1. Fermented Biomass as an Element of the Circular Economy

Agriculture is the most vulnerable sector of the economy to climate change. Changes in precipitation, temperature, CO

2 concentrations, and sea levels, as well as the increasing intensification and frequency of extreme weather events (including heat stress and its effects), significantly affect the quantity and quality of crops

[1]. Sustainable agriculture involves the efficient production of high-quality, agricultural products. The purpose is to protect and promote the natural environment, ensuring animal health and welfare, as well as sustainable social and economic conditions for farmers, workers, and local communities. In line with the principle of sustainable development, as defined by the 1987 World Commission on Environment and Development, economic systems should be adjusted as soon as possible to counteract the effects of climate change

[2]. The Common Agricultural Policy (CAP) for European Union member countries defines nine key social, environmental, and economic goals, including combating climate change, caring for the environment, and protecting health and food quality

[1].

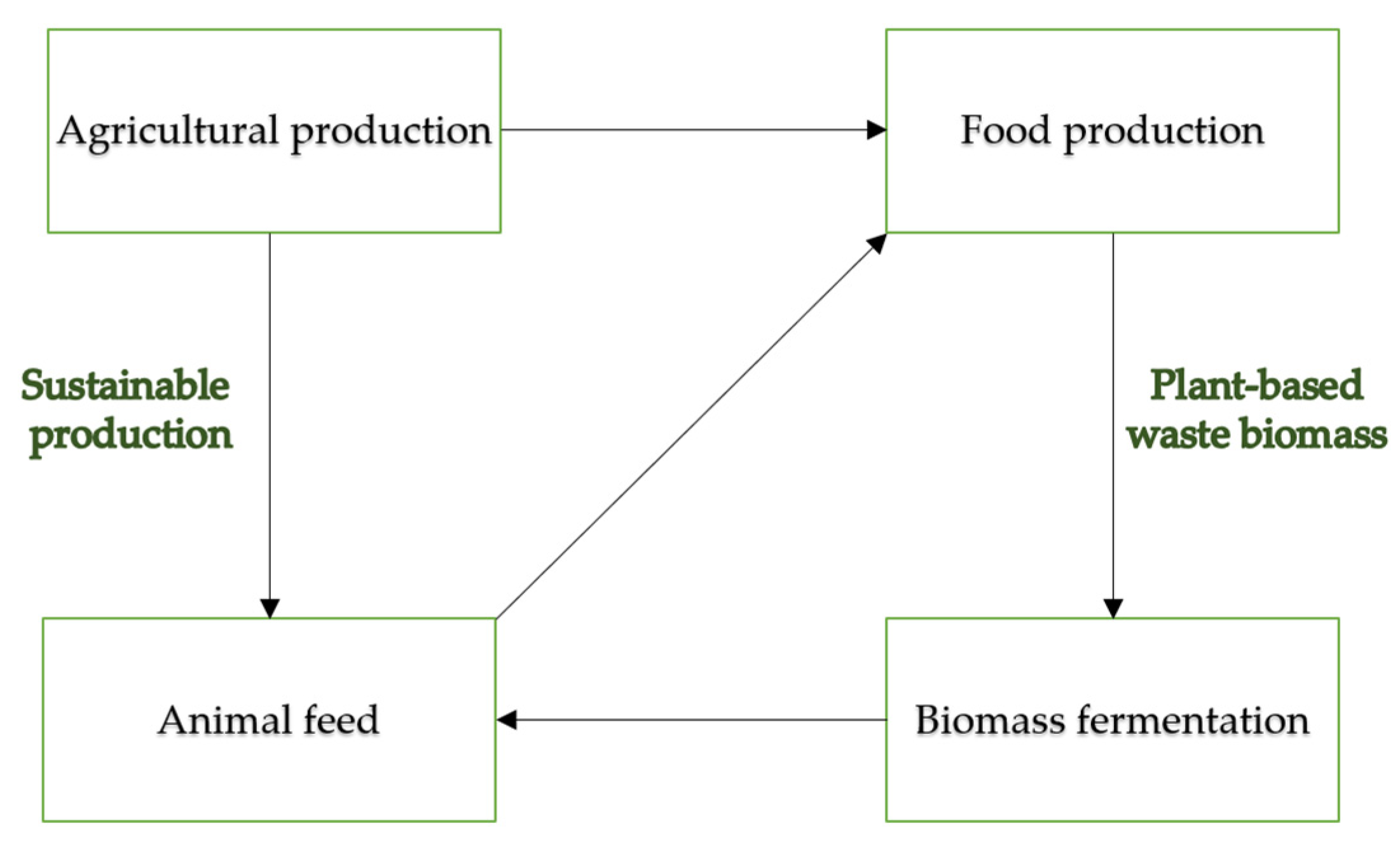

Population growth requires the production of more and more food, which results in more agro-industrial waste and economic losses. Often, production residues are rich in active compounds that can be used as additives in food and functional food, animal feed, pharmaceuticals, cosmetics, or bio-packaging. This not only reduces the amount of waste but also minimizes economic losses (

Figure 1). Industrial fermentation processes can be used to produce biologically active compounds from agricultural waste. The spectrum of substrates and the metabolic abilities of microorganisms determine the final product

[3]. The active compounds present in agricultural waste before fermentation include phenolic compounds, antioxidants, and compounds with anti-inflammatory and anticancer properties. Vegetable and fruit waste is attracting increasing attention as a source of biomass, due to its quantity and high content of unused nutrients

[4][5].

Figure 1. Fermented biomass as an element of the circular economy.

2. Contemporary Models Related to Pig Feeding

According to UN predictions, the human population is expected to reach almost 10 billion by 2050. Population growth is creating increased demand for meat products. At the same time, consumer standards are rising. Meat obtained by breeding animals, including pigs, must meet higher expectations, not only in terms of quality but also of appearance. This demand creates a shortage of animal feed, and contributes to the growing interest in the modification of plant waste into wholesome animal food

[2].

Increased meat production due to the growing population also has serious consequences for the climate. There are two ways in which animals can be fed and produce meat sustainably. The first method of meat production is based on the requirements of the animal. It involves the precise feeding of animals with genetically modified feed, produced with the use of improved production methods. In this method the animals are monitored for disease and welfare. However, this system may lead to lower animal welfare standards and contribute to a decline in animal immunity. This method is characterized by a high input and maximum efficiency, based on the uniform production of the protein on the smallest possible surface in such a way as to have a minimal impact on the environment. In addition, the potential loss of nutrients, the release of manure into the wastewater, and the production of large amounts of greenhouse gases can contribute to the opposite effect—meat production is unsustainable

[2][6].

The second system emphasizes environmental conditions and the availability of raw materials for feed, allowing local feeds, feedstuff co-products, or food waste to be fed to animals. This system assumes a reduced input and reduced production, as it is based on the selection of animals that are more resistant to climate change and are able to convert low-quality feed into meat

[6]. Experts believe that the use of the second system will be less economical due to reduced yield forecasts, the potential costs of reorganizing the feed supply chains, the need to supplement unsustainable nutrient quality, or the pretreatment of feed to, for example, reduce antinutritional factors, which will directly increase meat prices for consumers. Therefore, the best solution is to combine the two systems by assessing the amount of available feed and by-products in the local area, identifying available areas for plant and livestock production, setting production levels, and controlling production via established national and international bodies

[2][6].

According to Regulation (EC) No 1829/2003, genetically modified organisms cannot be used for food and/or feed if they are not covered by the EU authorization or if the conditions specified in this authorization are not met. The European Union member states (including Poland) are planning to introduce an order to limit the use of genetically modified ingredients in animal feed in the near future. This will exclude the use of feed with the addition of soy. High-protein alternatives are therefore being sought. One possibility is to use legumes grown in Poland and Europe

[7][8].

The diet of pigs, regardless of their age, is based on high-protein ingredients with a good content of amino acids (including lysine, methionine, and cysteine), such as yellow lupine or genetically modified soybeans. Pig feeding is a complex process, requiring specific methods for each stage of the pig’s development. The most sensitive stage is weaning piglets from sows and subsequent rearing. To minimize quantitative and economic losses, the breeder should take care to implement appropriate conditions and processes, including enzyme training, feeding, water availability, temperature, appropriate early feeding (when feeding the sows and taking care that the piglets do not eat the sow’s feed), feed acidification, the removal of uneaten feed, and veterinary control. Pigs reach full development of the digestive tract at the age of 5–6 months. Therefore, from the 5–7th day of life, piglets are given prestarters to accelerate their development, stimulating digestive processes and helping them learn how to feed independently

[6][9][10].

3. Fermented Biomass as a Feed Component

There is increasing interest in using fermented feed as food for pigs as an alternative to antimicrobial growth promoters. Fewer and fewer microbes react to the action of antibiotics, and resistance to antibiotics may also pose a threat to consumers. Probiotics are defined by the WHO and FAO as ‘living organisms which, when administered in appro-priate amounts, benefit the health of the host.’ In the case of pigs, they can promote growth and nutrient utilization, modulating their gut microflora. The use of probiotic bacteria can also increase anti-infective properties against pathogens and decrease the amount of

Salmonella sp. and

E. coli in excreted feces. Feed fermented with probiotic microorganisms reduces the effects of stress in young pigs after weaning and weight gain, preventing weight loss and diarrhea, which may lead to economic losses. Probiotic microorganisms also provide greater fermentation efficiency

[11][12]. Xu et al.

[13] evaluated the effect of fermentation on the amount of feed nutrients required, pig growth efficiency, and meat quality. They showed that fermented feed significantly increases the crude protein content of the meat. Moreover, in weaned piglets and fattening pigs, fermented feed increases the digestibility of nutrients and improves daily weight gain. Fermented feed has a positive effect on the quality (nutrient content, including protein), taste, and appearance of meat, improving its marbling and reducing the content of water

[13].

Fermentation is a process whereby water-soluble carbohydrates (WSC) are converted under anaerobic conditions into organic acids, mainly lactic acid, by lactic acid bacteria (LAB). This quickly lowers the pH of the ensiled biomass and interrupts the natural processes of nutrient decomposition by its own enzymes. Because the silage does not deteriorate, it can be stored for a long time, provided it has no contact with air. In an acidic environment, undesirable microorganisms that cause silage to rot and the protein to break down die, resulting in the formation of harmful substances. This slightly changes the chemical composition of silage compared with green forage: the concentration of sugars decreases and the content of neutral detergent fiber (NDF) increases, which may inhibit the absorption and use of other nutrients. Therefore, specific starters or fermentation modifications are applied. During forage ensiling, organic acids are used to ensure a sufficiently low pH and to protect against the proliferation of undesirable microorganisms, including

Enterobacteriaceae. The population of microorganisms used for fermentation must produce sufficient amounts of organic acids to inhibit pathogens and pollutants

[14][15].

There are diverse methods of plant biomass fermentation, which is influenced by the type of biomass, the starter used, and the process conditions Their course is influenced by the type of biomass, the starter used, and the process maintenance conditions. The following factors influence the fermentation of plant materials: the dry matter content and chemical composition of the silage plant; the compatibility between the silage plant and the inoculated organism; the number and diversity of living microorganisms in the inoculum, as well as their ability to dominate the natural microflora of the plant; the method of ensilage used; and the application of chemical and physical modifiers to the fermentation process and the aerobic stability of the silage

[14][15].

To ensure the development of lactic acid bacteria, the raw material should have a high sugar content, proper moisture content, and be finely ground. The purity of the ensiled material should be ensured through compaction and by quicky shutting off access to air (covering). The most optimal conditions for the growth of lactic acid bacteria are 30–35% dry matter content, minimum 30% starch in dry matter, and maximum 20% crude fiber in dry matter

[16]. When the biomass contains 70% water (30% dry weight), LAB are not restricted in their activity. A lower dry matter content of 30% can cause the growth of bacteria of the genus Clostridium. When the raw material is drier (more than 50% dry weight), LAB activity can be inhibited by 90%. Only 10% of LAB survive these extreme conditions, due to the lack of free water. During ensiling, the osmotic pressure in the ensiled biomass increases. The water available to bacteria in the dry raw material does not contain soluble carbohydrates, proteins, or minerals. Dry matter content above 50% makes it difficult to knead and remove air. This promotes the growth of aerobic bacteria and fungi. As much as 35% of dry matter means that some parts of the ensiled raw material contain up to 45% of dry matter

[16][17][18].

3.1. Use of Maize for the Production of Fermented Feed

Corn (

Zea mays) is a grain grown in North and South America, Asia, Africa, and Europe. About 850 million tons of grain are grown on 162 million hectares of land each year. The USA (37% of world production) and China (21% of world production) are the largest producers of maize. Maize silage is one of the most energetic foods for farm animals, providing high levels of fat and protein. Currently, about two-thirds of the world’s maize is used as animal feed

[19]. One of the main forms of maize used for animal feed is silage. Maize can be fermented with a high efficiency because it has a high content of soluble sugars. The dry matter content of the whole maize plant silage should be in the range of 32–35%. The parameters determining the nutritional quality of maize silage include the chemical composition and the content of nutrients, such as dry matter, total protein, total sugars, crude fat, crude fiber, NDF, ADF, and starch, as well as minerals such as calcium, phosphorus, potassium, magnesium, sodium, phosphorus, and sulfur

[16][17][18].

Properly produced maize silage should meet the following parameters

[18]:

-

dry weight: 30–35%;

-

starch: minimum 30% in dry matter;

-

crude fiber: maximum 20% in dry matter;

-

ADF: maximum 25% in dry matter;

-

NDF: maximum 45% in dry matter;

-

energy content: minimum 6.5 MJ NEL or 0.9 JPM in 1 kg of dry matter.

Corn grain has the highest energy value of any cereal, low fiber content, high concentrations of easily digestible carbohydrates, quite high fat content, and highly digestible nutrients. However, corn kernels have low levels of protein and amino acids such as lysine, tryptophan, and sulfur amino acids. The fat in corn kernels is rich in EFAs (Essential Fatty Acids), especially linoleic acid. Unfortunately, due to its high moisture content and content of simple sugars, corn is susceptible to pathogens and mold fungi of the genus

Fusarium and

Aspergillus. These fungi produce very dangerous mycotoxins that have a negative impact on the health of animals. Therefore, fermentation has become a popular method of preserving corn, especially as is about four times less expensive than drying

[17][20].

3.2. Use of Yellow and Narrow-Leaved Lupine in the Production of Fermented Feed

Like maize, lupine is grown all over the world. Poland is the third largest producer of lupine in the world (14.47% of world production), after Australia (47.14% of world production) and Russia (16.51% of world production). The amount of lupine produced in Poland has been increasing steadily since 2018. The most commonly used varieties of lupine bred for the production of animal feed are narrow-leaved husk (

Lupinus angustifolius L.) and yellow lupine (

Lupinus luteus L.). Replacing imported soybean feed with legumes is an interesting option for Polish agriculture, since legumes are cultivated locally and have a high crude protein content (40% in yellow lupine seeds). Lupine also has the ability to bind nitrogen, phosphorus, and other elements by releasing citrate into the soil. This is important because the cultivation of lupine can improve the condition of less fertile lands and prevent over exploitation, in accordance with the principles of sustainable agriculture. Lupine tolerates poor and acidic soils well, and is adapted to the temperate climate prevailing in Europe. Lupine has a similar high protein content and amino acid profile to soybeans, but it is less suitable for use in animal feed because of the presence of antinutritional substances, including protease inhibitors, alkaloids, lectins, tannins, and phytates. These substances can be reduced by various thermal treatments, or by the cultivation of sweet lupine varieties or varieties with a low concentration of undesirable substances. Compared to maize silage, lupine silage contains much more protein. Although it is a valuable protein feed, the large amount of protein and small amount of sugars do not favor the fermentation process. The use of primers can eliminate this problem. By influencing the rate and course of lactic acid fermentation, primers enable the long-term preservation of the fodder protein without reducing its biological value. To obtain good quality silage, the dry matter content of the green forage should be 28–35%

[9][21][22][23][24].

3.3. Other Plant-Based Biomass Used in the Production of Fermented Feed

3.3.1. Soy

Full fat and high protein (35–40% content

[25]) soybeans are a tasty and preferred component in pig feed, both alone and in combination with other vegetable protein sources. Apart from having significantly improved protein digestibility, soybean grains subjected to the extrusion process are also characterized by a better availability of energy. As a result, the fat is better absorbed by the intestinal villi of animals. A fermented soybean meal is rich in probiotics and functional metabolites, which facilitate digestion, absorption, and the use of soy protein in pigs, as well as inhibiting the growth of pathogens, including

Staphylococcus aureus and

Escherichia coli [26].

3.3.2. Rapeseed

Rapeseed is used in pig feed due to its high protein content (36–38%), which is similar to that in soy. However, rapeseed contains less lysine and more crude fiber than soy. Rapeseed meal is a by-product after oil extraction. Its use in pig feed also reduces problems and costs related to disposal. The extrusion of rapeseed meal makes it highly digestible, thanks to which there is great potential to significantly increase its share in the feed ration for pigs

[27][28].

3.3.3. Cereals

Since cereals are grown mainly for human consumption, rye and other cereals were for a long time not included as a feed component for pigs. An additional limitation was the ergot content of the old varieties. With the advent of genetically modified rye, its use as a feed ingredient has increased. The high concentration of nonstarch polysaccharides present in rye is undesirable in the diet of young pigs. However, the fermentation of these components contributes to the production of more butyrate and improves intestinal health, providing some prebiotic properties. Wheat is used in the form of decoctions, which are a by-product of ethanol production. This prevents excessive waste and reduces problems and costs related to disposal. Feed with the addition of fermented cereals contributes to reduce the susceptibility of pigs to diarrhea

[29][30].

This entry is adapted from the peer-reviewed paper 10.3390/su142114595