Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Metallurgy & Metallurgical Engineering

Intelligent manufacturing, defined as the integration of manufacturing with modern information technologies such as 5G, digitalization, networking, and intelligence, has grown in popularity as a means of boosting the productivity, intelligence, and flexibility of traditional manufacturing processes. The steel industry is a necessary support for modern life and economic development, and the Chinese steel industry’s capacity has expanded to roughly half of global production.

- intelligent manufacturing

- steel industry

- China

1. Introduction

The steel industry is one of the most commonly used green materials for its good accessibility, lower manufacturing cost, and widespread usage, which play an important role in our daily lives and industrial manufacture in modern civilization [1]. For instance, as a pillar of the national economy, it provides fundamental materials for contemporary building, transportation, bridges, vehicles, ships, household appliances, electric power, marine engineering, and other aspects in our daily life [2]. Simultaneously, the steel industry is dealing with considerable carbon dioxide emissions, poor working conditions, environmental pollution, safety difficulties generated by high temperatures and poisonous gases, high labor intensity for employees, and repetitive labor [3]. To address the aforementioned issues, large-scale steel firms have engaged in automation, information transformation, and upgrading during the last several decades, which has had a major driving influence on the steel industry’s production efficiency and automation level [4].

With the arrival of the new century and the progressive completion of industrialization and urbanization in China, the steel industry’s output has reached supersaturation [5]. Appearing to be intensely competitive, the industry is dealing with a scarcity of high-end items, a long new product R&D cycle, low worker efficiency, uneven quality, and overall low company profitability. This necessitates transforming the manufacturing model to provide clients with a more flexible bespoke product model while also shortening the product’s production cycle. How to promote the upgrading of product quality in the steel industry, improve intelligence, reduce the research and development cycle of new materials, and support the economy’s sustainable development are hot issues of concern to the entire society and can be addressed by utilizing the rapidly developing technologies of the Internet, artificial intelligence, and big data methods.

Intelligent manufacturing, defined as the integration of manufacturing with modern information technologies such as 5G, digitalization, networking, and intelligence, has grown in popularity as a means of increasing the productivity, intelligence, and flexibility of traditional manufacturing processes. It is currently one of the hotspots in worldwide research and industrial application, reflecting a significant shift away from the traditional production, manufacturing, and sales paradigm of the past and toward a customized production strategy oriented on customer needs. Governments around the world, led by developed countries such as Germany, United States, and Japan, have included intelligent manufacturing in their national development plans, with the goal of increasing the level of intelligence in the manufacturing industry, establishing an intelligent factory with personalized customization and optimal resource allocation that adapts to large specifications, and integrating customers and business partners in business and value processes to increase productivity.

On the basis of this concept, several experts have undertaken in-depth research on intelligent manufacturing. The infrastructure issues for the development of Industry 4.0 have all been introduced since the concept of Industry 4.0 was proposed for advancing manufacturing to realize short product life cycles and extreme mass customization in a cost-efficient manner [6]. These include the construction method [7], self-organization in the context of Industry 4.0 [8], standardization, integrated information system, training and education, and artificial intelligence applications [9]. Then, in Industry 4.0, the uses of intelligent manufacturing have been researched in a variety of industrial enterprises, including heavy industry [10], supply chain management [11], transforming production management [12], small- and medium-sized enterprises (SMEs) [13], and cyber-physical manufacturing metrology system (CP2MS) [14]. Ghobakhloo [15], Kamble [16], Osterrieder [17], Ching [18], Leng [19], and Chauhan [20] presented the 4.0 technologies utilized in sustainable industrial systems.

As a result, the digital twin is a new technology used in intelligent manufacturing that can understand the state of intelligent manufacturing systems in real time and predict system failures [21]. It has since emerged as the primary technology and tool for manufacturing industries to realize intelligent cyber-physical integration and digital transformation by leveraging these technologies [22]. The digital twin was described by Moeller et al. as a major enabler for the digital transformation of intelligent manufacturing [23]. By researching and evaluating the enhancement of the financial management model in the intelligent manufacturing model and the optimization of cost incurred, Tan evaluated the financial performance [24]. Wu analyzed the workings of a novel application framework for a digital-twin-driven ship intelligent manufacturing system [25]. Li et al. offered the digital-twin framework as the approach for the green performance evaluation of intelligent manufacturing [26]. It is a unique hybrid MCDM model based on fuzzy rough-sets AHP, multistage weight synthesis, and PROMETHEE II. Zhang suggested a collaborative framework based on digital-twin technology for complicated product design, production, and service integration [27]. Li conducted research on the need for conventional manufacturing companies to undergo a digital transformation before examining the digital innovation model for these companies using a case study of the “Internet Plant” of the Haier Group [28].

The framework, development, key technologies, and applications of BDA for intelligent manufacturing systems were discussed by Wang et al. [29]. In addition, the amount of data from manufacturing systems has been quickly growing due to the development of Internet of Things (IoT), 5G, and cloud-computing technologies. Deng conducted research on the spatial agglomeration and superior layout features of the intelligent manufacturing supply chain, which helps businesses and governments make decisions [30]. The supply chain, industry chain, cyber-physical system, big data, Internet of Things, cloud computing, industrial transformation, and value chain ideas were all considered by Ge et al. in their study of a typical intelligent manufacturing [31]. Li offered a theoretical analysis foundation for big-data-driven technology to direct decision-making in intelligent manufacturing, thoroughly establishing its viability in the field of intelligent manufacturing, including major benefits and internal motivation [32]. Guo et al. described an intelligent decision support system (DSS) based on data-mining technology that is applied to enterprises to create an Internet of Things based intelligent DSS for the manufacturing industry, supporting the decision-makers in making intelligent decisions through the intelligent DSS [33]. An intelligent workshop based on digital twinning was proposed by Yan et al. They first presented the theoretical model and system framework for the workshop’s digital twinning and then presented three important technologies for the workshop’s virtual simulation control [34].

Hu and colleagues examined the “perception analysis-choices” closed-loop mechanism of all data of the production process of electronic components using intelligent manufacturing technology based on industrial big data [35]. To make semiconductor production smarter, Ghahramani et al. performed a thorough investigation based on evolutionary computing and neural network techniques [36]. A paradigm for data-driven or intelligent manufacturing was created by Ma [37], Majeed [38], and Zhang [39] based on the demand response in various scenarios.

The primary areas of algorithm innovation in intelligent manufacturing’s big data analysis are process optimization, quality traceability, equipment problem detection, production enhancement and management efficiency, and lowering of labor intensity. Ben researched the key technologies for the radar complete machine’s intelligent assembly system, including virtual assembly for digital products, IoT-based intelligence in perception, intelligent material distribution, assembly line modeling and simulation optimization, and information system integration [40]. Wang et al. provided a summary of the diffusion model for implementing intelligent manufacturing in Hangzhou manufacturing enterprises. The impact of industrial policy accuracy on the spread of intelligent manufacturing applications is then examined using the improved SIR model and Matlab software [41]. The outstanding benefits of deep learning in intelligent-manufacturing-system modeling were detailed by Lan [42]. These benefits include an efficient method and strong tool for intelligent-manufacturing-system design, performance analysis, and running status monitoring; as well as a clear path for choosing, designing, or implementing the deep-learning architecture. Kong examined the effects of IoT technology on intelligent manufacturing and intelligent buildings, explained the integrated system framework for BIM technology (building information models), and suggested the system design for intelligent buildings and the architecture model for intelligent manufacturing based on IoT technology [43]. A cloud-assisted and edge-decision-making manufacturing architecture with production edges was introduced by Tang et al. [44]. Meanwhile, machine learning [45], the compound dual innovation capability model [46], the capability maturity model [47], the information model of a lithium ion battery intelligent manufacturing workshop [48], the neural network [49], the predictive maintenance method [50], and the multichain and data-chain partitioning algorithm [51,52,53] have also been studied to improve the intelligent methods in intelligent manufacturing.

More elements of intelligent manufacturing in addition to those that were mentioned above were also examined as being crucial to various intelligent manufacturing systems [54]. Time-saving under the revolutionary intelligent manufacturing cloud-control-systems architecture presented by Yan et al. was comprehensively analyzed [55]. Chen et al. [56] and Xing [57] examined the major technologies of intelligent manufacturing and robot application and forecasted their future development trend. In order to build intelligent process automation (IPA) in various sectors, Zhou et al. [58] and Lievano-Martinez [59] offered key ideas and suggested a framework for implementing IPA technology. Using the panel data of pertinent enterprises from 2011 to 2017 and the enterprise panel data of intelligent manufacturing implemented by China’s manufacturing industry from 2014 to 2019, Yang et al. [60] and Liu et al. [61] also looked into the impact of China’s intelligent policy on the performance of listed manufacturing companies. Furthermore, defect diagnosis and early warning for high-end equipment [62], deep integration of industrial artificial intelligence and the industrial Internet [63], the local workshop net [64], and the two-layer distributed hybrid industrial Internet of Things [65] have all been introduced.

Kang offered the intelligent manufacturing idea, the key system structure, and each key technology, and the future was predicted by conducting various evaluations on the application fields and technical development levels addressed [66]. Mittal and Ren [67,68] created an intelligent manufacturing framework based on big data analytics, including critical technologies and the notion of omnipresent servitization throughout the life cycle. Furthermore, a significant quantity of production process, equipment, quality, logistics, and other data is generated during the manufacturing process. Various types of industrial processes have traditionally had different operation objectives and modes. Guo suggested a self-adaptive collaborative control (SCC) mode for intelligent production-logistics systems to increase intelligence, flexibility, and resilience by utilizing cyber-physical systems (CPSs) and the industrial Internet of Things (IIoT) to address the aforementioned issues [69]. Tao and Xia [70,71] looked at the significance, application prospects, and research problems of digital-twin-driven intelligent manufacturing in the context of Industry 4.0.

Intelligent manufacturing, obviously, has a complete shape in both theory and reality, and it has steadily become a way of boosting production efficiency and product quality, cutting labor costs, and optimizing production processes. However, the steel industry has challenges such as a vast volume of data, a big number of equipment, a poor automation foundation, an incomplete mechanism model, and hysteresis in crucial process parameter detection. The steel industry’s production can be created to examine the relevant model in the aforementioned specific conditions. Yin proposed that the intelligentization of steel production lines should be based on the physical input and output of the geophysical system’s material, energy, and information flow networks to optimize the physical system structure of the manufacturing process and integrate the digital information system to achieve the intelligence state [72]. Yao [73], Liu [74], and Li [75] also suggested a steel intelligent factory composition analysis, steel process big data, steel production value chain restructuring, and artificial intelligence to boost intelligent manufacturing in China’s steel industry.

2. Analysis of Intelligent Development of Steel Industry of China

2.1. General Briefing on Intelligent Manufacturing in the Steel Industry of China

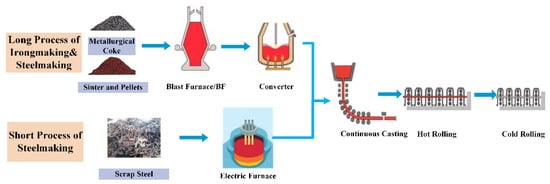

Figure 1 illustrates the two primary production models that are typically used in the steel industry: the long process of ironmaking and steelmaking procedure (LPISP) and the short process of steelmaking procedure (SPSP). The burden materials utilized in the LPISP are very different from those used in the SPSP. For instance, metallurgical coke, sinter, and pellets are used in the LPISP, while the SPSP uses scrap steel. In addition, the smelting furnace used in the steelmaking process differs depending on whether it is a converter or electric furnace (LPISP vs. SPSP).

Figure 1. Schematic diagram of different processes in steel industry.

Since 2015, China’s steel industry has begun to conduct small-scale intelligent transformation pilots to eliminate data islands, promote data sharing between processes, improve the quality control and traceability efficiency of the product production process, improve equipment fault diagnosis capabilities, improve energy efficiency, reduce logistics costs, reduce nonessential post staff, reduce the R&D cycle of new products, and reduce management. Table 1 shows the typical intelligent manufacturing projects used in China’s steel industry in recent years, which are mostly dispersed in the mine, rolling, and steelmaking and rolling processes, with the majority of them being carried out in the rolling procedure.

Table 1. Main intelligent manufacturing project in steel industry of China.

| Project Name | Main Production Lines | Enterprise | Time/Year |

|---|---|---|---|

| Digital metallurgical mine | Mine | Angang Mining Company | 2015 |

| Intelligent workshop for hot rolling | Rolling | Baosteel | 2015 |

| Intelligent factory for iron and steel enterprise | Steelmaking and rolling | Hesteel | 2016 |

| Intelligent factory for silicon steel in the cold rolling process | Rolling | Shougang | 2016 |

| Intelligent manufacturing of high-precision special steel wire | Rolling | Shengtong Steel | 2017 |

| Digital workshop for cold rolling | Rolling | Baosteel | 2017 |

| Digital workshop for stainless steel in cold continuous rolling | Rolling | Taisteel | 2017 |

| Intelligent manufacturing in the whole process of high-end wire rod | Steelmaking and rolling | ShaSteel | 2017 |

| Intelligent factory for seamless steel pipe | Pipe Rolling | Hengyang Valin Steel Pipe | 2018 |

| Intelligent manufacturing for steel plate | Plate Rolling | Nangang | 2018 |

| Intelligent manufacturing for steel thick plate | Plate Rolling | Angang Steel | 2018 |

On the one hand, the physical changes in materials during the rolling process can be easily defined by control models and detection methods; and the level of automation, informatization, and modeling is higher than in the smelting operation. On the other hand, as the final step in the steel production process, the problems that occurred during the previous smelting and continuous casting procedures must be corrected and eliminated from the rolling link in a timely manner. Otherwise, the product quality and brand of the entire steel production line will suffer, causing significant harm to the enterprise. Decision-makers at steel businesses, logically, are also focused on intelligent manufacturing in the rolling process.

China developed the “Guidelines for the Construction of the National Intelligent Manufacturing Standard System”; researched the fundamental similarities, key technologies, key industry standards, and specifications of intelligent manufacturing; built a standard test verification platform; carried out technical specifications and standards throughout the entire process of test verification; and actively promoted all manufacturing-related fields. First, we discussed some fundamental rules and principles. Standard fundamentals include term definition, reference model, metadata, object ID registration, and parsing. Standards for management evaluation include the evaluation index system, measurement method, and implementation guide. Standards for information security included architecture, security, management, and evaluation. They also include adaptability to the environment, equipment dependability, and other criteria for quality. Second, we then discussed important technological norms and requirements., including equipment and product standards for industrial robots, industrial software, intelligent IoT devices, additive manufacturing, human–computer interface, and other technologies. We also discussed standards for network design, connectivity, and interoperability; convergence of fieldbus and industrial Ethernet; industrial sensor networks; industrial wireless systems; and industrial gateway communication protocols and interfaces. Standards for “smart factories” include network collaborative production, intelligent detection, intelligent logistics, and accurate supply-chain management. Standards for the industrial big data and cloud include cloud services, data analysis, and quality. Industrial processes use energy efficiency analysis software standards and service-oriented manufacturing standards, such as personalized customization and remote operation and maintenance services. Third, we discussed important industry rules and standards. Digital workshop integration applications in typical discrete industries and smart factory integration applications in process industries each represent one of ten important areas of industry standards and requirements.

2.2. Aims for Intelligent Manufacturing

The steel industry, as a typical process industry, has many production procedures, a large number of pieces of equipment, a large amount of energy consumption, a large number of operators, and a large number of complex reactions, including chemical reactions during the smelting procedure and physical changes during the rolling procedure. The interweaving of various influencing elements provides a huge barrier to intelligent manufacturing of the whole steel production process, further complicating the quality, energy, and product management procedures. Specifically, in the steel industry, there are quality data islands in various manufacturing processes, process adjustment is complex and difficult to achieve, the product development cycle is long, and product quality control cannot be accurate to the process. Furthermore, quality control and traceability are difficult to implement, and the smelting process is largely reliant on manual experience. Intelligent manufacturing, as a new generation of information and communication technology and advanced manufacturing technology, can quickly respond to internal and external changes in enterprises and establish a new model of personalized customization and resource optimization configuration centered on customer needs by improving the manufacturing industry’s intelligence level.

Therefore, intelligent manufacturing has resulted in a significant transformation in the steel industry’s organizational structure, namely a transition from a production organization to a service-oriented manufacturing organization. As a result, the steel industry’s goals for intelligent manufacturing in China may be stated as follows. Manufacturing enterprise operations will shift from responsive to customized, with optimization shifting from local to global. While management is focused on backward and in-the-moment pre-event transformation to achieve flexible production, equipment control has shifted from automation to intelligence. The following four factors are the primary goals for the completion of intelligent manufacturing in China’s steel industry.

First and foremost, boost productivity. On the one hand, breaking down data silos within a single process and between multiple processes involving ironmaking, steelmaking, continuous casting, and steel rolling, as well as leading the substance, energy, and information flow, could be efficiently utilized to reduce defective product rates and eliminate production efficiency losses caused by data islands and information gaps. Robots, on the other hand, are being used in large numbers to replace humans in repetitive, harsh environments and labor-intensive positions, gradually merging the main control position, improving personnel efficiency and intelligence level, and real-time online monitoring and fault prediction maintenance of key equipment to reduce equipment failure rate and unplanned downtime.

Second, boost product quality. The production process status monitoring system will cover many dimensions such as raw materials, equipment, process parameters, and laboratory data, effectively avoiding the influence of abnormal working circumstances on the quality of the steel manufacturing process. Then, by raising the intelligence level of the production line, the equipment control accuracy and equipment failure online monitoring and early warning system may effectively avoid the occurrence of recurring quality mishaps. Finally, a quality monitoring and control system was implemented across the ironmaking and steelmaking processes to eliminate worker interference on product quality and increase the precision and dependability of quality control. In addition, product quality optimization was implemented; and digitization, networking, and intelligence of product quality control methods were improved through the traceability of the whole steel product life cycle.

Third, cut production expenses. An energy medium optimization system and an automatic batching system are built to achieve the automatic entry of molten iron and scrap into the furnace, minimize material preparation response time, optimize smelting rhythm, and reduce energy consumption. Then, to shorten the smelting time and enhance smelting efficiency, information technologies such as automated detection of molten steel components, intelligent blowing control, and automatic component analysis were used. Finally, lowering manufacturing costs via the use of robots and intelligent maintenance decreases the rate of faulty goods and increases the rate of worker productivity.

Fourth, reduce the development cycle of new products. A virtual simulation system for the entire ironmaking and steelmaking process is constructed, and the number of experiments for new product development is reduced by replacing the traditional experimental trial-and-error method with a digital process simulation system, thereby shortening the R&D cycle and improving product development efficiency.

Above all, following the aforementioned goals for intelligent transformation, the typical steel industry’s product research and development cycle is typically reduced by about 30%, the rate of product defects is decreased by 10–20%, the energy used to produce a ton of steel is decreased by 10%, the production cost is decreased by 10%, and the production efficiency is increased by 10–25%. From the standpoint of financial investment revenue, intelligent manufacturing is one of the key avenues for the development of the steel industry in the future. The investment in intelligent manufacturing of steel production lines is expected to pay for itself in 3 to 5 years.

2.3. Framework for Intelligent Manufacturing

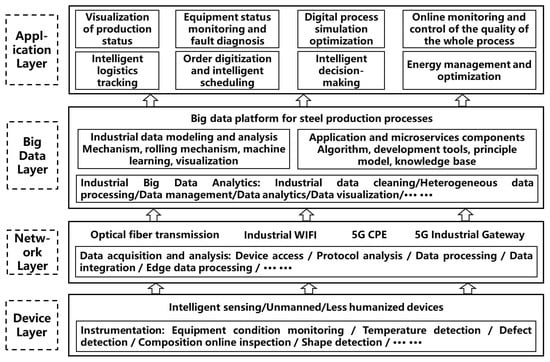

As illustrated in Figure 2, the levels of the framework for intelligent manufacturing in China’s steel industry were split into the device layer (DL), network layer (NL), big data layer (BDL), and application layer (AL).

Figure 2. Framework for intelligent manufacturing in China’s steel industry.

DL: The equipment parameters produced in the primary system, secondary system’s control model parameters, and tertiary system’s quality control parameters should be gathered in a timely and accurate manner during the overall ironmaking and steelmaking processes; particularly those affecting production efficiency, cost, and quality, such as key raw material parameters, process parameters, and quality process parameters. Equipment condition monitoring, temperature detection, defect detection, composition online inspection, shape detection, and other critical process parameters should all be detected online. Thus, the DL might provide a vast amount of raw data, laying a robust data basis for future big data applications and intelligent manufacturing.

NL: Due to the steel process’s big-scale, multi-equipment, and long process features, the physical distance between each piece of equipment is rather long, and huge data in diverse formats must be transmitted in real time across a significant number of networks. Not only this might help to enhance the manufacturing process’s reaction time, but it also could help to support BDL and AL applications. Therefore, data transport is mostly accomplished using optical fiber transmission, industrial Wi-Fi, 5G CPE, and a 5G industrial gateway. Data capture and analysis are dependent on device access, protocol analysis, data processing, data integration, and edge data processing.

BDL: Similar to the function of the data middle platform, the main objective of the BDL is to supply data sources and various application components for the application layer, as with the preceding data provision, data acquisition, and preprocessing. Thus, the BDL for steel production processes includes industrial data modeling and analysis, as well as application and microservices components. The former primarily consists of mechanism, rolling mechanism, machine learning, and visualization, whereas the latter provides the algorithm, development tools, primary model, and operating knowledge. Furthermore, the goals of big data analytics in the steel industry are mostly focused on industrial data cleansing, heterogeneous data processing, data management, data analytics, and data visualization.

AL: The primary goal of the AL is to realize real-time process diagnosis and optimization of the steel production process using a large number of data such as procedure, equipment, quality, logistics, order, and scheduling. In order to effectively improve production efficiency and the quality of the steel product, the rate of defective products and production costs should be reduced. Normally, a typical framework for intelligent manufacturing includes systems such as the visualization of production status system, equipment status monitoring and fault diagnosis system, digital process simulation–optimization system, online monitoring and control of quality in the entire ironmaking and steelmaking system, intelligent logistics tracking system, order digitization and intelligent scheduling system, intelligent decision-making system, energy management and optimization system, and intelligent decision-making system.

This entry is adapted from the peer-reviewed paper 10.3390/s22218194

This entry is offline, you can click here to edit this entry!