Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The construction industry utilizes a substantial number of resources, which has negative impacts on both environmental and socioeconomic aspects. Therefore, it is important to reduce these negative impacts and maintain sustainable development (SD). Studies suggest that integrating Industry 4.0 (also called Construction 4.0 (C4.0) in the construction industry) and SD may help address these concerns, which is a new and ever-evolving field.

- bibliometric analysis

- building information modeling

- factors

- construction industry

- digital transformaiton

1. Introduction

At the dawn of the 21st century, the world is experiencing the fourth industrial revolution of several organizations and industries, which is commonly referred to as Industry 4.0 (I4.0), in order to improve their quality and productivity [1]. I4.0 is a concept that links embedded system production technologies with intelligent production processes, and it is drastically reshaping the industry and production value chains and business structures [2]. This industrial revolution is brought about by a movement toward a physical-to-digital-to-physical relationship provided by digital technologies, including cognitive and high-performance computing, autonomous robots, big data analytics, the internet of things (IoT), and visualization technologies (virtual and augmented reality), among other technologies [1][2]. Since the proposal of the term “Industrie 4.0” in 2011, the digital transformation enabled by I4.0 has garnered instant attention from industrialists and researchers worldwide. Consistently, the effects of I4.0 on sustainability and the ways in which it might help sustainable growth are garnering greater attention.

Sustainability is a holistic concept with several definitions. The most frequently recognized definition is provided by Brundtland’s report (Our Common Future), which established the term sustainable development (SD) as “the development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [3]. In the wake of the first two major United Nations conferences on environmental and sustainable development, SD has been interpreted as an effort to strike to balance between environmental, economic, and social performance, i.e., the triple bottom line (TBL) [4]. The notion of SD in the context of I4.0 challenges traditional problem-solving approaches and necessitates more systematic approaches to change management. This implies that the present advancement of SD necessitates a move from homogenous systems of ‘doing things better’ to holistic systems of ‘doing better things’ [5]. Stock and Seliger [6] argued that I4.0 offers considerable promise in realizing sustainable industrial value development in the TBL. The construction industry has also profited from the growth of the fourth industrial revolution, which has been named Construction 4.0 (C4.0) [7][8].

Construction is one of the most important industries. However, it has historically relied heavily on craft-based processes and has been linked with poor performance and quality. The slow rate of innovation is significant due to the industry’s negative economic (e.g., low-profit margins, budget overruns, and significant project delays), social (e.g., high accident rate and poor working conditions), and environmental (e.g., high water, material, and energy consumption and waste generation) impacts [7][9][10]. Previous studies stated that C4.0 could help construction companies increase productivity, reduce project delays and cost overruns, manage project complexity, and enhance safety, quality, and resource efficiency [11]. According to World Economic Forum [12], full digitization in the non-residential building would result in annual worldwide cost reductions of 13 to 21 percent during the construction phase and 10 to 17 percent during the operating phase within ten years. In addition, by conserving water, energy, and natural resources via recycling, reuse, innovative waste design management, and pollution control, SD in the construction industry may assist in satisfying the demands of present and future generations [13][14].

Despite being in its nascent stages, the impacts of C4.0 on SD are anticipated to be significant. To the authors’ knowledge, only a small number of reviews have evaluated SD from a C4.0 standpoint. This suggests that the transitions between the C4.0 and SD paradigms are still in their infancy. Thus, researchers aims to extend existing knowledge of C4.0 and SD by clarifying their interrelationship and proposing a framework that addresses the critical success factors (CSFs) (i.e., antecedents) of using C4.0 for SD.

2. The Interaction between C4.0 and SD

C4.0 and SD are both developing research fields within the construction industry. The notion of C4.0 is derived from a convergence of trends and technologies that can potentially transform how built environment assets are conceived, created, and operated. C4.0’s primary characteristics include automation, integration, cooperation, innovation, optimization, decentralization, and sustainability [15]. Theoretically, C4.0 incorporates several cutting-edge technologies and tackles numerous theoretical concepts connected to the ongoing fourth industrial revolution in building. Its primary objective is to innovate the physical environment, boost productivity and collaboration, and optimize SD at the corporate and social levels.

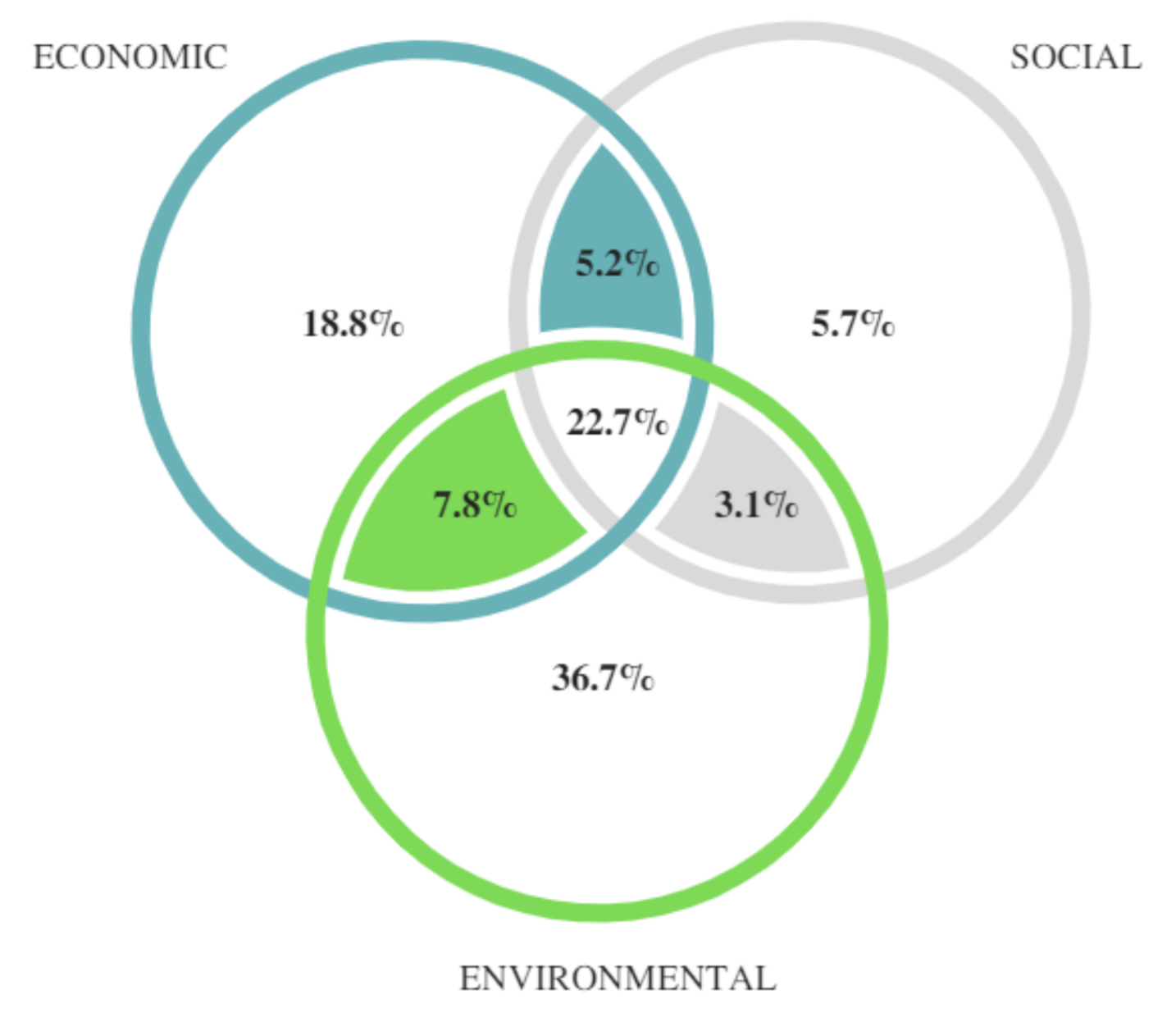

C4.0 is investigated primarily from the viewpoints of its implementation in order to realize TBL sustainability advantages; for instance, efficient use of resources, defect reduction, and other environmental enhancements make operations more sustainable. Many countries and organizations are adopting innovative technology, sustainable materials, clean and efficient processes, environmental protection, and renewables in order to reduce environmental impacts, utilize renewable energy, reuse new materials, and meet the present and future demands of society, as stated in [16]. Figure 1 depicts the Venn diagram of the TBL sustainability of gathered materials, based on the systematic review. 52 articles, or 22.7%, address all three pillars, as shown by the findings. The plurality of the research, 84 papers, or 36.7%, focused solely on the environmental pillar, as this is the one that is most addressed owing to legal requirements and market preference. In order to improve comprehension of C4.0 and its technological practices on TBL performance, the following part provides an overview of the technological impacts of C4.0 on SD.

Figure 1. Venn diagram of the SD pillars.

3. C4.0-Related Technologies and Sustainable Performance

This section illustrated the possible implications of C4.0-related technologies on TBL dimensions. The sustainability performance categories for both social and economic impacts are based on previous studies [17][18]. These social performance categories include ethics and privacy consideration, long-term value to society, stakeholder engagement and satisfaction, health and safety, and wages and working conditions. The economic performance categories are supply chain collaboration, financial and economic feasibility, cost, quality and schedule management, operational and maintenance costs, and innovation and productivity. According to the global reporting initiative (GRI) guidelines [19], the areas of environmental impact include raw materials used, recycled materials used, energy consumption, renewable energy utilized, effluents and waste, emissions, and environmental impact assessment.

3.1. Social Impacts

As for social performance, many studies highlight the potential use of C4.0 technologies for its improvement. The C4.0 technologies could help stakeholders to sustain business and life quality for the long term so as to create long-term value for society. Reviewed studies confirm, for instance, that BIM is expected to encourage stakeholders to agree with common value objectives during the whole project life cycle [20], which can guarantee the business performance of the project. Construction projects produce a large amount of data that could be processed by technologies to acquire more valuable information to ensure social value. Using a variety of sensors and actuators, for instance, the virtual world connects with the real world. IoT can facilitate the development of several applications that make use of vast quantities and types of data [21] and help assure societal benefits following the completion of a project [22]. Also, by using big data tools, stakeholders may better access and evaluate data collected from a range of sources. Wey and Peng [23] utilized big data to construct a dynamic model to simulate changes in the built environment and identify management strategies, thus improving social equity and livability.

In the operation and maintenance stages, user-generated data could be gathered and analyzed to monitor situations specific to a region, such as community necessities [24]. Some researchers have developed digital twin frameworks, enabling integrated data analytics solutions to improve the ability of volunteer respondents, residents, community members, and other stakeholders to cope with the events in the built environment [24][25][26]. Based on project data, Olukan et al. [27] used machine learning to classify laterites-compressed earth bricks, which is a viable alternative to traditional construction materials. Additionally, some studies [22][28][29] pointed out that 3D printing could be used for sustainable low-income housing delivery, supporting sustainable human settlement, especially for the urban poor.

In addition, C4.0 technologies can help improve the engagement and satisfaction of stakeholders. To support stakeholders in making decisions and predicting the risk of Engineering Procurement and Construction (EPC) projects, Choi et al. [30] established the Engineering Machine-learning Automation Platform (EMAP), a cloud-based comprehensive analytical tool based on the combination of big data, artificial intelligence (AI), and machine learning technologies. EMAP was further validated through case studies and proved to be effective for bid analysis, cost estimation, error checking, forecasting, and predictive maintenance. Also, BIM can be used as a powerful method for organizing various, multidisciplinary, and competing components in the life cycle of a project, allowing stakeholders to collaborate and share information, thus enhancing project control and management [31][32].

Similarly, on the basis of a decentralized peer-to-peer (P2P) infrastructure, blockchain provides uniform standards and protocols for information exchange with greater transparency and security. Jiang et al. [33] presented a blockchain-enabled platform to address the difficulties of information exchange among project participants in the Modular Integrated Construction (MiC) project. Based on the findings, the framework not only simplifies construction progress traceability and real-time KPI measurement, but also enhances information dependability, immutability, and transparency. Augmented reality (AR) generates the real-time display of a 3D building prototype with associated design information in a real-world context, which can aid stakeholders in creating and exchanging massive volumes of heterogeneous data [34]. In practice, to counteract the influence of the COVID-19 epidemic on social distance, Tea et al. [35] developed a multiuser immersive VR application that would enable stakeholders to communicate and participate in the same virtual space to facilitate real-time design review.

The construction industry is reported to be the fourth most hazardous industry in terms of deaths. The application of C4.0 technologies can bring positive impacts on health and safety (H&S) in the working environment. For instance, BuHamdan et al. [36] utilized BIM and discrete event simulation (DES) to evaluate and visualize health risks associated with cross-laminated wood construction processes, which may cause hand–arm vibration syndrome (HAVS) risks. To simulate the fire evacuation scenarios and minimize safety risks, Hosseini and Maghrebi [37] utilized the BIM and social force model (SFM) to model the scenarios and simulate the evacuation of complex construction sites. This strategy gives reliable safety decision-making support to project managers. In the study of [38], the effectiveness of IoT for accident prevention on construction sites was examined based on Heinrich’s domino theory of accident causation. The results quantified the potential of IoT to prevent construction accidents. In addition, Alibrandi [39] integrated digital twin and machine learning technologies to develop a risk-aware digital twin in order to conduct full consideration and model the related risks and uncertainties throughout the product’s lifecycle. Safety education is also an important strategy to promote a safe and healthy working environment in construction. To provide construction practitioners with real practical and safe experiences, Le et al. [40] suggested a framework for an online social VR system that enables role-playing, dialogic learning, and social interaction for construction and health education.

Some researchers demonstrated that C4.0 technologies could improve the working environment. For example, Zahid et al. [41] developed an optimization approach named ‘DynamicPMV’ to achieve the indoor thermal comfort for workers. By combining BIM and IoT, this approach takes advantage of the geometric and parametric depth of BIM models and the real-time streaming of environmental data (such as humidity, temperature, and carbon emissions) gathered by IoT. Additionally, a VR-enabled experiment was undertaken in the study [42] to attenuate the temperature-color interaction effects that influence thermal perception in terms of thermal acceptability, thermal comfort, and temperature estimation. The findings suggest that glazing technologies with saturated colors (e.g., transparent photovoltaics) can be used during the design phase, therefore enhancing the indoor comfort of employees.

On the other hand, C4.0 technologies may also bring negative effects on social performance in terms of ethics and privacy. The issues of ethics, data security, and privacy protection are major challenges to big data in construction [43][44]. Weak data security may quickly arouse individual or organizational opposition and can cause severe reputational harm to a corporation. Also, Abioye et al. [45] stated that the ethics and governance of AI technologies is a critical issue that is of great importance to society at large. The competencies of AI technologies could be dangerous if not properly regulated and governed.

3.2. Economic Development

Some studies examine the possible implications of C4.0 technologies on the economic and business performance of construction projects. In terms of supply chain collaboration and management, Liu and Lin [46] used the Delphi method and data envelopment analysis to analyze the performance of the application of artificial intelligence to supply chain management. They indicated that AI could enhance the performance of supply chain management from six categories, namely, understanding customers’ true value appeal, supply chain whole process visualization, building modularized supply chain operation structure, real-time supply chain planning and execution of connection system, supply chain early warning, and building operation-sensitized supply chains. In the study conducted by Teisserenc and Sepasgozar [47], they identified the benefits and drivers of sustainable a blockchain-based digital twin (BCTD) for the supply chain management. For instance, BCTDs can enable smart contracts to trace the provenance and usage of commodities and services, thus improving the transparency of regulation of the supply chain. The potential of using cloud computing and IoT for supply chain collaboration is also investigated by researchers. Ko et al. [48] presented a tracking system based on a cloud-computing service integrated with IoT technologies for automated tracking with ubiquitous access in the supply network (e.g., fabrication, delivery, and installation processes). The cloud-computing platform offers an efficient option for overcoming faults and delays in information flow and enhancing the collaboration of firms in the building supply chain, particularly for small and medium-sized businesses (SMEs).

With regard to a company’s financial and economic feasibility, some researchers argue that investment in C4.0 technologies can bring long-term economic profits to the company. Reizgevičius et al. [49] discussed and calculated the return on investments (ROI) in BIM based on interviews with stakeholders engaged in BIM-based design. The results show a strong relationship between ROI and the gross wage, estimating BIM may provide 20% ROI for the first year. In addition, Kim et al. [50] developed a survey questionnaire to investigate the anticipated impact of utilizing blockchain in construction. They indicated that the smart contract based on a blockchain platform could substantially enhance efficiencies during the contract negotiation and formation process, improving the financial feasibility of the company.

Moreover, the cost–quality–schedule trade-off within the project scope has become a significant criterion to judge whether the project is successful, which is a great concern of researchers and all parties in construction projects. Among the C4.0 technologies, BIM is regarded as an important approach to boosting construction project effectiveness. Vite and Morbiducci [51] stated that BIM could generate multiple benefits for the whole project lifecycle regarding quality and cost and optimize the project schedule. For infrastructure projects, Han et al. [52] linked BIM, IoT, and intelligent compaction to create a foundational platform for monitoring and managing project quality. The practicality and validity of the platform’s prototype system were assessed on an actual construction site. The case demonstrated that the BIM-IoT and intelligent compaction system provide quality real-time monitoring and construction schedule management for road construction. In the study of [53], a BIM-enabled VR platform was developed to track the cost and footprint of building projects during the design stage.

In addition, the design of composite material for practical applications is time-consuming and costly because of multiple parameters in experimental tests. To promote efficacy and efficiency in the development of composite material for cost and time savings, Mahjoubi et al. [54] proposed three machine learning models to predict the life-cycle cost, mechanical properties, and carbon footprint of strain-hardening cementitious composite (SHCC). The application of robotics in construction is also practical for cost reduction and quality improvement. Han et al. [55] conducted experiments to analyze the performance of robotics in steel pipe pile head-cutting works in terms of quality, cost, productivity, and safety. The results found that robotics can improve productivity (45.78%) and annual cost reduction (38.07%) in steel pipe pile head-cutting works.

Moreover, the importance of the operation and maintenance of buildings has been largely underestimated as it has been regarded as unproductive. According to Ihsan and Alshibani [56], building operation and maintenance costs account for more than fifty percent of the construction industry’s total input and more than sixty percent of the contracts awarded. Some researchers argue that the technologies of C4.0 may optimize the maintenance costs of existing buildings. For instance, Kaewunruen and Xu [25] investigated BIM adoption for railway station buildings for the purpose of maintenance and reconstruction. They proved that BIM could optimize maintenance operations and logistics, as well as cut costs and carbon impact. Kim et al. [50] provided a framework for the optimum maintenance a BIM-enabled decision-making model that takes into account eco-friendly materials decreasing building maintenance costs. The economic analysis demonstrated that BIM might save the net greatest amount of energy expenses during the building’s lifetime and incur the lowest renovation costs. In the study of [57], BIM was used in repairing and maintenance of a hospital building. They stated that BIM could provide the initial identification and judgment along with providing the required information on the existing building structure, which is one of the most time-consuming and costly issues of maintenance work. Additionally, Heiskanen [58] demonstrated that IoT evaluates the performance of buildings and equipment in order to forecast problems and respond more effectively through preventative maintenance in order to minimize costs.

Innovation and productivity have been identified as critical for achieving significant improvements in the construction industry [59]. Even though the construction business is recognized as one of the most important economic contributors, it has been criticized for its lack of innovation in comparison to areas such as manufacturing, entertainment, and retail [11]. To cope with trends of digital transformation and solve SD issues, researchers have contributed to exploring innovative approaches and technologies for production improvement and economic growth. For instance, IoT enables the exchange of real-time data within and between organizations and projects to continually monitor physical processes that may have a significant influence on productivity [22][60]. Similarly, additional technologies like BIM, 3D printing, and robots might be adopted to boost productivity by enhancing human–robot cooperation [61][62][63].

Also, researchers found that the application of machine learning and AI in predicting the structural parameters (e.g., compressive strength, flexural strength, and splitting tensile strength) of concrete has been effective [64][65][66][67], improving accuracy and reducing testing time and rework. Additionally, prefabrication technology is a manufacturing process for productivity improvement, which is regarded as the first level of industrialization in construction. C4.0 technologies (e.g., BIM, IoT, digital twin, robotic, and blockchain) can serve as eligible contributors for prefabrication construction improvement since they can mitigate the problems of the prefabrication process; for example, addressing the absence of process continuity, poor interoperability among heterogeneous stakeholders, inadequate visibility and traceability of real-time data [60].

3.3. Environmental Sustainability

Environmental sustainability comprises empirical research observing changes in resource consumption (i.e., the use of raw and recycled materials as well as non-renewable and renewable energy), waste creation, water use, emissions and air pollution, and environmental impact assessment. Environmental impact assessments are intended to identify the potential impact issues of a construction project, such as energy, water, waste, material, lighting, ventilation, and noise, as well as any alternatives or mitigation measures [68]. In general, most environmental assessment methods are developed based on LCA [69], which is an integrated ‘cradle to grave’ approach used to assess the environmental performance of products and services. In order to suit the environments and conditions of different countries, some green building certification systems of environmental assessment have been developed [70], such as Building Research Establishment Environmental Assessment Methodology (BREEAM) in the UK, Leadership in Energy and Environmental Design (LEED) in the US, Council Alliance for a Sustainable Built Environment (CASBE) in Japan and Building Environmental Performance Analysis System (BEPAS) in China. The systems have used LCA criteria for buildings as part of their plans to reduce the environmental impact of buildings [70].

Most studies included BIM and LCA technologies at the conceptual stage to assist designers in selecting components and materials that are relatively more environmentally friendly [71][72]. For example, Jalaei et al. [68] investigated the workability and usefulness of the BIM-LCA interface to estimate and calculate environmental impacts. The results show that the integration of BIM-LCA is efficient for environmental impact estimation, which can reduce waste and emissions at the early stage. In practice, Alhumayani et al. [73] applied LCA to evaluate the environmental effect of 3D printing with that of conventional construction processes employing two distinct types of building material (i.e., cob and concrete). The results indicate that the environmental impact of 3D-printed concrete is mostly dependent on the proportions of the mix’s components; thus, adjusted mixes can lessen the environmental impact of 3D-printed concrete. In addition, Yoffe et al. [74] highlighted that the use of big data could improve environmental impact assessment rating systems by providing spatial–temporal quantitative evaluation methodologies. Nevertheless, obstacles such as inconsistent data coverage, standardization of data formats, and unequal access to data by users may now hinder the adoption of big data in environmental impact assessment.

Also, several studies emphasize the C4.0 prospects for resource consumption enhancement through optimization, real-time monitoring, and management. Uddin et al. [75] investigated the BIM implementation for green buildings in terms of construction materials consumption by considering the availability of local construction materials. By utilizing BIM, the project team may optimize the different material combinations early in the process and arrive at the optimal option. Huang et al. [76] introduced a method that efficiently integrates BIM and IoT into a geographic information system in order to accomplish adequate soil recycling. The integrated system provides a fundamental digital building model for excavated soil recycling, irrespective of whether it is activated by current application software, or a program tailored to the needs of a particular company or its stakeholders.

Some researchers have explored the feasibility of using 3D printing to optimize the mechanical properties of rapid-hardening and environmentally friendly building materials. In the study [77], 3D printing was used to create an eco-friendly cementitious material by combining magnesium potassium phosphate cement (MKPC) with varied ratios of fly ash replacement. Bong et al. [78] developed an optimal 3D printable geopolymer mixture by optimizing the geopolymer mixture parameters (e.g., type of hydroxide solutions (HS), type of silicate solutions (SS), and SS/HS mass ratio) across multiple performance criteria, such as workability, shape retention ability, extrudability, and compressive strength. In addition, Xiao et al. [79] examined the hardening qualities and studied the feasibility of replacing natural fine aggregates with 100%-recycled fine aggregates via 3D printing. Results reveal that 3D-printed mortar combined with 100%-recycled fine aggregates has superior mechanical characteristics and deformation compared to mortar without fibers and natural fine aggregates.

Moreover, machine learning and AI technologies were utilized to optimize the mechanical characteristics of recycled aggregate concrete. In this instance, Nunez et al. [80] suggested machine learning models forecast the recycled aggregate concrete compressive strength and optimize its mixture design in order to reduce the carbon footprint and avoid the disposal of enormous quantities of building demolition debris. For various compressive strength classes, the machine learning model generated recycled aggregate concrete mixture designs with a decreased environmental footprint. In addition, Duan et al. [81] examined the 28-day compressive strength of recycled aggregate concrete using an AI-based meta-heuristic search of the socio-political algorithm and XGBoost model. They indicated that the proposed technique is effective for predicting the sufficient mechanical performance of recycled aggregate concrete and permitting its safe and environmentally friendly application for construction purposes.

According to the global status report in 2021 [82], the building and construction sectors are responsible for 37% of energy-related carbon dioxide emissions and 36% of final energy consumption. Therefore, it is necessary to increase the efficiency of energy resource utilization. Some researchers indicated that BIM is useful for energy efficiency since it allows for a variety of simulations and analyses of the produced model, such as lighting and energy analyses and natural ventilation studies [83]. Najjar et al. [84] developed a unique framework to combine BIM and life cycle assessment in order to improve the energy efficiency of running buildings. Using the framework, the yearly energy usage intensity may be lowered by around 45%, the life cycle energy consumption and cost can be reduced by more than 50%, and environmental consequences such as acidification and global warming potential can be reduced by more than 30%. Singh and Sadhu [85] presented a comprehensive energy study to optimize the design parameters and energy linkages between the buildings. Variables such as orientation, wall and roof materials, window-to-wall ratios, heating, ventilation and air-conditioning (HVAC) systems, and the Inter-Building Effect are examined and mimicked to study the energy performance.

In addition, a simpler and user-centric BIM-based strategy for improving energy efficiency in buildings was developed and tested in two classrooms of an educational facility [86]. The results showed that the approach based on daylight contribution reduced energy consumption by approximately 8% for one of the rooms and approximately 12% for the other, while the approach that utilized natural ventilation reduced energy consumption by approximately 7% for one of the rooms and approximately 9% for the other. Petri et al. [83] claimed that BIM for energy efficiency is an ongoing process that requires professional training to strengthen the skills and competences of employees and prepare the way for a fundamental shift in providing systematic, measurable, and effective energy-efficient buildings.

Moreover, other technologies like IoT, machine learning, AI, and digital twin may be utilized for energy-efficient matching optimization and to change system parameters routinely in order to better regulate energy usage. In order to lower the energy consumption of a building during the usage phase, IoT-collected data may give pertinent user recommendations. Wu et al. [87] studied distributed solar energy devices and the collaborative design of solar energy devices and buildings based on IoT in order to improve solar energy device monitoring. In addition, a number of studies assert that C4.0 technologies can facilitate the incorporation of renewable energy sources. Nutkiewicz et al. [88] proposed a unique data-driven energy modeling framework that incorporates machine learning approaches to capture the inter-building energy dynamics and effects of the urban setting. Toosi et al. [89] suggested a life cycle sustainability assessment-based optimization methodology to expedite the data processing and optimization of short-term energy storage devices. Moreover, Tariq et al. [90] enhanced the performance of a sun-facing wall-attached vertically oriented traditional solar chimney integrated with a building based on multicriteria for different climatic zones using a digital twin model.

As a result of its contribution to environmental degradation, construction and demolition (C&D) waste have become formidable obstacles for the SD. C4.0 technologies have garnered significant interest as vital solutions for C&D research. During the design phase, Gupta et al. [91] examined the BIM-based C&D waste management strategies and tools that can assist limit C&D waste. Based on the results, BIM may decrease material waste caused by rework, improper design, and design revisions. Su et al. [92] developed an estimating and evaluation method for building demolition waste by combining BIM, GIS, and life-cycle assessment. During the design phase, the tool is able to measure the quantity of waste and evaluate its effects, while automating waste estimation and impact evaluation. In addition, Kang et al. [93] applied BIM to maximize the reuse and recycling of demolition debris through three primary steps: scanning and surveying, building destruction, and garbage transportation. In this situation, demolition planning will be less arduous and not restricted by the expertise and experience of project managers.

In addition, Muthukrishnan et al. [94] explored the potential of incorporating supplementary cementing material of rice husk (i.e., rice husk ash) into 3D printable concrete. Results indicate that 20% of cement by weight can be substituted with rice husk ash, which significantly improves the rheology of mortar at the needed rate for large-scale 3D printing in construction. At the construction stage, prediction models and algorithms are useful for designing concrete mixtures to mitigate their environmental impacts, such as material waste. For instance, Naseri et al. [95] investigated the optimal mixture proportion of concrete based on machine learning. Yang et al. [96] utilized AI techniques to estimate the ultrasonic pulse velocity of concrete containing waste marble dust. In addition, Voorter and Koolen [97] employed blockchain to trace the C&D waste, in order to mitigate the waste from downstream waste-processing activities. Three key pillars in reducing waste in construction were identified based on VR in the study of [98], namely, education documentation and visualization. VR was utilized to visualize the strategies of building design and the bill of quantities and material stock included in the project.

Furthermore, with the increasing climate change, C4.0 technologies have been explored to quantify and reduce the carbon footprint. In this case, Yang et al. [99] provided a BIM-enabled LCA technique to support low-carbon design in this instance. Lu et al. [100] developed an analytical framework for carbon emissions based on BIM and LCA. The main steps involved in this framework include defining the boundary of carbon emissions in the life cycle, establishing a carbon emissions coefficients database, calculating carbon emissions, and reporting the results of carbon emissions calculation. Kamari et al. [53] combined BIM and VR to measure carbon footprint and cost, resulting in reduced emissions and expenses and improved design strategy decision making. In addition, predictive models based on machine learning may be linked with optimization approaches to decrease environmental consequences, such as carbon emissions, through design optimization. In the study [101], machine learning technology was used to reduce the embodied carbon content of high-strength concrete mixtures without compromising their mechanical qualities. Moreover, Mahjoubi et al. [54] created a system for predicting the carbon footprint, characteristics, and life-cycle cost of stain-hardening cementitious composites.

This entry is adapted from the peer-reviewed paper 10.3390/buildings12101708

References

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394.

- Brundtland. Report of the World Commission on Environment and Development: Our Common Future. Available online: https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf (accessed on 29 July 2022).

- Rogers, P.P.; Jalal, K.F.; Boyd, J.A. An Introduction to Sustainable Development; Routledge: London, UK, 2012.

- Sterling, S. Higher education, sustainability, and the role of systemic learning. In Higher Education and the Challenge of Sustainability; Springer: Dordrecht, The Netherlands, 2004; pp. 49–70.

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 2016, 40, 536–541.

- Wang, K.; Guo, F.; Zhang, C.; Hao, J.; Schaefer, D. Digital Technology in Architecture, Engineering, and Construction (AEC) Industry: Research Trends and Practical Status toward Construction 4.0. In Proceedings of the Construction Research Congress, Arlington, VA, USA, 9–12 March 2022; pp. 983–992.

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267.

- Araújo, A.G.; Carneiro, A.M.P.; Palha, R.P. Sustainable construction management: A systematic review of the literature with meta-analysis. J. Clean. Prod. 2020, 256, 120350.

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139.

- Wang, K.; Guo, F.; Zhang, C.; Schaefer, D. From Industry 4.0 to Construction 4.0: Barriers to the Digital Transformation of Engineering and Construction Sectors. Eng. Constr. Archit 2022. ahead of print.

- World Economic Forum. What’s the Future of the Construction Industry? Available online: https://www.weforum.org/agenda/2016/04/building-in-the-fourth-industrial-revolution/ (accessed on 29 July 2022).

- Hwang, B.G.; Tan, J.S. Green building project management: Obstacles and solutions for sustainable development. Sustainable development. 2012, 20, 335–349.

- De Almeida Barbosa Franco, J.; Domingues, A.M.; De Almeida Africano, N.; Deus, R.M.; Battistelle, R.A.G. Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities. Infrastructures 2022, 7, 43.

- Sawhney, A.; Riley, M.; Irizarry, J.; Riley, M. Construction 4.0; Sawhney, A., Riley, M., Irizarry, J., Eds.; Routledge: London, UK, 2020.

- Shahzad, M.; Qu, Y.; Javed, S.A.; Zafar, A.U.; Rehman, S.U. Relation of environment sustainability to CSR and green innovation: A case of Pakistani manufacturing industry. J. Clean. Prod. 2020, 253, 119938.

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction industry 4.0 and sustainability: An enabling framework. IEEE Trans. Eng. Manag. 2021. ahead of print.

- Stanitsas, M.; Kirytopoulos, K.; Leopoulos, V. Integrating sustainability indicators into project management: The case of construction industry. J. Clean. Prod. 2021, 279, 123774.

- GRI (Global Reporting Initiative). GRI Standards. Available online: https://www.globalreporting.org/how-to-use-the-gri-standards/gri-standards-english-language/ (accessed on 2 August 2022).

- Reychav, I.; Maskil Leitan, R.; McHaney, R. Sociocultural sustainability in green building information modeling. Clean Technol. Environ. Policy. 2017, 19, 2245–2254.

- Oke, A.E.; Arowoiya, V.A. Evaluation of internet of things (IoT) application areas for sustainable construction. Smart Sustain. Built Environ. 2021, 10, 387–402.

- Singh, R.; Gehlot, A.; Akram, S.V.; Gupta, L.R.; Jena, M.K.; Prakash, C.; Singh, S.; Kumar, R. Cloud manufacturing, internet of things-assisted manufacturing and 3D printing technology: Reliable tools for sustainable construction. Sustainability 2021, 13, 7327.

- Wey, W.M.; Peng, T.C. Study on building a smart sustainable city assessment framework using big data and analytic network process. J. Urban Plan. Dev. Div. 2021, 147, 04021031.

- Fan, C.; Jiang, Y.; Mostafavi, A. Social sensing in disaster city digital twin: Integrated textual–visual–geo framework for situational awareness during built environment disruptions. J. Manag. Eng. 2020, 36, 04020002.

- Kaewunruen, S.; Xu, N. Digital twin for sustainability evaluation of railway station buildings. Front. Built Environ. 2018, 4, 77.

- Tagliabue, L.C.; Cecconi, F.R.; Maltese, S.; Rinaldi, S.; Ciribini, A.L.C.; Flammini, A. Leveraging digital twin for sustainability assessment of an educational building. Sustainability 2021, 13, 480.

- Olukan, T.A.; Chiou, Y.C.; Chiu, C.H.; Lai, C.Y.; Santos, S.; Chiesa, M. Predicting the suitability of lateritic soil type for low cost sustainable housing with image recognition and machine learning techniques. J. Build. Eng. 2020, 29, 101175.

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.; Ndlovu, L. 3D Printing for sustainable low-income housing in South Africa: A case for the urban poor. J. Green Build. 2021, 16, 129–141.

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299.

- Choi, S.W.; Lee, E.B.; Kim, J.H. The engineering machine-learning automation platform (emap): A big-data-driven ai tool for contractors’ sustainable management solutions for plant projects. Sustainability 2021, 13, 10384.

- Baldauf, J.P.; Formoso, C.T.; Tzortzopoulos, P.; Miron, L.I.; Soliman-Junior, J. Using building information modelling to manage client requirements in social housing projects. Sustainability 2020, 12, 2804.

- Mazzoli, C.; Iannantuono, M.; Giannakopoulos, V.; Fotopoulou, A.; Ferrante, A.; Garagnani, S. Building information modeling as an effective process for the sustainable re-shaping of the built environment. Sustainability 2021, 13, 4658.

- Jiang, Y.; Liu, X.; Kang, K.; Wang, Z.; Zhong, R.Y.; Huang, G.Q. Blockchain-enabled cyber-physical smart modular integrated construction. Comput. Ind. 2021, 133, 103553.

- Mugumya, K.L.; Wong, J.Y.; Chan, A.; Yip, C.C. The Role of Linked Building Data (LBD) in Aligning Augmented Reality (AR) with Sustainable Construction. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 366–372.

- Tea, S.; Panuwatwanich, K.; Ruthankoon, R.; Kaewmoracharoen, M. Multiuser immersive virtual reality application for real-time remote collaboration to enhance design review process in the social distancing era. J. Eng. Des. Technol. 2021, 20, 281–298.

- BuHamdan, S.; Duncheva, T.; Alwisy, A. Developing a BIM and Simulation-Based Hazard Assessment and Visualization Framework for CLT Construction Design. J. Constr. Eng. Manag. 2021, 147, 04021003.

- Hosseini, O.; Maghrebi, M. Risk of fire emergency evacuation in complex construction sites: Integration of 4D-BIM, social force modeling, and fire quantitative risk assessment. Adv. Eng. Inform. 2021, 50, 101378.

- Yeo, C.J.; Yu, J.H.; Kang, Y. Quantifying the effectiveness of IoT technologies for accident prevention. J. Manag. Eng. 2020, 36, 04020054.

- Alibrandi, U. Risk-informed digital twin of buildings and infrastructures for sustainable and resilient urban communities. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2022, 8, 04022032.

- Le, Q.T.; Pedro, A.; Park, C.S. A social virtual reality based construction safety education system for experiential learning. J. Intell. Robot. Syst. 2015, 79, 487–506.

- Zahid, H.; Elmansoury, O.; Yaagoubi, R. Dynamic Predicted Mean Vote: An IoT-BIM integrated approach for indoor thermal comfort optimization. Autom. Constr. 2021, 129, 103805.

- Chinazzo, G.; Chamilothori, K.; Wienold, J.; Andersen, M. Temperature–color interaction: Subjective indoor environmental perception and physiological responses in virtual reality. Hum. Factors 2021, 63, 474–502.

- Gahi, Y.; Guennoun, M.; Mouftah, H.T. Big data analytics: Security and privacy challenges. In Proceedings of the 2016 IEEE Symposium on Computers and Communication (ISCC), Messina, Italy, 27–30 June 2016; pp. 952–957.

- Yu, T.; Liang, X.; Wang, Y. Factors affecting the utilization of big data in construction projects. J. Constr. Eng. Manag. 2020, 146, 04020032.

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299.

- Liu, K.S.; Lin, M.H. Performance Assessment on the Application of Artificial Intelligence to Sustainable Supply Chain Management in the Construction Material Industry. Sustainability 2021, 13, 12767.

- Teisserenc, B.; Sepasgozar, S. Project Data Categorization, Adoption Factors, and Non-Functional Requirements for Blockchain Based Digital Twins in the Construction Industry 4.0. Buildings 2021, 11, 626.

- Ko, H.S.; Azambuja, M.; Lee, H.F. Cloud-based materials tracking system prototype integrated with radio frequency identification tagging technology. Autom. Constr. 2016, 63, 144–154.

- Reizgevičius, M.; Ustinovičius, L.; Cibulskienė, D.; Kutut, V.; Nazarko, L. Promoting sustainability through investment in Building Information Modeling (BIM) technologies: A design company perspective. Sustainability 2018, 10, 600.

- Kim, K.; Lee, G.; Kim, S. A study on the application of blockchain technology in the construction industry. KSCE J. Civ. Eng. 2020, 24, 2561–2571.

- Vite, C.; Morbiducci, R. Optimizing the sustainable aspects of the design process through building information modeling. Sustainability 2021, 13, 3041.

- Han, T.; Ma, T.; Fang, Z.; Zhang, Y.; Han, C. A BIM-IoT and intelligent compaction integrated framework for advanced road compaction quality monitoring and management. Comput. Electr. Eng. 2022, 100, 107981.

- Kamari, A.; Paari, A.; Torvund, H.Ø. Bim-enabled virtual reality (vr) for sustainability life cycle and cost assessment. Sustainability 2020, 13, 249.

- Mahjoubi, S.; Barhemat, R.; Guo, P.; Meng, W.; Bao, Y. Prediction and multi-objective optimization of mechanical, economical, and environmental properties for strain-hardening cementitious composites (SHCC) based on automated machine learning and metaheuristic algorithms. J. Clean. Prod. 2021, 329, 129665.

- Han, J.H.; Yeom, D.J.; Kim, J.S.; Kim, Y.S. Life Cycle Cost Analysis of the Steel Pipe Pile Head Cutting Robot. Sustainability 2020, 12, 3975.

- Ihsan, B.; Alshibani, A. Factors affecting operation and maintenance cost of hotels. Prop. Manag. 2018, 36, 296–313.

- Akhoundan, M.R.; Khademi, K.; Bahmanoo, S.; Wakil, K.; Mohamad, E.T.; Khorami, M. Practical use of computational building information modeling in repairing and maintenance of hospital building-case study. Smart Struct. Syst. 2018, 22, 575–586.

- Heiskanen, A. The technology of trust: How the Internet of Things and blockchain could usher in a new era of construction productivity. Constr. Res. Innov. 2017, 8, 66–70.

- Noktehdan, M.; Shahbazpour, M.; Wilkinson, S. Driving innovative thinking in the New Zealand construction industry. Buildings 2015, 5, 297–309.

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.; Xiao, B.; Lai, X.; Zhao, Y. A blockchain-and IoT-based smart product-service system for the sustainability of prefabricated housing construction. J. Clean. Prod. 2021, 286, 125391.

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S. Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Adv. Eng. Inform. 2019, 42, 100989.

- Taher, A.H.; Lbeltagi, E.E. Integrating building information modeling with value engineering to facilitate the selection of building design alternatives considering sustainability. Int. J. Constr. Manag. 2021. ahead of print.

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923.

- Aljawder, A.; Al-Karaghouli, W. The adoption of technology management principles and artificial intelligence for a sustainable lean construction industry in the case of Bahrain. J. Decis. Syst 2022. ahead of print.

- Bansal, T.; Talakokula, V.; Mathiyazhagan, K. Equivalent structural parameters based non-destructive prediction of sustainable concrete strength using machine learning models via piezo sensor. Measurement 2022, 187, 110202.

- Pham, A.D.; Ngo, N.T.; Nguyen, Q.T.; Truong, N.S. Hybrid machine learning for predicting strength of sustainable concrete. Soft Comput. 2020, 24, 14965–14980.

- Shah, M.I.; Memon, S.A.; Khan Niazi, M.S.; Amin, M.N.; Aslam, F.; Javed, M.F. Machine learning-based modeling with optimization algorithm for predicting mechanical properties of sustainable concrete. Adv. Civ. Eng. 2021, 2021, 1–15.

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2021, 21, 784–801.

- Gu, Z.; Wennersten, R.; Assefa, G. Analysis of the most widely used building environmental assessment methods. Environ. Sci. 2006, 3, 175–192.

- Lee, W.L.; Burnett, J. Benchmarking energy use assessment of HK-BEAM, BREEAM and LEED. Build. Environ. 2008, 43, 1882–1891.

- Akhanova, G.; Nadeem, A.; Kim, J.R.; Azhar, S.; Khalfan, M. Building information modeling based building sustainability assessment framework for Kazakhstan. Buildings 2021, 11, 384.

- Jiménez-Roberto, Y.; Sebastián-Sarmiento, J.; Gómez-Cabrera, A.; Castillo, G.L.D. Analysis of the environmental sustainability of buildings using BIM (Building Information Modeling) methodology. Ing. Compet. 2017, 19, 241–251.

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental assessment of large-scale 3D printing in construction: A comparative study between cob and concrete. J. Clean. Prod. 2020, 270, 122463.

- Yoffe, H.; Plaut, P.; Grobman, Y.J. Towards sustainability evaluation of urban landscapes using big data: A case study of Israel’s architecture, engineering and construction industry. Landsc. Res. 2022, 47, 49–67.

- Uddin, M.N.; Wei, H.H.; Chi, H.L.; Ni, M.; Elumalai, P. Building information modeling (BIM) incorporated green building analysis: An application of local construction materials and sustainable practice in the built environment. J. Build. Pathol. Adapt. 2021, 6, 1–25.

- Huang, T.; Kou, S.; Liu, D.; Li, D.; Xing, F. A BIM-GIS-IoT-Based System for Excavated Soil Recycling. Buildings 2022, 12, 457.

- Weng, Y.; Ruan, S.; Li, M.; Mo, L.; Unluer, C.; Tan, M.J.; Qian, S. Feasibility study on sustainable magnesium potassium phosphate cement paste for 3D printing. Constr Build Mater. 2019, 221, 595–603.

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications. Materials 2019, 12, 902.

- Xiao, J.; Zou, S.; Ding, T.; Duan, Z.; Liu, Q. Fiber-reinforced mortar with 100% recycled fine aggregates: A cleaner perspective on 3D printing. J. Clean. Prod. 2021, 319, 128720.

- Nunez, I.; Marani, A.; Nehdi, M.L. Mixture optimization of recycled aggregate concrete using hybrid machine learning model. Materials 2020, 13, 4331.

- Duan, J.; Asteris, P.G.; Nguyen, H.; Bui, X.N.; Moayedi, H. A novel artificial intelligence technique to predict compressive strength of recycled aggregate concrete using ICA-XGBoost model. Eng. Comput. 2021, 37, 3329–3346.

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector: Nairobi, Kenya. Available online: https://globalabc.org/sites/default/files/2021-10/GABC_Buildings-GSR-2021_BOOK.pdf (accessed on 4 August 2022).

- Petri, I.; Kubicki, S.; Rezgui, Y.; Guerriero, A.; Li, H. Optimizing energy efficiency in operating built environment assets through building information modeling: A case study. Energies 2017, 10, 1167.

- Najjar, M.; Figueiredo, K.; Hammad, A.W.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382.

- Singh, P.; Sadhu, A. Multicomponent energy assessment of buildings using building information modeling. Sustain. Cities Soc. 2019, 49, 101603.

- De Lima Montenegro, J.G.C.; Zemero, B.R.; De Souza, A.C.D.B.; De Lima Tostes, M.E.; Bezerra, U.H. Building Information Modeling approach to optimize energy efficiency in educational buildings. J. Build. Eng. 2021, 43, 102587.

- Wu, X.; Yang, C.; Han, W.; Pan, Z. Integrated design of solar photovoltaic power generation technology and building construction based on the Internet of Things. Alex. Eng. J. 2022, 61, 2775–2786.

- Nutkiewicz, A.; Yang, Z.; Jain, R.K. Data-driven Urban Energy Simulation (DUE-S): A framework for integrating engineering simulation and machine learning methods in a multi-scale urban energy modeling workflow. Appl. Energy 2018, 225, 1176–1189.

- Toosi, H.A.; Lavagna, M.; Leonforte, F.; Del Pero, C.; Aste, N. A novel LCSA-Machine learning based optimization model for sustainable building design-A case study of energy storage systems. Build. Environ. 2022, 209, 108656.

- Tariq, R.; Torres-Aguilar, C.E.; Xamán, J.; Zavala-Guillén, I.; Bassam, A.; Ricalde, L.J.; Carvente, O. Digital twin models for optimization and global projection of building-integrated solar chimney. Build. Environ. 2022, 213, 108807.

- Gupta, S.; Jha, K.N.; Vyas, G. Proposing building information modeling-based theoretical framework for construction and demolition waste management: Strategies and tools. Int. J. Constr. Manag. 2020, 22, 2345–2355.

- Su, S.; Li, S.; Ju, J.; Wang, Q.; Xu, Z. A building information modeling-based tool for estimating building demolition waste and evaluating its environmental impacts. Waste Manag. 2021, 134, 159–169.

- Kang, K.; Besklubova, S.; Dai, Y.; Zhong, R.Y. Building demolition waste management through smart BIM: A case study in Hong Kong. Waste Manag. 2022, 143, 69–83.

- Muthukrishnan, S.; Kua, H.W.; Yu, L.N.; Chung, J.K. Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. J. Mater. Civ. Eng. 2020, 32, 04020195.

- Naseri, H.; Jahanbakhsh, H.; Hosseini, P.; Nejad, F.M. Designing sustainable concrete mixture by developing a new machine learning technique. J. Clean. Prod. 2020, 258, 120578.

- Yang, D.; Zhao, J.; Suhail, S.A.; Ahmad, W.; Kamiński, P.; Dyczko, A.; Salmi, A.; Mohamed, A. Investigating the Ultrasonic Pulse Velocity of Concrete Containing Waste Marble Dust and Its Estimation Using Artificial Intelligence. Materials 2022, 15, 4311.

- Voorter, J.; Koolen, C. The Traceability of Construction and Demolition Waste in Flanders via Blockchain Technology: A Match Made in Heaven? J. Eur. Environ. Plan. Law. 2021, 18, 347–369.

- O’Grady, T.M.; Brajkovich, N.; Minunno, R.; Chong, H.Y.; Morrison, G.M. Circular economy and virtual reality in advanced BIM-based prefabricated construction. Energies. 2021, 14, 4065.

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743.

- Lu, K.; Jiang, X.; Tam, V.W.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a carbon emissions analysis framework using building information modeling and life cycle assessment for the construction of hospital projects. Sustainability 2019, 11, 6274.

- Thilakarathna, P.S.M.; Seo, S.; Baduge, K.K.; Lee, H.; Mendis, P.; Foliente, G. Embodied carbon analysis and benchmarking emissions of high and ultra-high strength concrete using machine learning algorithms. J. Clean. Prod. 2020, 262, 121281.

This entry is offline, you can click here to edit this entry!