This short review is the applications section of our original paper that reviews materials and structures displaying non-conventional deformations as a response to different actuations (e.g., electricity, heat and mechanical loading).

- morphing

- shape adaptation

- coupling

1. Introduction

Due to the various kinds of actuation and targeted irregular deformation modes, the approaches in the literature show great diversity. Methods are systematized and tabulated based on the nature of actuation. Electrically and mechanically actuated shape changing concepts are discussed individually for their significance, while systems actuated by heat, pressure, light and chemicals are condensed in a shared section presenting examples and main research trends. Besides scientific research results, this entry features examples of real-world applicability of shape changing materials, highlighting their industrial value.

2. Real-World Applicability

More advanced Ford Mustang models use an active damping (suspension) system instead of a traditional one. The non-conventional deformation occurs on the microscale, where magnetic particles align themselves in lines when exposed to a magnetic field. This increases the apparent viscosity of the fluid, leading to increased stiffness of the damper. The change in viscosity happens in a few hundredths of a second and is reversible just as quickly. This way the car can adjust the stiffness of its suspension according to different driving situations (e.g., cornering), which results in a smoother and more efficient ride [1].

NextGen Aeronautics developed an aircraft capable of significant in-plane wing morphing to adapt to different flight scenarios. Multiple linear actuators modify the shape of the flexible elastomeric wing skin to achieve the complex deformations, and wind tunnel and even flight tests proved the functionality and positive aerodynamic effect of the system [2].

Thermally actuated deployable structures, such as SMP based systems, are great alternatives to conventional, heavier solutions for space applications. NASA, for instance, developed a 35-meter diameter radar to monitor weather anomalies (e.g., hurricanes) from space, but deploying such a huge structure requires novel solutions, for instance combining shape memory and inflatable structures to deploy the space radar [3].

In 2018, the Fraunhofer Institute for Wind Energy Systems (IWES) started the testing of bend-twist coupled composite wind turbine blades. The 20-meter long smart rotor blades are designed to adapt to the changing environmental conditions (i.e., wind speed and direction). This example shows that the concept is already at the level of industrial application [4].

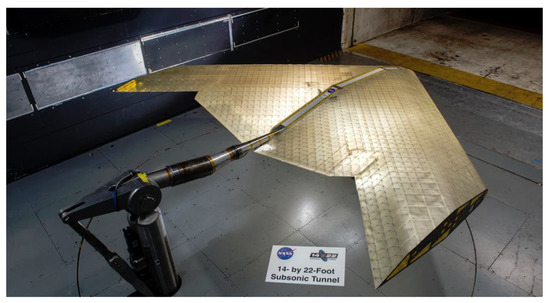

In 2019, MIT and NASA engineers developed a wing assembly capable of passive shape changes in response to changing flight conditions (i.e., mechanical loads). The researchers emphasized that the structure shows shape changes similar to what was already possible previously, but now morphing is passive. This means a smart structure that operates more efficiently under a variety of conditions than its conventional counterparts. The wing is an assembly of a large number of components of different stiffness forming a lightweight lattice framework covered by a polymeric skin. Due to the clever design of the structure, it behaves as a metamaterial on the structural level. It is both rubbery and stiff with extremely light weight and shape adaptation capabilities (Figure 1) [5].

Figure 1. Passively morphing aircraft capable of shape adaptation to different flight conditions [5]

Although numerous other examples could be presented here for the industrial application of morphing materials, the selected concepts sufficiently demonstrate that materials and structures with non-conventional shape changes offer advanced solutions even at the highest levels of engineering (e.g., aerospace). Also, it is important to identify the applicability of certain morphing concepts regarding the scale of the desired shape change. Usually, piezo-electric actuation is more suited for the micro applications, while motorized concepts can be used on the larger scales, for instance. Taking other considerations into account (e.g., static or dynamic actuation, actuation force, etc.) too, the optimal actuation concept is always dependent on the application scenario.

An extensive review on shape-changing materials can be found in the originally published review paper [6].

This entry is adapted from the peer-reviewed paper 10.3390/ma13061383

References

- Drummond, M. Magneride for Mustang. 2019. Available online: https://www.cjponyparts.com/resources/magneride-suspensions (accessed on 18/11/2019).

- Andersen, G.; Cowan, D.; Piatak, D. Aeroelastic modeling, analysis and testing of a morphing wing structure. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; p. 1734.

- Lin, J.; Dover Lp, I.; Fang, H.; Im, E.; Quijano, U. Concept study of a 35-m spherical reflector system for NEXRAD in space application. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006; Volume 1.

- Richard, C. “Bend-Twist Coupling” Tests Begin. 2018. Available online: https://www.windpowermonthly.com/article/1520855/bend-twist-coupling-tests-begin (accessed on 20/10/2019).

- Chandler, D.L. MIT and NASA Engineers Demonstrate a New Kind of Airplane Wing. 2019. Available online: http://news.mit.edu/2019/engineers-demonstrate-lighter-flexible-airplane-wing-0401 (accessed on 13/11/2019).

- Vermes, B.; Czigany, T. Non-conventional deformations: materials and actuation. Materials. 2020, 13, 1383.