Despite all the mentioned benefits, one needs to take the downsides of hydrogen into consideration:

2. Hydrogen Economy

Hydrogen has the potential to be the cost-effective substitution for fossil fuels because of the abundance of element hydrogen in the universe, the highest energy content, and its sustainability and environmentally friendly features—unlike hydrocarbons [

2]. We examine hydrogen economy in categories of production, storage, distribution, and applications.

Hydrogen can be produced using sustainable sources of energy like hydro, wind, solar or from fossil fuels. The latter release CO

2 emissions that need to be counterbalanced by the carbon capture and storage (CCS) procedures [

3]. In the production of green hydrogen from water, the price of electrolyzers influences the capital cost [

19], and the high electricity demand is another issue. Hydropower produces about 91.5% of electricity in Norway. Generating electricity in this way not only avoids carbon emissions but used to be also low in price, which was about 33–50 Øre/kWh (100 Øre = 1 NOK

≈ 0.1 €

≈ $0.1) in the first quarter of 2021 before the energy crisis happened in Europe. However, the price of electricity is still low in the northern part of Norway. In addition, there has been an exemption for the state electricity tariffs since 2019 for the companies producing hydrogen by electrolysis in Norway. The progress in the efficiency of electrolyzers also results in the cost-reduction [

3]. As a result, while most of hydrogen in the world is extracted from fossil fuels [

11], climate conditions in Norway offer a special advantage in the supply of green hydrogen at the lowest possible price and without environmental side effects. Fees for hydrogen production from water by electrolysis in terms of energy are estimated to be about $20/GJ (with the electricity price of $0.036/kWh), which is three times higher than when it is generated from natural gas with CCS ($6.9/GJ) [

20]. Although the price of hydrogen obtained from natural gas currently seems to be more reasonable economically, fossil fuel sources will not last forever. Moreover, hydrogen produced from water by electrolysis becomes more and more inexpensive over time. While recent studies in Norway reveal that the cost of hydrogen production can reach $3.6–4.9/kg, Norwegian NEL company plans to produce green hydrogen at the cost of $1.5/kg by 2025, which is equivalent to $12.5/GJ [

21]. Another investigation by DNV-GL projects the price of hydrogen produced in Norway by electrolysis to be in 2030 at the level of $2–6/kg [

22]. Technically, the larger amount of hydrogen is generated, the less it would cost [

2]. However, the effect of electricity price could not be neglected.

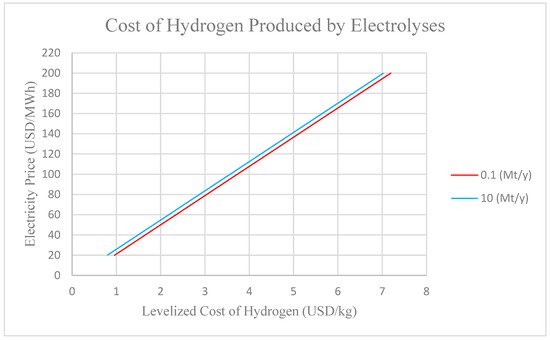

Figure 1 depicts how the electricity price and the scale of hydrogen production affect its final cost in the USA.

Figure 1. Levelized cost of hydrogen as a function of price for electricity (data from [

23]).

Liquefication and storage are other processes that determine hydrogen production cost. The specific energy quadruples when the hydrogen gas at 250 bar converts to LH

2 at 1 bar, but one-third of the energy content of hydrogen is consumed by liquefication. This makes LH

2 expensive. Therefore, neither the capacity of liquefaction is considerable in Europe (only 20 tons/day), nor it is produced in Norway [

3], although some companies start investing in LH

2 production. The relatively small size of current LH

2 plants is also responsible for the high price. If larger LH

2 plants are constructed, about 67% of additional cost reduction would be possible. The high price of LH

2 production could be compensated to some extent in other sectors, like in transportation [

3,

12]. In the storage sector, preparing the proper insulation is the main issue. While the amount of boil-off during the transportation is estimated to be about 0.2% per day [

24], NASA claims that the boil-off could be reduced to zero by an internal heat exchanger [

7,

22]. In any case, the issue of boil-off gas could be lifted in the maritime shipping sector by using it in the propulsion system [

23].

In 2050, 31,000–60,000 TWh/year of hydrogen is expected to be produced according to the EU scenario, while only a fraction of this amount will be transported [

25]. Thus, hydrogen storage is a critical factor in its use. Generally, hydrogen is stored at high pressure, up to 700 bar, but about 12% of energy content has to be consumed in the storage process [

2]. In addition, refueling the high-pressure hydrogen tanks is challenging due to a negative Joule–Thomson coefficient and embrittlement of the walls of the tanks [

6,

26]. Liquefication of hydrogen is another method to store it: LH

2 is more compact and is kept in low-pressure vessels, which helps to transmit more hydrogen by the trailers in safer conditions [

2]. Trucks can transport up to 4000 kg of LH

2, while it is typically 1000–1500 kg for the compressed hydrogen gas [

3,

27]. Therefore, transportation of hydrogen in cryogenic form is a cost-efficient method for long distances and large loads of hydrogen [

1,

12]. As an example, the transportation cost of LH

2 is almost four times lower than that of compressed hydrogen in terms of price per distance in Germany [

28]. In contrast, high energy demand for liquefication and difficulties in the insulation of the vessels restrict this application and increase the cost [

2]. However, in large plants, the cost-reduction in LH

2 distribution more than compensates for the cost imposed by LH

2 production [

1].

Hydrogen applications also play role in its cost-efficiency. Storing electricity is challenging, but, instead, excess electricity can be used to produce hydrogen from water. It then could be easily stored and later used to produce electricity by fuel cells [

20]. In transportation, batteries as storage of electricity might be a proper option for a short distance, but they do not have enough capacity for long journeys. Due to higher energy density in hydrogen fuel cells, they can replace batteries in the storage of energy [

19,

29]. Norway projects that, in 2030, about 23% of total hydrogen in the country would be consumed in the transportation sector [

4], where relevant industries can implement hydrogen fuel cells. Norway has already constructed factories to produce fuel cells to convert hydrogen to electricity. Due to compact volume of liquid, vehicles could use LH

2 as fuel both in internal combustion engines and fuel cells. Although hydrogen fuel cells consume hydrogen in gas form, LH

2 still can be considered as the storage option and primary source of gas. In this case, the amount of evaporation becomes crucial since its high rate may cause overpressure in the vessels, while low evaporation rate means a lack of fuel [

9,

10]. Overall, hydrogen fuel cells can provide the best energy efficiency in vehicles without carbon emissions. In addition, such vehicles can compete economically with gasoline and hybrid ones on a cost per kilometer both in urban and rural areas [

27,

30]. Hydrogen fuel cells can have stationary applications too [

12].

Fuel cell electric vehicles (FCEVs) are competitors for plug-in electric vehicles (PEVs), and they have the potential to compete with internal combustion engine vehicles (ICEVs). A fuel cell stack costs approximately $100/kW, while a lithium-ion battery values on average $270/kWh. If the retail price of hydrogen is reduced to $8/kg ($0.24/kWh)—which is cheaper than the electricity cost in most places—and governments set a high price (or restriction) for carbon emissions, FCEVs can even dominate ICEVs. The absence of carbon emission, low weight and lack of hazardous materials are other advantages of FCEVs over PEVs and ICEVs [

30,

31].

3. Superconductivity Applications

Due to unique features of superconductors, among them loss-free energy transfer, they can be used in a variety of sectors: transportation, electrical and mechanical devices [

32], medicine [

32,

33], and distribution of energy [

33,

34].

Wires and coils are important in the distribution sector, but they are also responsible for energy losses. Superconducting cables/wires could compensate electromagnetic fields around sensitive devices; help to avoid losses of energy; occupy less volume than conventional conductors; and are stable in various weather conditions such as strong wind, snow, and ice [

34]. Production of long HTS wires is challenging and costly, but MgB

2 wires have a reasonable price and are easy to produce—costing about one-tenth compared with HTS wires. The higher critical temperature is the main advantage of HTS wires since the cost of a cryogenic cooler also affects the total price [

34]. Low AC losses in MgB

2 wires are another advantage [

35]. Whenever the available coolant (such as LH

2) is appropriate for both cases, MgB

2 would be the first candidate for the superconducting wires. Wires/cables are used not only in most of the electrical devices but also for the distribution of electricity. Superconducting wires can pass electrical current with a density of 10–100 times higher than in conventional (Cu) wires with the same cross-section area [

33]. Hence, superconducting wires provide very high efficiency in the transmission of electricity.

Superconductors can be used in motors with a wide range of applications in vehicles and industrial devices. They can provide light weight, smaller size, low energy consumption and high-efficiency of the motors [

32,

36,

37] by making stronger magnetic fields that rotate rotors with stronger force, lead to a reduction of the amount of iron used in the motor, increase the torque and reduce the motor size [

33,

38]. In large-scale vehicles, such as a ship, superconductors can save space and considerably reduce noise [

33]. The torque density of a superconducting ship propulsion motor can reach 28 kN/m

3, while it is only 10 kN/m

3 for conventional motors [

34].

The superconducting generators can also provide a good solution for ever increasing electrical demands [

17]. Terao et al. [

39] compared superconducting generators with conventional ones for 10 MW wind turbine generators. In their study, the fully superconducting generators (FSCG) with yttrium barium copper oxide (YBCO) and MgB

2 coils were used instead of permanent magnets and copper coils, as in the conventional one known as a permanent magnet synchronous generator (PMSG). FSCG had two advantages compared with PMSG: the weight of the generator was reduced from 231.7 to 63.6 tons, and the copper energy loss was omitted. Copper causes 4% of the total energy loss in the PMSG, and its total efficiency is less than 90%. In contrast, FSCG had no copper loss, yet it suffered from AC losses in multifilament MgB

2 wires that were about 2%. In wind turbines, a superconducting generator allows for removing the gearbox, decreasing the size and weight, and reducing the cost [

40,

41]. The cooling system of such generators consumes negligible energy compared with its total loss [

36]. However, the cooling system still needs to be optimized by choosing a proper heat exchanger [

42].

Some mechanical devices, such as a bearing one, can also take advantage of superconductors. Superconductors can provide quasi-permanent magnetic flux [

32]. Therefore, the permanent magnet can be replaced by a superconducting magnet resulting in a magnetic levitation (maglev) unit [

43]. The superconducting bearings can stabilize and suspend flywheel rotors avoiding wearing and friction between them, which means having low energy loss [

36,

44]. These mechanical devices exist both in motors and generators.

Superconductors can completely change transportation providing high efficiency and low emission in vehicles [

34]. It was already pointed out that energy-loss-free characteristics of superconducting wires, electrical, and mechanical devices will benefit all kinds of vehicles: trains, planes, ships, and spaceships [

17]. However, there are many possibilities to increase the use of superconductors in transportation. For instance, the flux pinning in superconductors allows one to use them for maglev trains. The speed of maglev trains could reach 1000 km/h [

44]. Since a high magnetic field has to be generated to levitate a heavy train, long and large coils are required. Therefore, once again, MgB

2 seems to be the best option for this application because of its low cost [

35].

Berger et al. [

45] demonstrated that transformers could also operate more efficiently by using superconductors. In this study, the authors replaced the copper in the coils with YBCO, while the core remained to be iron. In this case, the efficiency increased from 99.6% to 99.9%, while the main loss of the superconducting transformer still stemmed from the iron core—67.2% of the total loss. Superconducting transformers could avoid up to 81% of energy loss per year. Other researchers have also investigated the development of superconducting transformers in several studies [

46,

47,

48].

The most successful commercial application of superconductivity has been in medical diagnostics, namely in magnetic resonance imaging (MRI) in which over 70% of the MRI scanners are using superconductors—mainly niobium-titanium (NbTi). The critical temperature of NbTi is about 10 K, so liquid helium (LHe) is the only proper coolant for it, but the price of LHe significantly increased in the last decade. The solution is to develop the next generation of MRI using HTS (including YBCO, other rare-earth barium copper oxides and bismuth strontium calcium copper oxides) or MgB

2. The critical temperature of MgB

2 (39 K) is lower than that of HTS (90–110 K), but the affordable price, availability of wire, and simplicity of making joints between the bulks make MgB

2 a superior option for this application [

49,

50,

51].

Superconductors can deliver a prominent outcome, but for most applications, the high price of the cooling deters commercial investments and hinders their development. Increasing the popularity of using LH2 in the industries and decreasing its cost could lift this barrier. It seems it is time to reconsider use of superconductivity in industrial applications taking into account the large-scale production of LH2.