Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Clothing is considered to be an important element of human social activities. With the increasing maturity of 3D printing technology, functional 3D printing technology can realize the perfect combination of clothing and electronic devices while helping smart clothing to achieve specific functions. Furthermore, the application of functional 3D printing technology in clothing not only provides people with the most comfortable and convenient wearing experience, but also completely subverts consumers’ perception of traditional clothing.

- 3D printing

- clothing

- traditional dress

- smart materials

1. Introduction and Motivation

Clothing is regarded as an important human social activity. At present, human beings not only pursue the beauty and comfort of clothing, but also pay attention to the expression of comfort and personality, which poses a new challenge to the clothing industry. The “smart clothing” made through the combination of traditional clothing and intelligent technology has unlimited market prospects because of its incomparable advantages over traditional clothing, and the outbreak of related industries is just around the corner. This so-called intelligent clothing refers to the introduction of sensing technology, microelectronic technology and information technology into people’s daily clothing, such as for health monitoring [1][2], energy collection [3], intelligent sensing [4], displaying information [5], data transmission and other modules [6][7]. Because of its unique preparation technology and product characteristics, 3D printing and wearable technology have experienced an explosion in popularity in the last couple of years in fashion disciplines from both industry and academia. This 3D printing technology is a great invention of the 20th century, which is called the iconic technology of the third industrial revolution. The advantage of 3D printing technology is particularly obvious in the clothing industry [8]. Since the first 3D-printed dress came out [5], it opened the door for new trends. Many well-known designers have applied 3D printing technology into clothing to design clothing with the science and technology of the future, which has brought unlimited possibilities to the clothing industry. Additionally, the application of 3D printing technology completely subverts consumers’ cognition of traditional clothing.

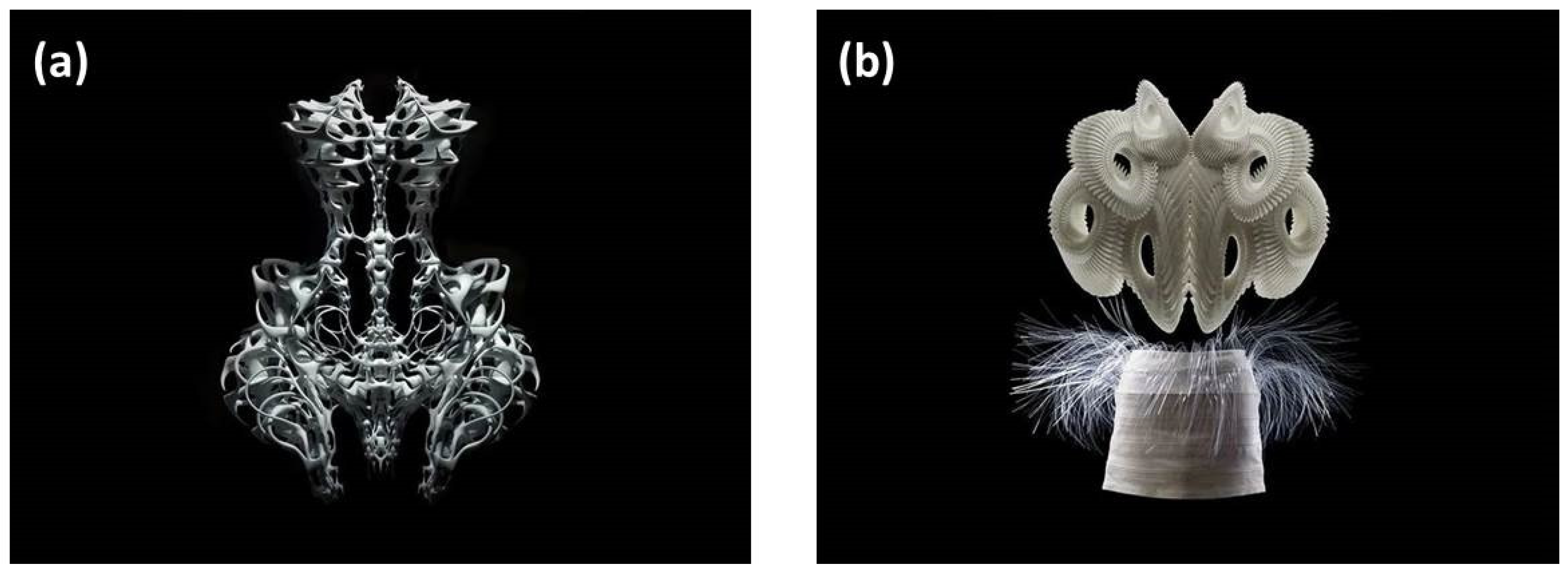

As an epoch-making technology, 3D printing plays a vital role in different fields, from the F-35 airplane [9] to the Urbee 2 automobile [10], and from surgical organ substitutes [11] to food printers [12]. Meanwhile, the application of 3D printing technology has also brought more inspiration and creativity to clothing designers. Compared with traditional clothing production, 3D printing technology can provide personalized customization by scanning the wearer’s body parts before printing [13][14]. This personalized customization ability of 3D printing technology has attracted much attention in the field of clothing. In fact, the research and applications of 3D printing in clothing at home and abroad are numerous. As the leaders of sportswear brands, Nike, Under Armour, Adidas and other companies lead the trends in the shoe market, for example, by making their products via 3D printing technology and emphasizing personalized customization. For example, Nike [15][16] made a pair of shoes for American national athlete Allyson Felix by using 3D printing technology. This technology shortens the cycle of shoe production from three months to a few hours, which makes it convenient for athletes to adjust the comfort of their shoes. Therefore, athletes can have the most suitable shoes in time. Subsequently, Under Armour [17][18][19] launched a 3D-printed sneaker called the “Archi-TechFuturist”. Compared with the original 3D-printed sneaker from Nike, it has made a change in the 3D-printed sole, which can provide better cushioning and more stable support for athletes. However, the product, as a limited edition, has not been mass-produced thus far. The Adidas Group [20][21] launched a corresponding 3D-printed shoe named the “3D Runner Pump”. Meanwhile, the team from Reebok [22] developed a pair of 3D-printed shoes called the “Reebok Liquid Speed”, which has unique numbers and is limited to 300 pairs. Recently, Chinese innovative footwear brands SCRY Lab and Heliot Emil designed a pair of 3D-printed shoes and displayed them at Paris International Fashion Week 2022. Additionally, Chinese well-known casual sports shoe brands Li Ning, Peak and Hongxing Erke have also launched 3D-printed shoes and achieved certain research results. The application of 3D printing in the clothing field attracted the attention of high-end designers in the fashion world and also caused a lot of creative inspiration. Iris Van Herpen [23] was the first fashion designer to put 3D-printed clothing on the fashion stage. Iris van Herpen is a young and talented female designer, who is especially good at designing according to the material of the clothing itself. She has worked with Alexander McQueen and Viktor & Rolf, and her design style has been influenced by these two major brands. The avantgarde and creative appearance of clothes makes Iris van Herpen’s works [24] (Figure 1) visually impactful and eye-catching. Functional 3D printing technology can realize the perfect combination of clothing and electronic devices. The combination has provided people with the most comfortable and convenient wearing experience and promoted smart clothing to realize specific functions. From the “fantasy” of the Space S series in 2011 to the “miniature” series in 2012, and from the 2013 clothing theme of “voltage” to the fashion show of the “hypnotic clothing” of the Fwhite W series in 2019, these were all conceptual clothing made using 3D printing technology. Due to their special formability and artistic expression, these clothes were once recognized as the leading experimental designs [25][26][27]. In 2012, the world’s first 3D-printed bikini, designed by fashion designer Mary Huang and 3D-modeling expert Jenna Fizel, also went on sale [28]. The swimsuit was printed by laser sintering and then seamlessly spliced. The swimsuit was printed from nylon, which is so wear-resistant and flexible that even thinner swimsuits do not have to worry about damage. The Chanel brand also launched 10 suits made by 3D printing technology, while the jewelry accessories were also 3D printed. Not long ago, the autumn and winter collection “Future Elf” (the Spirit of the Future), launched at Paris Fashion Week, was also a masterpiece of 3D printing. Subsequently, more and more fashion industries have introduced 3D printing technology into their products. The representative products are as follows: the suit and tie from Japanese design studio Monocircus, the DNA 3D-printed shoes designed by American designer Pensar and the 3D-printed hat by MGX in Belgium [29]. All of them represent the coexistence of beauty and technology.

Figure 1. Iris van Herpen’s 3D-printed clothing from 2010 (a) and 2011 (b) in high-definition series [24].

In addition, 3D printing has come to the fore in the commercialization of clothing. For example, the well-known Shapeways website, where customers can select templates uploaded by designers and place orders, provides the services of 3D printing and mailing of clothing products. The company is committed to printing one piece of clothing. In fact, Victoria’s Secret has worked with the site to print products. At the 3D Printshow in London in 2015, the company launched a 3D-printed dress which was printed into a ball and then unfolded with a greater variety of colors by using the ductility of the material. These cases will promote the wide application of 3D-printed clothing.

2. The Method of 3D Printing in Clothing

Three-dimensional printing technology, increases the spatial dimension based on two-dimensional printing, which makes the inkjet printing pattern have a three-dimensional height. Different from the traditional material-reduction processing technology (such as turning, milling, grinding and so on), 3D printing technology uses a layer-by-layer superimposed material-forming method. The basic principle is the following procedure: based on the digital computer-aided design (CAD) model, the three-dimensional model is sliced by layered technology to obtain the print path data of each layer, and then, the bindable materials such as powdered metal or plastic are superimposed layer by layer through the printer and bonded together. Generally speaking, 3D printing products need to go through the following four steps, namely, 3D modeling, layered slicing, printing and post-processing [30]. Thus far, there are dozens of types of 3D printing technology [31]. However, in the field of 3D-printed clothing, two kinds of forming technologies are mainly used, namely, fused deposition modeling (FDM) and selective laser sintering (SLS).

2.1. Fused Deposition Modeling (FDM)

The FDM process [32] uses high-temperature heated nozzles to melt and deposit materials layer by layer. The working temperature of common FDM printing equipment is about 300 °C, which means that the printing material not only has excellent thermoplastic processability, but also needs to have a lower molding temperature and certain solution strength. In addition, good adhesion is needed when bonding between layers to avoid cracking caused by thermal stress. As the most commonly used molding process, its main advantage is low-cost processing. However, this process can only print clothing with a simple shape based on the textile structure. Melnikova [33] pointed out that the FDM process can possibly form complex textile structures with the help of support structures. That is to say, it requires additional material consumption and time to deposit and print the fine support structure, and to remove the support in the post-processing stage. This not only increases the complexity of the molding process, but also limits the success rate of FDM molding printing due to the fine-structure printing [34].

2.2. Selective Laser Sintering (SLS)

The SLS process [35], firstly, preheats the powder material to below the melting-point temperature and, then, tiles the material. Subsequently, the controllable laser beam selectively carries out layer-by-layer sintering according to the layered cross-section during the slicing, and then, the finished product can be obtained by removing the excess powder after all the sintering of the tiled material is completed. Beecroft [36] explored the process of printing nylon powder by SLS to create flexible textile structures. It was found that the technology can print fabric structures with complex geometry without adding additional supporting structures during the process of forming clothing textiles. This shows that the SLS process is an ideal method for forming fine-structure textiles.

This entry is adapted from the peer-reviewed paper 10.3390/ma15207391

References

- Kang, J.; Tok, J.B.-H.; Bao, Z. Self-healing soft electronics. Nat. Electron. 2019, 2, 144–150.

- Wang, J.; Tang, F.; Wang, Y.; Lu, Q.; Liu, S.; Li, L. Self-Healing and Highly Stretchable Gelatin Hydrogel for Self-Powered Strain Sensor. ACS Appl. Mater. Interfaces 2020, 12, 1558–1566.

- Ge, G.; Lu, Y.; Qu, X.; Zhao, W.; Ren, Y.; Wang, W.; Wang, Q.; Huang, W.; Dong, X. Muscle-Inspired Self-Healing Hydrogels for Strain and Temperature Sensor. ACS Nano 2020, 14, 218–228.

- Zou, Y.; Tan, P.; Shi, B.; Ouyang, H.; Jiang, D.; Liu, Z.; Li, H.; Yu, M.; Wang, C.; Qu, X.; et al. A bionic stretchable nanogenerator for underwater sensing and energy harvesting. Nat. Commun. 2019, 10, 2695.

- 3D Printed clothing house microorganisms. Nat. Biotechnol. 2015, 33, 896.

- Liu, H.; Dong, M.; Huang, W.; Gao, J.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shen, C.; Guo, Z. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83.

- Nur, R.; Matsuhisa, N.; Jiang, Z.; Nayeem, M.O.G.; Yokota, T.; Someya, T. A Highly Sensitive Capacitive-type Strain Sensor Using Wrinkled Ultrathin Gold Films. Nano Lett. 2018, 18, 5610–5617.

- Spahiu, T.; Canaj, E.; Shehi, E. 3D printing for clothing production. J. Eng. Fibers Fabr. 2020, 15, 1–8.

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185.

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688.

- Shafiee, A.; Atala, A. Printing Technologies for Medical Applications. Trends Mol. Med. 2016, 22, 254–265.

- Liu, C.; Ho, C.; Wang, J. The development of 3D food printer for printing fibrous meat materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 284, 012019.

- Xiao, Y.-Q.; Kan, C.-W. Review on Development and Application of 3D-Printing Technology in Textile and Fashion Design. Coatings 2022, 12, 267.

- Sun, L.; Zhao, L. Envisioning the era of 3D printing: A conceptual model for the fashion industry. Fash. Text. 2017, 4, 25.

- Nike football accelerates innovation with 3D printed “concept cleat” for shuttle. Nike News 2014. Available online: http://news.nike.com/news/nike-football-accelerates-innovation-with-3d-printed-concept-cleat-for-shuttle (accessed on 15 June 2022).

- Nike zoom superfly flyknit. Nike News 2016. Available online: http://news.nike.com/news/allyson-felix-track-spike (accessed on 15 June 2022).

- McKenna, B. 3D-printed shoe race: How do Nike, Under Armour, and Adidas stack up. 2 April 2016. Available online: https://www.fool.com/investing/general/2016/04/02/3d-printed-shoes-nike-underarmor-adidas-newbalance.aspx (accessed on 15 June 2022).

- Under Armour 3d-architech. 2016. Available online: https://www.underarmour.com/en-us/3d-architech (accessed on 15 June 2022).

- Garfield, L. Under Armour 3D-printed soles for its new $300 sneakers with powder and lasers. Business Insider. 1 July 2016. Available online: http://www.businessinsider.com/under-armour-3d-prints-its-new-architech-shoes-2016-6/#this-is-the-architech-the-sneakers-are-fit-for-any-type-of-sport-the-lighthouses-director-adam-bayer-tells-tech-insider-1 (accessed on 15 June 2022).

- Adidas breaks the mould with 3D-printed performance footwear. Adidas Group. 7 October 2015.

- Burgess, M. Adidas is selling a limited number of 3D-printed runner shoes. 2016. Available online: http://www.wired.co.uk/article/adidas-3d-printed-running-shoe-cost-test (accessed on 15 June 2022).

- Reebok introduces new liquid factory. Reebok News 2016. Available online: http://news.reebok.com/global/latest-news/reebok-introduces-new-liquid-factory/s/8a87d7f7-8a93-49d2-9ddd-efee2d588b76 (accessed on 15 June 2022).

- Lee, S.-L. Study on Modern and Innovative Haute Couture Designer Iris van Herpen. Arch. Des. Res. 2014, 111, 175–195.

- Hemmings, J. Iris van Herpen: Transforming Fashion. Fash. Theory 2019, 24, 287–291.

- Logan, L. The Dutch designer who is pioneering the use of 3D printing in fashion. Smithsonian 2015. Available online: http://www.smithsonianmag.com/innovation/dutch-designer-who-pioneering-use-3d-printing-fashion-180957184/ (accessed on 15 June 2022).

- Luimstra, J. Artist got inspired by waves and created this 3D printed swimsuit. 2015. Available online: https://3dprinting.com/news/artist-got-inspired-waves-created-3d-printed-swimsuit/ (accessed on 15 June 2022).

- Fashion, S. When fashion meets technology, first look at how beautiful the skirt designed by 3D printing technology is. 2015. Available online: http://fashion.sina.com.cn/s/tr/2019-07-02/1609/doc-ihytcitk9184017.shtml (accessed on 15 June 2022).

- Song, H.; Lee, J. Study on the Tendency of Interest of Fashion Product Development based on 3D Printing according to College Students’ Fashion Life Style. J. Fash. Bus. 2019, 23, 101–115.

- Kwon, Y.M.; Lee, Y.-A.; Kim, S.J. Case study on 3D printing education in fashion design coursework. Fash. Text. 2017, 4, 26.

- Karakurt, I.; Lin, L. 3D printing technologies: Techniques, materials, and post-processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196.

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A.; Hatami, S. An overview of fused deposition modelling (FDM): Research, development and process optimisation. Rapid Prototyp. J. 2021, 27, 562–582.

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. IOP Conf. Ser. Mater. Sci. Eng. 2014, 62, 012018.

- Takahashi, H.; Kim, J. 3D printed fabric: Techniques for design and 3D weaving programmable textiles. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology, New Orleans, LA, USA, 20–23 October 2019; pp. 43–51.

- Kim, S.; Seong, H.; Her, Y.; Chun, J. A study of the development and improvement of fashion products using a FDM type 3D printer. Fash. Text. 2019, 6, 9.

- Beecroft, M. Digital interlooping: 3D printing of weft-knitted textile-based tubular structures using selective laser sintering of nylon powder. Int. J. Fash. Des. Technol. Educ. 2019, 12, 218–224.

This entry is offline, you can click here to edit this entry!