Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Magnesium alloys continue to be important in the context of modern and lightweight technologies. The increased use of Mg each year indicates a rise in demand for alloys containing Mg. With additive manufacturing (AM), components can be produced directly in a net shape, providing new ideas relating to the new prospects for Mg-based materials.

- magnesium

- laser-based powder fusion

- processing parameters

- mechanical characteristics

- post-processing approach

1. Introduction

The high feasibility of unique physical structures prepared by 3D printing widens the opportunities offering new advancements in additively manufactured Mg alloys. Magnesium (Mg) is the least dense of the engineering metals (1.74 g/cc), with densities that are roughly 65% lower than those of aluminum alloys, 38% lower than those of titanium, and 25% lower than those of steel [1][2][3]. Mg-based materials are desirable for lightweight applications in consumer electronics, aerospace, and automotive industries, resembling high specific strength [4]. With suitable biodegradability, the elastic modulus of Mg-based alloys is quite similar to that of natural bone i.e., 45 GPa [5][6] imparting protection against the stress shielding and providing sufficient healing to tissue. Mg-based materials are quite often found suitable for orthopedics in biomedical applications, such as fracture fixation, dynamic stability, joint replacement, cardiology, and maxillofacial applications [4][5][6][7]. Currently, casting (including precision die casting) accounts for more than 95% of the production of magnesium alloy products, whereas wrought magnesium alloys are only used in a restricted number of applications due to their poor formability and processability at room temperature [8][9].

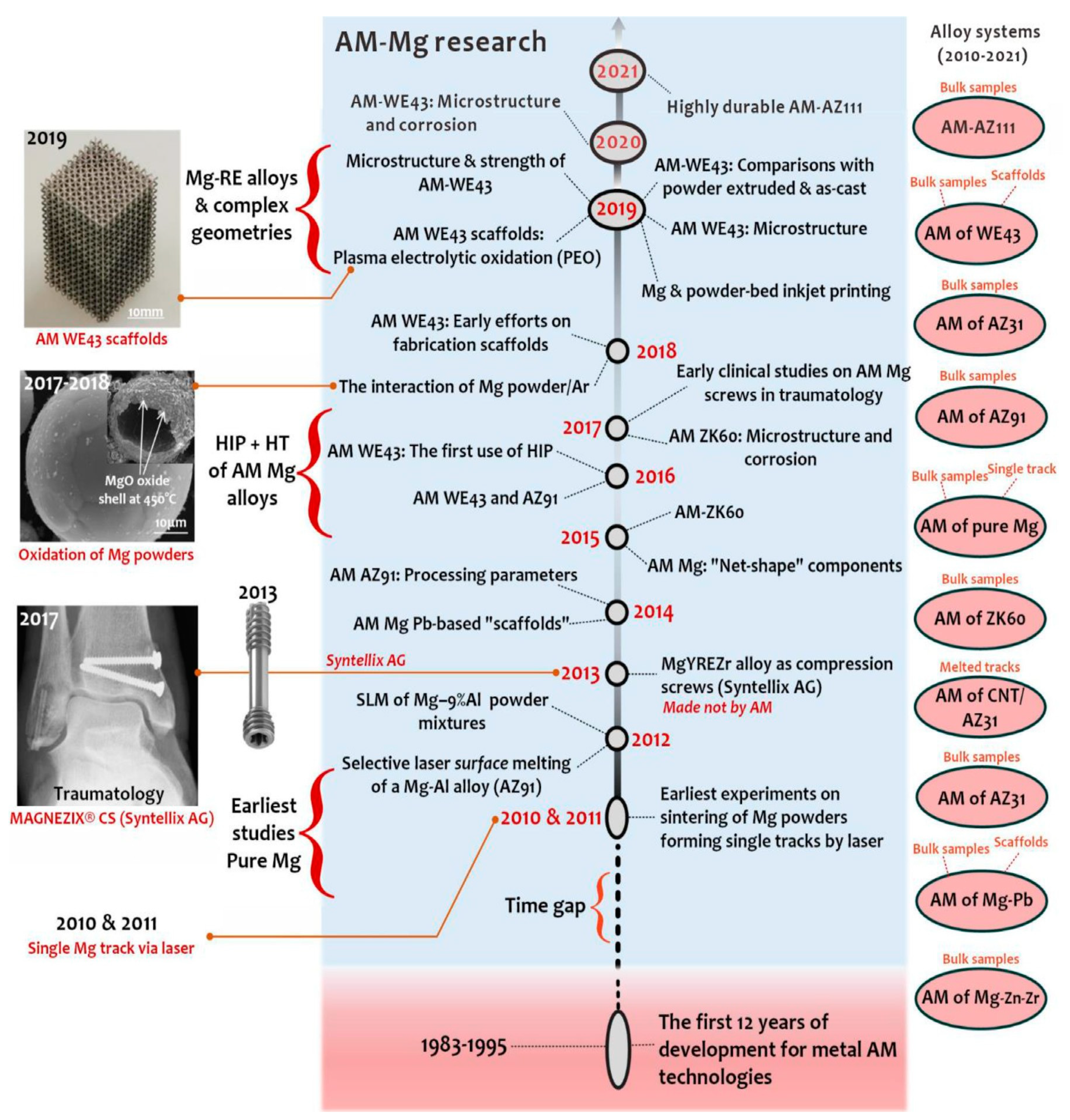

Since additive manufacturing (AM) enables design capabilities that are not possible with traditional manufacturing and maybe also because material properties are still unknown, the interest in Mg alloys among the materials community is expanding. Additive manufacturing offers several exceptional benefits, including design freedom (topology optimization), little resource waste, and low energy consumption [10]. The drawback of traditional (formative or sub-tractive) fabrication routes is also eliminated by AM. The construction of precise geometrical characteristics such as those seen in Figure 1 is made possible by the capacity to produce complicated external and internal geometries with great accuracy [11]. With design flexibility, it is possible to optimize topology and use free space as a design variable to form the lightest engineering materials more-lighter. Furthermore, components having a big surface area, when utilized as biomaterials, enabled cell development, bone regeneration, and proliferation; alternatively, when employed as Mg electrodes, these components would offer a sizable reaction area [12]. The AM technique used for Mg-based materials is proved to be advantageous in fulfilling the rising demands for high-performance implants (biodegradable) for vascular and orthopedic surgery and making technological production more patient-specific and optimized the topological implants practically [11][13]. Additionally, the exact control of the process variables might result in alloys with custom microstructures and characteristics. Numerous AM techniques have been successfully used in recent studies to produce novel alloys with improved properties that are based on Al, Fe, and Ti [14][15][16]. However, there hasn’t been much research done on AM-Mg alloys thus far. This may be partly because magnesium is reactive under air circumstances, which presents questions about health and safety as well as handling, oxidation, and evaporation of Mg-based materials. The research study from 2010 entails the controlling of risk factors while persisting with Laser-Powder Bed Fusion (LPBF) as depicted in Figure 2. The LPBF approach of additive manufacturing is extremely effective in preparing additively manufactured Mg-based material products with greater accuracy by varying the compositions of the Mg alloys [11]. The required objective adheres to the current developments in AM-based Mg materials, thoroughly examining and evaluating the findings so far, and identifying the critical element that controls the overall characteristics of AM-based Mg materials.

Figure 1. Laser powder-bed fusion (LPBF) created an Mg-shaped lattice structure in a magnesium alloy [11].

Figure 2. Advancement in the development of the Mg-based alloy via additive manufacturing powder-based approach [17].

2. Laser-Based Additive Manufacturing Approach

The most extensively researched energy source for AM-Mg is a laser, which offers certain distinct benefits over other energy sources. To melt the powder, lasers (high concentration of heat) are concentrated over the specified area of the powder bed for a short time duration. The molten powder is rapidly heated and quenched by this short-duration heat flux, which promotes fast solidification. The most extensively used additive manufacturing technique for magnesium alloys is attributed to LPBF, often recognized as SLM (Selective laser melting). Only a very small number of studies related to AM-based Mg materials are attributed to DLD (Direct laser deposition). Today, the LPBF method is regarded as a potent and effective additive manufacturing technique for creating intricate 3D forms with high levels of precision and reproducibility together with acceptable metallurgical qualities [18][19][20]. Mg has an evaporation point of 1091 °C, while Al and Ti have evaporation points of 2470 °C and 3287 °C, respectively [21]. As a result, the temperature during LPBF will undoubtedly be higher than the temperature at which magnesium vaporizes, changing the composition of magnesium alloys generally. Systematically examining the evaporation during LPBF was done by We et al. [22]. It was discovered that the melting pool’s rising temperature greatly quickens the rate at which magnesium burns. Several processing parameters, such as laser power, scan speed, hatch spacing, and layer thickness, have an impact on the melt pool’s temperature. Porosity was regarded as the most critical issue while dealing with the LPBF approach for Mg-based material that needs to address, in addition to evaporation. Table 1 summarizes the impact of processing factors on the porosity of magnesium particularly. It was discovered by analyzing the reference papers that LPBF powders are categorized as mixed Mg and Al powder, rather than Mg-Al powders that have already been pre-alloyed [11][23][24][25][26][27]. This indicates that achieving high relative density utilizing mixed elemental powders (metal) may be more challenging, since the various thermal characteristics of each element may generate substantial local incompatibility in rapid cooling.

Table 1. Processing parameters of Mg-based alloy prepared by Additive Manufacturing powder-based approach.

| Alloy Components |

Size (μm) and Shape of Powder | Methodology | Parameters Used in Powder-Based Additive Manufacturing Approach | Input Energy Density (J/mm3) | Relative Density (%) |

References | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Power (W) |

Spot Size (μm) |

Speed (mm/s) |

Layer Thickness (μm) |

Hatch Spacing (μm) |

||||||

| Mg (Pure) | Pre-alloyed 24 μm, spherical shape | Laser-powder bed fusion | 75 | 85 | 500 | 25 | 35 | 155 | 96.5 | [28] |

| 1240 | 63 | 88.2 | ||||||||

| Mg (Pure) | Pre-alloyed 43 μm, spherical shape | Laser-powder bed fusion | 85 | 90 | 90 | 25 | 90 | 290 | 96 | [29] |

| 85 | 100 | Less than 300 | ||||||||

| Mg-9Al alloy | Blended Mg with size 42 μm, irregular shape, and Al 17 μm, spherical shape | Laser-powder bed fusion | 10 | 30–75 | 10 | 50 | 80 | 250 | 74.5 | [30] |

| 15 | 20 | 187 | 78 | |||||||

| 15 | 40 | 94 | 86.1 | |||||||

| 20 | 40 | 125 | 82 | |||||||

| Mg-9Al alloy | Blended Mg with size 24 μm, spherical shape, and Al 28 μm, spherical shape | Laser-powder bed fusion | 70 | 80 | 500 | 30 | 30 | 156 | 95.7 | [31] |

| 750 | 104 | 88 | ||||||||

| 1000 | 78 | 83 | ||||||||

| 1250 | 63 | 81 | ||||||||

| AZ61 alloy | Pre-alloyed with powder size 48 μm, spherical shape | Laser-powder bed fusion | 145 | 75 | 300 | 45 | 65 | 210 | Less than 99 | [32] |

| 350 | 181 | |||||||||

| 400 | 158 | |||||||||

| 450 | 141 | |||||||||

| 400 | 85 | 157 | 99.1 | |||||||

| 400 | 110 | 95 | 98.1 | |||||||

| AZ61 alloy | Powder size with 70 μm, spherical shape | Laser-powder bed fusion | 65 | 155 | 400 | 55 | 55 | 6000 | 77 | [33] |

| 75 | 7000 | 89 | ||||||||

| 85 | 8000 | 99 | ||||||||

| 95 | 9000 | 95 | ||||||||

| AZ91 alloy | Powder size with 59 μm, spherical shape | Laser-powder bed fusion | 210 | 333 | 45 | 95 | 168 | 99.57 | [34] | |

| AZ91 alloy | Powder size with 53–75 μm, spherical shape | Laser-powder bed fusion | 125 | 85 | 10 | 355 | 510 | 70 | 96.62 | [35] |

| AZ91 alloy | Powder size with 25–63 μm, spherical shape | Laser-powder bed fusion | 110 | 95 | 800 | 35 | 45 | 105 | Less than 99 | [36] |

| AZ91 alloy | Powder size with 30 μm, spherical shape | Laser-powder bed fusion | 45 | – | 200 | 35 | 35 | 279 | 98 | [37] |

| AZ91/SiC composite | Powder size with 50 nm, SiC particles | 98.2 | ||||||||

| WE43 alloy | Powder size with 25 μm, spherical shape | Laser-powder bed fusion | 125 | 95 | 960 | 35 | 45 | 105 | 98.5 | [17] |

| Powder size with 30 μm, spherical shape | 145 | 1200 | 105 | 99.1 | ||||||

| Powder size with 63 μm, spherical shape | 310 | 1200 | 209 | 99.4 | ||||||

| WE43 alloy | Powder size with 25–63 μm, spherical shape | Laser-powder bed fusion | 205 | 95 | 700 | 35 | 45 | 239 | 99.78 | [38] |

| WE43 alloy | Powder size with 25–63 μm, spherical shape | Laser-powder bed fusion | 205 | 75 | 1100 | 45 | 135 | 38 | 99.6 | [39] |

| WE43 alloy | Powder size with 25–63 μm, spherical shape | Laser-powder bed fusion | 205 | 130 | 700 | 35 | 45 | 239 | 99.89 | [40] |

| WE43 alloy | Powder size with 25–63 μm, spherical shape | Laser-powder bed fusion | 200 | 110 | 800 | 35 | 210 | 42 | 99.75 | [41] |

| 200 | 800 | 245 | 35 | 98.4 | ||||||

| 200 | 1200 | 210 | 29 | 96.6 | ||||||

| 200 | 1200 | 210 | 20 | 87.7 | ||||||

| G10K alloy | Powder size with 63 μm, spherical shape | Laser-powder bed fusion | 85 | – | 200 | 35 | 90 | 135 | 99.3 | [42] |

| GZ112K alloy | Powder size with 31–44 μm, spherical shape | Laser-powder bed fusion | 85 | 110 | 100 | 35 | 90 | 268 | 98.9 | [43] |

| 300 | 90 | 99.8 | ||||||||

| 500 | 54 | 99.4 | ||||||||

| 700 | 39 | 99.5 | ||||||||

| 1000 | 28 | 96.4 | ||||||||

| 1500 | 19 | 71.9 | ||||||||

| 500 | 45 | 106 | 99.4 | |||||||

| 500 | 145 | 37 | 96.4 | |||||||

| GZ151K alloy | Powder size with 25–65 μm, spherical shape | Laser-powder bed fusion | 210 | – | 700 | 35 | 75 | 138 | 98 | [44] |

| Mg-1Zn alloy | Blended Mg-5.5Zn with Powder size of 36 μm involving Mg powder size 31 μm and Zn powder size 19 μm; spherical shape | Laser-powder bed fusion | 185 | 140 | 700 | 25 | 75 | 184 | 99.1 | [45] |

| Mg-2Zn alloy | 98.5 | |||||||||

| Mg-6Zn alloy | 94.9 | |||||||||

| Mg-12Zn alloy | 99 | |||||||||

| ZK60 alloy | Powder size with 30 μm, spherical shape | Laser-powder bed fusion | 210 | 140 | 300 | 25 | 85 | 418 | 95 | [46] |

| 500 | 255 | 94 | ||||||||

| 700 | 180 | 89 | ||||||||

| 900 | 140 | 85 | ||||||||

While some degree of porosity is acceptable because it is unavoidable, hot ripping and cracking must be avoided. The most serious problems that lower the as-built component’s quality in LPBF are hot tearing and cracks [47][48][49]. In general, low constitutional supercooling gives rise to the formation of columnar grains, but the temperature gradient is still substantial, making them particularly susceptible to hot ripping. Along with volumetric shrinkage during solidification, the thermal contraction between the columnar grains, attributed to hot tearing and cavities formation, results in enhancement in the length of columnar grains when temperature and liquid volume fraction drop [50]. No evidence related to the effects of processing parameters and alloying elements on hot tearing evolved in Mg-based materials advancing to the LPBF technique. Therefore, as per the future aspect, the significance of alloying elements might be considered a better option along with processing parameters identifying the behavior of tearing in Mg materials. Empirically, an alloy (Mg-6Zn) that has columnar grains and entails a high solidification range might be considered more vulnerable to cracking [51][52][53][54]. Furthermore, research can be accomplished in evaluating the fracture mechanism of additively manufactured Mg-based material identified as a function of process parameters of LPBF and the composition of the alloy.

3. Investigation of Mg Alloy via Additive Manufacturing

Advancing to additive manufacturing approach for Mg-based materials, very few combinations have been studied when compared to wrought and cast alloys. This is primarily due to the high expense of producing atomized pre-alloyed powder on a customized basis, which is highly expensive compared with the customized composition of wrought and cast alloy. Pure magnesium, AZ91, and WE43 are now the most widely used compositions of magnesium-based materials used for additive manufacturing [55][56][57][58][59][60]. These alloys are attributed to superior printability, sustainability in structural and biological applications, and attracting market demand (for being lightweight). The detailed research outcomes of the various research studies have been compiled in the section below to identify the development relating to the AM approach to Mg alloy. The study paved a way for future research related to additively manufactured Mg-based materials.

3.1. Pure Mg Alloy

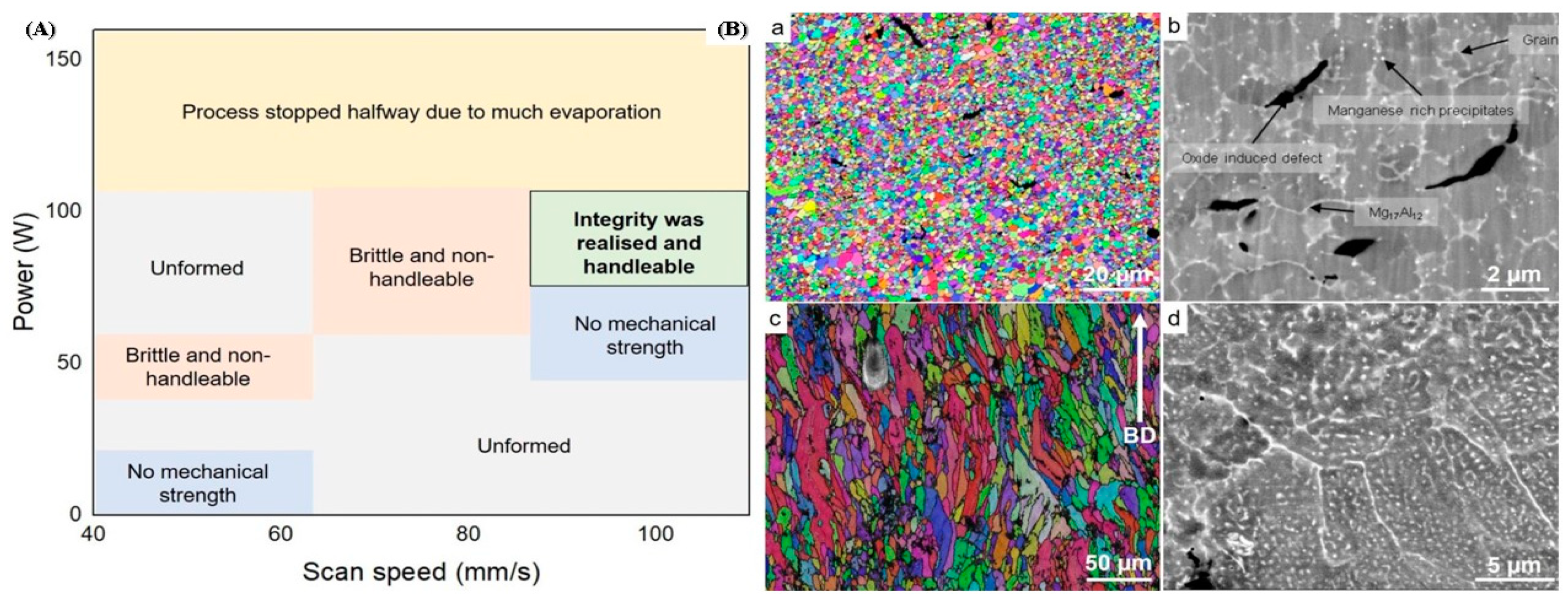

At the initial stage the researcher, Ng et al. examined the first experimental approach to produce customized equipment using a laser-based additive manufacturing approach relating to Mg-based material [61]. The Nd-YAG laser was used primarily as a source of heat to melt the powder over the powder bed in the LPBF approach. For a single-track laser scan, several laser powers and scan speeds were tested during the initial research relating the Mg-based material to the LPBF approach. The variation of laser power with scan speed was depicted in Figure 3A [61][62]. It was concluded from various research studies that the LPBF approach of additive manufacturing does not succeed with irregular and coarse powder. Other than that, the LPBF approach holds good accountability with spherical and atomized fine powder under the pre-requisite condition of processing parameters [61]. The variability of grain size with pure Mg obtained via LPBF was observed in the range of 2 to 5 μm. To incorporate such a tiny grain size in pure Mg is quite a difficult task before advancing to the LPBF. Only an extreme plastic deformation approach at low-temperature conditions was able to accommodate the tiny grain size distribution in pure Mg materials [63][64]. Therefore, the LPBF approach plays a significant role in refining the microstructure of material over traditional casting and thermomechanical processing. Furthermore, research studies identified that the LPBF single-track sample has an extremely high hardness as well as a significant density of cracks around the grain boundaries and formed the oxide layers around the boundary [65][66][67]. The researcher Hu et al. developed the first bulk Mg relating to the LPBF approach used in producing customized parts of Mg material. For the spherical shape of powder, the high density of gas pores was obtained through the LPBF approach, while the irregular shape of powder marks the abundance of fusion pores but resembles the structure depicting certain interconnectivity between the pores [68][69]. Pure Mg material relating to the additive manufacturing approach can be produced by the DLD approach (Direct laser deposition) of additive manufacturing in addition to the LPBF approach [70][71].

Figure 3. (A) Processing parameters of laser-based powder approach, (B) (a–c) depicted EBSD orientation, (b–d) SEM characterization of AZ91 alloy formed by laser powder bed fusion [11].

3.2. Mg-Al Alloy

The most significant commercial composition of Mg-Al-based alloys in the cast and wrought forms is AZ31 [72][73][74]. While the majority of the formation of AZ31 alloy-based additively manufactured parts is attributed to the wire-arc approach but there is very little literature on laser-powder-based additive manufacturing. In actuality, high-Al concentration Mg-Al alloys, such as AZ91, make up the majority of laser-based Mg-Al alloys [75]. This is because the addition of Al necessitates grain refinement of the alloys through super-heating or inoculation, enhances castability (hence printability), and offers reinforcement through the solute and β-Mg17Al12 intermetallic phase [75][76]. Coming to the LPBF approach, Pawlak et al. investigated the fabrication of AZ31 alloy-based material parts via the LPBF approach and attributed it to the low porosity level of around 0.5% [77]. In LPBF, AZ61 and AZ91 also attain such a low porosity level, proving the alloy’s acceptable printability [11][78]. The AZ91 and AZ61 alloys forming through the LPBF approach attributed to equiaxed and fine grain distribution, as well as attaining the texture that was almost randomly distributed [79][80][81][82]. Figure 3(Ba) marks the variation in the grain size distribution ranging from 1 to 3μm in Mg-Al alloy prepared via the LPBF approach. According to some research, the β-Mg17Al12 intermetallic is primarily absent from the grain interior and is instead scattered along the grain boundaries and linked, as seen in Figure 3(Bb) [11]. However, some results display grains that are extended in the construction direction seen in Figure 3(Bc). While the intermetallic phase (β-Mg17Al12) finds around the grain boundary. Furthermore, the research identified that there exist abundant spherical intermetallic (β-Mg17Al12) nanoparticles inside grain boundaries attaining a diameter of around 300 nm as identified in Figure 3(Bd) [11].

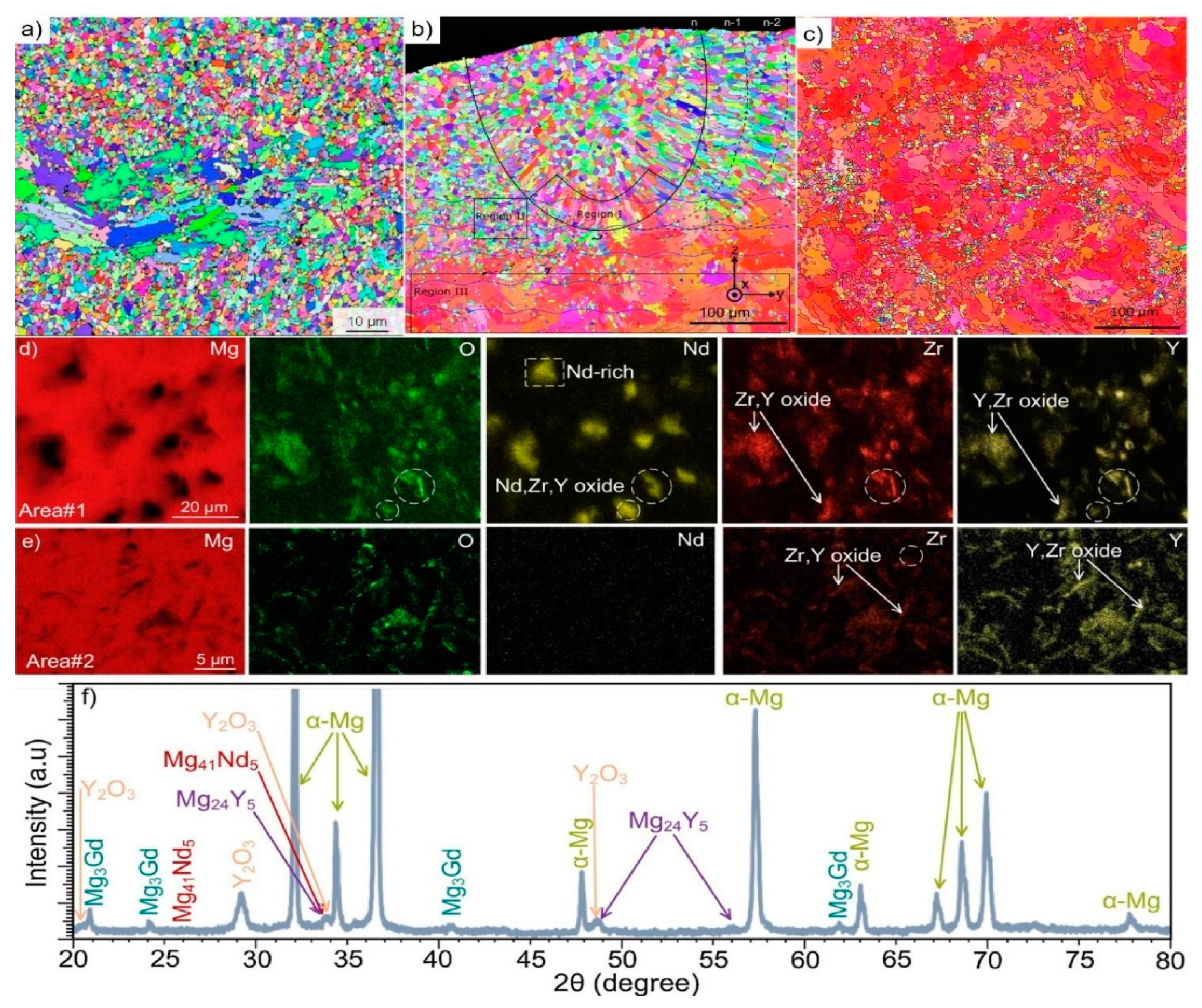

3.3. Mg-RE Alloy

The additively manufactured Mg-RE alloy has received the greatest attention for use in biomedical implants especially WE43 alloy. Although WE43 alloy attains significant importance in biomedical applications, it also has good printability which accounts for a new doorway in order to achieve the reduced porosity [83][84], better than AZ91 as discussed in [77]. Being biocompatible, WE43 alloy does not cause any negative cell reactions such as cytotoxicity, whereas Aluminum in Mg-Al alloy accounted for cytotoxicity. Al is a neurotoxic element that is prohibited from bioabsorbable magnesium alloys due to the high concern relating to Alzheimer’s disease. Consequently, WE43 alloy has garnered increased interest as a biodegradable implant material in scaffold applications [11]. Despite, very few grains with aberrant grain development during LPBF, Zumdick and Jauer’s early tests of LPBF over WE43 showed the formation of equiaxed grains around the boundary and provides a pathway to the refinement in the grain size, depicted in Figure 4a [11]. Intriguingly, the LPBF approach over WE43 alloy exhibited a completely different microstructure way back in 2019 pertaining to the similar processing parameters illustrated by the same research team, entailing the dominance of large, strongly basal-textured grains with irregular shapes [40]. Figure 4b–d shows that although the laser beam’s quick solidification of the melt pool produces fine, columnar, equiaxed grains [17][40]. The succeeding laser scans in the LBPF process result in heat treatment, which leads to grain development with a distinct [0001]/BD texture. It is demonstrated that, following a single-layer deposition, there is significant grain development and that, following the formation of two layers, the grains achieve their maximum size. It is uncertain what precise mechanism results in such vast grain expansion and textural development. In contrast, no such grain development can be seen in Figure 4a [11]. The authors suggested that yttrium oxide (Y2O3) particles, which are thought to offer Zener-pinning to inhibit grain formation, may be present in varying proportions in powders from various vendors [85][86]. In actuality, oxygen and the early RE elements have a strong affinity towards inhibiting the formation of grains. In comparison to MgO (596 kJ/mol), the Gibbs free energy required for the production of Y2O3 and Nd2O3 is 1815 and 1806 kJ/mol, respectively [11][87]. Therefore, a significant proportion of RE oxide has been present in all LPBF-WE43 publications to the date shown in Figure 4e,f [40]. The big and basal-oriented grains are nonetheless predominant in the WE43 alloy formed by the LPBF approach concluded by Esmaily et al., despite the high density of RE oxide that doubts the efficiency of RE oxide in preventing grain development from Zener Pinning [88][89]. In actuality, the concentration and types of solute particles often referred to as the Growth Restriction Factor proposed by St John, have a greater impact on grain growth during solidification [90][91]. The Growth Restriction Factor (Q) in this model is

where K relates to the equilibrium distribution coefficient, C0 related to the composition of solute particles, and m relates to the liquidus line slope.

Q = C0m(k − 1)

Figure 4. EBSD image shows equiaxed, fine, and random grain representation in (a) bulk LPBF-WE43, (b) last melt pool corresponds to basal- orientated, large, and irregular shape grains, (c) basal- orientated, large, irregular shape grains in the bulk sample, (d,e) EDS image at different magnification for same materials, and (f) XRD image depicted intermetallic and oxygen-rich elements in WE43 alloy [11][17][40].

A larger solute concentration causes a greater thermodynamic limit on grain development that has been observed in various research studies [92][93][94]. Therefore, the low concentration of solute particles relating to the RE element in the powder prevents the oxidation of WE43 alloy powder during production, transportation, and storage. Due to the inability of the low solute particle concentration in powder to prevent preferred development, the result is the massive, basally oriented grains as seen in Figure 4b,c [40]. Therefore, researchers have customized the composition of powder and inherited various compositions resembling the Mg-Gd systems in addition to experiments based on commercial WE43 powder [95][96]. The as-LPBF Mg-Gd-based alloy incorporated the significant grain refinement (1–2 μm), resembling equiaxed grain with the random distribution of grains around the boundary [11]. The relative density of the alloy can reach 99.95%, and it has few oxides and pores. Similar behavior was obtained in DLD (Direct Laser Deposition) manufactured Mg-10Gd-3Y-0.4Zr alloy with spherical powder (100–300 μm) pertaining to the randomness in the distribution of the equiaxed grains [11]. DLD reveals that the alloy sample has a bigger grain size and a higher pore percentage. Therefore, in order to limit the enhancement in the grain size of basal-oriented grains, the appropriate amount of Gd content (>10 wt.%) should be primarily used during solidification, irrespective of any approach used (DLD or LPBF) [97][98].

3.4. Mg-Zn Alloy

Despite Zn being biocompatible in nature, Advancement to Mg-Zn alloy has not been explored significantly as comparable to Mg-RE and Mg-Al alloys. The research studies suggested that the wide range of solidification and low eutectic temperature (325 °C) of Mg-Zn alloy, accounts for the poor printability as compared with Mg-RE and Mg-Al alloys [11]. Only at very low (less than 1 wt.%) and very high (12 wt.%) concentrations of Zn will produce an acceptable level of porosity. Resembling ZK60 alloy where Zn concentration opt at 6 wt.%, the hot cracking and higher density of pores were accommodated in the additively manufactured ZK60 alloy [99][100]. As a result, the alloy is rendered useless and unusable. The research studies concluded that ZK60 alloy produced by the LPBF approach produces a relative density of around 97%. Therefore, the addition of Zn as an alloying element in the additively manufactured Mg-based materials via a laser-based approach adheres to the minimal quantity. In addition to the Mg-Zn, Mg-RE, and Mg-Al-based alloys, the research studies explored the Mg-Sn alloy with the blended powder and Mg-Ca alloy with pre-alloyed powder [11]. The outcomes depicted the short range of solidification and high value of eutectic temperature (466 °C and 510 °C for Mg-Sn and Mg-Ca alloy system) which accounts for the higher printability of these alloys as compared with Mg-Zn alloy. Along with good printability, these alloys incorporated the equiaxed grain and prompted the refinement of the microstructures [101]. But for a future perspective, more research needs to be carried out on these alloys via LPBF identifying the behavior of solidification, the evolution of the microstructure, and the mechanical and electrochemical properties [102][103][104][105][106].

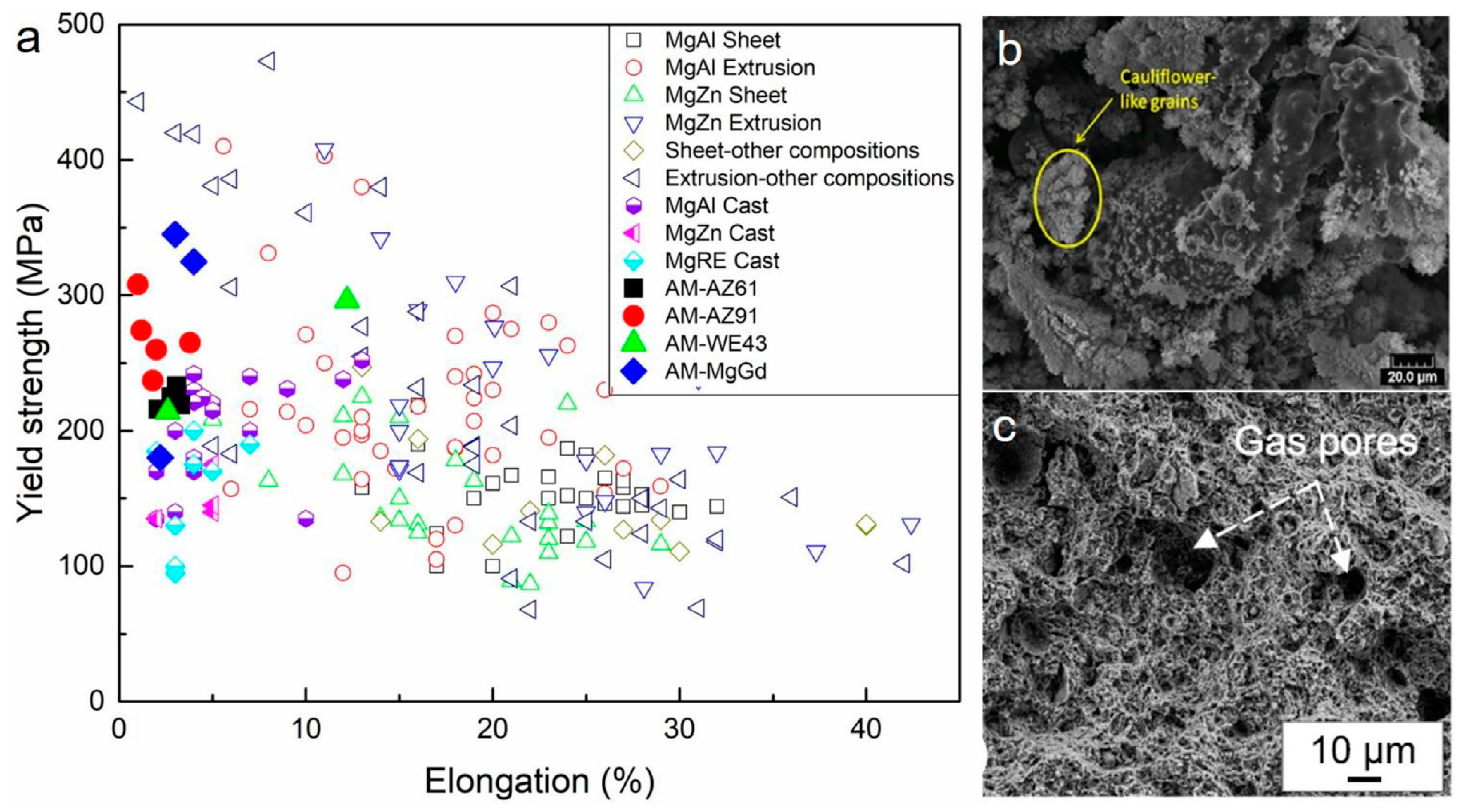

4. Mechanical Properties of Laser-Based Additive Manufacturing Approach

Accounting for the mechanical characteristics of additively manufactured Mg materials with a laser-based approach, the research outcomes are concluded in Table 2 for future research perspective. The graphical variation in the yield strength with elongation (%) for various wrought alloys (extruded and rolled) and cast alloys is shown in Figure 5a [11]. For laser-based additively manufactured parts, the compression or hardness test are pre-requisite in order to analyze the mechanical behavior of the AM-Mg alloy as prepared parts via LPBF account for the ductility of less than 5%, while some of the alloys have none at all which is unacceptable for engineering material. Other than low ductility, some alloys pertain the weak texture, or equiaxed, fine grains, and resemble low porosity during the microstructure behavior, irrespective of low ductility [107][108][109]. Low porosity accounts for good printability of the alloying material. Furthermore, research studies were focused in order to identify the reason for low ductility in laser-based additively manufactured Mg materials. Firstly, the quick solidification causes the as-LPBF to have significant residual stress, which lowers the alloy’s ductility [108]. Secondly, the examined alloys such as Mg-Gd, WE43, and AZ91 alloys, include significant amounts of alloying elements addition incorporated in the intermetallic phase around the grain boundaries. Therefore, due to the formation of the intermetallic phase around the grain boundary, the brittle behavior as well as local failure around grain boundaries were observed. The presence of local failure showcases the inability of material to cause the plastic deformation (twining and slipping around the boundary as well as sliding of grain boundary etc.). Low ductility encountered in the laser-based additively manufactured part was due to the poor redeposition of powder or vapor over the surface of parts that weakened the bond between the particles. The fracture surface’s cauliflower-like characteristic is shown in Figure 5b. The WE43 alloy currently has the highest documented ductility among laser-additive-produced magnesium alloys at 12.2% [11]. Despite the presence of some gas pores, the fracture surfaces were clearly visualized in Figure 5c that the sample has broken in a ductile manner. A high-temperature annealing approach can increase the ductility of an alloy. The enhancement in the ductility of WE43 alloy formed by LPBF encountered 2.5% in the as-built state to 4.5% after heat treatment by annealing at 535 °C for 24 h and aging at 205 °C for 48 h [110]. FSP (Friction stir processing) dramatically reduces the residual stresses, and grain size, and redistributed the intermetallic of Mg-10Gd-0.3Zr alloy, leading to a more striking increase in ductility from 2.2 to 7.5% [11]. Although it is unlikely that the net shape component formed via the LPBF approach will be produced by the friction stir processing approach in actual applications of engineering showcasing that the alloy formed by the LPBF approach is not inherently brittle in nature [111]. Therefore, the optimization of processing parameters, composition of the alloy, and quality of powder material used improves the ductility of additively manufactured Mg alloy by the LPBF approach. The detailed description of the investigation of mechanical characteristics of Mg-based alloy prepared by powder-based fusion approach of additive manufacturing.

Table 2. Various properties of laser beam additively manufactured Mg-alloy.

| Alloy | Input Energy Density (J/mm3) |

Grain Size (μm) |

Micro-Hardness (HV) |

Yield Strength (MPa) | Ultimate Tensile Strength (MPa) |

Elongation. (%) | Electrochemical Solution | Icorr (μA/cm2) |

Mass Loss mm/Year | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Mg (Pure) | 97–88 | 1–5 | – | – | – | – | Hank’s solution | 75–180 | 5–33 | [28] |

| Mg (Pure) | 295 | – | 52.4 | – | – | – | – | – | – | [29] |

| Mg-9Al | 251 | 15–25 | 71 | – | – | – | – | – | [30] | |

| Mg-9Al | 150 | 1.5–3.5 | – | 274 | 1.1 | – | – | – | [31] | |

| AZ61 | 140 | 1.5 | – | 220 | 275 | 3.5 | – | – | – | [32] |

| 155 | 1.7 | 235 | 285 | 3.0 | ||||||

| 180 | 2.0 | 220 | 260 | 2.9 | ||||||

| 205 | 2.4 | 214 | 240 | 2.2 | ||||||

| AZ61 | 125 | 4.5 | 71 | – | – | – | Simulated body fluid solution | 2.8 | [33] | |

| 145 | 9 | 81 | 2.5 | |||||||

| 161 | 10 | 94 | 1.3 | |||||||

| 181 | 12 | 91 | 1.6 | |||||||

| AZ91 | 165–85 | 1.5–3 | 86–105 | 27 | 296 | 1.2 | [34] | |||

| 83 | 2.9 | 237 | 254 | 1.8 | ||||||

| AZ91 | 68 | 1–11 | 114 | – | – | – | [35] | |||

| AZ91 | 103 | 1–2 | – | 270 | 330 | 3.9 | [36] | |||

| AZ91 | 280 | 3.5 | – | 310 | 350 | 1.1 | – | – | – | [37] |

| AZ91-SiC | 280 | 1.2 | – | 265 | 310 | 2.1 | – | – | – | |

| AZ91–2Ca | – | – | – | 240 | 335 | 3.3 | – | – | – | [11] |

| WE43 | 125 | 35 | – | – | – | – | NaCl (0.1 M) | 5.1 | 6.1 | [11] |

| 150 | 28 | 5.0 | – | |||||||

| 300 | 19 | 4.6 | ||||||||

| WE43 | 240 | 1.5 | – | 300 | 310 | 12.1 | – | – | – | [38] |

| WE43 | 40 | 1–4 | – | 215 | 255 | 2.8 | – | – | – | [39] |

| WE43 | 240 | 20.5 | – | – | – | – | – | – | – | [40] |

| WE43 | [41] | |||||||||

| G10K | 135 | 28 | 81 | 187 | 230 | 2.3 | – | – | – | [42] |

| GZ112K | 90 | 1.8 | – | 330 | 335 | 4.2 | – | – | – | [43] |

| GZ151K | 140 | 2.1 | 350 | 370 | 3.2 | – | – | – | [44] | |

| Mg-1Zn | 185 | – | 52 | 150 | 11.1 | – | – | – | [45] | |

| Mg-2Zn | 45 | 75 | 2.4 | |||||||

| Mg-6Zn | 66 | 55 | 1.4 | |||||||

| Mg-12Zn | 84 | 80 | 3.3 | |||||||

| ZK30 | 2000 | – | 81 | – | – | – | Simulated body fluid solution | 17.8 | 1.20 | [11] |

| ZK30-Cu | 99 | 47.8 | 2.25 | |||||||

| Pure Mg | – | – | – | – | – | – | NaCl (3 wt.%) | 999 | 144 | [11] |

5. Electrochemical Durability of Mg-Based Alloy Prepared by Lased-Based Powder Fusion

Biodegradable implants are attributed to the most promising aspect of additively manufactured Mg-based materials. For better implantation outcomes, oral and maxillofacial implants retained sufficient mechanical integrity for the initial first month before gradually deteriorating, becoming completely dissolved and metabolized after three months [112]. Given that magnesium and its alloys are known to have low corrosion resistance in the majority of aqueous settings, this demands adequate electrochemical durability. With regard to the LPBF approach, the corrosion current density (Icorr) of Mg (pure) in Hank’s solution is far better than the cast Mg (pure) ingot tested under the same conditions (23.6 µm/cm2) and varies from 74 to 177 µm/cm2 [113]. Depending on the processing conditions, the mass loss rate ranges from 3 to 32 mm/year. In a solution of 3 wt.% NaCl, the corrosion rate of pure Mg produced by DLD is about 144 mm/year [11]. The loosely fused Mg clusters and sintered Mg powder provide a negative effect attributing to corrosion resistance. As a result of the higher corrosion rate, the parts formed by the LPBF approach inherited some defects, advancing localized corrosion [114]. The rate of degradation increases with the number of faults and defects in the parts formed. Similar to the cast alloy, the LPBF WE43 alloy displayed significantly less corrosion resistance. In r-SBF solution (revised simulated body fluid) containing fetal bovine serum up to 5%, the corrosion current density varies from 20 to 60 µm/cm2, and in a solution of 0.1 M sodium chloride, the mass loss rate is approximately 6 times greater as compared with cast WE43 alloy (0.8–1.2 mm/year) [40][115]. Irrespective of higher relative density (<99%), the micro galvanic reaction, attributed to a high density of RE oxide and reactive magnesium matrix, resulted in an improvement in the rate of corrosion [116]. If the surface of the LPBF-WE43 scaffold is not exposed to PEO (Plasma electrolytic oxidation), it has been reported that the structural integrity of the scaffold will lose after 21 days of immersion in simulated body fluid (SBF). The research studies concluded that the corrosion resistance of the cast alloy is superior to that of the Mg-Al-based alloy. The degradation rate for AZ61 alloy formed by the LPBF approach was approximately 6 to 8 mm/year during the state of as-immersion, and subsequently, it decreased and gets stabilized in SBF, reducing the degradation rate to about 1.2 to 2.7 mm/year [11]. The aforementioned degradation is comparable to the cast AZ61 alloy in SBF depicting the rapid rise in the rate of corrosion to around 6.5 mm/year, but slowing down to 1.299 mm/year after 24 days of immersion [117][118]. The research data concluded that ZK60 alloy formed by the LPBF approach provides superior corrosion resistance as compared with cast ZK60 alloy, based on the hydrogen evolution rate and corrosion current density data [119]. Apparently, the surface of the ZK60 alloy formed by the LPBF approach indicates a more severe corrosion rate [11]. By combining ZK powders with Cu powders, Shuai et al. increased the antibacterial activity of Mg-Zn-Zr implants by adding diluted concentrations of Cu to ZK30 and ZK60 alloy formed by the LPBF approach [11]. It was concluded that the LPBF ZK-Cu alloy formed by the LPBF approach degrades more quickly when Cu is added. Therefore, Cu serves as the suitable alloying element to control the degradation rate of the Mg-Zn-based alloy system.

6. Biocompatibility of Mg-Based Alloy Prepared by Lased-Based Powder Fusion

The biocompatibility of LPBF-Mg alloys must be taken into account because biodegradable implants are the most promising application for AM-Mg alloys. Being the crucial component of the human body, the degradation rate of magnesium-based material shifts the stresses from the implant to the rebuilt bone. Mg-based materials are equivalent to human bone in terms of both density (1.7 g/cm3) and young’s modulus (45GPa) [120]. Mg is both biocompatible and bioactive, which considerably encourages cellular division and proliferation [121]. The stabilization of RNA and DNA, as well as bone formation and healing, all benefit from it. Therefore, the biocompatibility of the alloying components added to the Mg-based materials attributing to the biodegradable implantation. Furthermore, the research studies depicted that the neurotoxicity of aluminum ion (Al3+), attributing to the accumulation of these ions in the nervous system, resulted in Alzheimer’s disease. Al addition can increase printability such as Cu, which may have some antibacterial effects but is primarily cytotoxic [122]. Therefore, it is doubtful that alloys comprising Al and Cu will be found suitable for clinical application. Numerous research has so far confirmed the in-vitro biocompatibility of WE43 alloy formed by LPBF as a scaffold implant [40][54][123]. Although RE-based magnesium alloys themselves don’t appear to have any cytotoxic potential. The extensive reactivity of the bare metal surface is attributed to the high evolution of hydrogen gas. The high evolution of hydrogen gas leads to the shifting of pH, which interferes with cell metabolism [11]. Only a few dead cells could be seen after direct live/dead staining, and no viable cells could be seen on the WE43 alloy formed by LPBF for scaffold applications [123]. The conclusive evidence for surface modification, such as plasma electrolytic oxidation, can address this problem since it slows the production of degradation by-products and, as a result, encourages hardly any evidence of cell damage [124]. Passivating ceramic-like surfaces also appear to provide a good option for adherent cells [125]. In addition to WE43 alloy, it was reported that the LPBF scaffold was also made using a pre-alloyed system of Mg-Nd-Zn-Zr, commonly referred to as JDBM [11]. Comparable to WE43 alloy formed by the LPBF approach, the research study obtained by cell adhesion test identified that dicalcium phosphate dihydrate coating over the scaffold attributed to the generation of more cells that attached to the scaffold rather than uncoated scaffold [11]. Neither the coated JDBM scaffold nor the uncoated JDBM scaffold formed by LPBF contributed to any significant difference in the assessment of cytotoxicity. As a result, both samples promoted cell proliferation. From the research perspective, it was quite unacceptable that the uncoated sample of additively manufactured Mg material will not at least irritate direct cell response, hence this finding requires a more thorough investigation and verification in the future.

7. Challenges Inherited in Laser-Based Approach Relating to Mg-Based Material

The necessary manufacturing of pre-alloyed powder is difficult with regard to the laser-based additive manufacturing approach. Evidence, however, points to the suitability of combining elements with a combination of pre-alloyed powders. Further research is needed in the area of consistency and blending of magnesium powder. To fully comprehend the physical characteristics of Mg alloys prepared by AM, mechanistic studies are still needed. Undoubtedly, laser-prepared AM alloys show distinct characteristics on comparing to non-AM Mg alloys but the physical basis resembling such differences is still open (i.e., the impact of additive manufacturing on ductility and strengthening mechanisms). While addressing to laser-based additively manufactured approach relating to Mg-based material, ductility remains to be the primary concern [40]. It is recommended to have the smallest amount of powder while dealing with LPBF. However, the handling and storage of powder should be kept away from the ignition, limiting atmospheric exposure. Research findings also revealed that there exists a research gap in relation to the recycling of Mg-alloy powder that hasn’t been investigated yet. Furthermore, compositional and process parameter modification has not yet been researched. The sintering-based approach is a new technique that needs to be explored relating to Mg-based materials. More work can be accomplished on Mg-based material by binder jetting approach. There is a need to look into the post-processing approach, including a homogeneous/uniform coating on the porous scaffolds relating to Mg-alloys that has not been investigated.

This entry is adapted from the peer-reviewed paper 10.3390/ma15228122

References

- Qin, Y.; Wen, P.; Guo, H.; Xia, D.; Zheng, Y.; Jauer, L.; Poprawe, R.; Voshage, M.; Schleifenbaum, J.H. Additive manufacturing of biodegradable metals: Current research status and future perspectives. Acta Biomater. 2019, 98, 3–22.

- Vanmeensel, K.; Lietaert, K.; Vrancken, B.; Dadbakhsh, S.; Li, X.; Kruth, J.-P.; Krakhmalev, P.; Yadroitsev, I.; van Humbeec, J. Additively manufactured metals for medical applications. Addit. Manuf. 2018, 261–309.

- Singh, S.; Bhatnagar, N. A survey of fabrication and application of metallic foams (1925–2017). J. Porous Mater. 2018, 25, 537–554.

- Kayode, O.; Akinlabi, E.T. An overview on joining of aluminium and magnesium alloys using friction stir welding (FSW) for automotive lightweight applications. Mater. Res. Express 2019, 6, 112005.

- Sharma, S.K.; Saxena, K.K. An outlook on the influence on mechanical properties of AZ31 reinforced with graphene nanoparticles using powder metallurgy technique for biomedical application. Mater. Today Proc. 2022, 56, 2278–2287.

- Sharma, S.K.; Saxena, K.K.; Kumar, K.B.; Kumar, N. The effect of reinforcements on the mechanical properties of AZ31 composites prepared by powder metallurgy: An overview. Mater. Today Proc. 2022, 56, 2293–2299.

- Alaneme, K.K.; Kareem, S.A.; Olajide, J.L.; Sadiku, R.E.; Bodunrin, M.O. Computational biomechanical and biodegradation integrity assessment of Mg-based biomedical devices for cardiovascular and orthopedic applications: A Review. Int. J. Lightweight Mater. Manuf. 2022, 5, 251–266.

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865.

- Sharma, S.K.; Saxena, K.K.; Malik, V.; Mohammed, K.A.; Prakash, C.; Buddhi, D.; Dixit, S. Significance of Alloying Elements on the Mechanical Characteristics of Mg-Based Materials for Biomedical Applications. Crystals 2022, 12, 1138.

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760.

- Zeng, Z.; Salehi, M.; Kopp, A.; Xu, S.; Esmaily, M.; Birbilis, N. Recent progress and perspectives in additive manufacturing of magnesium alloys. J. Magnes. Alloy. 2022, 10, 1511–1541.

- Ning, C.; Zhou, Z.; Tan, G.; Zhu, Y.; Mao, C. Electroactive polymers for tissue regeneration: Developments and perspectives. Prog. Polym. Sci. 2018, 81, 144–162.

- Alam Ansari, M.A.; Golebiowska, A.; Dash, M.; Kumar, P.; Jain, P.K.; Nukavarapu, S.; Ramakrishna, S.; Nanda, H.S. Engineering biomaterials to 3D-print scaffolds for bone regeneration: Practical and theoretical consideration. Biomater. Sci. 2022, 10, 2789–2816.

- Putra, N.E.; Mirzaali, M.J.; Apachitei, I.; Zhou, J.; Zadpoor, A.A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20.

- Murty, B.S.; Ranganathan, S.J.M.R. Novel materials synthesis by mechanical alloying/milling. Int. Mater. Rev. 1998, 43, 101–141.

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164.

- Esmaily, M.; Zeng, Z.; Mortazavi, A.N.; Gullino, A.; Choudhary, S.; Derra, T.; Benn, F.; D’Elia, F.; Müther, M.; Thomas, S.; et al. A detailed microstructural and corrosion analysis of magnesium alloy WE43 manufactured by selective laser melting. Addit. Manuf. 2020, 35, 101321.

- Mohamed, A.; Tirth, V.; Kamel, B.M. Tribological characterization and rheology of hybrid calcium grease with graphene nanosheets and multi-walled carbon nanotubes as additives. J. Mater. Res. Technol. 2020, 9, 6178–6185.

- Gradl, P.R.; Tinker, D.C.; Ivester, J.; Skinner, S.W.; Teasley, T.; Bili, J.L. Geometric feature reproducibility for laser powder bed fusion (L-PBF) additive manufacturing with Inconel 718. Addit. Manuf. 2021, 47, 102305.

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552.

- Tekumalla, S.; Nandigam, Y.; Bibhanshu, N.; Rajashekara, S.; Yang, C.; Suwas, S.; Gupta, M. A strong and deformable in-situ magnesium nanocomposite igniting above 1000 C. Sci. Rep. 2018, 8, 7038.

- Wang, H.-Y.; Lo, Y.-L.; Tran, H.-C.; Raza, M.M.; Le, T.-N. Systematic approach for reducing micro-crack formation in Inconel 713LC components fabricated by laser powder bed fusion. Rapid Prototyp. J. 2021, 27, 1548–1561.

- Deng, Q.; Wu, Y.; Wu, Q.; Xue, Y.; Zhang, Y.; Peng, L.; Ding, W. Microstructure evolution and mechanical properties of a high-strength Mg-10Gd-3Y–1Zn-0.4 Zr alloy fabricated by laser powder bed fusion. Addit. Manuf. 2022, 49, 102517.

- Zhao, C.; Wang, Z.; Li, D.; Xie, M.; Kollo, L.; Luo, Z.; Zhang, W.; Prashanth, K.G. Comparison of additively manufacturing samples fabricated from pre-alloyed and mechanically mixed powders. J. Alloys Compd. 2020, 830, 154603.

- Babu, A.P.; Kairy, S.K.; Huang, A.; Birbilis, N. Laser powder bed fusion of high solute Al-Zn-Mg alloys: Processing, characterisation and properties. Mater. Des. 2020, 196, 109183.

- Niu, X.; Shen, H.; Xu, G.; Zhang, L.; Fu, J.; Deng, X. Effect of aluminium content and processing parameters on the microstructure and mechanical properties of laser powder-bed fused magnesium-aluminium (0, 3, 6, 9 wt%) powder mixture. Rapid Prototyp. J. 2019, 25, 744–751.

- Ron, T.; Leon, A.; Popov, V.; Strokin, E.; Eliezer, D.; Shirizly, A.; Aghion, E. Synthesis of Refractory High-Entropy Alloy WTaMoNbV by Powder Bed Fusion Process Using Mixed Elemental Alloying Powder. Materials 2022, 15, 4043.

- Niu, X.; Shen, H.; Fu, J.; Yan, J.; Wang, Y. Corrosion behaviour of laser powder bed fused bulk pure magnesium in hank’s solution. Corros. Sci. 2019, 157, 284–294.

- Hu, D.; Wang, Y.; Zhang, D.; Hao, L.; Jiang, J.; Li, Z.; Chen, Y. Experimental investigation on selective laser melting of bulk net-shape pure magnesium. Mater. Manuf. Process. 2015, 30, 1298–1304.

- Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on properties of selective laser melting Mg–9% Al powder mixture. Mater. Des. 2012, 34, 753–758.

- Niu, X.; Shen, H.; Fu, J. Microstructure and mechanical properties of selective laser melted Mg-9 wt% Al powder mixture. Mater. Lett. 2018, 221, 4–7.

- Liu, S.; Yang, W.; Shi, X.; Li, B.; Duan, S.; Guo, H.; Guo, J. Influence of laser process parameters on the densification, microstructure, and mechanical properties of a selective laser melted AZ61 magnesium alloy. J. Alloys Compd. 2019, 808, 151160.

- He, C.; Bin, S.; Wu, P.; Gao, C.; Feng, P.; Yang, Y.; Liu, L.; Zhou, Y.; Zhao, M.; Yang, S.; et al. Microstructure evolution and biodegradation behavior of laser rapid solidified Mg–Al–Zn alloy. Metals 2017, 7, 105.

- Wei, K.; Gao, M.; Wang, Z.; Zeng, X. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy. Mater. Sci. Eng. A 2014, 611, 212–222.

- Zhu, Z.; Zhang, M.; Chen, C. Effect of selective laser melting on microstructure and properties of AZ91D alloy. Mater. Werkst. 2019, 50, 1484–1494.

- Lucas, J.; Meiners, W.; Vervoort, S.; Gayer, C.; Zumdick, N.A.; Zander, D. Selective laser melting of magnesium alloys. In European Congress and Exhibition on Powder Metallurgy, Proceedings of the European PM Conference, Hamburg, Germany, 9–13 October 2016; The European Powder Metallurgy Association: Brussels, Belgium, 2016; pp. 1–6.

- Niu, X.; Shen, H.; Fu, J.; Feng, J. Effective control of microstructure evolution in AZ91D magnesium alloy by SiC nanoparticles in laser powder-bed fusion. Mater. Des. 2021, 206, 109787.

- Zumdick, N.A.; Jauer, L.; Kersting, L.C.; Kutz, T.N.; Schleifenbaum, J.H.; Zander, D. Additive manufactured WE43 magnesium: A comparative study of the microstructure and mechanical properties with those of powder extruded and as-cast WE43. Mater. Charact. 2019, 147, 384–397.

- Hyer, H.; Zhou, L.; Benson, G.; McWilliams, B.; Cho, K.; Sohn, Y. Additive manufacturing of dense WE43 Mg alloy by laser powder bed fusion. Addit. Manuf. 2020, 33, 101123.

- Bär, F.; Berger, L.; Jauer, L.; Kurtuldu, G.; Schäublin, R.; Schleifenbaum, J.H.; Löffler, J.F. Laser additive manufacturing of biodegradable magnesium alloy WE43: A detailed microstructure analysis. Acta Biomater. 2019, 98, 36–49.

- Gangireddy, S.; Gwalani, B.; Liu, K.; Faierson, E.J.; Mishra, R.S. Microstructure and mechanical behavior of an additive manufactured (AM) WE43-Mg alloy. Addit. Manuf. 2019, 26, 53–64.

- Deng, Q.; Wu, Y.; Su, N.; Chang, Z.; Chen, J.; Peng, L.; Ding, W. Influence of friction stir processing and aging heat treatment on microstructure and mechanical properties of selective laser melted Mg-Gd-Zr alloy. Addit. Manuf. 2021, 44, 102036.

- Deng, Q.; Wu, Y.; Luo, Y.; Su, N.; Xue, X.; Chang, Z.; Wu, Q.; Xue, Y.; Peng, L. Fabrication of high-strength Mg-Gd-Zn-Zr alloy via selective laser melting. Mater. Charact. 2020, 165, 110377.

- Fu, P.; Wang, N.; Liao, H.; Xu, W.; Peng, L.; Chen, J.; Hu, G.; Ding, W. Microstructure and mechanical properties of high strength Mg− 15Gd− 1Zn− 0.4 Zr alloy additive-manufactured by selective laser melting process. Trans. Nonferrous Met. Soc. China 2021, 31, 1969–1978.

- Wei, K.; Zeng, X.; Wang, Z.; Deng, J.; Liu, M.; Huang, G.; Yuan, X. Selective laser melting of Mg-Zn binary alloys: Effects of Zn content on densification behavior, microstructure, and mechanical property. Mater. Sci. Eng. A 2019, 756, 226–236.

- Wei, K.; Wang, Z.; Zeng, X. Influence of element vaporization on formability, composition, microstructure, and mechanical performance of the selective laser melted Mg–Zn–Zr components. Mater. Lett. 2015, 156, 187–190.

- Yang, K.-T.; Kim, M.-Y.; Kim, D.; Suhr, J. Investigation of laser powder bed fusion manufacturing and post-processing for surface quality of as-built 17-4PH stainless steel. Surf. Coat. Technol. 2021, 422, 127492.

- Megahed, M.; Mindt, H.; Willems, J.; Dionne, P.; Jacquemetton, L.; Craig, J.; Ranade, P.; Peralta, A. LPBF right the first time—The right mix between modeling and experiments. Integr. Mater. Manuf. Innov. 2019, 8, 194–216.

- Prasad, K.; Obana, M.; Ishii, Y.; Ito, A.; Torizuka, S. The effect of laser scanning strategies on the microstructure, texture and crystallography of grains exhibiting hot cracks in additively manufactured Hastelloy X. Mech. Mater. 2021, 157, 103816.

- Nabawy, A.M.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. Influence of additions of Zr, Ti–B, Sr, and Si as well as of mold temperature on the hot-tearing susceptibility of an experimental Al–2% Cu–1% Si alloy. J. Mater. Sci. 2012, 47, 4146–4158.

- Qin, H.; Yang, G.; Zheng, X.; Luo, S.; Bai, T.; Jie, W. Effect of Gd content on hot-tearing susceptibility of Mg-6Zn-xGd casting alloys. China Foundry 2022, 19, 131–139.

- Park, S.S.; Park, W.-J.; Kim, C.H.; You, B.S.; Kim, N.J. The twin-roll casting of magnesium alloys. JOM 2009, 61, 14–18.

- Maeng, D.Y.; Kim, T.S.; Lee, J.H.; Hong, S.J.; Seo, S.K.; Chun, B.S. Microstructure and strength of rapidly solidified and extruded Mg-Zn alloys. Scr. Mater. 2000, 43, 385–389.

- Yang, Y.; Xiong, X.; Chen, J.; Peng, X.; Chen, D.; Pan, F. Research advances in magnesium and magnesium alloys worldwide in 2020. J. Magnes. Alloy. 2021, 9, 705–747.

- Patel, B.K.; Patel, F.P.; Badheka, V.J. Review on Friction-Based Additive Manufacturing Processes: Types, Defects, and Applications. In Recent Advances in Manufacturing Processes and Systems; Springer: Singapore, 2022; pp. 885–903.

- Karunakaran, R.; Ortgies, S.; Green, R.; Barelman, W.; Kobler, I.; Sealy, M. Accelerated Corrosion Behavior of Additive Manufactured WE43 Magnesium Alloy. In Proceedings of the 2021 International Solid Freeform Fabrication Symposium, Virtual, 2–4 August 2021; University of Texas at Austin: Austin, TX, USA, 2021.

- Cao, X.; Jahazi, M.; Immarigeon, J.P.; Wallace, W. A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 2006, 171, 188–204.

- Zhang, Z.; Tan, Z.J.; Li, J.Y.; Zu, Y.F.; Liu, W.; Sha, J. Experimental and numerical studies of re-stirring and re-heating effects on mechanical properties in friction stir additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 104, 767–784.

- Cedeño-Viveros, L.D.; Olivas-Alanis, L.H.; Lopez-Botello, O.; Rodriguez, C.A.; Vazquez-Lepe, E.; García-López, E. A novel method for the fabrication of tubular WE43 magnesium scaffold based on laser micro-spot welding. Eng. Sci. Technol. Int. J. 2022, 34, 101096.

- Sekar, P.; Narendranath, S.; Desai, V. Recent progress in in vivo studies and clinical applications of magnesium based biodegradable implants—A review. J. Magnes. Alloy. 2021, 9, 1147–1163.

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of micro selective laser melting: The state of the art and future perspectives. Engineering 2019, 5, 702–720.

- Christine, S.J. Alternative Processing Methods for Mg Alloy WE43. Ph.D. Thesis, University of California, Davis, CA, USA, 2020.

- Sun, H.Q.; Shi, Y.-N.; Zhang, M.-X.; Lu, K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy. Acta Mater. 2007, 55, 975–982.

- Yuri, E.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817.

- Stopyra, W.; Gruber, K.; Smolina, I.; Kurzynowski, T.; Kuźnicka, B. Laser powder bed fusion of AA7075 alloy: Influence of process parameters on porosity and hot cracking. Addit. Manuf. 2020, 35, 101270.

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729.

- Talignani, A.; Seede, R.; Whitt, A.; Zheng, S.; Ye, J.; Karaman, I.; Kirka, M.M.; Kato, Y.; Wang, Y.M. A review on additive manufacturing of refractory tungsten and tungsten alloys. Addit. Manuf. 2022, 58, 103009.

- Catherine, F.A. Laser Powderbed Fusion (LPBF) of Tungsten and Tungsten Alloys for Nuclear Fusion Applications. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2020.

- Irrinki, H. Material-Process-Property Relationships of 17-4 Stainless Steel Fabricated by Laser-Powder Bed Fusion Followed by Hot Isostatic Pressing. Ph.D. Thesis, University of Louisville, Louisville, KY, USA, 2018.

- Dunbar, A.J.; Denlinger, E.R.; Heigel, J.; Michaleris, P.; Guerrier, P.; Martukanitz, R.; Simpson, T.W. Development of experimental method for in situ distortion and temperature measurements during the laser powder bed fusion additive manufacturing process. Addit. Manuf. 2016, 12, 25–30.

- Levkulich, N.C.; Semiatin, S.L.; Gockel, J.E.; Middendorf, J.R.; DeWald, A.T.; Klingbeil, N.W. The effect of process parameters on residual stress evolution and distortion in the laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 2019, 28, 475–484.

- Nakata, T.; Xu, C.; Ohashi, H.; Yoshida, Y.; Yoshida, K.; Kamado, S. New Mg–Al based alloy sheet with good room-temperature stretch formability and tensile properties. Scr. Mater. 2020, 180, 16–22.

- Zhang, A.; Hao, H.; Liu, X.; Zhang, X. Effects of precipitates on grain size and mechanical properties of AZ31-x% Nd magnesium alloy. J. Rare Earths 2014, 32, 451–457.

- Ali, Y.; Qiu, D.; Jiang, B.; Pan, F.; Zhang, M. Current research progress in grain refinement of cast magnesium alloys: A review article. J. Alloys Compd. 2015, 619, 639–651.

- Jana, S.; Olszta, M.; Edwards, D.; Engelhard, M.; Samanta, A.; Ding, H.; Murkute, P.; Isgor, O.B.; Rohatgi, A. Microstructural basis for improved corrosion resistance of laser surface processed AZ31 Mg alloy. Corros. Sci. 2021, 191, 109707.

- Luo, A.A.; Sachdev, A.K.; Apelian, D. Alloy development and process innovations for light metals casting. J. Mater. Process. Technol. 2022, 117606.

- Deng, Q.; Wang, X.; Lan, Q.; Chang, Z.; Liu, Z.; Su, N.; Wu, Y.; Liu, D.; Peng, L.; Ding, W. Limitations of linear energy density for laser powder bed fusion of Mg-15Gd-1Zn-0.4 Zr alloy. Mater. Charact. 2022, 190, 112071.

- Motallebi, R.; Savaedi, Z.; Mirzadeh, H. Post-processing heat treatment of lightweight magnesium alloys fabricated by additive manufacturing: A review. J. Mater. Res. Technol. 2022, 20, 1873–1892.

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 38, 101804.

- Luo, X.; Li, D.D.; Yang, C.; Gebert, A.; Lu, H.Z.; Song, T.; Ma, H.W.; Kang, L.M.; Long, Y.; Li, Y.Y. Circumventing the strength–ductility trade-off of β-type titanium alloys by defect engineering during laser powder bed fusion. Addit. Manuf. 2022, 51, 102640.

- Ma, X.L.; Prameela, S.E.; Yi, P.; Fernandez, M.; Krywopusk, N.M.; Kecskes, L.J.; Sano, T.; Falk, M.L.; Weihs, T.P. Dynamic precipitation and recrystallization in Mg-9 wt.% Al during equal-channel angular extrusion: A comparative study to conventional aging. Acta Mater. 2019, 172, 185–199.

- Maghsoudi, M.H.; Zarei-Hanzaki, A.; Abedi, H.R.; Shamsolhodaei, A. The evolution of γ-Mg17Al12 intermetallic compound during accumulative back extrusion and subsequent ageing treatment. Philos. Mag. 2015, 95, 3497–3523.

- Cifuentes, S.C.; Soler, S.G.A.P. Processing and Characterization of Novel Biodegradable and Bioresorbable PLA/Mg Composites for Osteosynthesis. Ph.D. Thesis, Universidad Carlos III de Madrid, Getafe, Spain, 2015.

- Sharma, S.K.; Kodli, B.K.; Saxena, K.K. Micro Forming and its Applications: An Overview. Key Eng. Mater. 2022, 924, 73–91.

- Xiang, Z.; Wang, F.; Yan, X.; Li, X.; Hattar, K.; Cui, B. Nanostructured Oxide-Dispersion-Strengthened CoCrFeMnNi High-Entropy Alloys with High Thermal Stability. Adv. Eng. Mater. 2021, 23, 2100291.

- Murty, B.S.; Shankar, P.; Raj, B.; Rath, B.B.; Murday, J. Textbook of Nanoscience and Nanotechnology; Springer Science & Business Media: Berlin, Germany, 2013.

- Sharma, S.K.; Saxena, K.K. Effects on microstructure and mechanical properties of AZ31 reinforced with CNT by powder metallurgy: An overview. Mater. Today Proc. 2022, 56, 2038–2042.

- Mohammadzadeh, K.V. Microstructures and Mechanical Properties of Al 6061/Al2O3-TiB2 Hybrid Nano-Composite Layer Produced via Friction Stir Processing Using Optimized Process Parameters. Ph.D. Thesis, Eastern Mediterranean University, Mersin, Turkey, 2019.

- Sahu, M.R.; Kumar, T.S.S.; Chakkingal, U. A review on recent advancements in biodegradable Mg-Ca alloys. J. Magnes. Alloy. 2022, 10, 2094–2117.

- Mark, E.; StJohn, D. An analysis of the relationship between grain size, solute content, and the potency and number density of nucleant particles. Metall. Mater. Trans. A 2005, 36, 1911–1920.

- Hänzi, A.C.; Sologubenko, A.S.; Uggowitzer, P.J. Design strategy for microalloyed ultra-ductile magnesium alloys for medical applications. In Materials Science Forum; Trans Tech Publications Ltd.: Wallerau, Switzerland, 2009; Volume 618, pp. 75–82.

- Alan, E.M.; StJohn, D.H. A model of grain refinement incorporating alloy constitution and potency of heterogeneous nucleant particles. Acta Mater. 2001, 49, 1867–1878.

- Robson, J.D.; Prangnell, P.B. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys. Acta Mater. 2001, 49, 599–613.

- Sharma, S.K.; Saxena, K.K.; Kumar, N. Effect of SiC on Mechanical Properties of Al-Based Metal Matrix Composites Produced by Stir Casting. Met. Sci. Heat Treat. 2022, 64, 316–320.

- McGhee, P. Effect of Microstructure on the Mechanical Properties of Extruded Magnesium and a Magnesium Alloy. Ph.D. Thesis, North Carolina Agricultural and Technical State University, Greensboro, NC, USA, 2017.

- Sharma, S.K.; Saxena, K.K.; Salem, K.H.; Mohammed, K.A.; Singh, R.; Prakash, C. Effects of various fabrication techniques on the mechanical characteristics of metal matrix composites: A review. Adv. Mater. Process. Technol. 2022, 1–18.

- Tzong-Horng, L. Preparation and characterization of nano-structured silica from rice husk. Mater. Sci. Eng. A 2004, 364, 313–323.

- Burton, A.W.; Ong, K.; Rea, T.; Chan, I.Y. On the estimation of average crystallite size of zeolites from the Scherrer equation: A critical evaluation of its application to zeolites with one-dimensional pore systems. Microporous Mesoporous Mater. 2009, 117, 75–90.

- Fan, L.; Xue, M.; Kang, Z.; Li, H.; Qiu, S. Electrospinning technology applied in zeolitic imidazolate framework membrane synthesis. J. Mater. Chem. 2012, 22, 25272–25276.

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442.

- Rometsch, P.A.; Zhu, Y.; Wu, X.; Huang, A. Review of High-Strength Aluminium Alloys for Additive Manufacturing by Laser Powder Bed Fusion. Mater. Des. 2022, 219, 110779.

- Helmut, C.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215.

- Mertens, A.I.; Delahaye, J.; Lecomte-Beckers, J. Fusion-based additive manufacturing for processing aluminum alloys: State-of-the-art and challenges. Adv. Eng. Mater. 2017, 19, 1700003.

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.S.; Goyal, D.K. Selective laser melting of Ti6Al4V alloy: Process parameters, defects and post-treatments. J. Manuf. Process. 2021, 64, 161–187.

- Fachyrtdinov, R.S.; Kuznetsova, P.E.; Savichev, I.D. Structure, properties and heat treatment of aluminum alloy BAC1 synthesized by 3D printing. In IOP Conference Series: Materials Science and Engineering; IOP: Bristol, UK, 2020; Volume 934, p. 012043.

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.-U.; Ugues, D.; et al. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–75.

- Tirth, V.; Algahtani, A.; Aziz, M.A.; Edacherian, A. Optimum Aging Parameters of 6063/Al2O3p-SiCp Hybrid Composites. Met. Sci. Heat Treat. 2020, 61, 750–755.

- Ponnusamy, P.; Rashid, R.A.R.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical properties of SLM-printed aluminium alloys: A review. Materials 2020, 13, 4301.

- Cao, S.; Zou, Y.; Lim, C.V.S.; Wu, X. Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: Process, post-process treatment, microstructure, and property. Light Adv. Manuf. 2021, 2, 313–332.

- Putra, N.E.; Borg, K.G.N.; Diaz-Payno, P.J.; Leeflang, M.A.; Klimopoulou, M.; Taheri, P.; Mol, J.M.C.; Fratila-Apachitei, L.; Huan, Z.; Chang, J.; et al. Additive manufacturing of bioactive and biodegradable porous iron-akermanite composites for bone regeneration. Acta Biomater. 2022, 148, 355–373.

- Niranjan, Y.C.; Channabasavanna, S.G.; Krishnapillai, S.; Velmurugan, R.; Kannan, A.R.; Mohan, D.G.; Karganroudi, S.S. The Unprecedented Role of 3D Printing Technology in Fighting the COVID-19 Pandemic: A Comprehensive Review. Materials 2022, 15, 6827.

- Han, H.-S.; Loffredo, S.; Jun, I.; Edwards, J.; Kim, Y.-C.; Seok, H.-K.; Witte, F.; Mantovani, D.; Glyn-Jones, S. Current status and outlook on the clinical translation of biodegradable metals. Mater. Today 2019, 23, 57–71.

- Zamani, Y.; Ghazanfari, H.; Erabi, G.; Moghanian, A.; Fakić, B.; Hosseini, S.M.; Mahammod, B.P. A review of additive manufacturing of Mg-based alloys and composite implants. J. Compos. Compd. 2021, 3, 71–83.

- Okoro, V.U. Irradiation Assisted Corrosion of Cast A360. 1 and Additively Manufactured AlSi10Mg Aluminum Alloys in Seawater Environments. Ph.D. Thesis, University of New Brunswick, Fredericton, NB, Canada, 2021.

- Li, M.; Benn, F.; Derra, T.; Kröger, N.; Zinser, M.; Smeets, R.; Molina-Aldareguia, J.M.; Kopp, A.; Lorca, J.L. Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications. Mater. Sci. Eng. C 2021, 119, 111623.

- Song, G.L.; Atrens, A. Corrosion mechanisms of magnesium alloys. Adv. Eng. Mater. 1999, 1, 11–33.

- Sezer, N.; Evis, Z.; Koc, M. Additive manufacturing of biodegradable magnesium implants and scaffolds: Review of the recent advances and research trends. J. Magnes. Alloy. 2021, 9, 392–415.

- Das, P.; Kumar, T.S.S.; Sahu, K.K.; Gollapudi, S. Corrosion, stress corrosion cracking and corrosion fatigue behavior of magnesium alloy bioimplants. Corros. Rev. 2022, 40, 289–333.

- Liang, J.; Lei, Z.; Chen, Y.; Fu, W.; Wu, S.; Chen, X.; Yang, Y. Microstructure evolution of laser powder bed fusion ZK60 Mg alloy after different heat treatment. J. Alloys Compd. 2022, 898, 163046.

- Zeng, R.; Dietzel, W.; Witte, F.; Hort, N.; Blawert, C. Progress and challenge for magnesium alloys as biomaterials. Adv. Eng. Mater. 2008, 10, B3–B14.

- Zhang, Y.Z.; Venugopal, J.; Huang, Z.-M.; Lim, C.T.; Ramakrishna, S. Characterization of the surface biocompatibility of the electrospun PCL-collagen nanofibers using fibroblasts. Biomacromolecules 2005, 6, 2583–2589.

- Gutierrez, E.; Burdiles, P.A.; Quero, F.; Palma, P.; Olate-Moya, F.; Palza, H. 3D printing of antimicrobial alginate/bacterial-cellulose composite hydrogels by incorporating copper nanostructures. ACS Biomater. Sci. Eng. 2019, 5, 6290–6299.

- Ferrández-Montero, A.; Lieblich, M.; González-Carrasco, J.L.; Benavente, R.; Ferrari, B. Tailoring biodegradable and bioactive polymer/Mg composites for additive manufacturing. In Proceedings of the FINAL Program, 11th Symposium on Biodegradable Metals, Alicante, Spain, 1 August 2019.

- Yusop, M.; Hakim, A.; al Sakkaf, A.; Nur, H. Modifications on porous absorbable Fe-based scaffolds for bone applications: A review from corrosion and biocompatibility viewpoints. J. Biomed. Mater. Res. Part B Appl. Biomater. 2022, 110, 18–44.

- Nair, M.B.; Varma, H.K.; Mohanan, P.V.; John, A. Tissue-engineered triphasic ceramic coated hydroxyapatite induced bone formation and vascularization at an extraskeletal site in a rat model. Bull. Mater. Sci. 2011, 34, 1721–1731.

This entry is offline, you can click here to edit this entry!