensors 2021, 21, 3806.

- Zhang, T.; Yang, T.; Zhang, M.; Bowen, C.R.; Yang, Y. Recent Progress in Hybridized Nanogenerators for Energy Scavenging. iScience 2020, 23, 101689.

- Xu, C.; Song, Y.; Han, M.; Zhang, H. Portable and wearable self-powered systems based on emerging energy harvesting technology. Microsyst. Nanoeng. 2021, 7, 25.

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246.

- Feynman, R.P. There’s Plenty of Room at the Bottom. Eng. Sci. 1960, 23, 63–76.

- Schüssler-Fiorenza Rose, S.M.; Contrepois, K.; Moneghetti, K.J.; Zhou, W.; Mishra, T.; Mataraso, S.; Dagan-Rosenfeld, O.; Ganz, A.B.; Dunn, J.; Hornburg, D.; et al. A longitudinal big data approach for precision health. Nat. Med. 2019, 25, 792–804.

- Sharma, A.; Badea, M.; Tiwari, S.; Marty, J.L. Wearable Biosensors: An Alternative and Practical Approach in Healthcare and Disease Monitoring. Molecules 2021, 26, 748.

- Lee, P.M.; Xiong, Z.; Ho, J. Methods for powering bioelectronic microdevices. Bioelectron. Med. 2018, 1, 201–217.

- Afroz, A.S.; Romano, D.; Inglese, F.; Stefanini, C. Towards Bio-Hybrid Energy Harvesting in the Real-World: Pushing the Boundaries of Technologies and Strategies Using Bio-Electrochemical and Bio-Mechanical Processes. Appl. Sci. 2021, 11, 2220.

- Zou, Y.; Bo, L.; Li, Z. Recent progress in human body energy harvesting for smart bioelectronic system. Fundam. Res. 2021, 1, 364–382.

- Li, J.; Long, Y.; Yang, F.; Wang, X. Respiration driven triboelectric nanogenerators for biomedical applications. EcoMat 2020, 2, e12045.

- Pourshaban, E.; Karkhanis, M.U.; Deshpande, A.; Banerjee, A.; Ghosh, C.; Kim, H.; Mastrangelo, C.H. A Magnetically-Coupled Micromachined Electrostatic Energy Harvester Driven by Eye Blinking Motion. In Proceedings of the 2021 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021; pp. 960–963.

- Pu, X.; An, S.; Tang, Q.; Guo, H.; Hu, C. Wearable triboelectric sensors for biomedical monitoring and human-machine interface. iScience 2021, 24, 102027.

- Ruiz, L.L.; Lin, V.; Fitzgerald, L.; Zhu, J.; Borish, L.; Quinn, D.; Lach, J. Piezoelectric-Based Respiratory Monitoring: Towards Self-Powered Implantables for the Airways. In Proceedings of the 2021 IEEE 17th International Conference on Wearable and Implantable Body Sensor Networks (BSN), Athens, Greece, 27–30 July 2021; pp. 1–5.

- Khalid, S.; Raouf, I.; Khan, A.; Kim, N.; Kim, H.S. A Review of Human-Powered Energy Harvesting for Smart Electronics: Recent Progress and Challenges. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 821–851.

- Beyaz, M.İ. An acoustic blood pressure sensing scheme using time of flight and shear wave elastography techniques. Sens. Actuators A Phys. 2021, 330, 112865.

- Chen, Y.; Yang, Y.; Li, M.; Chen, E.; Mu, W.; Fisher, R.; Yin, R. Wearable Actuators: An Overview. Textiles 2021, 1, 283–321.

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864.

- Veronica, A.; Hsing, I.m. An Insight into Tunable Innate Piezoelectricity of Silk for Green Bioelectronics. ChemPhysChem 2021, 22, 2266–2280.

- Nagaraj, M.J.; Shantha, V.; Nishanth, N.; Parthsarathy, V. Study and Optimization of Piezoelectric Materials for MEMS Biochemical Sensor Applications. In Advances in Renewable Energy and Electric Vehicles; Sanjeevikumar, P., Nagesh, p., Suryanarayana, K., Eds.; Springer: Singapore, 2022; Volume 767, pp. 419–425.

- Wang, D.-H.; Peng, Y.-H.; Tang, L.-K.; Yu, H.-Q. A multi-chamber piezoelectric pump based on pumping unit with double circular piezoelectric unimorph actuators. Smart Mater. Struct. 2021, 30, 095023.

- Tong, Z.; Hu, H.; Wu, Z.; Xie, S.; Chen, G.; Zhang, S.; Lou, L.; Liu, H. An Ultrasonic Proximity Sensing Skin for Robot Safety Control by Using Piezoelectric Micromachined Ultrasonic Transducers (PMUTs). IEEE Sens. J. 2021, 22, 17351–17361.

- Vijayakanth, T.; Liptrot, D.J.; Gazit, E.; Boomishankar, R.; Bowen, C.R. Recent Advances in Organic and Organic–Inorganic Hybrid Materials for Piezoelectric Mechanical Energy Harvesting. Adv. Funct. Mater. 2022, 32, 2109492.

- Soleimani, Z.; Zoras, S.; Ceranic, B.; Cui, Y.; Shahzad, S. A comprehensive review on the output voltage/power of wearable thermoelectric generators concerning their geometry and thermoelectric materials. Nano Energy 2021, 89, 106325.

- Lay, R.; Deijs, G.S.; Malmström, J. The intrinsic piezoelectric properties of materials—A review with a focus on biological materials. RSC Adv. 2021, 11, 3657–3673.

- Surmenev, R.A.; Chernozem, R.V.; Pariy, I.O.; Surmeneva, M.A. A review on piezo- and pyroelectric responses of flexible nano- and micropatterned polymer surfaces for biomedical sensing and energy harvesting applications. Nano Energy 2021, 79, 105442.

- Sultana, A.; Alam, M.M.; Middya, T.R.; Mandal, D. A pyroelectric generator as a self-powered temperature sensor for sustainable thermal energy harvesting from waste heat and human body heat. Appl. Energy 2018, 221, 299–307.

- Koroglu, L.; Ayas, E.; Ay, N. 3D Printing of Polyvinylidene Fluoride Based Piezoelectric Nanocomposites: An Overview. Macromol. Mater. Eng. 2021, 306, 2100277.

- Montero, K.L.; Laurila, M.M.; Mäntysalo, M. Fully Printed Unobtrusive and Skin-conformable Piezoelectric Energy Harvester. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Manchester, UK, 20–23 June 2021; pp. 1–4.

- Zhang, J.; Yu, X.; Zhao, W.; Qu, D. A piezoelectric vibration energy harvester based on the reverse-rhombus double-bridge force amplification frame. J. Phys. D Appl. Phys. 2021, 54, 365501.

- Kumar, N.; Mahale, B.; Muzata, T.S.; Ranjan, R. Energy harvesting with flexible piezocomposite fabricated from a biodegradable polymer. Int. J. Energy Res. 2021, 45, 19395–19404.

- Sun, J.; Guo, H.; Ribera, J.; Wu, C.; Tu, K.; Binelli, M.; Panzarasa, G.; Schwarze, F.W.M.R.; Wang, Z.L.; Burgert, I. Sustainable and Biodegradable Wood Sponge Piezoelectric Nanogenerator for Sensing and Energy Harvesting Applications. ACS Nano 2020, 14, 14665–14674.

- Gu, L.; Liu, J.; Cui, N.; Xu, Q.; Du, T.; Zhang, L.; Wang, Z.; Long, C.; Qin, Y. Enhancing the current density of a piezoelectric nanogenerator using a three-dimensional intercalation electrode. Nat. Commun. 2020, 11, 1030.

- Xu, Z.; Jin, C.; Cabe, A.; Escobedo, D.; Hao, N.; Trase, I.; Closson, A.B.; Dong, L.; Nie, Y.; Elliott, J.; et al. Flexible Energy Harvester on a Pacemaker Lead Using Multibeam Piezoelectric Composite Thin Films. ACS Appl. Mater. Interfaces 2020, 12, 34170–34179.

- Thainiramit, P.; Yingyong, P.; Isarakorn, D. Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters. Sensors 2020, 20, 5828.

- Song, Y.; Wang, N.; Hu, C.; Wang, Z.L.; Yang, Y. Soft triboelectric nanogenerators for mechanical energy scavenging and self-powered sensors. Nano Energy 2021, 84, 105919.

- Zou, Y.; Raveendran, V.; Chen, J. Wearable triboelectric nanogenerators for biomechanical energy harvesting. Nano Energy 2020, 77, 105303.

- Pharino, U.; Sinsanong, Y.; Pongampai, S.; Charoonsuk, T.; Pakawanit, P.; Sriphan, S.; Vittayakorn, N.; Vittayakorn, W. Influence of pore morphologies on the mechanical and tribo-electrical performance of polydimethylsiloxane sponge fabricated via commercial seasoning templates. Radiat. Phys. Chem. 2021, 189, 109720.

- Ahmed, A.; Hassan, I.; Helal, A.S.; Sencadas, V.; Radhi, A.; Jeong, C.K.; El-Kady, M.F. Triboelectric Nanogenerator versus Piezoelectric Generator at Low Frequency (<4 Hz): A Quantitative Comparison. iScience 2020, 23, 101286.

- Zhang, R.; Olin, H. Material choices for triboelectric nanogenerators: A critical review. EcoMat 2020, 2, e12062.

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6.

- Zhang, Z.; Jie, Y.; Zhu, J.; Zhu, Z.; Chen, H.; Lu, Q.; Zeng, Y.; Cao, X.; Wang, N.; Wang, Z. Paper triboelectric nanogenerator designed for continuous reuse and quick construction. Nano Res. 2021, 15, 1109–1114.

- Jiang, J.; Guan, Q.; Liu, Y.; Sun, X.; Wen, Z. Abrasion and Fracture Self-Healable Triboelectric Nanogenerator with Ultrahigh Stretchability and Long-Term Durability. Adv. Funct. Mater. 2021, 31, 2105380.

- Wu, M.; Gao, Z.; Yao, K.; Hou, S.; Liu, Y.; Li, D.; He, J.; Huang, X.; Song, E.; Yu, J.; et al. Thin, soft, skin-integrated foam-based triboelectric nanogenerators for tactile sensing and energy harvesting. Mater. Today Energy 2021, 20, 100657.

- Guan, X.; Xu, B.; Huang, J.; Jing, T.; Gao, Y. Fiber-shaped stretchable triboelectric nanogenerator with a novel synergistic structure of opposite Poisson’s ratios. Chem. Eng. J. 2022, 427, 131698.

- Liao, W.; Liu, X.; Li, Y.; Xu, X.; Jiang, J.; Lu, S.; Bao, D.; Wen, Z.; Sun, X. Transparent, stretchable, temperature-stable and self-healing ionogel-based triboelectric nanogenerator for biomechanical energy collection. Nano Res. 2021, 15, 2060–2068.

- Sheng, F.; Yi, J.; Shen, S.; Cheng, R.; Ning, C.; Ma, L.; Peng, X.; Deng, W.; Dong, K.; Wang, Z.L. Self-Powered Smart Arm Training Band Sensor Based on Extremely Stretchable Hydrogel Conductors. ACS Appl. Mater. Interfaces 2021, 13, 44868–44877.

- Yang, Y.; Chen, L.; He, J.; Hou, X.; Qiao, X.; Xiong, J.; Chou, X. Flexible and Extendable Honeycomb-Shaped Triboelectric Nanogenerator for Effective Human Motion Energy Harvesting and Biomechanical Sensing. Adv. Mater. Technol. 2021, 7, 2100702.

- Ryu, H.; Park, H.-m.; Kim, M.-K.; Kim, B.; Myoung, H.S.; Kim, T.Y.; Yoon, H.-J.; Kwak, S.S.; Kim, J.; Hwang, T.H.; et al. Self-rechargeable cardiac pacemaker system with triboelectric nanogenerators. Nat. Commun. 2021, 12, 4374.

- Iqbal, M.; Nauman, M.M.; Khan, F.U.; Abas, P.E.; Cheok, Q.; Iqbal, A.; Aissa, B. Multimodal Hybrid Piezoelectric-Electromagnetic Insole Energy Harvester Using PVDF Generators. Electronics 2020, 9, 635.

- Li, Z.; Luo, J.; Xie, S.; Xin, L.; Guo, H.; Pu, H.; Yin, P.; Xu, Z.; Zhang, D.; Peng, Y.; et al. Instantaneous peak 2.1 W-level hybrid energy harvesting from human motions for self-charging battery-powered electronics. Nano Energy 2021, 81, 105629.

- Zhou, W.; He, J.; Peng, P.; Chen, L.; Cao, K. Reliability of Microelectromechanical Systems Devices. In Reliability and Maintenance: An Overview of Cases; IntechOpen: London, UK, 2020.

- Jiang, D.; Ouyang, H.; Shi, B.; Zou, Y.; Tan, P.; Qu, X.; Chao, S.; Xi, Y.; Zhao, C.; Fan, Y.; et al. A wearable noncontact free-rotating hybrid nanogenerator for self-powered electronics. InfoMat 2020, 2, 1191–1200.

- Li, Y.; Chen, Z.; Zheng, G.; Zhong, W.; Jiang, L.; Yang, Y.; Jiang, L.; Chen, Y.; Wong, C.-P. A magnetized microneedle-array based flexible triboelectric-electromagnetic hybrid generator for human motion monitoring. Nano Energy 2020, 69, 104415.

- Lai, Y.-C.; Lu, H.-W.; Wu, H.-M.; Zhang, D.; Yang, J.; Ma, J.; Shamsi, M.; Vallem, V.; Dickey, M.D. Elastic Multifunctional Liquid–Metal Fibers for Harvesting Mechanical and Electromagnetic Energy and as Self-Powered Sensors. Adv. Energy Mater. 2021, 11, 2100411.

- Hsu, T.-H.; Manakasettharn, S.; Taylor, J.A.; Krupenkin, T. Bubbler: A Novel Ultra-High Power Density Energy Harvesting Method Based on Reverse Electrowetting. Sci. Rep. 2015, 5, 16537.

- Wu, Z.; Cao, Z.; Ding, R.; Wang, S.; Chu, Y.; Ye, X. An electrostatic-electromagnetic hybrid generator with largely enhanced energy conversion efficiency. Nano Energy 2021, 89, 106425.

- Boisseau, S.; Despesse, G.; Seddik, B. Electrostatic Conversion for Vibration Energy Harvesting. In Small-Scale Energy Harvesting; BoD–Books: Norderstedt, Germany, 2012.

- Pourshaban, E.; Karkhanis, M.U.; Deshpande, A.; Banerjee, A.; Ghosh, C.; Kim, H.; Mastrangelo, C.H. Flexible Electrostatic Energy Harvester Driven by Cyclic Eye Tear Wetting and Dewetting. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Manchester, UK, 20–23 June 2021; pp. 1–4.

- Erturun, U.; Eisape, A.A.; Kang, S.H.; West, J.E. Energy harvester using piezoelectric nanogenerator and electrostatic generator. Appl. Phys. Lett. 2021, 118, 063902.

- Cao, Y.; Nie, D.; Zhang, J.; Wang, Y.; He, R.; Zhao, Z.; Wu, J.; Ji, B.; Xie, J.; Tao, K. Investigation of electrostatic-piezoelectric hybrid vibrational power generators with different frequency broadening schemes. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021; pp. 528–532.

- Boroujeni, F.G.; Raissi, B.; Jafarabadi-Ashtiani, S.; Riahifar, R.; Sahba-Yaghmaee, M. Droplet-based energy harvester considering electrowetting phenomena. Eng. Res. Express 2020, 2, 045028.

- Wu, H.; Mendel, N.; van der Ham, S.; Shui, L.; Zhou, G.; Mugele, F. Charge Trapping-Based Electricity Generator (CTEG): An Ultrarobust and High Efficiency Nanogenerator for Energy Harvesting from Water Droplets. Adv. Mater. 2020, 32, 2001699.

- Adhikari, P.R.; Tasneem, N.T.; Reid, R.C.; Mahbub, I. Electrode and electrolyte configurations for low frequency motion energy harvesting based on reverse electrowetting. Sci. Rep. 2021, 11, 5030.

- Srinivasan, V.; Pamula, V.K.; Fair, R.B. An integrated digital microfluidic lab-on-a-chip for clinical diagnostics on human physiological fluids. Lab. A Chip 2004, 4, 310–315.

- Yoon, J.-Y.; Garrell, R.L. Preventing Biomolecular Adsorption in Electrowetting-Based Biofluidic Chips. Anal. Chem. 2003, 75, 5097–5102.

- Tasneem, N.T.; Biswas, D.K.; Mahbub, I.; Adhikari, P.R.; Reid, R. Self-Powered Motion Tracking Sensor Integrated with Low-Power CMOS Circuitry. In Proceedings of the 2021 IEEE International Symposium on Circuits and Systems (ISCAS), Daegu, Korea, 22–28 May 2021; pp. 1–5.

This entry is offline, you can click here to edit this entry!