The respiratory protective devices (RPD) can protect workers only if their protective properties are adequate to the conditions in the workplace. Therefore, specialists have developed criteria for the selection of proper, adequate respirators, including the Assigned Protection Factors (APF) - the decrease of the concentration of harmful substances in the inhaled air, which (is expected) to be provided with timely and proper use of a certified respirator of certain types (design) by taught and trained workers (after individual selection with a tight-fitting mask and fit testing), when the employer performs an effective respiratory protective device programme.

- protective device

- protective devices

- protective properties

1. Background

1.1. The Different Methods of Protection from Air Pollution and Their Effectiveness

The imperfection of technological processes, machines and other equipment can lead to air contamination with harmful substances in the workplace. Protecting of the workers' health in this situation may be achieved with different ways, listed below in order of decreasing of their effectiveness:

| Hierarchy of hazard control[1][2] | |

|---|---|

| 1. | The use of alternative substances which are less hazardous. |

| 2. | The substitution of a given substance in a form that is less hazardous, e.g. replacing a fine powder by a coarser powder, pellets, or by a solution |

| 3. | The substitution of a process by an alternative process likely to generate lower airborne concentrations of substances |

| 4. | Total or partially enclosed process and handling systems |

| 5. | Partial enclosure with local exhaust ventilation |

| 6. | Local exhaust ventilation |

| 7. | General ventilation |

| 8. | Reducing period of exposure |

| 9. | The introduction of appropriate working practices and systems of work, e.g. to close and store containers securely when not in use |

| 10. | Use of monitors and warning devices to give a clear indication when unsafe airborne concentrations are present |

| 11. | Good housekeeping |

| 12. | Provision of a respiratory protective device programme |

If the use of these methods is impossible, or if their use did not reduce the concentration of harmful substances to a safe value, workers must use respirators. These respirators must be sufficiently effective, and they should correspond to known or expected conditions at the workplace. However, it is the least effective method of protection; and the reasons for the decrease of their efficiency often are: non-usage of the respirators in the contaminated atmosphere; leakage of unfiltered air through the gaps between the mask and face; and delayed replacement of gas cartridges.

1.2. The Effectiveness of Respirators with Different Designs

Different terms may be used to describe the protective properties of respirators:

- Penetration = (the concentration of harmful substances under mask) / (concentration outside the mask);

- Efficiency = ( (concentration outside the mask) - (the concentration of harmful substances under mask) ) / (concentration outside the mask) = 1 - Penetration;

- Protection Factor (PF) = (the concentration of harmful substances on the outside of the mask) / (concentration under mask) = 1 / Penetration.

The term "Protection Factor PF" has been used in the U.S., and the term "Penetration" was used in the soviet literature from the 1960s.

In the first half of the 20th century, experts carried out measurements protective properties of respirators in the laboratories. They used different control substances (argon,[3] halogenated hydrocarbon vapour,[4] aerosols of sodium chloride and oil mist,[5] fluorophores,[6] dioctyl phthalate,[7][8] and others, and they measured their concentrations under the mask, and outside masks (simultaneously). The ratio of the measured concentrations is an indicator of the protective properties of different types of respirators. These measurements showed that if the efficiency of filters is enough high, then the gaps between the mask and the face become the main way of penetration of air contaminations under the mask.

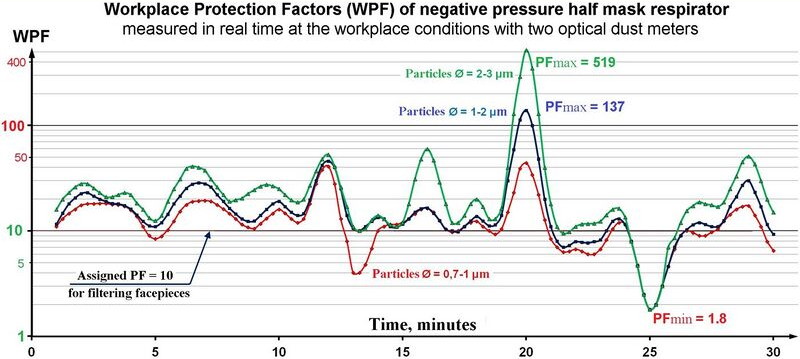

The shape and size of these gaps is not constant, and depends on many factors (the degree of fit the mask to the face - by shape and size; the correct donning the mask; the mask slippage on the face during the work due to execution of different movements; the design of the mask). The respirator's PF may change dozens of times during of several minutes; and the two average PF (that were measured for the same worker in one day; for example - before and after the lunch break) can differ by more than 12 000 times.[10]

Experts believed that the measurement of protection factors in the laboratory allows them to correctly evaluate, predict the RPD efficiency in the workplace conditions. But after the detection of cases of excessive harmful exposure on employees who used high quality respirators with HEPA particle filters in the nuclear industry of the USA, the experts changed their opinion.[11] Studies have been carried out to measure the protection factors for the various types of respirators - not only in the laboratories, but also at the workplaces.[12] Dozens of such field studies have shown that the performance of serviceable respiratory protective equipment at the workplaces may be significantly less than in laboratory conditions. Therefore, the usage of laboratory results to assess the real efficiency is incorrect; and can lead to a wrong choice of such respirators that can not reliably protect workers.

1.3. Terminology to Describe the Different PF, and Methods for APF Development

The experts used the results of measurements at the laboratories and at the workplaces to develop more completely terminology for description of the respirators' performance;[13][14][15][16] and this terminology has been applied officially,[17] and in the preparation of research results for publication.[18] Specialists began to use different terms to describe the protection factors, which were measured at workplaces with continuous use of respirators; and measured in the workplace when the workers used of respirators intermittently; measured not in the workplace while fit testing; measured in the laboratories under the simulation workplace's conditions; and for the protection factors, that can be expected (in most cases) when the workers properly used the respirators at the workplace.

| The modern terminology for RPD performance description (pp. 22–26[17]) | |

|---|---|

| Protection Factor | A description of the term |

| Assigned Protection Factor (APF) | The minimum anticipated protection provided by a properly functioning respirator or class of respirators to a given percentage of properly fitted and trained users. |

| Fit Factor | A quantitative measure of the fit of a specific respirator facepiece to a particular individual (FF are measured during fit test). |

| Simulated Workplace Protection Factor (SWPF) | A surrogate measure of the workplace protection provided by a respirator (SWPF are measured in laboratory conditions, that imitate real workplace conditions during "work") |

| Workplace Protection Factor (WPF) | A measure of the protection provided in the workplace only while the respirator was properly worn and used during normal work activities (WPF are measured at the workplaces, after fit testing; and without mask doffing during measurement). |

A significant difference between respirator performance in the laboratories compared to the efficiency at the workplaces not allowed to use the laboratory results to predict the degree of protection offered in practice. And instability of respirators' protective properties (for the same RPD design, and in the same usage conditions) prevented evaluate their efficiency. For solving these problems, scientists Donald Campbell and Steven Lenhart suggested to use the results of measurements of Workplace PF values for development of Assigned (expected in practice) PF values (APF) - as the lower 95% confidence interval of WPF values.[19] The results of measurements of WPF has been used in the development of APF by ANSI (for the recommended standard, that is not mandatory).[20] The same was made during the development of the APF[21] by OSHA (in the development of the standard,[22] that is mandatory for the employer).

1.4. Development of APF Values for the Various Respirator Types

Results of measurements of WPF in the US and the UK became the basis for the development of APF for UK standard[1] and for English version of EU standard.[2] In some cases, there was no information on the effectiveness for respirators of specific design (type) in the workplace. This is due to the fact that the measurement of workplace PF is very difficult, time consuming, and expensive work, which was carried out not very often. For these types of respirators experts used the results of WPF measurements of other types of respirators, which are similar. For example, the effectiveness of the Supplied Air Respirators (SARs, with hose) was considered similar to the efficiency of Powered Air Purifying Respirators (PAPRs), if they have the same facepieces and the same air supply mode. Finally, in the absence of this information, specialists could use the results of Simulated WPF measurements; or estimates of competent experts.[20]

2. Correction of Assigned PF Values

Measurement of workplace protection factors surprisingly revealed the low efficiency of some designs of respirators, and that results have led to a sharp tightening of the requirements for application limits for respirators of such designs.

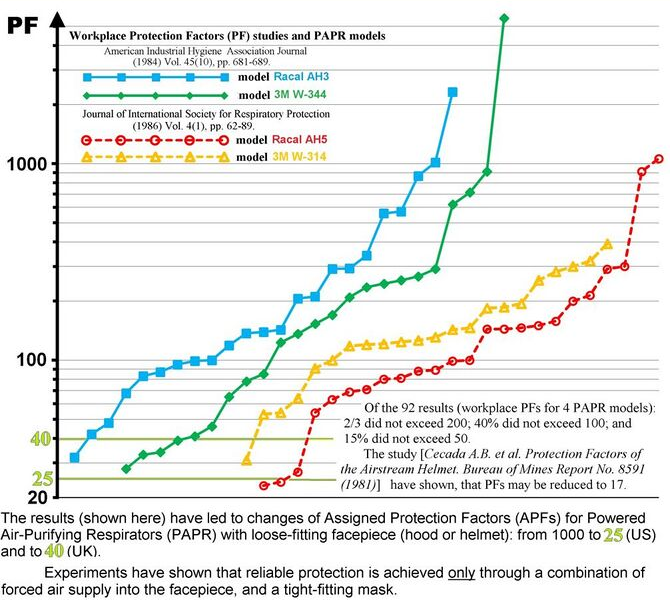

- PAPR with helmets or hoods

Measuring WPF of Powered Air Purifying Respirators (PAPR) with helmets (that is not tight-fitted to the face) showed that the ingress of harmful substances in the inhaled air can be very high[23] (PF = 28 and 42 for two models). It was a surprise, since earlier studies in the laboratory showed that the flow of clean filtered air from the inside to the outside of the helmet prevents ingress of harmful substances under the helmet (PF > 1000). Additional studies[24] have confirmed the result of the first study: the minimum values of the workplace protection factors of 2 models of respirators were 31 and 23; and leakage of unfiltered air achieved 16% in some cases in wind tunnel at 2 m/s air velocity[25]

Therefore, the use of such RPD types was limited 25 PEL in the U.S.,[22] and 40 OEL in the UK.[1][2]

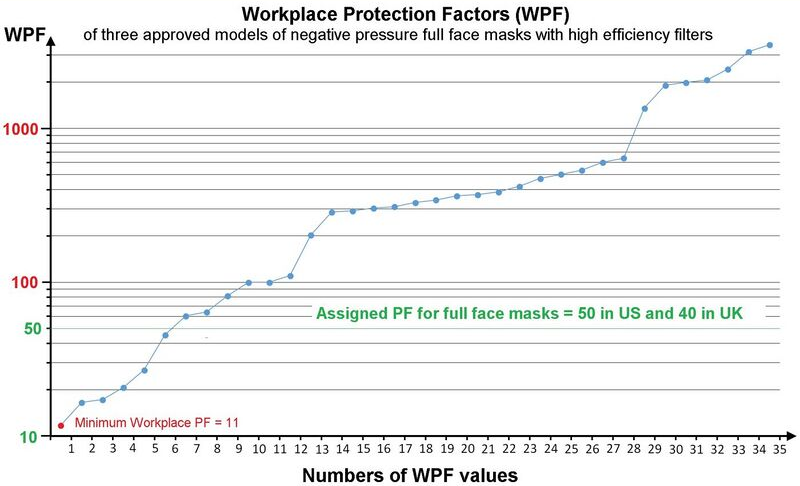

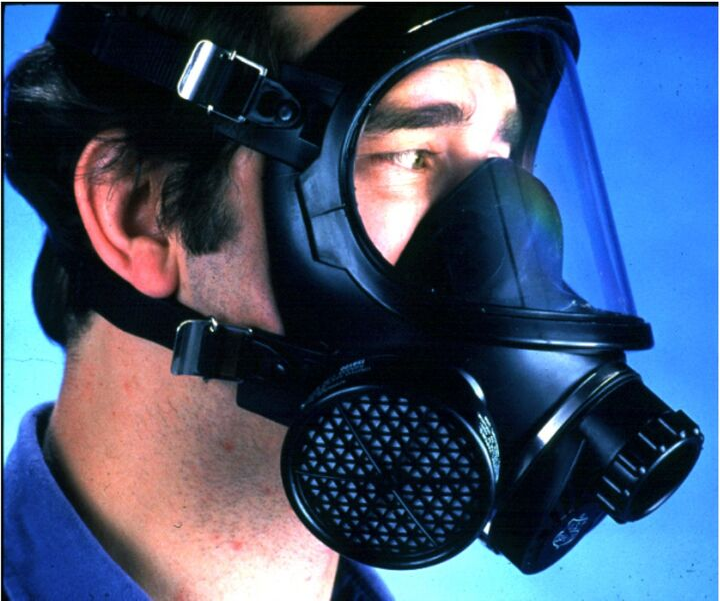

- Negative pressure full face masks.

Measurement of protection factors of negative pressure full face masks with high-efficiency filters in the laboratory revealed a risk of decrease in protective properties to a small values.[27] Therefore, the use of such respirators has been limited to the values 50 or 100 PEL in the United States. However, the experts in the UK believed that the quality of their masks is higher than American masks, and were allowed to use up to 900 OEL. But the study[26] showed that the value of the protection factor of > 900 has been achieved in practice infrequently. Minimum protection factors of 3 different models of full facepiece respirators were 11, 18 and 26. So, the new standards[1][2] limit usage of these respirators up to 40 OEL in UK (after this study).

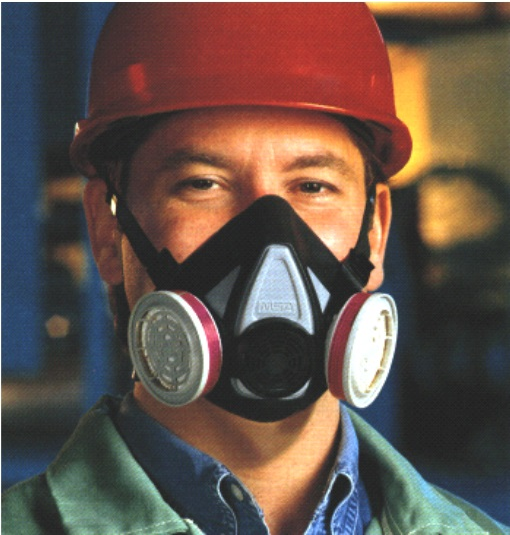

- Negative pressure half mask respirators (after fit testing)

Fit testing of tight-fitting masks of negative-pressure respirators became widely used in US industry in 1980-s. At the beginning, it was thought that the half-mask fit quite well to the worker's face, if during a fit test the protection factor (fit factor) is not less than 10 (later, experts began to use "safety factor" = 10 during the fit test; threshold fit factor become 10 × 10 = 100). The widespread use of fit testing in the industry gives professionals optimism, and they allowed to the employers restrict the use of half mask respirators in accordance with the values of worker's personal fit factor (the maximum concentration of pollutants = personal Fit Factor × PEL), but not more than 100 × PEL. However, scientific studies have shown that although such test increases the effectiveness of protection, the risk of leakage of large amounts of unfiltered air is maintained. Furthermore, the studies have shown that non-filtered air under the mask is not uniformly mixed with the filtered air, which leads to large errors in the measurement of the in-facepiece concentration of contaminants, and subsequent calculations of fit factors - the latter is often much smaller than the "measured" value. So, specialists recommend not allowed usage negative pressure half mask respirators then harmful substances' concentrations exceeds 10 PEL.[28] Therefore, OSHA standards require to restrict using of half-mask negative-pressure respirators up to 10 PEL after obtaining fit factor greater than or equal to 100 during the mask selection for the worker (they used a safety factor = 10).

3. Comparison of APF in the US and the UK

The table lists the APF values for the most common respirator types (for US and UK).

| The Assigned Protection Factors for some main (equivalent) RPD types (developed on the basis of results of Workplace Protection Factors studies) | |||

|---|---|---|---|

| RPD type in US | APF in US[22] | RPD type in UK | APF in UK[1][2] |

| N95 negative pressure air-purifying half mask respirators

(filtering facepieces or elastomeric) |

10 | FFP2 filtering facepieces or elastomeric half masks with P2 filters | 10 |

| N99 or N100 negative pressure air-purifying half mask respirators

(filtering facepieces or elastomeric) |

10 | FFP3 filtering facepieces or elastomeric half masks with P3 filters | 20 |

| Negative pressure air-purifying respirators with full facepieces with P100 filters | 50 | Negative pressure air-purifying respirators with full facepieces with P3 filters | 40 |

| Powered Air-Purifying Respirators (PAPRs) with loose-fitting hood or helmet, and P100 filters | 25 | PAPRs with loose-fitting hood or helmet, and P3 filters | 40 |

| Supplied Air Respirators (SARs) or Self Contained Breathing Apparatus (SCBA) with full mask and air supply on demand | 50 | SARs or SCBAs with full face mask and negative pressure demand air supply | 40 |

| SARs with full mask and pressure demand air supply | 1 000 | SARs with full face mask and positive pressure demand air supply | 2 000 |

| SCBAs with full mask and pressure demand air supply | 10 000 | SCBAs with full face mask and positive pressure demand air supply | 2 000 |

US particle filters N95 are similar to P2; and P100 (HEPA) are similar to P3; filtering materials in US N95 filtering facepieces are similar to FFP2.

The difference of the APF for air purifying negative pressure full-facepiece masks are not large. The difference between PAPR with helmets a few more. But measurements showed that the real effectiveness of RPD (at the workplace conditions) is strongly dependent on the conditions of their use, not only from the design, and this partly explains the difference in APF values. The APF for negative pressure half mask respirators are twofold. But this difference cannot be considered separately from recommendations for use of respirators. The use of half-face masks in the US is limited to 10 PEL for the "worst case" - work in the polluted atmosphere of 8 hours per day, 40 hours a week. But British experts took into account large experience of the use of negative pressure air purifying RPDs, and they concluded that to achieve continuous wear respirator 8 hours a day is impossible (because of the negative impact on the health of workers). For this reason, they recommend to the employer to give the job to the workers so that they work in the polluted atmosphere not during entire shift, but only a part of the shift. The remaining time the employee needs to work in a non-polluted atmosphere (without the respirator). The fact that the employee is in a non-polluted atmosphere some part of working time provide additional protection of his health, and therefore, the requirements to the efficiency of the respirator may be less stringent.

The development of the Assigned PF in the United States and Britain were based on measurements of the effectiveness of respirators in the workplace (after statistical processing). Also used opinions of experts, based on the similarity of the respirators with different designs (for example, powered air purifying filtering respirators (PAPR), and a similar supplied air respirators SAR) - provided that the mode and the quantity of air supply, and the facepieces (masks) were the same. Experts in the two countries often used the results of the same studies of WPF (because of their limited number). For example, British standard[1] had been developed with usage of results of 1897 WPF measurements during 31 studies; and 23 of this 31 studies had been conducted in United States.

Therefore, the values of the assigned PF in the US and in the UK are evidence-based; and they are very similar to each other.

4. The Values of the APF in EU and Other Countries

Studies of respirator's performance was carried out not very often, and almost all of these studies were conducted in USA (and UK). It is possible that the lack of information about the RPD efficiency in the workplaces, was the reason behind developing these assigned PF in several European countries, whose values differ significantly from the evidence-based values of APFs in the US and UK.

| The Assigned Protection Factors for some main RPD types, developed in several EU countries[2] | ||||

|---|---|---|---|---|

| RPD type | APF in several EU countries | |||

| Finland | Germany | Italy | Sweden | |

| FFP2 filtering facepices | 10 | 10 | 10 | 10 |

| Elastomeric half masks with P2 filters | 10 | 10 | 10 | 10 |

| FFP3 filtering facepices | 20 | 30 | 30 | 20 |

| Elastomeric half masks with P3 filters | - | 30 | 30 | - |

| Negative pressure air-purifying respirators with full face mask and P2 filters | 15 | 15 | 15 | 15 |

| Negative pressure air-purifying respirators with full face mask and P3 filters | 500 | 400 | 400 | 500 |

| Powered Air-Purifying Respirators (PAPRs) with loose-fitting hood or helmet, and THP3 filters | 200 | 100 | 200 | 200 |

| PAPRs with full face mask, and TMP3 filters | 1000 | 500 | 400 | 1000 |

| SARs with full facepiece and negative pressure demand air supply | 500 | 1000 | 400 | 500 |

| Supplied Air Respirators (SARs) with full facepiece and positive pressure demand air supply | 1000 | 1000 | 400 | 1000 |

| SCBAs with full facepiece and positive pressure demand air supply | - | ≥ 1000 | 1000 | - |

Most European countries (except UK) did not conduct very complex and expensive studies on the effectiveness of respirators in the workplaces, or spent very little of such research. Therefore, it may be that some countries do not take full account of results of foreign researches (that showed a significant difference between the effectiveness of respirators in a laboratory environment; and in applying them in the workplaces). For example, after the study[26] in 1990, the APF value of negative pressure full face masks was reduced from 900 to 40 (1997)[1] in UK. But in other countries, similar research was not carried out; and a similar decrease did not occur.

The study[26] showed that the three models of full face masks had a significant leakage of unfiltered air through the gaps between the mask and the face. The minimum values of the workplace protection factors (WPF) of each of the three negative pressure full face mask models were 11, 17 and 26. The maximum value of the WPF from one of the models did not exceed 500 no times at all. And for all results together, the WPF was not more than 100 in ~ 30% of the measurements. So, for this reason, the values of the APFs for this RPD type in Germany (400), Finland (500), Italy (400), and Sweden (500), may not fully take into account the lower this type respirators' performance at the workplace compared to the performance in the laboratory (during certification). The same was true for other RPD types and their APF.

State standard in India [29] points to the need to use the workplace protection factors for restricting the permissible use of respirators, but does not set any values of the APFs. The standard also recommends the use of those PFs, which are obtained during the certification (in the laboratories, but not at workplaces). These values greatly exceed the values used in the USA and in the UK.

The Ukraine version of the EU standard EN 529 does not set any values of the APFs for the selection of respirator in this country.[30] This document only listed the values of APFs in several European countries (for reference); and declares the inadmissibility of the use of laboratory efficiency for predicting the protective properties at the workplace.

The APFs are not developed in Russia ,[31] in South Korea , as well as in many other countries, and selection of respirators is not regulated by its national legislation. This contributes to errors, and the usage of such respirator's types, which are not able to reliably protect the workers due to its design (even at high quality of specific certified models).

| The Assigned Protection Factors1 for different RPD types in several countries | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Facepiece type

по лицевой части |

Country | Minimum values,

measured at the workplaces4 |

|||||||||

| USA[32] | United Kingdom[33] | Australia[34] | Canada[35] | China[36] | Japan[37] | South Korea2[38] | France3 | Germany3[39] | RF2[31] | ||

| Negative pressure respirators (without forsed air supply into the mask) | |||||||||||

| Half mask | 10 | 20 | 10 | 10 | 10 | 10 | 10 | 20 | 30 | 50 | 2,3;[40] 2,5[41] ... |

| Full face mask | 50 | 40 | 100 | 100 | 100 | 50 | 100 | 40 | 400 | 2 000 | 11; 17 ...[42] |

| Powered air purifying respirators (with forsed air supply into the facepiece) | |||||||||||

| Half mask | 50 | 40 | - | 50 | 50 | 50 | 50 | 40 | 500 | 16; 19 ...[43] | |

| Full face mask | 1000 | 40 | >100 | 1000 | 1000 | 100 | 200 | 40 | 500 | 5; 12 ...[44] | |

| Hood or helmet | 25/10004 | 40 | >100 | 1000 | 25/1000 | 25 | 200 | 40 | 100 | 23; 24 ...[45] | |

| Supplied air respirators (with forsed air supply into the facepiece) | |||||||||||

| Half mask | 1000 | - | 50 | 50 | 50 | 50 | 50 | 200 | 100 | - | |

| Full face mask | 2 000 | 2 000 | >100 | 1000 | 1000 | 1000 | 1000 | ~ 250 | 1000 | - | |

| Hood or helmet | 25/10005 | 40 | >100 | 1000 | 25/1000 | 25 | 1000 | 100 | - | - | |

| Self-contained breathing apparatus

with full facepiece mask |

10 000 | 2 000 | >100 | >1000 | >1000 | 5 000 | 2 000 | Maximum | >1000 | - | |

| 1 - The APF values in the table are the maximum values for the selected RPD type, that is:

1.1. The air purifuing respirators (negative pressure; and powered PAPR) - with high efficiency filters (>99.95%); 1.2. The supplied air respirators - with positive pressure demand air supply to the masks; and with continuous flow air supply to the helmets or hoods. 2 The APF for South Korea and RF are not mandatory, but recommended values only. 3 - There is no information that would show that the values of these APFs were developed so that the difference in efficiency at the workplaces and in the laboratories is taken into account to the full extent (as in the US and UK). 4 - For reference: there are the minimum values of the protection factors, measured in the workplace during work in the last column of the table. 5 - APF = 25 for all approved PAPR; and APF = 1000 only for those approved respirators, that have been further tested in the workplace and there have shown high performance (WPF > 1000). |

|||||||||||

5. The Use of the APFs When Selecting Respirators for Known Workplace Conditions

US law obliges the employer to accurately measure air pollution at workplaces. The results of such measurements are used to assess whether short-term inhalation of harmful substances may lead to irreversible and significant deterioration of health, or death (IDLH concentrations). If concentrations exceed the IDLH, the standard allows the use of only the most reliable respirators - SAR or self-contained breathing apparatus: with pressure-demand air supply in the full facepiece mask ( §(d)(2)[22]).

If the concentration of a harmful substance is less than the IDLH, the coefficient of air pollution for the harmful substance (Hazard Factor) is determined, which is equal to the ratio of this concentration to the PEL (TLV, OEL) for the harmful substance. The APF of the selected respirator type must equal or exceed the Hazard Factor.[17][46]

If there are several harmful substances in the workplace air, then the selected respirator must meet the following requirement:[17]

C1/(APF×PEL1) + C2/(APF×PEL2 ) + C3/(APF×PEL3 ) + ... + Cn/(APF×PELn) ≤ 1

where C1, C2 ... and Cn are the concentrations of harmful substances number 1, 2 ... n; and PEL is the maximum allowable concentration for corresponding harmful substances in the breathing zone.

If this requirement is not met, the employer needs to choose a different type of respirator, which has a greater APF value.

In all cases, if they employer selects a respirator with tight-fitting facepiece (full face mask, elastomeric half-mask or quarter-mask, or filtering facepiece respirator), all employee must be fit tested (to prevent the leakage of unfiltered polluted air through gaps between their faces and the tight-fitting masks, which may not match to their faces). Appendix A[22] provides a detailed description of this testing.

Values of IDLH concentrations and detailed recommendations for the selection of respirators (and self-rescuers) are available in the NIOSH directory.[47]

6. International Standard for RPD Selection and Usage

ISO is developing two international standards that govern the certification of respirators;[48] and their selection and application[49][50]

The standards governing the selection of respirators use the APF value. But HSE specialists critique these documents[51], noting these standards are set to values of APF that differ from those established in the US and the UK; and these values are set not for a specific RPD type but rather for any RPD that meets approval requirements:

| New ISO RPD classification and APF | ||

|---|---|---|

| ISO RPD type | ISO requirements for approval[52] | Protection level |

| PC6 | TIL < 0.001% | 10 000 |

| PC5 | TIL < 0.01% | 2000 |

| PC4 | TIL < 0.1% | 250 |

| PC3 | TIL < 1% | 30 |

| PC2 | TIL < 5% | 10 |

| PC1 | TIL < 20% | 4 |

The report concluded that new ISO standards set insufficiently high APF values and recommended that these values should not be used in practice, and to continue work on APF justification for the different types of respirators.

The content is sourced from: https://handwiki.org/wiki/Engineering:Respirator_assigned_protection_factors

References

- Technical Committee PH/4, Respiratory protection, ed (1997). "4 Overall protective programme" (in en). British Standard BS 4275:1997 "Guide to implementing an effective respiratory protective device programme" (3 ed.). 389 Chiswick High Road, London: British Standards Institution. p. 3. ISBN 0-580-28915 X.

- European Committee for Standardization (2005). "6 Verfahren zur Gefährdungsbeurteilung". in Technischen Komitee CEN/TC 79 "Respiratory protective devices" (in de). DIN EN 529:2006 "Atemschutzgeräte - Empfehlungen für Auswahl, Einsatz, Pflege und Instandhaltung - Leitfaden" (Deutsche Fassung EN 529:2005 ed.). Brüssel, rue de Stassart, 36: Deutsche Gremium ist NA 027-02-04 AA «Atemgeräte für Arbeit und Rettung» im Normenausschuss Feinmechanik und Optik (NAFuO). p. 50.

- Griffin, G. and D.J. Longson (1970). "The Hasard Due Inward Leakage of Gas into a Full Face Mask" (in en). The Annals of Occupational Hygiene 13 (2): 147–151. doi:10.1093/annhyg/13.2.147. ISSN 0003-4878. PMID 5431896. http://annhyg.oxfordjournals.org/content/13/2.toc.

- Hounam, R. F., D. J. Morgan, D. T. O'Connor and R. J. Sherwood (1964). "The Evaluation of Protection Provided by Respirators" (in en). The Annals of Occupational Hygiene 7 (4): 353–363. doi:10.1093/annhyg/7.4.353. ISSN 0003-4878. PMID 14266238. http://annhyg.oxfordjournals.org/content/7/4.toc.

- Gorodinski, Semyon (1979). "Chapter 4. Methods for PPE performance measurement" (in ru). Personal protective equipment from radioactive substances (3rd edition, updated and expanded ed.). Moscow: The state Committee of the USSR Council of Ministers on the use of atomic energy, "Атомиздат" publ.. pp. 106–112.

- Burgess, William, Leslie Silverman S.D. & Felix Stein S.B. (1961). "A New Technique for Evaluating Respirator Performance" (in en). American Industrial Hygiene Association Journal 22 (6): 422–429. doi:10.1080/00028896109343432. ISSN 0002-8894. PMID 13874833. http://www.tandfonline.com/toc/aiha20/22/6.

- Bureau of Mines (1965) (in en). Respiratory Protective Devices - Tests for Permissibility; Fees: Schedule 21B, Filter-Type Dust, Fume, and Mist Respirators. Code of Federal Regulations Ref. 30 CFR Part 14, Jan. 19, 1965; amended March 23, 1965, and June 12, 1969..

- Hyatt, E. C., J. A. Pritchard & C.P. Richards (1972). "Respirator Efficiency Measurement Using Quantitative DOP Man Tests" (in en). American Industrial Hygiene Association Journal 33 (10): 635–643. doi:10.1080/0002889728506721. ISSN 0002-8894. PMID 4512979. http://www.tandfonline.com/toc/aiha20/33/10.

- Lee, Shu-An, Sergey Grinshpun (2005). "Laboratory and Field Evaluation of a New Personal Sampling System for Assessing the Protection Provided by the N95 Filtering Facepiece Respirators against Particles" (in en). The Annals of Occupational Hygiene 49 (3): 245–257. doi:10.1093/annhyg/meh097. ISSN 0003-4878. PMID 15668259. https://dx.doi.org/10.1093%2Fannhyg%2Fmeh097

- Zhuang, Ziqing; Christopher C. Coffey; Paul A. Jensen; Donald L. Campbell; Robert B. Lawrence; Warren R. Myers (2003). "Correlation Between Quantitative Fit Factors and Workplace Protection Factors Measured in Actual Workplace Environments at a Steel Foundry" (in en). American Industrial Hygiene Association Journal 64 (6): 730–738. doi:10.1080/15428110308984867. ISSN 1542-8117. http://www.tandfonline.com/toc/uaih20/64/6.

- Cralley, Lewis et al. (1985) (in en). Patty's Industrial Hygiene and Toxicology. 3A (2 ed.). London: Willey-Interscience. pp. 677–678. ISBN 0 471-86137-5.

- Kirillov, Vladimir (2014). "Overview of Industrial Testing Outcome of Respiratory Organs Personal Protection Equipment" (in English, Russian). Toxicological Review 6 (129): 44–49. doi:10.17686/sced_rusnauka_2014-1034. ISSN 0869-7922. http://en.toxreview.ru/magazine/?c4a=20140600.

- Hack, Alan; Fairchild, Chack; Scaggs, Barbara (1982). "the forum..." (in en). American Industrial Hygiene Association Journal 43 (12): A14. ISSN 1542-8117. http://www.worldcat.org/issn/1542-8117

- Dupraz, Carol (1983). "The Forum" (in en). American Industrial Hygiene Association Journal 44 (3): B24–B25. ISSN 1542-8117. http://www.worldcat.org/issn/1542-8117

- Myers, Warren; Lenhart, Steven; Campbell, Donald; Provost, Glendel (1983). "The Forum" (in en). American Industrial Hygiene Association Journal 44 (3): B25–B26. ISSN 1542-8117. http://www.worldcat.org/issn/1542-8117

- Guy, Harry (1985). "Respirator Performance Terminology)" (in en). American Industrial Hygiene Association Journal 46 (5): В22, B24. ISSN 1542-8117. http://www.worldcat.org/issn/1542-8117

- Bollinger, Nancy; Campbell, Donald; Coffey, Christopher (2004). "III. Respirator Selection Logic Sequence" (in en). NIOSH Respirator Selection Logic. DHHS (NIOSH) Publication No. 2005-100. NIOSH Respirator Policy Group; Heinz Ahlers, Roland BerryAnn, Frank Hearl, Richard Metzler, Teresa Seitz, Douglas Trout and Ralph Zumwalde. Cincinnati, OH: The National Institute for Occupational Safety and Health (NIOSH). p. 39. https://www.cdc.gov/niosh/docs/2005-100/.

- Dupraz, Carol (1986). "Letter to the Editor" (in en). American Industrial Hygiene Association Journal 47 (1): A12. ISSN 1542-8117. http://www.worldcat.org/issn/1542-8117

- Lenhart, Steeven; Donald L. Campbell (1984). "Assigned protection factors for two respirators types based upon workplace performance testing" (in en). The Annals of Occupational Hygiene 28 (2): 173–182. doi:10.1093/annhyg/28.2.173. ISSN 1475-3162. http://annhyg.oxfordjournals.org/content/28/2/.

- Nelson, Thomas (1996). "The Assigned Protection Factor According to ANSI" (in en). American Industrial Hygiene Association Journal 57 (8): 735–740. doi:10.1080/15428119691014594. ISSN 1542-8117. PMID 8765202. http://www.tandfonline.com/toc/aiha20/57/8.

- Federal Register vol. 68, No 109 / Friday, June 6, 2003 pp. 34036-34119 Assigned Protection Factors https://www.osha.gov/FedReg_osha_pdf/FED20030606.pdf

- OSHA standard 29 CFR 1910.134 "Respiratory Protection" http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=12716

- Myers, Warren; M.J. Peach; K. Cutright; W. Iskander (1984). "Workplace Protection Factor Measurements on Powered Air-Purifying Respirators at a Secondary Lead Smelter: Results and Discussion" (in en). American Industrial Hygiene Association Journal 45 (10): 681–688. doi:10.1080/15298668491400449. ISSN 1542-8117. PMID 6496315. https://dx.doi.org/10.1080%2F15298668491400449

- Myers, Warren; Michael J. Peach III; K. Cutright; W. Iskander (1986). "Field Test of Powered Air-Purifying Respirators at a Battery Manufacturing Facility" (in en). Journal of the International Society for Respiratory Protection 4 (1): 62–89. ISSN 0892-6298. http://www.isrp.com.

- Cecala, Andrew B.; Volkwein, Jon C.; Thomas, Edward D.; Charles W. Urban (1981) (in en). Protection Factors of the Airstream Helmet. Bureau of Mines Report No. 8591. p. 10.

- Tannahill, S.N.; R.J. Willey; M.H. Jackson (1990). "Workplace Protection Factors of HSE Approved Negative Pressure Full-Facepiece Dust Respirators During Asbestos Stripping: Preliminary Findings" (in en). The Annals of Occupational Hygiene 34 (6): 541–552. doi:10.1093/annhyg/34.6.547. ISSN 1475-3162. http://annhyg.oxfordjournals.org/content/34/6/.

- Hyatt, E.C. (1976) (in en). Respirator Protection Factors. Report No. LA-6084-MS. Los Alamos: Los Alamos Scientific Laboratory.

- "Critical Issues Conference On In-Facepiece Sampling" (in en). Journal of the International Society for Respiratory Protection 6 (1): 25. 1988. ISSN 0892-6298. http://www.isrp.com.

- IS 9623:2008 Recommendations for the selection, use and maintenance of respiratory protective devices https://upload.wikimedia.org/wikipedia/commons/3/38/%D0%93%D0%9E%D0%A1%D0%A2_%D0%98%D0%BD%D0%B4%D0%B8%D0%B8_%D0%92%D1%8B%D0%B1%D0%BE%D1%80_%D0%B8_%D0%BE%D1%80%D0%B3%D0%B0%D0%BD%D0%B8%D0%B7%D0%B0%D1%86%D0%B8%D1%8F_%D0%BF%D1%80%D0%B8%D0%BC%D0%B5%D0%BD%D0%B5%D0%BD%D0%B8%D1%8F_%D0%A1%D0%98%D0%97%D0%9E%D0%94_is.9623.2008.pdf

- Ukrainian state standard (national version EN 529) ДСТУ EN 529:2006. Засоби індивідуального захисту органів дихання. Рекомендації щодо вибору, використання, догляду і обслуговування. Настанова (EN 529:2005, IDT) (Respiratory protective devices. Recommendations for selection, use and maintenance. - in Ukrainian).

- RF state standard ГОСТ Р 12.4.279-2012 СИЗОД. Рекомендации по выбору, применению и техническому обслуживанию. (RPD selection, use and maintenance - in Russian) had no one APF value et all; but the authors of this document (which has been developed by RPD manufacturer and seller - corporation "ROSKHIMZASCHITA" / "Russian Chemical Protection" ), declare the document as a "national version of the EU standard EN 529". And this standard is non-mandatory for employers. http://protect.gost.ru/document.aspx?control=7&id=183450

- "1910.134(d)(3)(i)(A) Assigned Protection Factors (APFs)" (in en). OSHA Standard: 29 Code of Federal Register 1910.134 "Respiratory Protection". Personal Protective Equipment. Occupational Safety and Health Administration (OSHA). 2011. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=12716. Retrieved 4 June 2018.

- BSI PH/4 Committee (2005). "Appendix C. Protection Factors." (in en). BS EN 529:2005 Respiratory protective devices. Recommendations for selection, use, care and maintenance. Guidance document. London: British Standards Institution (BSI). ISBN 978-0-580-46908-4. https://shop.bsigroup.com/ProductDetail?pid=000000000030100880.

- Joint Technical Committee SF-010, Occupational Respiratory Protection (2009). "Section 4. Selection of RPE" (in en). Australian/New Zealand Standard AS/NZS 1715:2009 Selection, use and maintenance of respiratory protective equipment (5 ed.). Sydney (Australia) - Wellington (New Zealand): Standards Australia. p. 28. ISBN 978-0-7337-9000-3.

- Canadian Standards Association (2011) (in en). CAN/CSA-Z94.4-11 Selection, use, and care of respirators (4 ed.). Mississauga (Ontario, Canada). https://www.scc.ca/en/standardsdb/standards/26100.

- National Personal Protective Equipment Standardization Technical Committee, 3M China Ltd. (2002). Yao, Hong (姚红); She, Qiyuan (佘启元); Ding, Songtao (丁松涛) et al.. eds (in zh). p. 6.

- Japanese Standards Association (2006). "Appendix 1. RPD selection" (in ja). Tokyo: JSA. p. 14. http://kikakurui.com. Retrieved 3 June 2018.

- Korea Occupational Safety and Health Agency (KOSHA) (2012) (in ko). Ulsan: Korea Occupational Safety and Health Agency. p. 21.

- CEN/TC 79 - Atemschutzgeräte (2005). "Protection Factors [Anhang C. Schutzfactoren. C.2 Gebrauch von Schutzfaktoren]" (in de). DIN EN 529:2006-01 Selection, use and maintenance of respiratory protective devices [Atemschutzgeräte - Empfehlungen für Auswahl, Einsatz, Pflege und Instandhaltung - Leitfaden]. Leitfaden: Gremium NA 027-02-04 AA “Atemgeräte für Arbeit und Rettung”. pp. 35–36.

- Wallis G., Menke R., Chelton C. (1993). AIHA & ACGIH. ed. "Workplace field testing of a disposable negative pressure half-mask dust respirator (3M 8710)" (in en). American Industrial Hygiene Association Journal 54 (10): 576–583. doi:10.1080/15298669391355080. https://dx.doi.org/10.1080%2F15298669391355080

- Myers W.R., Z. Zhuang, T. Nelson (1996). AIHA & ACGIH. ed. "Field Performance Measurements of Half-Facepiece Respirators—Foundry Operations" (in en). American Industrial Hygiene Association Journal 57 (2): 166–174. doi:10.1080/15428119691015106. PMID 8615325. https://dx.doi.org/10.1080%2F15428119691015106

- Tannahill S.N., R.J. Willey and M.H. Jackson (1990). The British Occupational Hygiene Society. ed. "Workplace Protection Factors of HSE Approved Negative Pressure Full-Facepiece Dust Respirators During Asbestos Stripping: Preliminary Findings" (in en). The Annals of Occupational Hygiene 34 (6): 541–552. doi:10.1093/annhyg/34.6.547. PMID 2291579. http://annhyg.oxfordjournals.org/content/34/6/.

- Myers W.R., M.J. Peach III (1983). The British Occupational Hygiene Society. ed. "Performance measurements on a powered air-purifying respirator made during actual field use in a silica bagging operation" (in en). The Annals of Occupational Hygiene 27 (3): 251–259. doi:10.1093/annhyg/27.3.251. PMID 6314865. http://annhyg.oxfordjournals.org/content/27/3/.

- Howie R.M., Johnstone J.B.G., Weston P., Aitken R.J. and Groat S. (1996). "Tables". Workplace effectiveness of respiratory protective equipment for asbestos removal work. HSE Contract research report No. 112/1996 (Institute of Occupational Medicine ed.). Edinburgh: Crown. pp. 73, 75, 77. ISBN 978-0-7176-1201-7. http://www.hse.gov.uk/research/crr_pdf/1996/crr96112.pdf.

- Myers W. R., Michael J. Peach III, K. Cutright and W. Iskander (1986). International Society for Respiratory Protection. ed. "Field Test of Powered Air-Purifying Respirators at a Battery Manufacturing Facility" (in en). Journal of the International Society for Respiratory Protection 4 (1): 62–89. ISSN 0892-6298. http://www.worldcat.org/issn/0892-6298

- Nancy J. Bollinger, Robert H. Schutz, ed (1987) (in en). NIOSH Guide to Industrial Respiratory Protection. DHHS (NIOSH) Publication No 87-116. Cincinnati, Ohio: National Institute for Occupational Safety and Health. p. 305. doi:10.26616/NIOSHPUB87116. https://www.cdc.gov/niosh/docs/87-116/.

- Michael E. Barsan (Technical Editor), ed (2007) (in en). NIOSH Pocket guide to chemical hazards. DHHS (NIOSH) Publication No. 2005-149 (3 ed.). Cincinnati, Ohio: National Institute for Occupational Safety and Health. p. 454. doi:10.26616/NIOSHPUB87108. https://www.cdc.gov/niosh/docs/87-108/. . New on-line version on NIOSH site (more detailed version).

- ISO 17420 Respiratory protective devices. Performance requirements.

- ISO/TS 16975-1 Respiratory protective devices. Selection, use and maintenance. Part 1: Establishing and implementing a respiratory protective device programme

- ISO/TS 16975-2:2016 Respiratory protective devices. Selection, use and maintenance. Part 2: Condensed guidance to establishing and implementing a respiratory protective device programme

- Clayton, Mike (2014) (in en). Validation of ISO Protection Levels: Initial Steps. (presentation on 17-th ISRP Biennial Conference). Prague. http://www.isrp.com.

- TIL, Total Inward Leakage (of air pollution from breathing zone to in-mask cavity) - the sum of its leakage through gaps betwing RPD mask and the face; and penetration through the air-purifying element.