An attractive alternative to the use of fossil fuels is biodiesel, which can be obtained from a variety of feedstock through different transesterification systems such as ultrasound, microwave, biological, chemical, among others. The efficient and cost-effective biodiesel production depends on several parameters such as free fatty acid content in the feedstock, transesterification reaction efficiency, alcohol: oil ratio, catalysts type, and several parameters during the production process. However, biodiesel production from vegetable oils is under development, causing the final price of biodiesel to be higher than diesel derived from petroleum. An alternative to decrease the production costs will be the use of economical feedstocks and simple production processes. Castor oil is an excellent raw material in terms of price and quality, but especially this non-edible vegetable oil does not have any issues or compromise food security. Recently, the use of castor oil has attracted attention for producing and optimizing biodiesel production, due to the high content of ricinoleic fatty acid and the possibility to esterify with only methanol, which assures low production costs. Additionally, biodiesel from castor oil has different advantages over conventional diesel. Some of them are biodegradable, non-toxic, renewable, they can be used alone, low greenhouse gas emission, among others. This review discusses and analyzes different transesterification processes, technologies, as well as different technical aspects during biodiesel production using castor oil as a feedstock.

- Biodiesel

- Castor oil

- Ricinus communis

1. Vegetable Oils to Produce Biodiesel

During biodiesel production it is necessary to consider the ecological and economic benefits during its production and its use as a biofuel. The biodiesel production cost depends greatly on the feedstock price. It is advisable to produce biodiesel in the same regions where the feedstock is located to decrease costs and environmental footprint related to feedstock transport [1].

The primary feedstock to produce biodiesel is raw vegetable oils and used cooking oils, as well as different animal grease. To produce biodiesel, several vegetable oils can be used such as rapeseed, soybean, cotton, peanut, corn, olive, sesame, safflower, and sunflower [2]. Some examples of tropical oily crops containing good quality oil that can be transesterified are Raphanus sativus (radish), Jatropha curcas (physic nut), Cyperus esculentus (tiger nut), Simmondsia chinensis (jojoba), Gratissima persea (avocado), Lupinus albus (white lupin), Caryocar brasiliense (pequi), the palm species Acrocomia aculeata, Mauritia flexuosa, Elaeis oleifera, Syagrus coronata, Attalea speciose, and R. communis (castor seeds) [3]. Table 1 shows some raw materials used in biodiesel production. However, the most common feedstock is raw vegetable oils extracted from energy and non-energy crops such as soybean, rapeseed, sunflower, coconut, and palm oil, which are cultivated around the world [4].

Table 1. Examples of oil-feedstock used in biodiesel production.

| Feedstock Source (Oil Content, %) |

Characteristics | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|

| Castor beans (46–55) |

Liquid at room temperature, light yellow color, and slightly pungent *US$824/tonne of oil |

Transesterification can be performed at room temperature Miscible in alcohol Non-edible Low acid value High flashpoint |

Generation of toxic solid waste High viscosity Decrease fuel atomization |

[5][6] |

| Jatropha (34–60) |

Colorless after extraction (fresh) and pale yellow after standing time, liquid at room temperature **US$250/tonne of oil |

Biodiesel obtained is stable during storage Non-edible High cetane number, good oxidation stability, low viscosity |

Engine corrosion due to free fatty acids Generation of toxic solid waste High cloud point Not suitable at low temperature High acid value |

[7][8] |

| Soybean (12–22) |

Fresh has a pale light color, and dark after storage, liquid at room temperature ***US$746/tonne of oil |

The yield of 98% crude biodiesel in refined oils High thermal stability Low viscosity |

The high cost of production Biodiesel production in long-term is unsustainable Edible High acid value |

[9][10] |

| Sunflower (38–50) |

Refined has a clear and vaguely yellowish-brown color Liquid at room temperature ***US$689/tonne of oil |

Low viscosity | Used to produce food and fiber Biodiesel production in long-term is unsustainable Edible High acid value |

[10][11] |

| Palm (18–40) |

Semi-solid at room temperature, reddish and clear color, depending on extraction source (pulp or kernel) ***US$535/tonne of oil |

96% yield of crude biodiesel in refined oils Cheap feedstock Good oxidation stability Acceptable ratio of saponification High flashpoint |

High cloud point Conversion to biodiesel may not be sustainable long term Edible |

[9][12] |

| Used cooking oil | Depends on the cooking process can vary yellow to dark brown, liquid at room temperature ****US$500/tonne of oil |

Low cloud point Environmentally friendly Low price of feedstock Non-edible High thermal stability |

High ratio of acid esterification High ratio of saponification High acid value |

[11][13] |

Reported price from [14] (refined oil); ** Reported price from [15]; *** Reported price from [16]; **** Reported price from [17].

The preferred characteristics of oily raw materials to produce biodiesel are crop adaptability to grow under local conditions (precipitation, soil, latitude, temperature, etc.), availability, high oil content, appropriate composition, high adaptability with agricultural infrastructure, access to agricultural supplies (water, fertilizers, pesticides), potential to commercialize the different agricultural co-products generated as well as to obtain crops from marginal land [18]. R. communis meets most of the properties considered desirable to produce useful feedstocks in biodiesel production, except the high viscosity of oil that may limit its use. They are composed mainly of triglycerides and slight amounts of free fatty acids. Table 2 shows the most abundant fatty acids in vegetable oils (palmitic, oleic, and linoleic acids) from several sources. As mentioned above, castor oil, unlike other vegetable oils, has little variability in fatty acid content as compared to other species. In addition to ricinoleic acid, depending on its origin, R. communis may contain small quantities of oleic, linoleic, palmitic, stearic, and linolenic acids [19].

Table 2. Main fatty acids in vegetable oils used as feedstock in biodiesel production.

| Oil | Fatty Acid Composition (wt%) | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Saturated | Monounsaturated | Polyunsaturated | |||||||

| C14:0 | C16:0 | C18:0 | C18:1 cis-9 | C18:1* | C18:2 | C18:3 | Others | ||

| Castor | - | 1.1 | 1.0 | 3.3 | 87.7 | 4.7 | 0.7 | 1.5 | [20] |

| Jatropha | - | 12.80 | 6.20 | 39.94 | - | 45.40 | - | <1.0 | [8] |

| Soybean | - | 11.46 | 3.08 | 23.30 | - | 53.32 | 0.31 | 8.53 | [20][21] |

| Sunflower | 0.08 | 8.03 | 3.26 | 29.27 | - | 59.32 | - | 0.04 | [23] |

| Palm | 0 | 46.8 | 3.80 | 37.60 | - | 10.50 | - | 1.3 | [24] |

| Canola | - | 3.90 | 1.10 | 64.40 | - | 20.4 | 9.60 | 0.6 | [25] |

Vegetable oils as a feedstock for biodiesel production is a promising source. However, most of them are used for food purposes and their use is restricted for this activity. Hence, castor oil for biofuel production shows several advantages over conventional edible oils. Due to its non-edible oil and its main fatty acid (ricinoleic acid) with hydroxyl groups that have a higher solubility in alcohol, it represents a great advantage to obtain methyl esters at low temperatures.

2. Castor Oil Biodiesel Production and Features

Castor oil is a light yellow and slightly pungent liquid, that is used in several industries around the world. Some of these industries are pharmaceutical, cosmetic, chemical, among others. However, in recent years this non-edible vegetable oil has been investigated to produce biofuels, specifically biodiesel. The above is due to the physicochemical, chemical, and physical characteristics of castor oil (Table 3) give to biodiesel when this is used as a feedstock.

Table 3. Main characteristics of raw castor oil.

| Parameter | Zhang et al. [26] | Molefe et al. [27] | Kaur and Bhaskar [28] |

| Acid value /(mg.g−1) | 1 | 2.07 | <4 |

| Saponification value /(mg.g−1) | 180 | 175 | 178 |

| Iodine value (g/100 g) | 86 | 84 | 85 |

| Refractive index (n20 D) | 1.48 | 1.48 | 1.47 |

| Relative density (g/cm3) | 0.956 | 0.961 | 0.965 |

| Flashpoint (℃) | 322 | 145 | 229 |

| Specific heat (kJ/kg/K) | nd | 0.089 | 0.089 |

| Ricinic acid (%wt) | 88 | 89.5 | 87-90 |

| Oleic acid (%wt) | 7 | 3 | 2-7 |

| Linoleic acid (%wt) | 5 | 4 | 1-5 |

| Linolenic acid (%wt) | 1 | 0.3 | nd |

nd: not determined

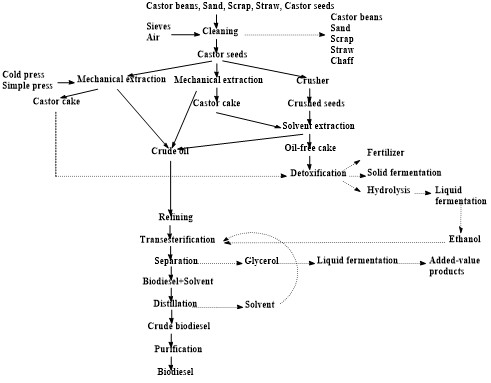

The process to produce biodiesel from oilseeds usually starts with oil extraction using a mechanical press or solvents. Figure 1 shows a general scheme for castor oil extraction. To perform mechanical oil extraction from castor beans it is necessary to consider the high oil viscosity. On the contrary, this is not necessary if the oil is extracted with solvents, but an evaporation step would be needed to recover the solvent. After extraction, different refining steps such as filtration, centrifugation, deodorization, discoloration, or winterization would be necessary to improve biodiesel quality.

Figure 1. General scheme to produce biodiesel from castor oil (adapted from [29][30]).

Once the biodiesel is obtained, this can be used directly in a neat form (100%) or blended with petrodiesel (25%, 50%, and 75%, commonly). However, to ensure that the biodiesel or the blend does not represent a potential risk to the vehicle engine, biodiesel needs to conform to specific parameters established by different entities such as Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels (ASTM D 6751–06a) or European Committee for Standardization for biodiesel (EN 14214). Table 4 shows key parameters for biodiesel from castor oil and its comparison with the two standards mentioned above, as well as with petrodiesel characteristics. Castor oil biodiesel has different advantages in comparison with fossil diesel, the most significant are biodegradable, non-toxic, renewable, it can be used alone, low greenhouse gas emission (80% less carbon dioxide emissions and not sulfur content), and during combustion, it decreases the unburned and aromatic hydrocarbons. Nevertheless, one of the main disadvantages that castor oil biodiesel has is related to its high viscosity, as compression ignition is difficult, especially at low temperatures, which causes a decrease of volatility and as a consequence of burning ratio, without a complete burn provoking deposit. The above facts harm the injection system, as well as blocking the fuel filter [31]. Likewise, high values of density can cause some problems in the injection system as well as in the fuel pump.

Table 4. Main characteristics of biodiesel produced using castor oil as a feedstock.

|

Product |

Kinematic Viscosity (mm2/s at 40 °C) |

Density (kg/m3) |

Acid Value (mgKOH/g) |

Flash Point (°C) |

Water Content (%) |

Calorific Value (MJ/kg) |

Cetane Number |

Cloud Point (°C) |

Pour Point (°C) |

Iodine Value (gI2/100 g) |

Ref. |

|

*Biodiesel from castor oil |

23 |

960 |

13.12 |

262 |

nd |

30.18 |

nd |

3 |

−13 |

nd |

[32] |

|

14 |

926 |

nd |

164 |

nd |

37.90 |

nd |

−23 |

nd |

nd |

[33] |

|

|

15 |

946 |

0.63 |

194 |

0.15 |

38.34 |

43 |

nd |

−30 |

nd |

[34] |

|

|

26 |

961 |

1.19 |

nd |

0.31 |

nd |

nd |

nd |

nd |

80.5 |

[28] |

|

|

18 |

920 |

0.25 |

170 |

0.006 |

39.5 |

nd |

nd |

nd |

nd |

[35] |

|

|

14 |

923 |

nd |

273.1 |

nd |

37.34 |

50 |

nd |

nd |

83.40 |

[36] |

|

|

**Biodiesel according ASTM D 6751–06a |

1.9–6.0 |

860–900 |

≤0.50 |

≥130 |

≤0.50 |

nd |

≥47 |

−3–−12 |

−15-10 |

nd |

[37] |

|

**Biodiesel according EN 14214 |

3.5–5.0 |

860–900 |

≤0.50 |

≥101 |

≤0.50 |

nd |

≥51 |

nd |

nd |

nd |

[37] |

|

***Fossil Diesel |

2.5–4.5 |

820–860 |

nd |

68–80 |

nd |

≥45.56 |

≥46 |

−15–5 |

−35–15 |

nd |

[38] |

*Without blend (B100)

** Limit values

***According to ASTM D975 for diesel grade LS#1 and LS#2

nd: not determined

ASTM D 6751–06a: Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels.

EN 14214: European Committee for Standardization for biodiesel.

Biodiesel production around the world is produced from different feedstocks and specifically vegetable oils. Moreover, a wide variety of methods to obtain this biofuel exist, however, the most common is through transesterification. Biodiesel from castor oil offers environmental and technical benefits, therefore, it can be considered as a viable alternative in the present and future to other forms of biodiesel. R. communis plants have a strong adaptation to different weather, and one of the main characteristics of these plants is being able to grow in marginal soils. This characteristic contributes directly to decrease land use for biofuel production and preserve it to cultivate products used for human consumption. Moreover, non-edible vegetable oil from castor bean seeds is a suitable feedstock to replace 40%–50% of edible oil currently used in biodiesel production. Furthermore, the ricinoleic fatty acid offers advantages to the transesterification process such as high miscibility in alcohol, low reaction temperature, low iodine content, and low freezing point. Biodiesel from castor oil offers a wide range of benefits, among them, is that it is biodegradable, non-toxic, renewable, and safe handling, it can be used alone, and it presents low greenhouse gas emission, high flash point, and similar energetic content to fossil diesel. However, when castor biodiesel is used without blending (B100) some challenges are present, for example, the high viscosity and high density decrease its ignition and can be a potential risk for vehicle engines. Finally, it is necessary to improve the transesterification process to decrease the final price and can be competitive with petrodiesel cost.

This entry is adapted from the peer-reviewed paper 10.3390/en13102467

References

- Sadegh Azizzadeh Hajlari; Bahman Najafi; Sina F. Ardabili; Castor oil, a source for biodiesel production and its impact on the diesel engine performance. Renewable Energy Focus 2019, 28, 1-10, 10.1016/j.ref.2018.09.006.

- Ragul Karthick Elango; Kiruthika Sathiasivan; Chandrasekaran Muthukumaran; Viruthagiri Thangavelu; Mathur Rajesh; Krishnamurthi Tamilarasan; Transesterification of castor oil for biodiesel production: Process optimization and characterization. Microchemical Journal 2019, 145, 1162-1168, 10.1016/j.microc.2018.12.039.

- Nuria Sánchez; José María Encinar; Sergio Nogales-Delgado; Juan González; Biodiesel Production from Castor Oil by Two-Step Catalytic Transesterification: Optimization of the Process and Economic Assessment. Catalysts 2019, 9, 864, 10.3390/catal9100864.

- Atiya Banerjee; Devyani Varshney; Surendra Kumar; Payal Chaudhary; Vinod Kumar Gupta; Biodiesel production from castor oil: ANN modeling and kinetic parameter estimation. International Journal of Industrial Chemistry 2017, 8, 253-262, 10.1007/s40090-017-0122-3.

- Bueno, A.V.; Pereira, M.P.B.; de Oliveira Pontes, J.V.; de Luna, F.M.T.; Cavalcante, C.L.; Performance and emissions characteristics of castor oil biodiesel fuel blends. Appl. Therm. Eng. 2017, 125, 559-566, .

- Hamed Bateni; Alireza Saraeian; Chad Able; Keikhosro Karimi; Biodiesel Purification and Upgrading Technologies. Biofuel and Biorefinery Technologies 2018, 0, 57-100, 10.1007/978-3-030-00985-4_4.

- A.E. Atabani; Arridina Susan Silitonga; H.C. Ong; T. M. I. Mahlia; H.H. Masjuki; Irfan Anjum Badruddin; H. Fayaz; Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renewable and Sustainable Energy Reviews 2013, 18, 211-245, 10.1016/j.rser.2012.10.013.

- Khandual Sanghamitra; Ramirez Victorin Oramas; Rout Nutan Prasad; Comparative Yeild and Oil Quality of Toxic and Non-Toxic Mexican Jatropha curcas Grown in the Same Agroclimatic Conditions. American Journal of Plant Sciences 2013, 5, 230-234, 10.4236/ajps.2014.52030.

- Titipong Issariyakul; Ajay K. Dalai; Biodiesel from vegetable oils. Renewable and Sustainable Energy Reviews 2014, 31, 446-471, 10.1016/j.rser.2013.11.001.

- Ayten Sagiroglu; Hakki Mevlut Ozcan; Sebnem Selen Isbilir; Hatice Palüzar; Neslihan M. Toprakkiran; Alkali Catalysis of Different Vegetable Oils for Comparisons of Their Biodiesel Productivity. Journal of Sustainable Bioenergy Systems 2012, 3, 79-85, 10.4236/jsbs.2013.31011.

- Sara Pinzi; David Leiva; M. Pilar Dorado; Isabel Lopez Garcia; M. Dolores Redel-Macías; Latest trends in feedstocks for biodiesel production. Biofuels, Bioproducts and Biorefining 2013, 8, 126-143, 10.1002/bbb.1435.

- Laura Cristina Barra Raiol; Fernando Kuss; André Guimarães Maciel E Silva; Bruno Cabral Soares; Karla Débora Santana De Souza; Juliana Cristina Nogueira Colodo Colodo; José De Brito Lourenço Júnior; Sandra Cristina De Ávila; Nutrient intake and digestibility of the lipid residue of biodiesel from palm oil in sheep. Revista Brasileira de Zootecnia 2012, 41, 2364-2368, 10.1590/s1516-35982012001100010.

- Ming Li; Yan Zheng; Yixin Chen; Xifeng Zhu; Biodiesel production from waste cooking oil using a heterogeneous catalyst from pyrolyzed rice husk. Bioresource Technology 2014, 154, 345-348, 10.1016/j.biortech.2013.12.070.

- Buy Organic & Kosher Castor Oil - Drums, Pails, & Bags | 18c . Buy Organic & Kosher Castor Oil - Drums, Pails, & Bags. Retrieved 2020-5-25

- JatrophaOil Crude JatrophaOil/crude . JatrophaOil Crude JatrophaOil/crude. Retrieved 2020-5-25

- International Prices of Oilseeds and Oilmeals Unchanged, Those of Vegetable Oils Appreciate Further . International Prices of Oilseeds and Oilmeals Unchanged, Those of Vegetable Oils Appreciate Further. Retrieved 2020-5-25

- Used cooking oil (uco) -International Market Price . Used cooking oil (uco) -International Market Price. Retrieved 2020-5-25

- Andres Aguirre; Salvador Peiru; Florencia Eberhardt; Leandro Vetcher; Rodolfo Cabrera; Hugo Menzella; Enzymatic hydrolysis of steryl glucosides, major contaminants of vegetable oil-derived biodiesel. Applied Microbiology and Biotechnology 2013, 98, 4033-4040, 10.1007/s00253-013-5345-4.

- Hincapié, G.; Moreno, A.; López, D.; Transesterificación de aceite de higuerilla crudo utilizando catalizadores heterogéneos-estudio preliminar. Dyna 2011, 78, 176-181, .

- Hatice Mutlu; Michael A. R. Meier; Castor oil as a renewable resource for the chemical industry. European Journal of Lipid Science and Technology 2009, 112, 10-30, 10.1002/ejlt.200900138.

- Kalyani Rajkumari; Lalthazuala Rokhum; A sustainable protocol for production of biodiesel by transesterification of soybean oil using banana trunk ash as a heterogeneous catalyst. Biomass Conversion and Biorefinery 2020, 0, 1-10, 10.1007/s13399-020-00647-8.

- Rafael Cardoso Rial; Osmar Nunes De Freitas; Carlos Eduardo Domingues Nazário; Luíz Henrique Viana; Biodiesel from soybean oil using Porcine pancreas lipase immobilized on a new support: p-nitrobenzyl cellulose xanthate. Renewable Energy 2020, 149, 970-979, 10.1016/j.renene.2019.10.078.

- Jelena M. Avramović; Olivera S. Stamenković; Zoran Todorovic; Miodrag L. Lazić; Vlada B. Veljković; The optimization of the ultrasound-assisted base-catalyzed sunflower oil methanolysis by a full factorial design. Fuel Processing Technology 2010, 91, 1551-1557, 10.1016/j.fuproc.2010.06.001.

- Patrícia C. M. Da Rós; Larissa Freitas; Victor Haber Perez; Heizir F. De Castro; Enzymatic synthesis of biodiesel from palm oil assisted by microwave irradiation. Bioprocess Engineering 2012, 36, 443-451, 10.1007/s00449-012-0801-6.

- A.C.F. Batista; A.T. Vieira; H.S. Rodrigues; T.A. Silva; R.M.N. Assunção; M.A. Beluomini; H.P. Rezende; Manuel Gonzalo Hernandez-Terrones; PRODUCTION AND PHYSICOCHEMICAL CHARACTERIZATION OF METHYLIC AND ETHYLIC BIODIESEL FROM CANOLA OIL / OBTENÇÃO E CARACTERIZAÇÃO DO BIODIESEL DE CANOLA PELAS ROTAS METÍLICA E ETÍLICA. Revista Brasileira de Engenharia de Biossistemas 2014, 8, 289, 10.18011/bioeng2014v8n4p289-298.

- Jinyong Yan; Xianliang Zheng; Lei Du; Shengying Li; Integrated lipase production and in situ biodiesel synthesis in a recombinant Pichia pastoris yeast: an efficient dual biocatalytic system composed of cell free enzymes and whole cell catalysts. Biotechnology for Biofuels 2014, 7, 55-55, 10.1186/1754-6834-7-55.

- Kasirajan Ramachandran; Pandian Sivakumar; Tamilarasan Suganya; Sahadevan Renganathan; Production of biodiesel from mixed waste vegetable oil using an aluminium hydrogen sulphate as a heterogeneous acid catalyst. Bioresource Technology 2011, 102, 7289-7293, 10.1016/j.biortech.2011.04.100.

- Ravneet Kaur; Thallada Bhaskar; Potential of castor plant (Ricinus communis) for production of biofuels, chemicals, and value-added products. Waste Biorefinery 2019, 0, 269-310, 10.1016/b978-0-12-818228-4.00011-3.

- Jandora Severo Poli; Mirra Angelina Neres Da Silva; Ezequias P. Siqueira; Vânya M.D. Pasa; Carlos Augusto Rosa; Patricia Valente; Microbial lipid produced by Yarrowia lipolytica QU21 using industrial waste: A potential feedstock for biodiesel production. Bioresource Technology 2014, 161, 320-326, 10.1016/j.biortech.2014.03.083.

- Keera, S.T.; Sabagh, S.M.E.; Taman, A.R.; Castor oil biodiesel production and optimization. Egypt. J. Pet. 2018, 27, 979-984, .

- Adriana Aranda-Rickert; Laura Morzán; Sebastian Fracchia; Seed oil content and fatty acid profiles of five Euphorbiaceae species from arid regions in Argentina with potential as biodiesel source. Seed Science Research 2010, 21, 63-68, 10.1017/s0960258510000383.

- Ambarish Datta; Bijan Mandal; Use of Jatropha Biodiesel as a Future Sustainable Fuel. Energy Technology & Policy 2013, 1, 8-14, 10.1080/23317000.2014.930723.

- Aihua Zhang; Qin Wang; Yidan He; Pengying Lai; Yifu Miu; Zhihong Xiao; Preparation of Biodiesel Based on Alkaline Ionic Liquid [Bmim]OH Catalyzed Castor Oil. IOP Conference Series: Materials Science and Engineering 2020, 729, 012048, 10.1088/1757-899x/729/1/012048.

- Masego Molefe; Diakanua Nkazi; Hembe E Mukaya; Method Selection for Biojet and Biogasoline Fuel Production from Castor Oil: A Review. Energy & Fuels 2019, 33, 5918-5932, 10.1021/acs.energyfuels.9b00384.

- Jibrin Mohammed Danlami; Agus Arsad; Muhammad Abbas Ahmad Zaini; Characterization and process optimization of castor oil (Ricinus communis L.) extracted by the soxhlet method using polar and non-polar solvents. Journal of the Taiwan Institute of Chemical Engineers 2015, 47, 99-104, 10.1016/j.jtice.2014.10.012.

- Kiany S.B. Cavalcante; Maria N.C. Penha; Karlene K.M. Mendonça; Hilton C. Louzeiro; Antonio C.S. Vasconcelos; Adeilton P. Maciel; Antonio G. De Souza; Fernando Silva; Optimization of transesterification of castor oil with ethanol using a central composite rotatable design (CCRD). Fuel 2010, 89, 1172-1176, 10.1016/j.fuel.2009.10.029.

- Hemant Y Shrirame; N. L. Panwar; B. R. Bamniya; Bio Diesel from Castor Oil – A Green Energy Option. Low Carbon Economy 2010, 2, 1-6, 10.4236/lce.2011.21001.

- Dilip Kumar; Tapas Das; Balendu Shekher Giri; Bhawna Verma; Preparation and characterization of novel hybrid bio-support material immobilized from Pseudomonas cepacia lipase and its application to enhance biodiesel production. Renewable Energy 2020, 147, 11-24, 10.1016/j.renene.2019.08.110.