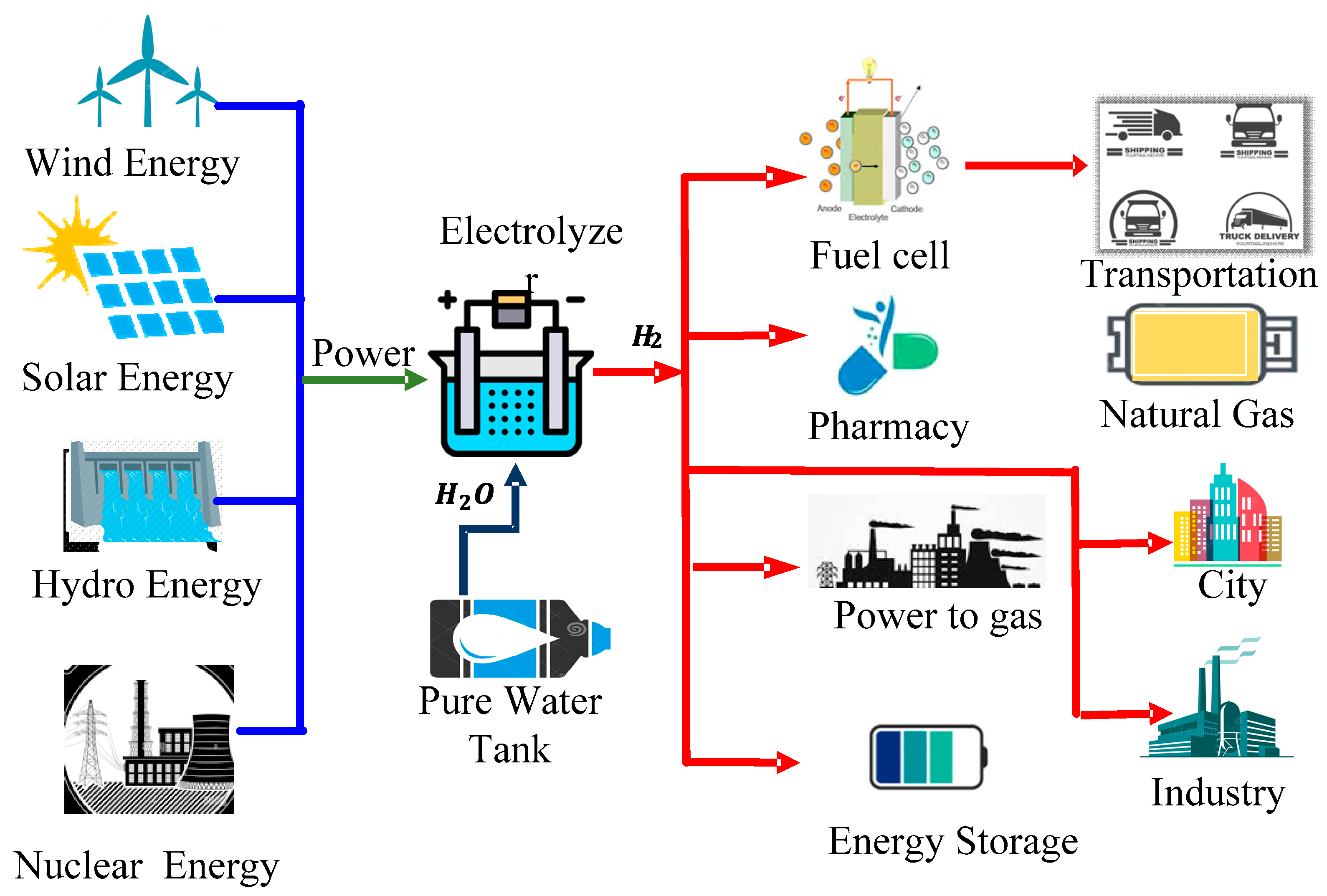

Hydrogen is acknowledged as a potential and appealing energy carrier for decarbonizing the sectors that contribute to global warming, such as power generation, industries, and transportation. Many people are interested in employing low-carbon sources of energy to produce hydrogen by using water electrolysis. Additionally, the intermittency of renewable energy supplies, such as wind and solar, makes electricity generation less predictable, potentially leading to power network incompatibilities. Hence, hydrogen generation and storage can offer a solution by enhancing system flexibility. Hydrogen saved as compressed gas could be turned back into energy or utilized as a feedstock for manufacturing, building heating, and automobile fuel.

- hybrid microgrid

- bidirectional AC-DC converter

- hydrogen energy

- wind energy

- energy management

1. Introduction

2. Literature Work

3. Hydrogen Production

3.1. Coal and Other Hydrocarbon Gasification

3.2. Steam Reforming

3.3. Electrolysis

3.4. Solar Hydrogen

3.5. Thermochemical Process

3.6. Nuclear Energy

3.7. Biomass

3.8. Off-Gas Cleanup

|

Authors |

Publication Year |

Method |

Observations |

|---|---|---|---|

|

Qureshi., et al., [55]. |

2022 |

Gasification |

How to use biomass, water, and fossil fuels to transform solid material into hydrogen and carbon monoxide after reacting with carbonaceous oxygen and steam was considered. |

|

Chandrasekar., et al., [56], |

2022 |

Steam reforming |

The process of producing hydrogen and gaseous or liquid fuels using biofuels and fossil fuels was considered. |

|

Dai, et al. [58], |

2022 |

Electrolysis |

It was explored how to break down water and steam using electrical and thermal energy to drive electrochemical processes that separate the materials into oxygen and hydrogen. |

|

Milewski et al., [64]. |

2022 |

Nuclear energy |

It was discussed how to operate a nuclear reactor utilizing the water splitting technique. The cooling methods for reactors, including gas cooling, liquid metal cooling, and molten salt cooling, were compared. |

|

Taipabu., et al., [65] |

2022 |

Biomass |

Biochemical and photonic energy played in the process of extracting hydrogen from biodegradable materials using biological energy was examined. |

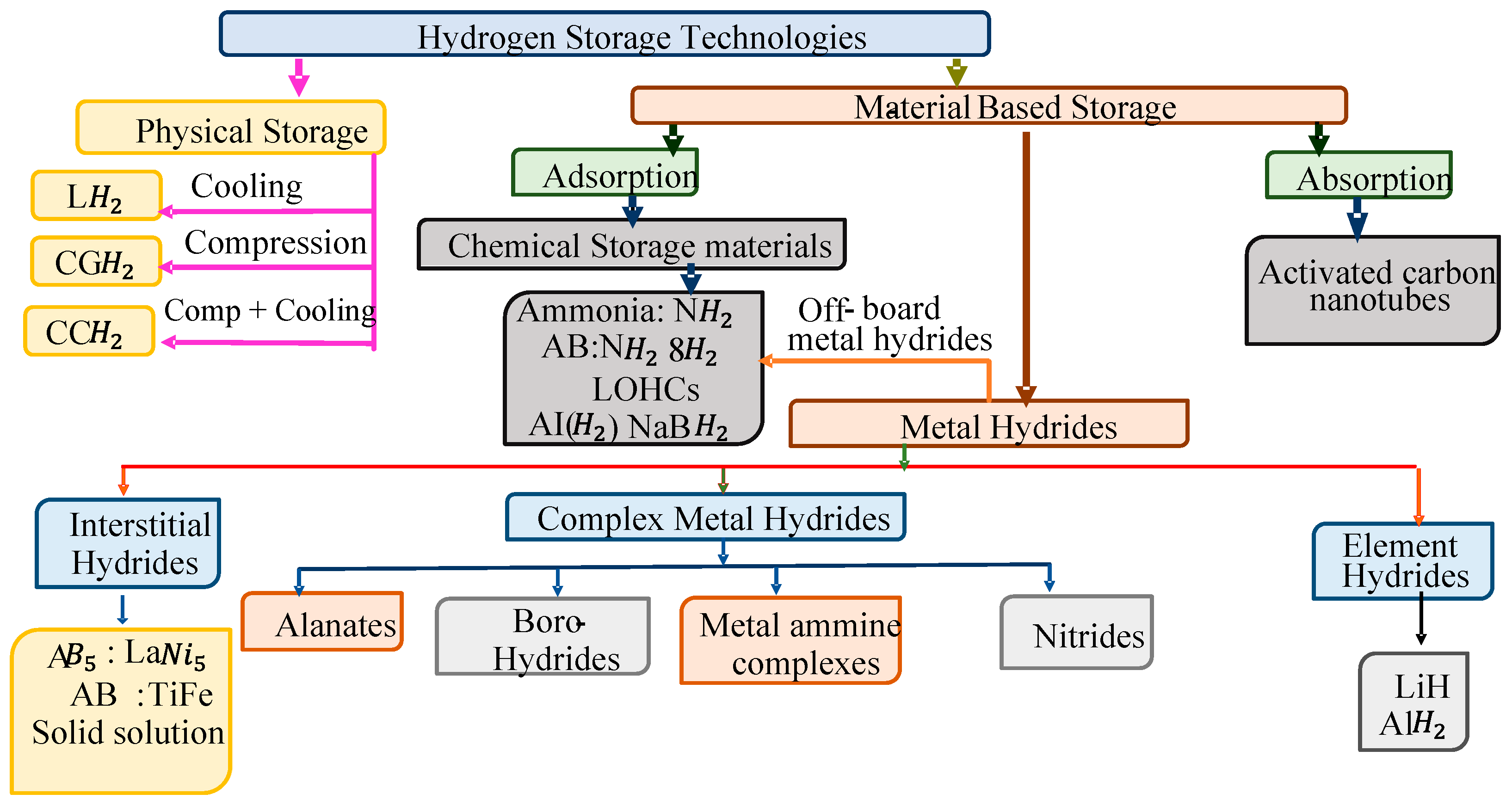

4. Hydrogen Storage Technologies

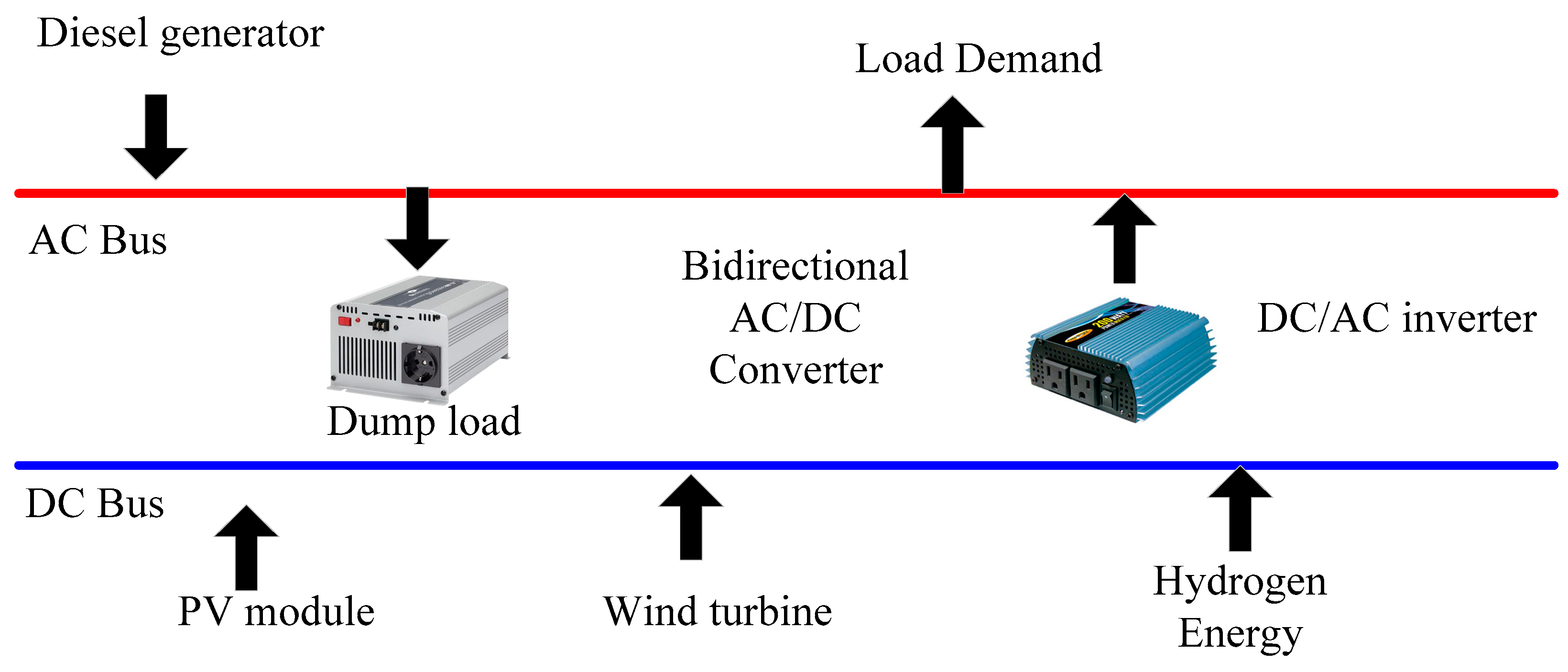

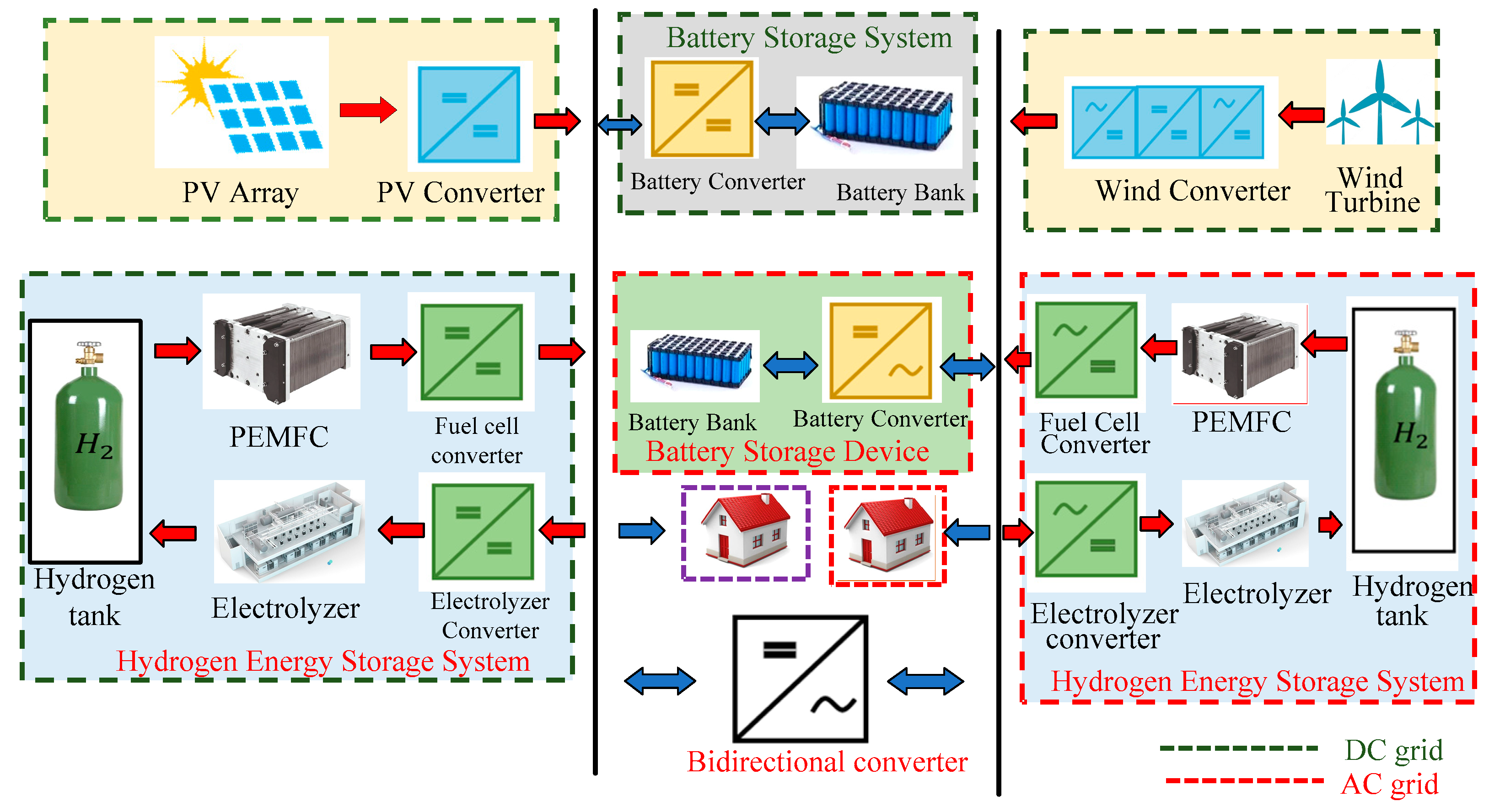

5. Hydrogen Based HMG

6. Hydrogen Energy Integration in HMG

This entry is adapted from the peer-reviewed paper 10.3390/en15217979

References

- Guilbert, D.; Vitale, G. Hydrogen as a Clean and Sustainable Energy Vector for Global Transition from Fossil-Based to Zero-Carbon. Clean Technol. 2021, 3, 881–909.

- World Energy Outlook 2019. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 31 August 2022).

- Solar Futures Study. Available online: https://www.energy.gov/eere/solar/solar-futures-study (accessed on 31 August 2022).

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019, 112, 170–182.

- Kumtepeli, V.; Zhao, Y.; Naumann, M.; Tripathi, A.; Wang, Y.; Jossen, A.; Hesse, H. Design and analysis of an aging-aware energy management system for islanded grids using mixed-integer quadratic programming. Int. J. Energy Res. 2019, 43, 4127–4147.

- Del Granado, P.C.; Pang, Z.; Wallace, S.W. Synergy of smart grids and hybrid distributed generation on the value of energy storage. Appl. Energy 2016, 170, 476–488.

- Amara, S.; Toumi, S.; Salah, C.B.; Saidi, A.S. Improvement of techno-economic optimal sizing of a hybrid off-grid micro-grid system. Energy 2021, 233, 121166.

- Islam, A.; Teo, S.H.; Awual, M.R.; Taufiq-Yap, Y.H. Improving the hydrogen production from water over MGO promoted Ni-Si/CNTs photocatalyst. J. Clean. Prod. 2019, 238, 117887.

- Slam, A.; Teo, S.H.; Awual, M.R.; Taufiq-Yap, Y.H. Ultrathin Assembles of Porous Array for Enhanced H2 Evolution. Sci. Rep. 2020, 10, 2324.

- Islam, A.; Teo, S.H.; Awual, M.R.; Taufiq-Yap, Y.H. Assessment of clean H2 energy production from water using novel silicon photocatalyst. J. Clean. Prod. 2020, 244, 118805.

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491.

- Argyrou, M.C.; Christodoulides, P.; Kalogirou, S.A. Energy storage for electricity generation and related processes, Technologies appraisal and grid scale applications. Renew. Sustain. Energy Rev. 2018, 94, 804–821.

- Chevalier, V.; Martin, J.; Peraltab, D.; Rousseyb, A.; Tardif, F. Performance of HKUST-1Metal-Organic Framework for a VOCs mixture adsorption at realistic. Environ. Sci. 2018, 67, 171–178.

- Hydrogen Storage. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-storage (accessed on 12 August 2022).

- Zhao, L.; Zhao, Q.; Zhang, J.; Zhang, S.; He, G.; Zhang, M.; Su, T.; Liang, X.; Huang, C.; Yan, W. Review on studies of the emptying process of compressed hydrogen tanks. Int. J. Hydrogen Energy 2021, 46, 22554–22573.

- Abohamzeh, E.; Salehi, F.; Sheikholeslami, M.; Abbassi, R.; Khan, F. Review of hydrogen safety during storage, transmission, and applications processes. J. Loss Prev. Process Ind. 2021, 72, 104569.

- Schrotenboer, A.H.; Veenstra, A.A.; uit het Broek, M.A.; Ursavas, E. A Green Hydrogen Energy System, Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744.

- Available online: https://www.shell.nl/media/venster/eerder-verschenen/hydrogen-makes-progression.html# (accessed on 5 July 2022).

- Available online: https://www.ntpc.co.in/en/media/press-releases/details/ntpc-awards-india%E2%80%99s-first-green-hydrogen-microgrid-project (accessed on 15 August 2022).

- Ramu, S.K.; Irudayaraj, G.C.R.; Paramasivam, S.K.; Murugesan, R.; Muthusamy, S.; Sundararajan, S.C.M.; Meena, R.S. A simplified methodology for renewable energy integration and harmonic current reduction in hybrid micro grid. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–23.

- Ghadrdan, M.; Peyghami, S.; Mokhtari, H.; Blaabjerg, F. Condition Monitoring of DC-link Electrolytic Capacitor in Back-to-Back Converters Based on Dissipation Factor. IEEE Trans. Power Electron. 2022, 37, 9733–9744.

- Pandiyan, P.; Sitharthan, R.; Saravanan, S.; Prabaharan, N.; Tiwari, M.R.; Chinnadurai, T.; Devabalaji, K.R. A comprehensive review of the prospects for rural electrification using stand-alone and hybrid energy technologies. Sustain. Energy Technol. Assess. 2022, 52, 102155.

- Xia, Y.; Wei, M.; Peng, Y.; Tang, J. Decentralized multi-time scale power control for a hybrid AC/DC microgrid with multiple subgrids. IEEE Trans. Power Electron. 2017, 33, 4061–4072.

- Wu, W.; Taipabu, M.I.; Chang, W.C.; Viswanathan, K.; Xie, Y.L.; Kuo, P.C. Economic dispatch of torrefied biomass polygeneration systems considering power/SNG grid demands. Renew. Energy 2022, 196, 707–719.

- Jithin, S.; Rajeev, T. Novel adaptive power management strategy for hybrid AC/DC microgrids with hybrid energy storage systems. J. Power Electron. 2022, 1–13.

- Jani, A.; Karimi, H.; Jadid, S. Multi-time scale energy management of multi-microgrid systems considering energy storage systems: A multi-objective two-stage optimization framework. J. Energy Storage 2022, 51, 104554.

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180.

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869.

- Najjar, Y.S. Hydrogen safety: The road toward green technology. Int. J. Hydrogen Energy 2013, 38, 10716–10728.

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294.

- Ji, M.; Wang, J. Review and comparison of various hydrogen production methods based on costs and life cycle impact assessment indicators. Int. J. Hydrogen Energy 2021, 46, 38612–38635.

- Lane, B.; Reed, J.; Shaffer, B.; Samuelsen, S. Forecasting renewable hydrogen production technology shares under cost uncertainty. Int. J. Hydrogen Energy 2021, 46, 27293–27306.

- Steinberger-Wilckens, R.; Radcliffe, J.; Al-Mufachi, N.; Abad, A.V. The Role of Hydrogen in Delivering Energy, H2FC Supergen. 2017. Available online: http://www.h2fcsupergen.com/wp-content/uploads/2015/08/IMPJ5213-H2FC-Supergen-Energy-Security-032017-WEB (accessed on 5 September 2022).

- Available online: https://www.energy.gov/eere/fuelcells/fuel-cells (accessed on 5 September 2022).

- Edathil, S.L.; Singh, S.P. ACO and CS-based hybrid optimisation method for optimum sizing of the SHES. IET Renew. Power Gener. 2019, 13, 1789–1801.

- Abo-Elyousr, F.K.; Elnozahy, A. Bi-objective economic feasibility of hybrid micro-grid systems with multiple fuel options for islanded areas in Egypt. Renew. Energy 2018, 128, 37–56.

- Diab AA, Z.; Sultan, H.M.; Mohamed, I.S.; Kuznetsov, O.N.; Do, T.D. Application of different optimization algorithms for optimal sizing of PV/wind/diesel/battery storage stand-alone hybrid microgrid. IEEE Access 2019, 7, 119223–119245.

- Arévalo, P.; Benavides, D.; Lata-García, J.; Jurado, F. Energy control and size optimization of a hybrid system (photovoltaic-hidrokinetic) using various storage technologies. Sustain. Cities Soc. 2020, 52, 101773.

- Mahani, K.; Liang, Z.; Parlikad, A.K.; Jafari, M. A Joint optimization of operation and maintenance policies for solar-powered microgrids. IEEE Trans. Sustain. Energy 2018, 10, 833–842.

- Cai, G.; Kong, L. Techno-economic analysis of wind curtailment/hydrogen production/fuel cell vehicle system with high wind penetration in China. CSEE J. Power Energy Syst. 2017, 3, 44–52.

- El-Taweel, N.A.; Khani, H.; Farag, H.E. Hydrogen storage optimal scheduling for fuel supply and capacity-based demand response program under dynamic hydrogen pricing. IEEE Trans. Smart Grid 2018, 10, 4531–4542.

- Coppitters, D.; De Paepe, W.; Contino, F. Robust design optimization and stochastic performance analysis of a grid-connected photovoltaic system with battery storage and hydrogen storage. Energy 2020, 213, 118798.

- Luo, F.; Loo, K.H.; Lai, Y.M. A hybrid AC/DC microgrid control scheme with voltage-source inverter-controlled interlinking converters. In Proceedings of the 2016 18th European Conference on Power Electronics and Applications IEEE, Karlsruhe, Germany, 5–9 September 2016; pp. 1–8.

- Majumder, R.A. hybrid microgrid with DC connection at back to back converters. IEEE Trans. Smart Grid 2013, 5, 251–259.

- Li, P.; Guo, T.; Li, Y.; Han, X.; Wang, P.; Li, X.; Wang, Z. An adaptive coordinated optimal control method for parallel bidirectional power converters in AC/DC Hybrid Microgrid. Int. J. Electr. Power Energy Syst. 2021, 126, 106596.

- Toghani Holari, Y.; Taher, S.A.; Mehrasa, M. Power management using robust control strategy in hybrid microgrid for both grid-connected and Islanding modes. J. Energy Storage 2021, 39, 102600.

- Tian, H.; Wen, X.; Li, Y.W. A harmonic compensation approach for interlinking voltage source converters in hybrid ac-dc microgrids with low switching frequency. CSEE J. Power Energy Syst. 2018, 4, 39–48.

- Liu, Q.; Li, Y. An inductive filtering-based parallel operating transformer with shared filter for power quality improvement of Wind Farm. IEEE Trans. Power Electron. 2020, 35, 9281–9290.

- Kumar, R.S.; Raj, I.G.C.; Saravanan, S.; Leninpugalhanthi, P.; Pandiyan, P. Impact of power quality issues in residential systems. In Power Quality in Modern Power Systems; Academic Press: Cambridge, MA, USA, 2021; pp. 163–191.

- Wang, J.; Dong, C.; Jin, C.; Lin, P.; Wang, P. Distributed uniform control for parallel bidirectional interlinking converters for resilient operation of hybrid AC/DC Microgrid. IEEE Trans. Sustain. Energy 2021, 13, 3–13.

- Mohseni, S.; Brent, A.C. Economic viability assessment of sustainable hydrogen production, storage, and utilisation technologies integrated into on-and off-grid micro-grids: A performance comparison of different meta-heuristics. Int. J. Hydrogen Energy 2020, 45, 34412–34436.

- Abdelshafy, A.M.; Jurasz, J.; Hassan, H.; Mohamed, A.M. Optimized energy management strategy for grid connected double storage (pumped storage-battery) system powered by renewable energy resources. Energy 2020, 192, 116615.

- Bukar, A.L.; Tan, C.W.; Lau, K.Y. Optimal sizing of an autonomous photovoltaic/wind/battery/diesel generator microgrid using grasshopper optimization algorithm. Solar Energy 2019, 188, 685–696.

- Li, Y.; Yang, Z.; Zhao, D.; Lei, H.; Cui, B.; Li, S. Incorporating energy storage and user experience in isolated microgrid dispatch using a multi-objective model. IET Renew. Power Gener. 2019, 13, 973–981.

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022, 316, 123317.

- Sharma, S.; Ghoshal, S.K. Hydrogen the future transportation fuel: From production to applications. Renew. Sustain. Energy Rev. 2015, 43, 1151–1158.

- Cao, Y.; Hani, E.H.B.; Mansir, I.B.; Diyoke, C.; Dhahad, H.A. Exergy and exergo-economic investigation of a novel hydrogen production and storage system via an integrated energy system. Int. J. Hydrogen Energy 2022, 47, 26770–26788.

- Qureshi, F.; Yusuf, M.; Kamyab, H.; Zaidi, S.; Khalil, M.J.; Khan, M.A.; Alam, M.A.; Masood, F.; Bazli, L.; Chelliapan, S.; et al. Current trends in hydrogen production, storage and applications in India: A review. Sustain. Energy Technol. Assess. 2022, 53, 102677.

- Chandrasekar, M.; Gopal, P.; Kumar, C.R.; Geo, V.E. Effect of solar photovoltaic and various photovoltaic air thermal systems on hydrogen generation by water electrolysis. Int. J. Hydrogen Energy 2022, 47, 3211–3223.

- Park, S.I.; Jung, S.M.; Kim, J.Y.; Yang, J. Effects of Mono-and Bifunctional Surface Ligands of Cu–In–Se Quantum Dots on Photoelectrochemical Hydrogen Production. Materials 2022, 15, 6010.

- Dai, L.; Sun, F.; Fan, Q.; Li, H.; Yang, K.; Guo, T.; Fu, P. Carbon-based titanium dioxide materials for hydrogen production in water-methanol reforming: A review. J. Environ. Chem. Eng. 2022, 10, 107326.

- Pushpalatha, N.; Naveenkumar, D.; Kishore, K.; Pravin, S.; Mohankumar, A. Vaccine Temperature Controller Equipment. In Proceedings of the 2022 8th International Conference on Smart Structures and Systems (ICSSS), Chennai, India, 21–22 April 2022; pp. 1–6.

- Hariharan, R.; Pushpalatha, N.; Rubikaa, M.; Jeeva, M.; Kunguma Divya, M.; Jayakumar, S. An Intelligence Gathering Cyborg Aided by the Internet of Things (IoT). In Proceedings of the 2022 8th International Conference on Smart Structures and Systems (ICSSS), Chennai, India, 21–22 April 2022; pp. 1–6.

- Arun, V.; Kannan, R.; Ramesh, S.; Vijayakumar, M.; Raghavendran, P.S.; Siva Ramkumar, M.; Anbarasu, P.; Sundramurthy, V.P. Review on Li-Ion Battery vs Nickel Metal Hydride Battery in EV. Adv. Mater. Sci. Eng. 2022, 2022, 7910072.

- Yogeswari, B.; Khan, I.; Kumar, M.S.; Vijayanandam, N.; Devarani, P.A.; Anandaram, H.; Chaturvedi, A.; Misganaw, W. Role of Carbon-Based Nanomaterials in Enhancing the Performance of Energy Storage Devices: Design Small and Store Big. J. Nanomater. 2022, 2022, 4949916.

- Gager, E.; Frye, M.; McCord, D.; Scheffe, J.; Nino, J.C. Reticulated porous lanthanum strontium manganite structures for solar thermochemical hydrogen production. Int. J. Hydrogen Energy 2022, 47, 31152–31164.

- Milewski, J.; Kupecki, J.; Szczęśniak, A.; Uzunow, N. Hydrogen production in solid oxide electrolyzers coupled with nuclear reactors. Int. J. Hydrogen Energy 2021, 46, 35765–35776.

- Taipabu, M.I.; Viswanathan, K.; Wu, W.; Hattu, N.; Atabani, A.E. A Critical review of the Hydrogen Production Biomass-based Feedstocks: Challenge, Solution, and Future Prospect. Process Saf. Environ. Prot. 2022, 164, 384–407.

- Lee, S.M.; Xu, N.; Kim, S.S.; Li, A.; Grace, J.R.; Lim, C.J.; Schaadt, A. Palladium/ruthenium composite membrane for hydrogen separation from the off-gas of solar cell production via chemical vapor deposition. J. Membr. Sci. 2017, 541, 1–8.

- Wu, W.; Pai, C.T.; Viswanathan, K.; Chang, J.S. Comparative life cycle assessment and economic analysis of methanol/hydrogen production processes for fuel cell vehicles. J. Clean. Prod. 2021, 300, 126959.

- Tarhan, C.; Çil, M.A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J. Energy Storage 2021, 40, 102676.

- Zhang, F.; Zhao, P.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. Int. J. Hydrogen Energy 2016, 41, 14535–14552.

- Mehrizi, M.Z.; Abdi, J.; Rezakazemi, M.; Salehi, E. A review on recent advances in hollow spheres for hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 17583–17604.

- Li, Q.; Lin, X.; Luo, Q.; Chen, Y.A.; Wang, J.; Jiang, B.; Pan, F. Kinetics of the hydrogen absorption and desorption processes of hydrogen storage alloys: A review. Int. J. Miner. Metall. Mater. 2022, 29, 32–48.

- Aljafari, B.; Subramanian, V.; Indragandhi, V.; Rhanganath, V. Optimization of DC, AC, and Hybrid AC/DC Microgrid-Based IoT Systems: A Review. Energies 2022, 15, 6813.

- Abo-Elyousr, F.K.; Guerrero, J.M.; Ramadan, H.S. Prospective hydrogen-based microgrid systems for optimal leverage via metaheuristic approaches. Appl. Energy 2021, 300, 117384.

- Yang, H.; Li, Q.; Zhao, S.; Chen, W.; Liu, H. A hierarchical self-regulation control for economic operation of AC/DC hybrid microgrid with hydrogen energy storage system. IEEE Access 2019, 7, 89330–89341.

- Ramu, S.K.; Irudayaraj, G.C.R.; Subramani, S.; Subramaniam, U. Broken rotor bar fault detection using Hilbert transform and neural networks applied to direct torque control of induction motor drive. IET Power Electron. 2020, 13, 3328–3338.

- Hassan, I.A.; Ramadan, H.S.; Saleh, M.A.; Hissel, D. Hydrogen storage technologies for stationary and mobile applications: Review, analysis and perspectives. Renew. Sustain. Energy Rev. 2021, 149, 111311.

- Loganathan, D.; Rajkumar, M.; Vigneshwaran, M.; Senthilkumar, R. An enhanced time effective particle swarm intelligence for the practical economic load dispatch. In Proceedings of the 2014 IEEE 2nd International Conference on Electrical Energy Systems (ICEES), Chennai, India, 7–9 January 2014; pp. 44–50.