Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Electrical & Electronic

As the impacts of environmental change become more severe, reliable and sustainable power generation and efficient aerodynamic power collection of onshore and offshore wind turbine systems present some of the associated key issues to address.

- aerodynamic power extraction

- environmental challenges

- pitch/yaw and torque control systems

1. Introduction

Research investigations into the technologies that make renewable energy possible and strategies to enhance them have seen tremendous advances in the past few decades. Although global warming and climate change are regarded as severe warnings across the globe, many governments and organizations are taking action by imposing green rules on the energy sector [1,2,3,4]. The world-installed wind power capacity has grown to 12.4% in 2021 by reaching 837 GW, an increase of 93.6 GW from the previous high in 2020. In addition, 2017 recorded the second-lowest year for new onshore wind installations, but still reached a record high at 72.5 GW. At the same time, 2021 will be a record year for the offshore wind industry with over 21 GW of grid-connected wind energy systems [5]. This is a three-fold increase over the previous year owing to the superior power generation capacity, substantially lower cost, and minimal environmental impact [6,7,8]. Many experts and organizations have proposed various strategies for scaling wind turbines to meet the ever-increasing demand for power consumption [9]. This is because super-large wind turbines produce more net electricity and have a lower Levelized Cost of Energy (LCOE) [10,11]. However, trade-offs are associated with increasing scale, such as increasing the volume of production and construction cost [12]. Therefore, it has always been a challenging feat to construct large-scale wind turbines (WTs) with optimal weight, volume, and mass [13,14].

WTs are often designed to endure extreme wind conditions but cannot tolerate high rotating speeds and torques. The turbine is configured with a cut-off speed that decelerates from top speed until it stops. Therefore, the absence of a cutout speed increases aerodynamic torque and rotational speed, placing enormous forces on the WT blades and different turbine elements and damaging the WTs. Vertical-axis wind turbines (VAWTs) and horizontal-axis wind turbines (HAWTs) are the two primary types of WT that have been implemented to meet rising energy needs [15,16]. Researchers have paid particular attention to HAWTs because of the many advantages that they provide, including high-power production efficiency [17,18], dependability [19], and variable speed operation [20,21]. In terms of maximizing energy extraction and minimizing structural stress, the performance of the WT is directly affected by the moving wind speed situation and the critical moment of inertia of the HAWTs.

On the other hand, climate change creates severe challenges to wind power generation by altering atmospheric dynamics and influencing wind patterns [22,23]. Wind output is difficult to predict due to the increased unpredictability of available wind resources. Annual wind density and wind quality variations are caused by climate change [24,25]. Wind speed is an essential factor in wind turbine systems (WTS) that can affect climate change. As a result, it is more important than ever to estimate the impact of future climate change scenarios on the various factors that can affect wind speed and wind output. Moreover, wind speed fluctuations complicate the process of determining whether or not a project is financially viable [26,27]. In this regard, among the many effects of climate change on the global meteorological system, the impact on wind resources and the wind energy industry is receiving more attention.

2. Aerodynamic Power Extraction Challenges in Super-Large WTS

Wind power output is affected by climate change due to a variety of reasons. As a result, component life spans are decreased, and maintenance expenses are raised. Interestingly, many studies have emphasized the need for accurate wind data forecasts for optimizing electricity production and distribution processes in WTSs. However, climate change continues to affect wind speed, and the values are uncertain among the perceived wind models. Therefore, the aerodynamic power extraction is automatically reduced. In this regard, the impact of climate change, such as hot and cold climates, should be assessed to minimize wind speed uncertainty. It should be mentioned here that aerodynamic power fluctuations in climate change can be accurately modeled using the following three environmental factors, (i)iced WT in cold climates, (ii) temperature with humidity effects, and (iii) rainfall effects.

Subsequently, much research has been focused on the impact of icing on WT blades, characteristics, and comparative investigations between the ice protection systems [46,47,48]. As a result, the annual power output of the super-large WTS is reduced by between 0.005% and 50%. To address this problem, the authors proposed an advanced ice-protection control technique for the super-large WTS. Furthermore, in [49], the authors presented a comprehensive review of ice protection schemes and their characteristics in the super-large WTS. On the other hand, the effect of temperature and humidity significantly impact wind speed, leading to a 20%∼30% decrease in aerodynamic power [50]. Recently, the authors in [51] considered the temperature effects in aerodynamic modeling to propose maximum power extraction control techniques using cascaded neural networks. However, humidity effects are not considered in the aerodynamics of WTS. As a result, it was found that the effect of temperature and humidity significantly affected the air density impact on the amount of electricity produced by WTS. Therefore, a study on the function of WTS should be conducted to determine whether such an effect exists.

Raindrops significantly impact power generation losses even with the same amount of rainfall [52]. WT blades perform akin to bird feathers in heavy rain. A similar scenario occurs when the rain suddenly changes direction. In short, due to the abrupt change in wind speed and direction during poor weather conditions and the complex factors of WT control, the blade surface is attacked by wind along with the rainfall load, and the amount of power generation subsequently decreases, which in turn affects the performance of the WTS [53,54]. Recently, studies on the effects of rain have not been mentioned much, and there are only a few studies on the aerodynamic analysis or simulation of rain falling on the blades. In particular, the authors in [55] found that the power generator output of super-large WTS is decreased by 26% under rainfall. Therefore, further investigation in this area is needed to understand the operational performance of offshore WTS and rainy climates. In this regard, this study seeks to inform researchers of the most delinquent technological and climate impacts, such as temperature and rainfall effects, on the maximum power generation of super-large WTS.

3. Recent Pitch, Yaw, and Torque Control Methods for Super-Large WTS with and without Environmental Changes

3.1. Review of Pitch Control for Super-Large WTS

Pitch control allows the system to adjust the aerodynamic performance by changing the pitch angle of the WT blades. The pitch angle is a vital WT factor since it controls the wind’s angle of attack. Thus, rotating the blades around the axis modifies the rotor’s relative wind flow and the aerodynamic load. The pitch angle also affects the power factor Cp(λ,βb)

, which affects the WTS’s power capture. Therefore, pitch angle control serves power management and load reduction. This is especially noticeable when operating in region-3, where power must be kept to a minimum, and high wind speeds strain the WT structure and rotor significantly. Over the years, various concepts have been proposed for power control and load reduction in WTs. The aerodynamic properties of the blades were used to control the initial WT passively. The airfoil is built with passive stall control to stall in windy areas. Since no additional actuators were required, simple and inexpensive power control was possible. However, the controllability was limited because it was based on a spontaneous stall phenomenon without active control. The WT is subjected to greater power fluctuations, torque spikes, and varying load efforts from passive stall control [17].

In region-3, the pitch control system accelerates or decelerates the turbine while adjusting pitch angle, wind torque, and speed. The control objectives of region 3 are as follows,

- (1)

-

To maintain a constant rotor speed, the generator torque must often remain constant to achieve stable output power operation.

- (2)

-

To track the active power reference and real-time balancing between the aerodynamic (input) and electric (output) power of the super-large WTS.

The pitch command values are often the same for all three blades in collective pitch control, and the pitch control loop uses the rotor speed as feedback [84,85,86]. Furthermore, the rotor mechanical output is used directly as feedback [87,88,89]. In addition, discrete pitch control techniques are also the subject of on-going research explicitly aimed at reducing the load while maintaining the output power at its rated value. This is achieved by individually adjusting the pitch angle of the three blades to reduce various flap direction bending moments and low rotor loads [90,91,92].

3.2. Coordinated Pitch and Generator Speed Control for Active Power Regulation of Super-Large WTSs

This subsection shows the coordinated pitch and generator speed control for active power regulation of the super-large WTS. While supplying a specific demand, super-large WTs must follow desired power standards to provide active power control. Rotor speed control (RSC) and pitch angle control (PAC) approaches can be used for variable speed and variable pitch WT, but the latter, which uses WT inertia as an energy buffer, has less pitch activation and is consequently more desirable for wind energy. In the conventional PAC method, the pitch actuator is activated when the operating speed reaches the upper-speed limit of the power reference. This PAC control requires a higher pitch operating speed and significant fatigue load for the pitch servo system of the super-large WTS [93,94].

Furthermore, in the conventional Preftracking of the WT control, the maximum speed limit of the pitch actuator ωu is the optimal power curve Popt(ωm) of WT intersects the Pref line in Pad−ωm curve. As per the definition of MPPT and (2), it can be writed:

In the condition Pref<Pr, the turbine must run at the speed Pref=Popt(ωm). The operating speed at this point for a given Pref can be expressed as ωl and the existing pitch control scheme assigns ωu=ωl. However, the pitch control operation can be enhanced by utilizing the kinetic energy buffer of rotor inertia. The torque assignment to the generator through reference current is switched based on the rotor speed ωm. Here, the activation speed of the pitch controller is set to ωu=ωr. So Wt works in MPPT mode for ωm<ωl and switches to power tracking mode for ωl<ωm<ωu [95]. Furthermore, temperature and humidity effects on air density are considered for MPPT operation.

The above-adjusted rotor speed and pitch actuation control improve WT operation, but the rotor speed range ωl−ωu is utilized for tracking Pref only at zero pitch angle.

In addition, an integration mechanism is introduced to achieve minimum pitch operation in order to improve the method discussed above. For ωm>ωl, the WT system utilizes a variable speed range of ωl−ωu to track the reference power as a change in rotor speed. Pitch operation is then activated for active power control for further increases in wind speed. Furthermore, if the rotor decelerates below ωu due to reduced wind speed, the pitch angle is kept constant at an arbitrary value to take advantage of the range of rotor speed fluctuations first. For further deceleration from ωm below the value of ωl+Δωm until the pitch angle is 0 to keep Pref will be adjusted. When the wind speed drops further, the WT switches to MPPT mode of operation [84].

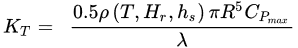

as the point at which the Popt intersects the Pref line. Moreover, for the variation in speed under non-pitch regulation with some arbitrary pitch angle, the Pβbopt’s intersection point with Pref line is denoted as ωβbopt. Hence, the speed ωβbopt increases the range of speed variation under non-pitch regulation operation as discussed in [96]. In all these co-ordinated methods, the KT=f(T,Hr,hs) is used for MPPT tracking operation.

3.3. Review of Yaw Control for Large-Scale WTS

The yaw control method is used to ensure that the turbine rotor is always pointed in alignment with the direction of the wind to maximize output, reduce loads caused by yaw misalignment, and reduce the wake effect in wind turbines. Usually, while dealing with the pitch control and generator torque control of the wind turbine, the rotor of the WT is assumed to be facing the wind without any error, which implies that the yaw controller is ideal. However, there is always a yaw misalignment present during WT operation because of the varying wind direction and the slow-moving yaw mechanism. This will considerably impact the power extraction efficiency of a large-scale wind turbine. The yaw control of WT has the following primary objectives [97],

- (1)

-

Maximizing the energy capture of a wind turbine by aligning the nacelle of WT exactly with the direction of wind velocity under region-2 operation.

- (2)

-

Ensuring load reduction and maximum energy capture by establishing a coordinated pitch and yaw control with minimum actuation for efficient operation.

- (3)

-

Decreasing a single WT’s fatigue load, and maximizing the total amount of power produced by a wind farm while optimizing load.

An environmental-impact-incorporated zero-point shifting diagnosis of wind turbine yaw angle is proposed in [98] to stabilize variations in output power at different yaw angles. The work utilizes sparse Gaussian process regression to incorporate the zero-point shifting diagnosis procedure. The individual and coupling effects of temperature are analyzed and validated through real operation data. The above work has justified the improvements in diagnostic accuracy and calibration based on zero-point shifting with temperature information, contributing to an increase in wind turbine profit by around 9%.

Next, a quantitative evaluation of yaw-misalignment and aerodynamic wake-induced fatigue loads of offshore wind turbines is analyzed in [99,100]. A wake redirection control is introduced to redirect the wake by purposely yawing the upstream turbines. A comprehensive database for tower and blade damage loads is established in addition to a polynomial load assessment model. In addition, the wind velocities and turbulence intensity are identified as the dominant factors of fatigue load. Further, yaw-offset and wake effects are interchangeably more important than others, respectively, for rated conditions and below-rated condition operation.

In addition, coordinated control of WTSs via optimized operation either with power coefficient Cp or yaw angle offsets for the maximization of net energy production was introduced in [101]. Although, the method employed in [102] introduced a multi-objective particle swarm optimization-based method to optimize the control parameters of yaw actuators through which the yaw actuation requirement is significantly reduced without affecting the power extraction efficiency.

Alternatively, an energy capture efficiency enhancement of wind turbines via stochastic model predictive yaw control based on intelligent scenarios generation is presented in [103]. The inaccuracy in prediction of wind direction is addressed through intelligent scenarios generation-based stochastic model predictive yaw control. In this work, the uncertainty in wind direction prediction is characterized by intelligent scenario generation and the yaw actions are optimized to improve energy capture efficiency. The significant improvement in profit was verified as was the energy capture improvement. Other than this, the cooperative-suspension-maglev yaw control system [104], differential yaw reduction approach [105], MPPT-integrated control [106], optimal control [107], and induction yaw control [108] present few of the techniques worth mentioning here regarding the control aspect of super-large WTSs.

This entry is adapted from the peer-reviewed paper 10.3390/en15218161

This entry is offline, you can click here to edit this entry!