Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

Production of cement and aggregate used in cement-based composites causes many environmental and energy problems. Decreasing the usage of cement and aggregate is a crucial and currently relevant challenge to provide sustainability. Inert materials can also be used instead of cement and aggregates, similar to pozzolanic materials, and they have positive effects on cement-based composites. One of the inert materials used in cement-based composites is wollastonite (calcium metasilicate-CaSiO3), which has been investigated and attracted attention of many researchers.

- wollastonite

- fibrous concrete

- mechanical properties

1. Introduction

Concrete, which is the most used construction material thanks to its superior properties [1], increases production every year, and it is estimated that it reaches approximately 11 billion metric tons annually [2,3,4]. Cement, which constitutes 10–15% of concrete by volume [4,5], is the most expensive component of concrete and causes the main environmental and energy consumption problems [6,7]. For example, cement, which is responsible for over 5% of global CO2 emissions [8,9], generates approximately 50% of these emissions during the calcination phase of carbonate raw material [9,10,11]. Because global CO2 emissions reached approximately 30 billion tons with an increase of 2% in 2020 [12], along with the increasing global warming effect, production of cement must be reduced. In addition to this problem, environmental and energy problems in the supply and transportation of aggregate must be considered for concrete production. The usage of pozzolanic additives, such as fly ash, blast furnace slag and silica fume, which have binding properties, has been experimented with in many studies to reduce cement or aggregate production. These pozzolanic additives have enhanced the performance properties of concrete and have reduced devastating environmental problems in cement-aggregate production. Not only pozzolanic materials but also inert materials can be used as alternatives to cement or aggregates [13].

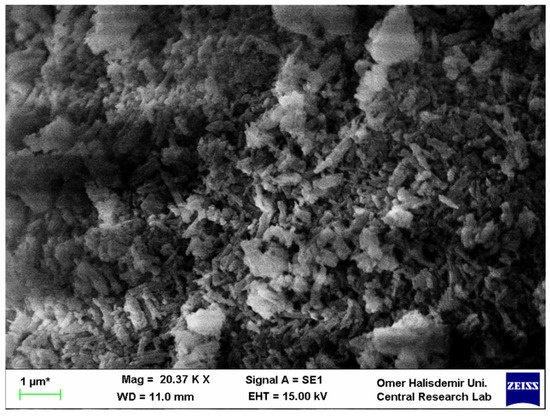

One of the most used inert materials is wollastonite. Wollastonite was discovered in 1886 by British chemist Sir Wollaston and was named after him [14,15]. Wollastonite, which consists of two main basic components, 48.3% CaO and 51.7% SiO2, has a molecular weight of 116.2 [15,16,17]. The chemical composition of wollastonite is provided in Table 1. Small amounts of Al2O3, Fe2O3, MgO and Na2O could also be available in the chemical composition of wollastonite. Wollastonite is also called calcium metasilicate, and the chemical formula of this mineral is CaSiO3 [18]. A scanning electron microscopy (SEM) image of wollastonite is shown in Figure 1. It is a white-colored natural mineral that occurs as a result of a reaction between limestone and silica at 400 °C–450 °C, and it has an acicular or needle-like shape [13,14,19,20,21]. The melting point of wollastonite is 1540 °C [15], the modulus of elasticity of wollastonite is approximately in the range of 300 to 530 GPa and the tensile stress is approximately in the range of 2700 to 4100 Mpa [13]. Wollastonite has thermal stability, low dielectric constant, low dielectric loss, corrosion resistance and chemical inertness [22,23,24,25]. Therefore, wollastonite has a very wide usage area, such as ceramic, dental, paint plastic and many other fields [26,27,28]. Moreover, wollastonite can enhance environmental sustainability and durability properties in cement-based composites [13], and it has the capability to decrease the cost of cement-based composites. However, its availability is limited because it is a natural mineral [14]; thus, researchers have focused on production of synthetic wollastonite [7,13,29].

Figure 1. SEM image of wollastonite.

Table 1. Chemical composition of wollastonite based on Ref. [7].

| Chemical Analysis (%) | Wollastonite |

|---|---|

| CaO | 44.55 |

| SiO2 | 50.78 |

| Al2O3 | 0.83 |

| Fe2O3 | 0.17 |

| MgO | 0.47 |

| SO3 | 0.04 |

| K2O | 0.001 |

| Na2O | 0.363 |

| TiO2 | 0.49 |

Wollastonite can be artificially synthesized with different materials. For example, it was produced with eggshell and silica [30], rice husk ash, silica ferrochrome, diatomite, quartz and calcined marble tailings in the literature [14,31]. Protection of natural wollastonite resources and use of waste material provide a significant advantage for synthetic wollastonite. There are three different methods for production of synthetic wollastonite. These methods are the wet method, which has lower than 200 °C and high pressure; the solid-state reaction method, which involves reaction of silica with calcium oxide or calcium carbonate at a temperature higher than 800 °C and liquid phase reaction method, which is higher than 1400 °C [13]. Each method contains different advantages and disadvantages in itself. However, the aspect ratio of synthetic wollastonite with acicular particle structure is not as high as that of natural wollastonite. Therefore, a new technique that brings together the three-step process, which includes the mechanochemical process, hydrothermal process and solid-state reaction, was developed [13]. Wollastonite is available in nature with aspect ratios of 3:1 to 20:1 [32], but wollastonite with an aspect ratio of 23:1 [13] and even 44:1 [33] was developed in productions synthetically. Therefore, the use of synthetic wollastonites in cement-based composites or in different fields is precious and has a promising future to study.

2. Cement Paste and Mortar

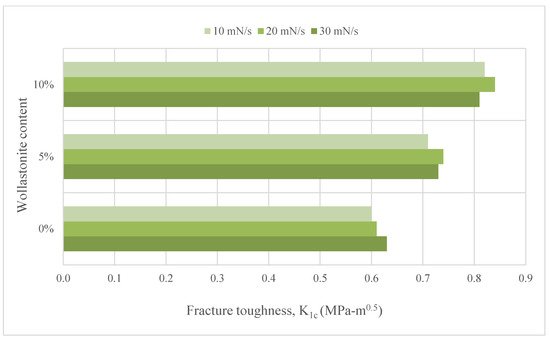

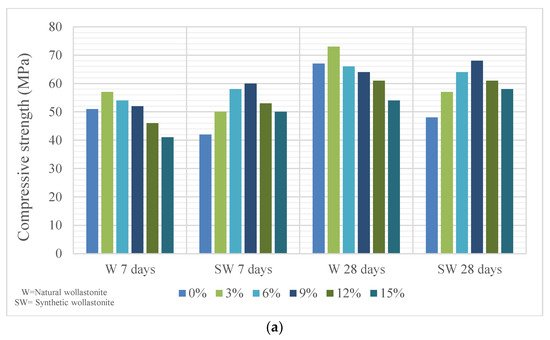

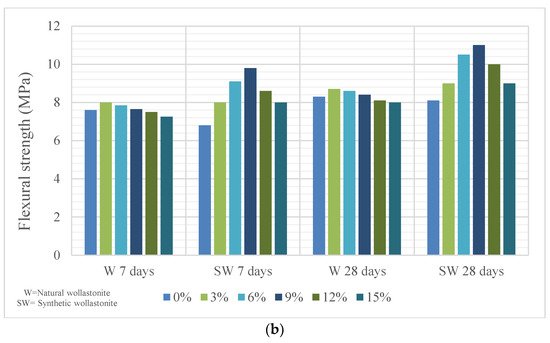

Cement paste consists of cement and water; mortar consists of cement, water and fine aggregate. Studies on cement paste or mortar were performed in the form of using wollastonite replacement of sand and/or cement. Doner et al. [34] used 5% and 10% wollastonite by mass replacement of cement in their study. Figure 2 shows the fracture toughness of wollastonite content. They observed that the use of 5% and 10% wollastonite increased the fracture toughness by 17.88% and 33.71%, respectively. The toughening effects of wollastonite usage result from the acicular nature of wollastonite that significantly bridge cracks at the micro-level. In this way, it delays microcrack coalescence. In a study where natural wollastonite from 0% to 15% by 3% increments was used instead of cement [35], the best mixture containing 3% wollastonite performed better than the control mixture for capillary water permeability and gas permeability. The compressive and flexural strengths of the mixtures are provided in Figure 3. The strength increase in the use of 3% wollastonite could be explained by the acicular particle structure and high modulus of elasticity of the wollastonite. The use of wollastonite at rates of 6% or more could cause deterioration of the microstructure and decrease in strength.

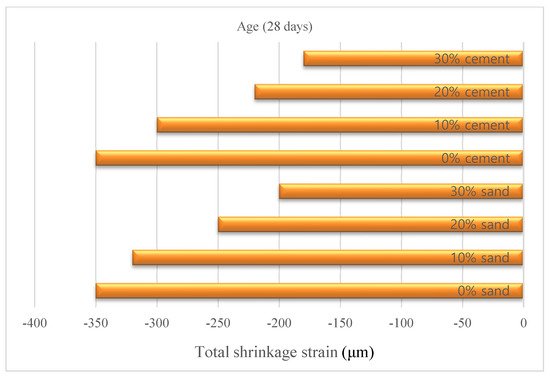

Figure 2. Fracture toughness of wollastonite content based on Ref. [34].

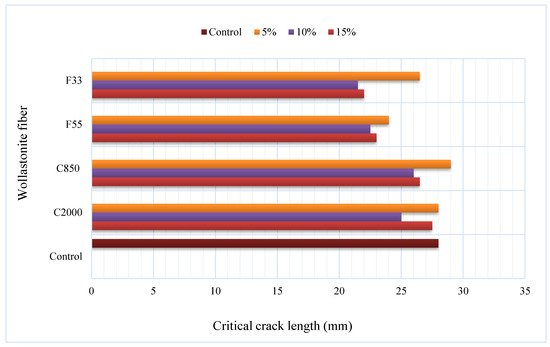

In some studies, comparisons were performed by using wollastonite and an additional material. In a study in which the effect of wollastonite average particle size was taken into account, 3.5 µm and 9.0 µm average particle size wollastonite was used at a rate of 10%, 20%, 30%, 40% and 50% by mass in replacement of cement [36]. In addition, the results of wollastonite and limestone were compared by using limestone in the same proportions. The use of wollastonite decreased the workability of mortar mixes but increased cement hydration. Using 10% limestone reduced the compressive strength of the mortar by approximately 20%. For the same strength range, wollastonite-3.5 µm can be used in replacement of 40% cement. The use of wollastonite-3.5 µm instead of 30% of the cement reduced the 28-day compressive strength by only a rate of 10%. In other words, wollastonite can be used to replace high ratio of cement up to 30% in mixes without remarkably reducing strength. Dey et al. [28] took into account aspect ratio in addition to average particle size. They used 5% silica fume instead of cement to form a control mixture and also 5%, 10% and 15% wollastonite instead of cement; four grades of wollastonite fibers with average particle size ranging from 33 to 2000 µm, with aspect ratios varying from 3:1 to 20:1, were used. The results of the study showed that the wollastonite fibers moderately increased the compressive strength and also significantly increased the fracture strength and toughness and, finally, enhanced ductility. At optimum dosage, an increase in 28-day compressive strength up to 30%, an increase in flexural strength of up to 41% and an increase in toughness of up to 147% were observed compared to the control mixture. The crack results of this study are provided in Figure 4. C refers to coarse grades, F refers to fine grades and the number refers to the average particle size in Figure 4. Wollastonite increased crack growth resistance. This can be attributed to matrix packing and its bridging of microcracks that lead to delayed microcrack coalescence thanks to usage of wollastonite. Moreover, the optimum replacement was dependent on the wollastonite fiber type. In a study where wollastonite and additional material were evaluated instead of cement, Ransinchung and Kumar [20] investigated the effect of wollastonite, microsilica and combination of wollastonite + microsilica on cement-based composites. Wollastonite increased the initial–final setting time, and 10% wollastonite+7.5% microsilica combination provided the highest strength value. The combination of 15% wollastonite+7.5% microsilica also showed higher strength than the control mix. In a study in which wollastonite was used instead of both sand and cement, 10%, 20% and 30% wollastonite were used instead of sand and cement, thus forming seven mixtures including the control mixture [37]. The initial setting time increased by using wollastonite, but this increase had a negligible effect on cement replacement. The use of wollastonite up to 20% instead of sand increased the compressive and flexural strength. When using wollastonite instead of 20% sand, 28-day compressive strength increased by 45%, and flexural strength increased by 28% compared to the control mixture. The mechanical strength of using wollastonite instead of 30% sand was also higher than the control mixture. When using wollastonite instead of 10% cement, the compressive strength decreased by 12% and the flexural strength decreased by 2% compared to the control mixture. The strengths were much lower when wollastonite was used instead of 20–30% cement. The total shrinkage strain is displayed in Figure 5. Usage of wollastonite decreased the drying shrinkage with 30% cement replacement and 30% sand replacement at the rates of 47% and 44%, respectively. From the studies, the increase in strength and durability with the use of wollastonite was attributed to the effect of densifying the microstructure of the matrix and the filling effect of wollastonite. Leeman et al. [38] used carbonated wollastonite clinker instead of 30% of cement by weight. They found that this mixture increased the Si/Ca ratio by 15% compared to the control mixture but decreased the 28-day compressive strength by 7.8%.

Figure 4. Critical crack length in cured 28 days based on Ref. [28].

Figure 5. Total shrinkage strain based on Ref. [37].

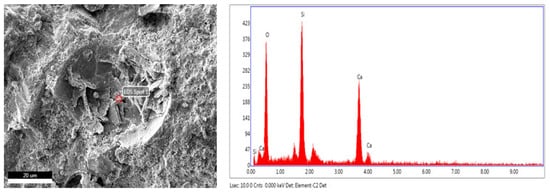

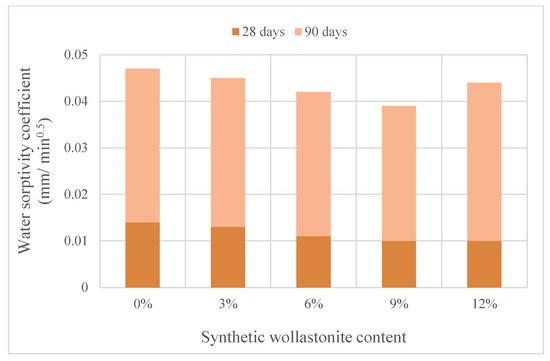

In addition, studies on the use of synthetic wollastonite on mortars were also carried out. Kalkan et al. [29] used 0%, 0.5%, 1%, 2%, 5%, 10%, 15% and 20% synthetic wollastonite instead of cement. The use of wollastonite reduced the workability, and the initial and final setting times were delayed. Water absorption decreased up to 2% replacement. It enhanced at 2% replacement in the mechanical properties of mortars. Moreover, 5% replacement can be a usable ratio and indicated higher strength than 0% replacement. The increase in flexural strength with the use of wollastonite was higher than the percent compressive strength. Moreover, thermal conductivity decreased as replacement ratio increased. Yücel and Özcan [13] formed a total of six mixtures, including a control mixture and usage of wollastonite from 0% to 15% by 3% steps of increment replacing cement. Slump flow diameter decreased with use of wollastonite. Figure 3 shows the compressive and flexural strengths of synthetic wollastonite. The compressive and flexural strengths increased up to 9% usage and reached their maximum value at 9%. In addition, the mechanical properties of the 12% and 15% replacement mixtures provided better results than the control mixture. Synthetic wollastonite fills the porous structure of cement and forms a more compact mortar [13,37,39]. When natural wollastonite and synthetic wollastonite are compared, according to Figure 3, it is observed that the optimum dosage and rate of increase are higher for synthetic wollastonite. The SEM images and energy dispersive X-ray (EDX) analysis of synthetic wollastonite are presented in Figure 6. The acicular structure of synthetic wollastonite is also shown in Figure 6. The enhancement in the mechanical properties can be explained by the physical property (acicular structure) of synthetic wollastonite acting as a fiber in the matrix. Moreover, these results supported that synthetic wollastonite is an inert material and, thus, does not show any chemical reaction. CaCO3 tended to decrease with the addition of synthetic wollastonite. Öz and Güneş [7], on the other hand, examined the effects of synthetic wollastonite on high-performance mortars. A total of five mixtures were formed: control mixture and usage of synthetic wollastonite at 3%, 6%, 9% and 12% ratios instead of cement. Use of wollastonite reduced workability. The compressive and flexural strengths increased up to 9% usage. At 12% usage, the mechanical properties were worse than those of the control mix. The water sorptivity coefficient is provided in Figure 7. The performance properties of the water sorptivity coefficient, rapid chloride permeability and gas permeability, which were tested for durability, improved up to 9% usage. Thanks to the synthetic wollastonite filling effect, the microstructure in the cement matrix condensed. Therefore, synthetic wollastonite reduced the water absorption of the material and provided pore discontinuity in the cement [7,20,32,39]. While the Yücel and Özcan [13] 12% synthetic wollastonite mixture was better than the control mixture, it was worse than the control mixture in the study by Öz and Güneş [7]; this difference is due to the w/c ratio. Usage of synthetic wollastonite up to a 10% ratio also indicates very valuable findings for future studies. When the usage of wollastonite on cement paste and mortar is examined, it is found that wollastonite was used instead of sand and/or cement; further, these uses were tested with wollastonite + different material combinations. In addition, it is observed that synthetically produced wollastonites were also used. Cement paste or mortars that have higher mechanical and durability properties were formed with usage of natural or synthetic wollastonite.

Figure 6. SEM images and EDX analysis of synthetic wollastonite.

Figure 7. The water sorptivity coefficient and synthetic wollastonite content based on Ref. [7].

3. Conventional Concrete

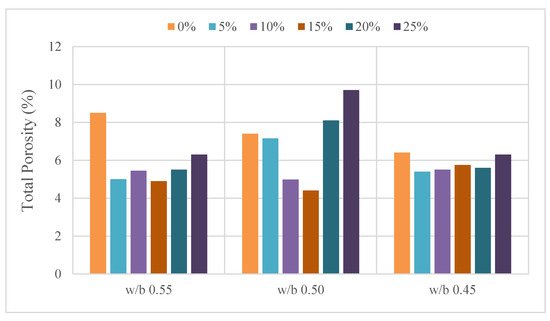

Concrete is formed by mixing cement, water, coarse aggregate, fine aggregate, chemical additives and mineral additives at a certain rate. The usage of wollastonite in concrete was performed in three different ways: replacement of sand, cement and their combination. Kh [40] used 10%, 15% and 20% wollastonite by mass replacement of sand. A compressive toughness test, which is significant for quantitative analysis of the energy distributing ability of materials, was implemented for these mixtures. It was observed that the use of 15% wollastonite increased 23–25% in 28-day results compared to the control mixture. This increase was observed as 20% at 10% usage of wollastonite. In a study evaluating the durability properties, Aziza and Kh [41] used wollastonite replacement of 30% sand and found that it improved the durability properties by 32%. In a study where wollastonite was used in replacement of cement, 5% and 10% wollastonite were used [42]. It was determined that the use of 10% wollastonite increased the compressive toughness by 40% and the flexure toughness by 32%. These values were increased by 21% and 20% at 5% usage, respectively. In a study where the w/b ratio was taken into account in addition to the use of wollastonite replacement of cement, the compressive strength increased up to use of 10% wollastonite in all w/b ratios [32]. Flexural strength increased up to use of 15% wollastonite at 0.55 w/b ratio and increased up to use of 10% wollastonite at 0.50 and 0.45 w/b ratios. Porosity and wollastonite replacement is provided in Figure 8. As noted in other studies [7,13,20,32,39], the addition of wollastonite resulted in reduced pores and densification of the concrete microstructure. It was found that 10–15% wollastonite substitution instead of cement improves the durability properties of concrete, such as water permeability, porosity, carbonation, chloride diffusion and corrosion, in different w/b ratios.

Figure 8. Porosity and wollastonite replacement based on Ref. [32].

In some studies for concrete, different material combinations were attempted, including wollastonite replacement of cement or replacement of cement+fine aggregate. Kalla et al. [43] examined the effect of the combination of wollastonite and fly ash replacement of cement, taking into account the w/b ratio. They used 40% fly ash (fixed ratio) instead of cement, as well as wollastonite from 0% to 25% by 5% steps of increment in replacement of cement. The mechanical properties increased up to use of 55% combination wollastonite (15%) + fly ash (40%) at a 0.55 w/b ratio and increased up to use of 60% combination wollastonite (20%) + fly ash (40%) at 0.50 and 0.45 w/b ratios. Additionally, permeability 55–60%, carbonation resistance 45%, diffusion 45–60%, corrosion 45–55% and shrinkage resistance at the rate of 55–60% wollastonite+fly ash combination enhanced its durability properties. It was found that the usage of wollastonite + fly ash combination in the range of 40–55% and wollastonite in the range of 5–15% affect the mechanical and durability properties of concrete positively. The wollastonite + fly ash combination was investigated in replacement of both cement and sand in another study [39]. It was stated that the mixture of fly ash instead of 20% cement + wollastonite instead of 10% sand increased the 28-day compressive strength by 28% and flexural strength by 36% compared to the mixture using only fly ash in replacement of cement at 20%. In addition, it was stated that the combination of fly ash in replacement of 20% cement + wollastonite in replacement of 10% sand and only wollastonite in replacement of 10% sand showed higher mechanical strength compared to the control mixture (no fly ash and no wollastonite). Finally, it was found that the usage of wollastonite (single or in combination with fly ash) reduces water absorption, drying shrinkage and abrasion loss. These findings obtained from the studies [39,43] show that fly ash and wollastonite could be a preferable alternative material combination.

This entry is adapted from the peer-reviewed paper 10.3390/ma15196904

This entry is offline, you can click here to edit this entry!