O&M refers to activities related to daily operations and maintenance needed to preserve an asset so that it continues to provide services and maintain functioning. With the increasing attention paid to sustainable development worldwide, improving energy efficiency and applying effective means of energy saving have gradually received worldwide attention. As the largest energy consumers, manufacturing industries are inevitably facing pressures on energy optimization evolution from both governments and competitors. Among these enterprise activities, O&M of manufacturing systems are considered to have the most prospects for energy optimization. To address these issues, we review the existing O&M optimization approaches with energy management and divide them into several operation levels: single-machine, production-line, factory, and supply-chain levels. We also discuss recent research trends in O&M optimization with energy-management considerations in manufacturing systems.

- sustainable

- energy optimization

- operation and maintenance

- manufacturing systems

1. Introduction

With the rising concern about the environmental pollution of fossil energy, the concept of sustainable development has gained worldwide attention. A huge number of measures have been proposed to achieve the global sustainable goal from various perspectives of energy policy, technology, etc. [1][2][3]. Renewable energy is recommended to gradually replace fossil energy, and the calls for applications of energy efficiency increases and effective energy saving have become much more urgent [4]. As the important pillar of development as well as the main sector of energy consumption, industry consumed 28.9% of the world’s total final energy, 38% of total electricity consumption, and especially 81.9% of coal consumption [5]. Therefore, reasonably improving the sustainable development level of the industry, especially the optimization of energy consumption, plays an important role in promoting the transformation to a sustainable manufacturing mode [6].

Under the background of sustainable development, industrial enterprises not only need to improve their energy efficiency and reduce waste to obtain greater competitiveness but also have to face a more challenging energy transformation environment such as energy source changes and emission punishment, which brings more considerations and constraints for the decision-making process. Effective energy-saving measures can help enterprises save costs, resist the risk of policy changes, and can also reflect the social responsibility of enterprises, driving long-term sustainable development [7].

For a classical industrial enterprise, the energy consumption sources can be mainly divided into two categories according to the usage purpose of the consumption terminal [8]. One is used to support the normal functioning of enterprises, such as lighting and heating of all buildings, which is more stable and easier to predict. This kind of energy consumption can be reduced through the systematic application of green building and management [9][10]. The other is mainly consumed in operation and maintenance (O&M) activities, which are directly related to the manufacturing process and have a strong correlation with the energy consumption of the system [11]. Compared with the former energy consumption source, O&M-related energy optimization faces more severe challenges. Since the production activities involve both products and machines, the randomness of production orders, the diversity of production-line structures, and the complexity of the machine working environment all increase the difficulty of O&M decision-making.

In recent years, O&M decision-making with energy-management considerations has been noticeable and studied from various perspectives. Many valuable reviews have been published to summarize different ways of energy management in manufacturing systems. Park et al. [12] reviewed energy consumption reduction strategies and energy-saving technologies in different countries. Jasiulewicz [13] concluded recent maintenance technologies for sustainable manufacturing to avoid sudden breakdown and decrease energy and material consumption. In addition, Gham et al. [14] constructed a study framework for energy-efficient scheduling and made a sufficient review. These studies on energy management in the O&M field usually focus on totally different objects and are scattered among different processing stages. However, they have not carried out more specific and systematic generalizations for the concrete optimization problems and solving methodologies.

This paper classifies various energy management approaches in the field of O&M, focusing on the energy optimization of manufacturing systems, and reviews from mainly four processing levels: machine level, production-line level, factory level, and supply-chain level. The remainder of this paper is arranged as follows: In Section 2, the O&M methods for manufacturing systems with an energy-saving consideration are reviewed, and the challenge factors are elaborated. Sections 3 and 4 summarize the new research on energy optimization in the field of O&M from the machine level and production-line level, respectively. Section 5 briefly introduces current developments of O&M optimization with energy management in the factory level and supply-chain level. Section 6 further discusses the future development trend in this research field, and, finally, Section 7 summarizes the work of the full text.

2. History

O&M are the main business activities within manufacturing enterprises. In a broad sense, they refer to all related activities needed to preserve the functioning and productivity of a system. For a manufacturing system, O&M are the collection of a series of system management activities, including product scheduling, machine management, product quality control, inventory control, and supply-chain management, as well as after-sale service. These are used to analyze the characteristics of different manufacturing system structures, apply systematic optimization methods, and make improvements to the performance of the whole system, including production cost, system efficiency, machine reliability, and product quality.

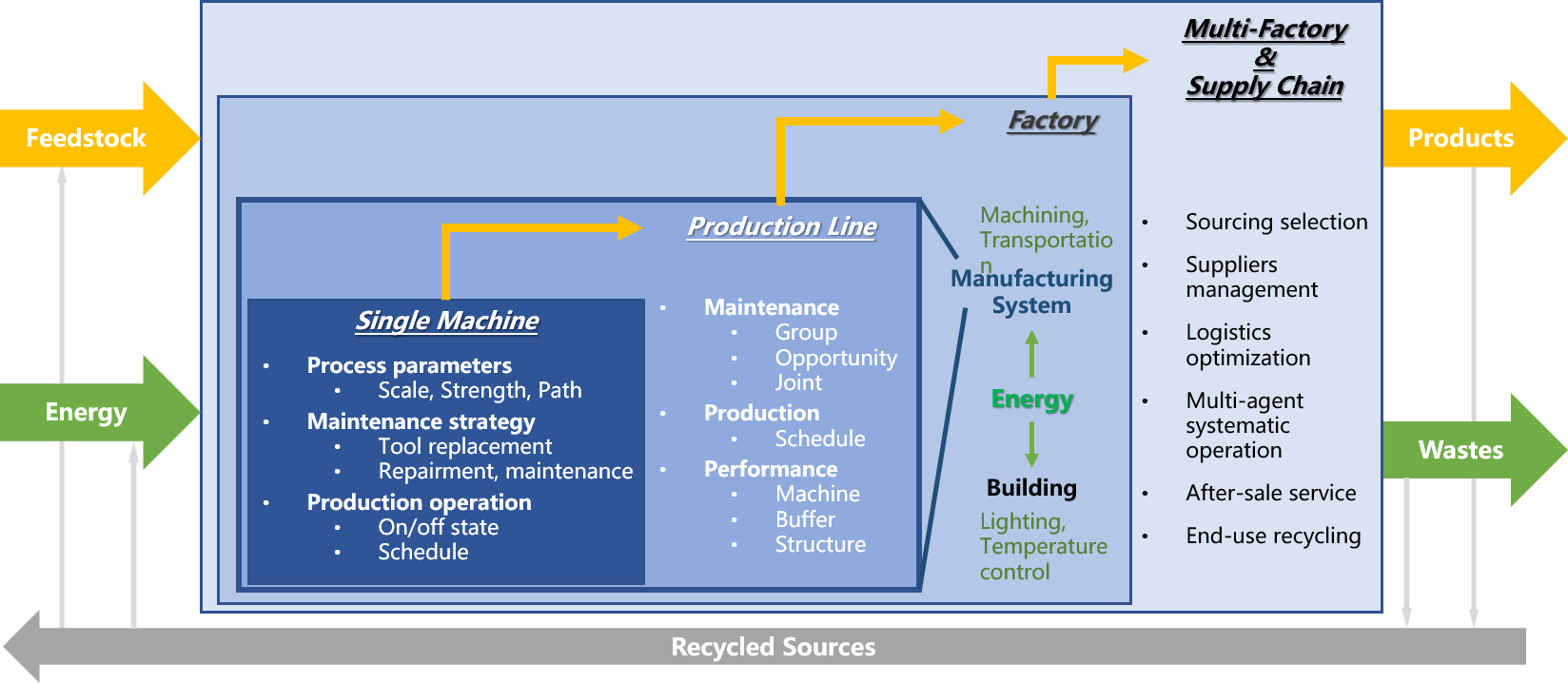

Since O&M activities are carried out in multiple forms at different levels of manufacturing systems, the optimization can be categorized according to the organization of manufacturing systems [15], which can also be defined as the manufacturing process. In this context, the manufacturing optimization activities can be decomposed into several levels: the machine level where unit optimization is carried out, the production-line level with the consideration of interactions between machines and products, and the factory level, which is defined as monitoring the whole performance of the factory through various aspects, including building energy monitoring and manufacturing system energy optimization, and the multi-factory and supply-chain level, where energy management is applied from suppliers to customers. The main activities and elements concerning in different decision levels are presented in Figure 1.

Figure 1. Decision levels of O&M in a manufacturing process.

The O&M research on the machine level mainly studies the degradation trend and machine status through in-depth analysis of the processing details, so as to improve the processing performance. Inputs for a machine processing procedure are the processing parameters and operation schemes, and some noticeable performance outputs include machine degradation status, product quality, and processing costs. Therefore, O&M on a single-machine system usually focuses on the process parameters of machines, degradation of machines [16], production schedules, and single-machine maintenance strategies [17][18], which can be further divided into sub-tool replacement, whole-machine maintenance, etc. Many studies also take product quality into consideration and perform joint modeling and optimization [19][20]. The analysis of the single machine is also the foundation for system-level optimization and provides a more specific optimization angle to realize energy savings.

The system research on the production-line level pays more attention to the structure of the production line and the processing sequence. In addition to the machine status and scheduling problems, which are considered at the machine level, production-line-level optimization starts to concentrate on the interaction among procedures and between machines and products.

At the same time, the application of the Manufacturing Execution System (MES) broadens the meaning of O&M to the factory level [21]. Through additional management systems, the synchronous optimization can be accomplished by real-time monitoring and precise simulation, combined with systematic analysis. In addition, building energy optimization can be included in the operational activities of enterprises. Moreover, energy optimization between factories within the supply chain is also considered to be a promising research field, which includes supplier management, logistics optimization, and so on.

This review focuses on the O&M optimization strategies in the manufacturing system, that is, the related activities at the machine level and production-line level. Since the system profit and energy consumption are directly related to the product production schemes and machine maintenance behaviors, O&M optimization in the manufacturing system pays more attention to the production scheduling and system maintenance strategies. As two key activities in the manufacturing system management, these two kinds of activities are coupled with each other through the reliability and availability of the machine [22]. Maintenance aims to ensure the health of the machine and thus ensure production efficiency and product quality [23], whereas production scheduling can in turn affect the formulation of machine degradation. Therefore, the difficulties of joint decision-making of maintenance and production scheduling are mainly reflected in three aspects:

- The independence of the machine degradation

The function and working environment differ between machines in different procedures among the whole system, and the fact that the degradation distributions of any two machines are independent of each other due to the variation among machine components further proves the necessity of full consideration of independent machines’ degradation modeling [24].

- Multiple couplings brought by production operation

The production of workpieces often needs to go through multiple processes; as a result, the machine in each process is connected through the processing sequence of the workpieces. It also unexpectedly influences the reliability of machines and increases the difficulty of overall decision-making at the system level in the formulation of production and maintenance strategies. Moreover, maintenance actions are performed in machines, which occupies the feasible time for product processing and influences the final productivity of the system.

- Interactions between energy consumption and O&M operation

Maintenance and production are related to machine status and thus related to the energy consumption levels of machines. The processing machine usually consumes more energy when it is on for production, and is shut down or kept idle during maintenance. Therefore, reasonable and effective maintenance and production scheduling can reasonably utilize the status of each machine in the system, so as to find the opportunity for energy balance, thereby reducing energy consumption.

Meanwhile, more and more attention has been paid to energy consumption and energy efficiency during processing in the context of sustainable development [25]. The consideration of energy savings in O&M optimization of the manufacturing system also brings changes to the traditional joint decision-making of production and maintenance:

- Additional targets or constraints brought from energy consideration

The consideration of energy consumption can usually be added to the model in two ways, one as an optimization objective and the other as a model constraint. However, no matter what form the addition takes, it increases the solution complexity of the original model. In particular, when energy consumption is taken as the optimization objective, it may greatly affect the original solution space and the optimization direction of the solution.

- Changes in modeling methods under a new energy policy background

Simple additional goals or constraints will not change the original model too much. However, with the gradual deepening of energy-saving considerations, the updated energy consumption policies will also become a new research point for system optimization. Under the influence of these circumstances, in addition to the revision of the original model, it is more likely to completely subvert the original model, and force researchers to build a new system optimization model and seek new energy-saving opportunities.

Based on the difficulties and changes mentioned above, the following sections will give a detailed overview of O&M optimization methods with the consideration of energy management from the perspective of single-machine and production-line levels.

3. New Research Developments on Machine Level

The manufacturing system is formed by series and parallel connections of machines with different functions in different processes. Therefore, the machine can be regarded as the most important part, constituting the production line. At the same time, the machine itself is a complex system. From the structural aspect, typical machining equipment is composed of tools, spindles, motors, and other components. In addition, from the perspective of the machining process, it can be divided into rotation, positioning, feeding, and other processes, which have different energy consumption characteristics. Therefore, machine-level operations can be divided into two categories. One is to optimize the processing parameters for different processes to reduce energy consumption and the other is to achieve energy consumption minimization through whole-machine actions such as on/off control and single-machine production scheduling. Similarly, the maintenance of machines can also be summarized into two types. On the one hand, the machine can be taken as a whole, and data-driven methods can be used to optimize the overall maintenance action. On the other hand, each component can be taken as the focus of optimization to study the maintenance and replacement strategies of each part. In addition, some researchers also additionally introduce reliability assessment or optimization with product quality control consideration [26]. Therefore, the O&M optimization of energy management on the machine level can usually be summarized into three main aspects: process parameters optimization, energy-efficient maintenance optimization, and energy-efficient production optimization.

3.1. Process Parameters Optimization

From the perspective of process parameter optimization, many papers focus on the optimal design of cutting parameters [27][28][29][30]. This kind of research is mainly carried out in three ways: real experimental-design-based optimization, optimization based on fitting experimental data, and impact-analysis-based optimization.

In addition, there is a complex mapping of machining energy consumption to tool selection and tool usage conditions in the machining process. It has been demonstrated that both cutting parameters and energy consumption also vary significantly depending on the tool wear conditions when using worn tools [31]. Therefore, tool selection [32][33], tool wearing conditions [34][35][36], and machining quality control [26][37][38] are usually also taken into account in new studies.

3.2. Energy-Efficient Maintenance Optimization

The most common maintenance actions used in maintenance optimization decisions for a single machine can be divided into two categories: corrective maintenance (CM) and preventive maintenance (PM). CM, which is also known as minimal maintenance [39], refers to actions of taking the necessary repairs to restore the machine to function when a failure has already occurred. This type of maintenance action is not effective enough in ensuring machine reliability because failures are unpredictable and happen randomly. In contrast, PM is a pre-act maintenance strategy, in which the machine is overhauled and repaired according to a pre-defined strategy before a failure occurs, thereby eliminating the failure in advance and avoiding major economic losses caused by sudden breakdown. In the construction of a single-machine maintenance strategy, the above two actions are usually considered at the same time, and the strategy is optimized mainly for preventive maintenance.

For the construction of the maintenance optimization model, machine reliability, productivity, maintenance cost, etc., are usually considered as objectives. The impact of energy consumption is also integrated into the decision model in order to fully consider the impact of sustainability objectives on the decision-making process.

Focusing on the machine itself, it is also composed of multiple sub-components. Therefore, some constructions of the model also address the machine maintenance optimization integrated preventive maintenance and component replacement strategies to achieve a system improvement.

3.3. Energy-Efficient Production Optimization

Production-related energy consumption optimization usually consists of two aspects: one is the production scheduling problem and the other is the machine on/off state switching problem.

The single-machine scheduling problem is the set of all scheduling problems that perform sequencing on a single machine and is usually used to guide the optimization of the workpiece processing order. The general description is as follows: A number of N and mutually independent workpieces are sorted according to specific sorting rules and scheduled to be processed on a single machine. Each workpiece can only be processed once on that machine and the machine can only process one workpiece at the same time. In a sustainable manufacturing context, machining energy consumption is usually added to the model as a goal or constraint.

In addition to considering production scheduling sequence optimization, some studies were also devoted to energy consumption optimization with the help of machine state switching. For machines with high standby power and long production waiting intervals, through timely machine status switching, the standby energy consumption of machines can be saved by a certain amount. Moreover, production scheduling can be further used to optimize the energy consumption of machines systematically.

Single-machine production scheduling does not always bring a significant effect on energy consumption reduction; in this context, some studies have explored a series of joint optimization considering both machine status and production-related elements. Usually, a multi-objective model with energy and productivity objectives is designed in these kinds of studies.

All O&M optimization topics at the single-machine level mentioned above are summarized in Table 1.

Table 1. Energy-optimization opportunities and challenges in O&M at single-machine level.

|

Area |

Sub-Area |

Energy-Optimization Principles |

Challenges |

|

Process Parameters Optimization |

Feed parameters |

Reduce energy consumption by improving machining efficiency and quality |

Processing steps’ division Energy consumption calculation Optimization modeling |

|

Tool movement trajectory |

Reduce energy consumption during movement through efficient path planning |

||

|

Machine Maintenance |

Tool replacement |

Reduce excess energy consumption due to machine degradation by improving machine reliability |

Machine degradation modeling Reliability threshold determination Maintenance strategy selection |

|

System maintenance |

|||

|

Machine Production |

Machine state control |

Reduce idle time by switching on/off |

Settings of switch principles |

|

Batch scheduling |

Reduce idle time through efficient production scheduling |

Construction of efficient scheduling models |

|

|

Production scheduling |

|||

|

State analysis |

Reduce idle time using simulation analysis |

State transition analysis |

4. New Research Developments on Production-Line Level

With the widespread use of complex manufacturing systems consisting of different types of multiple machines in series and parallel construction forms according to process requirements, production-line level O&M optimization strategies have become a hot topic for urgent research. O&M optimization at the production-line level is usually planned using traditional operations research methods and solved by intelligent algorithms.

Compared with single-machine O&M planning, production-line-level optimization scheduling is more complex in terms of decision constraint consideration, overall optimization objectives, machine-related analysis, and dynamic optimization processes. If there is no dependency between machines, the single-device optimization model can be directly adopted. However, the multi-device optimization strategy not only needs to consider the characteristics of each machine itself, but also should comprehensively analyze the interdependencies between machines, which include economic dependencies (the productivity of the system is dependent on the bottleneck machine with the lowest production efficiency), fault dependencies (different health decline processes of the machine may interfere with the health status of other devices), and structure dependency (downtime of one machine in the system structure can mean simultaneous downtime of several machines).

In the production-line-level optimization stages, it is necessary to systematically analyze the interdependencies between machines and perform the systematic scheduling of each machine planning to achieve the decision goal of improving the overall system efficiency. At the same time, as the system structure becomes more complex, it also expands the research space on sustainable optimization. The system structure can be fully utilized to find new opportunities for energy savings. Production-line-level O&M optimization with energy management has been studied to some extent, and the most widely used methods among this research can be summarized into three main categories: system maintenance strategy, production scheduling optimization, and system performance optimization. Based on the above three categories of studies, joint optimization in multiple directions is often performed. New angles of energy savings are also explored to add to the traditional model in order to make certain extensions to the current study.

4.1. System Maintenance

The energy-consumption-oriented system maintenance strategy is an extension of the single-machine maintenance strategy, and the rational scheduling of the maintenance plan has a positive effect on the optimization of the system energy consumption [40]. In the process of production-line level maintenance planning, it is necessary to fully consider the maintenance synchronization between machines and the energy-saving opportunities brought by production, effectively use group maintenance and opportunity maintenance strategies to take advantage of system scale, and reduce system energy-consumption costs.

Maintenance planning at the production-line level has been maturely studied, and the research was mainly optimized to ensure system reliability and production efficiency. While the research on maintenance planning considering energy consumption optimization is limited, the related current research methods are mainly carried out in the following areas: group maintenance, opportunistic maintenance, and maintenance in conjunction with production.

4.2. System Production Scheduling

In the optimization of production systems, production scheduling is another cornerstone of system O&M management in addition to maintenance planning. Research in production scheduling is also mature enough. In recent years, with the promotion of sustainable manufacturing, the optimization of production energy consumption has been added to the modeling of production scheduling, which can be reflected in three main aspects: energy-constraint-based scheduling, energy-target-based scheduling, and time-dependent energy-cost-based scheduling.

4.3. System Performance Optimization

In addition to maintenance and production decisions, direct control of machine conditions and other energy-saving opportunities have been studied to some extent. To take full advantage of energy-saving opportunities, in addition to taking maintenance and production actions, it is also possible to proactively adjust the machine’s working states. Therefore, this type of production-line-level optimization often draws on changes to machine status, using operations such as switching on and off, to actively find and even create energy-saving opportunities and achieve effective reductions in system energy costs.

The energy-optimization opportunities and challenges in O&M optimization at the production-line level are summarized below in Table 2.

Table 2. Energy-optimization opportunities and challenges in O&M at production-line level.

|

Area |

Sub-Area |

Energy-Optimization Opportunities |

Challenges |

|

System Maintenance |

Group maintenance |

Machine maintenance shutdown |

Grouping strategies Maintenance energy calculation |

|

Opportunistic maintenance |

Machine breakdown |

Opportunity searching Maintenance energy calculation |

|

|

Maintenance and production |

Preventive maintenance schedule Sudden breakdown Production changeover |

Multi-objective scheduling Action interactivities |

|

|

System Production Scheduling |

Energy target and constraints |

Production scheduling (machine selection, processing period selection) |

Adding objectives/constraints to the original model |

|

Energy usage background |

Innovative modeling and analysis |

||

|

System Performance Optimization |

Machine states |

Machine on/off control |

Effects on production scheduling Effects on machine reliability |

|

Buffer states |

Buffer threshold |

System structure analysis |

|

|

Dynamic observation |

Integrated methods |

Observation index selection |

5. New Research Developments on Factory and Supply-Chain Levels

In addition to the O&M optimization for manufacturing systems considering machines and production lines, in a broader sense, systems at any level in the manufacturing process can be identified as manufacturing-related systems, such as manufacturing factories and supply-chain systems. The O&M optimization of these two levels often faces more difficulties in coordination between system elements, and the scenarios are more complex, bringing more diverse problems into the research field.

The O&M at the factory level is mainly aimed at the management of system components beyond the production lines, such as inventory systems, and building facilities. Such management includes but is not limited to factory facility control, such as lighting and heating control, floor layout optimization, and energy monitoring of the whole factory [15]. With the advancement of Industry 4.0, data-driven management methods have also been identified as the main contributors to factory monitoring and optimization [41][42].

For the O&M optimization at the multi-factory and supply-chain level, the coordination and collaboration between factories are usually considered, and typical problems involve logistics management, warehousing location optimization, etc. These optimization problems focus on objectives such as logistics cost and transportation efficiency. In the context of sustainable manufacturing, energy-related objectives are gradually considered in the modeling of the original problems.

6. Summary and Future Research Trends

This paper aims at providing an overview and classification of O&M energy-optimization methods for manufacturing systems under a sustainable background. The sustainable manufacturing paradigms have been promoted with the deepening of the energy revolution to ensure the competitiveness of enterprises. Moreover, a more urgent and specific methodology for O&M optimization with energy management needs to be constructed. This paper mainly focuses on the energy optimization of O&M activities at the single-machine and production-line levels. In such studies, operations research methods have been applied to different levels of O&M strategies.

At the single-machine level, current energy consumption analysis focuses on the machine itself and the machining process, where the energy consumption of each stage is modeled and analyzed according to the actual physical processing stages of machining. The energy-consumption level of a single machine often depends on multiple factors such as process parameters, machine selection, machine status, tool selection, etc. Among them, the optimization of process parameters has been widely and deeply studied, while less research has been devoted to maintenance and production strategies, and there is still much space for improvement.

At the production-line level, the main consideration is the system consumption structure and the interaction between workpieces and machines, often taking the system productivity and energy consumption as objectives, modeling the problem using optimization methods, and solving it using exact or heuristic algorithms. The research at the production-line level focuses more on the scheduling problems of production and maintenance. Through effective scheduling strategies, scheduling optimization is used to reduce the cost of sustainable production and achieve energy savings without over-changing the system structure.

At the system level, energy consumption optimization is often based on the application of management systems and overall policy considerations. Compared with the above two levels, its optimization is more inclined to the upgrading of management methods and innovation of management modes, and there is still a long way for improvement with practical implementation and application.

Based on the above analysis, we believe that future research trends are mainly reflected in the following points:

- From the methodology perspective:

- Unification of the analysis and evaluation system

The current model construction is more individualized, and the actual energy consumption flow and energy consumption transformation relationship of the research object have not yet been comprehensively described clearly, either at the single-machine level or at the production-line level. Therefore, the subsequent research can consider unifying the definition of process energy consumption calculation, defining system boundaries, unifying input and output variables, and finally establishing a unified evaluation system to provide systematic guidance for the research of sub-problems.

- Construction of systematic theory

At present, the optimization at each level is basically isolated. Through the construction of systematic energy consumption optimization theory such as the manufacturing system energy flow model, the relationship of each sub-problem can be clarified and further interaction between more decision variables can be discovered.

- Refinement of management theory

To put these energy-optimization methodologies into practice, we need to rely on the efficient management tools of enterprises. At present, the consideration of energy optimization at the system management level is not sufficient; hence, the promotion of technology application is somewhat limited. Innovations in energy management theory can be made in the future to promote energy-saving methods.

- From the application perspective:

- Development of control and management software

As a key driving factor of Industry 4.0, the development of industrial software is an important measure of the manufacturing competitiveness of countries. In a sustainable background, good industrial software can not only improve production efficiency but also achieve energy savings. From the machine level, machines are driven by control software. Therefore, in addition to focusing on production efficiency and quality, the development of control software can put more attention on the combining of the optimization of process parameters and energy consumption. Moreover, from the factory level, the combination of energy management in the MES is also gradually becoming an essential part of the industry site management measures.

- Application of new technologies

With the progress of science and technology, the iteration of machine tools and the upgrading of manufacturing paradigms bring challenges to optimizing energy consumption. Industry 5.0, characterized by being human-centric, resilient, and sustainable, further promotes the industrial transformation toward an environment-friendly manufacturing model. Explorations on clean production technology, energy savings, environmental protection technology, and recycling manufacturing all have great prospects.

7. Conclusions

The problem of energy consumption optimization in manufacturing systems has received attention with the rising concern of sustainability. This paper reviews articles in the field of energy optimization of O&M of manufacturing systems, covering several aspects related to the optimization procedures such as model construction, solution methods, and application areas. The main contributions of this paper are as follows:

- The current research perspectives on energy optimization of O&M are described.

- A detailed classification and problem overview of energy-optimization methods of the O&M of manufacturing systems are outlined.

- The current research framework is summarized and future research trends are proposed.

For the research related to energy optimization, we believe that it has high application value and vast research space. Through reasonable O&M scheduling, energy savings can be achieved without changing production system structures, which will pave the way for the progressive promotion of sustainable manufacturing paradigms. Research in this area is expected to achieve greater attention and policy preferences. The systematic review of this paper can provide some references for future studies.

This entry is adapted from the peer-reviewed paper 10.3390/en15197338

References

- Mitlin, D. Sustainable Development: A Guide to the Literature. Environ. Urban. 1992, 4, 111–124. https://doi.org/10.1177/095624789200400112.

- Hopwood, B.; Mellor, M.; O’Brien, G. Sustainable Development: Mapping Different Approaches. Sustain. Dev. 2005, 13, 38–52. https://doi.org/10.1002/sd.244.

- Oikonomou, V.; Becchis, F.; Steg, L.; Russolillo, D. Energy Saving and Energy Efficiency Concepts for Policy Making. Energy Policy 2009, 37, 4787–4796. https://doi.org/10.1016/j.enpol.2009.06.035.

- Tanaka, K. Review of Policies and Measures for Energy Efficiency in Industry Sector. Energy Policy 2011, 39, 6532–6550. https://doi.org/10.1016/j.enpol.2011.07.058.

- IEA. Data & Statistics . Available online: https://www.iea.org/data-and-statistics/data-browser (accessed 15 August 2022).IEA (2022), Energy Statistics Data Browser, IEA, Paris. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser (accessed 15 August 2022).

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A Framework to Achieve Sustainability in Man-ufacturing Organisations of Developing Economies Using Industry 4.0 Technologies’ Enablers. Comput. Ind. 2020, 122, 103280. https://doi.org/10.1016/j.compind.2020.103280.

- Ke, J.; Price, L.; Ohshita, S.; Fridley, D.; Khanna, N.Z.; Zhou, N.; Levine, M. China’s Industrial Energy Consumption Trends and Impacts of the Top-1000 Enterprises Energy-Saving Program and the Ten Key Energy-Saving Projects. Energy Policy 2012, 50, 562–569. https://doi.org/10.1016/j.enpol.2012.07.057.

- Hesselbach, J.; Herrmann, C.; Detzer, R.; Thiede, L.M.S.; Hesselbach, J.; Herrmann, C.; Detzer, R.; Martin, L.; Thiede, S.; Lüdemann, B. Energy Efficiency through Optimized Coordination of Production and Technical Building Services. In Pro-ceeding of the 15th Conference on Life Cycle Engineering; Sydney, Australia, 17–19 March 2008 ; pp. 624–628.

- Smarra, F.; Jain, A.; de Rubeis, T.; Ambrosini, D.; D’Innocenzo, A.; Mangharam, R. Data-Driven Model Predictive Control Using Random Forests for Building Energy Optimization and Climate Control. Appl. Energy 2018, 226, 1252–1272. https://doi.org/10.1016/j.apenergy.2018.02.126.

- González-Briones, A.; De La Prieta, F.; Mohamad, M.S.; Omatu, S.; Corchado, J.M. Multi-Agent Systems Applications in Energy Optimization Problems: A State-of-the-Art Review. Energies 2018, 11, 1928. https://doi.org/10.3390/en11081928.

- Xia, T.; Dong, Y.; Pan, E.; Zheng, M.; Wang, H.; Xi, L. Fleet-Level Opportunistic Maintenance for Large-Scale Wind Farms Integrating Real-Time Prognostic Updating. Renew. Energy 2021, 163, 1444–1454. https://doi.org/10.1016/j.renene.2020.08.072.

- Park, C.-W.; Kwon, K.-S.; Kim, W.-B.; Min, B.-K.; Park, S.-J.; Sung, I.-H.; Yoon, Y.S.; Lee, K.-S.; Lee, J.-H.; Seok, J. Energy Consumption Reduction Technology in Manufacturing—A Selective Review of Policies, Standards, and Research. Int. J. Precis. Eng. Manuf. 2009, 10, 151–173. https://doi.org/10.1007/s12541-009-0107-z.

- Jasiulewicz-Kaczmarek, M.; Gola, A. Maintenance 4.0 Technologies for Sustainable Manufacturing—An Overview. IFAC-PapersOnLine 2019, 52, 91–96. https://doi.org/10.1016/j.ifacol.2019.10.005.

- Gahm, C.; Denz, F.; Dirr, M.; Tuma, A. Energy-Efficient Scheduling in Manufacturing Companies: A Review and Research Framework. Eur. J. Oper. Res. 2016, 248, 744–757. https://doi.org/10.1016/j.ejor.2015.07.017.

- Reich-Weiser, C.; Vijayaraghavan, A.; Dornfeld, D. Appropriate Use of Green Manufacturing Frameworks. In Proceedings of the 17th CIRP International Conference on Life Cycle Engineering, Hefei, China, 19–21 May 2010.

- Yang, Z. (Max) ; Djurdjanovic, D.; Ni, J. Maintenance Scheduling in Manufacturing Systems Based on Predicted Machine Degradation. J. Intell. Manuf. 2008, 19, 87–98. https://doi.org/10.1007/s10845-007-0047-3.

- Cui, W.-W.; Lu, Z.; Pan, E. Integrated Production Scheduling and Maintenance Policy for Robustness in a Single Machine. Comput. Oper. Res. 2014, 47, 81–91. https://doi.org/10.1016/j.cor.2014.02.006.

- Sortrakul, N.; Nachtmann, H.L.; Cassady, C.R. Genetic Algorithms for Integrated Preventive Maintenance Planning and Production Scheduling for a Single Machine. Comput. Ind. 2005, 56, 161–168. https://doi.org/10.1016/j.compind.2004.06.005.

- Lu, B.; Zhou, X.; Li, Y. Joint Modeling of Preventive Maintenance and Quality Improvement for Deteriorating Single-Machine Manufacturing Systems. Comput. Ind. Eng. 2016, 91, 188–196. https://doi.org/10.1016/j.cie.2015.11.019.

- Yin, H.; Zhang, G.; Zhu, H.; Deng, Y.; He, F. An Integrated Model of Statistical Process Control and Maintenance Based on the Delayed Monitoring. Reliab. Eng. Syst. Safe. 2015, 133, 323–333. https://doi.org/10.1016/j.ress.2014.09.020.

- Shojaeinasab, A.; Charter, T.; Jalayer, M.; Khadivi, M.; Ogunfowora, O.; Raiyani, N.; Yaghoubi, M.; Najjaran, H. Intelligent Manufacturing Execution Systems: A Systematic Review. J. Manuf. Syst. 2022, 62, 503–522. https://doi.org/10.1016/j.jmsy.2022.01.004.

- Hu, J.; Jiang, Z.; Liao, H. Joint Optimization of Job Scheduling and Maintenance Planning for a Two-Machine Flow Shop Considering Job-Dependent Operating Condition. J. Manuf. Syst. 2020, 57, 231–241. https://doi.org/10.1016/j.jmsy.2020.08.013.

- Gu, X.; Jin, X.; Guo, W.; Ni, J. Estimation of Active Maintenance Opportunity Windows in Bernoulli Production Lines. J. Manuf. Syst. 2017, 45, 109–120. https://doi.org/10.1016/j.jmsy.2017.08.005.

- Xia, T.; Dong, Y.; Xiao, L.; Du, S.; Pan, E.; Xi, L. Recent Advances in Prognostics and Health Management for Advanced Manufacturing Paradigms. Reliab. Eng. Syst. Saf. 2018, 178, 255–268. https://doi.org/10.1016/j.ress.2018.06.021.

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical Energy Requirements for Manufacturing Processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; Volume 31, pp. 623–638.

- Yansong Guo; Jef Loenders; Joost Duflou; Bert Lauwers; Optimization of Energy Consumption and Surface Quality in Finish Turning. Procedia CIRP 2012, 1, 512-517, 10.1016/j.procir.2012.04.091.

- Zhong, Q.; Tang, R.; Peng, T. Decision Rules for Energy Consumption Minimization during Material Removal Process in Turning. J. Clean. Prod. 2017, 140, 1819–1827. https://doi.org/10.1016/j.jclepro.2016.07.084.

- Wang, Q.; Liu, F.; Wang, X. Multi-Objective Optimization of Machining Parameters Considering Energy Consumption. Int. J. Adv. Manuf. Technol. 2014, 71, 1133–1142. https://doi.org/10.1007/s00170-013-5547-z.

- Ma, F.; Zhang, H.; Cao, H.; Hon, K.K.B. An Energy Consumption Optimization Strategy for CNC Milling. Int. J. Adv. Manuf. Technol. 2017, 90, 1715–1726. https://doi.org/10.1007/s00170-016-9497-0.

- Bi, Z.M.; Wang, L. Energy Modeling of Machine Tools for Optimization of Machine Setups. IEEE Trans. Autom. Sci. Eng. 2012, 9, 607–613. https://doi.org/10.1109/TASE.2012.2195173.

- Guanghui Zhou; Shengze Yuan; Qi Lu; Xiaoping Xiao; A carbon emission quantitation model and experimental evaluation for machining process considering tool wear condition. The International Journal of Advanced Manufacturing Technology 2018, 98, 565-577, 10.1007/s00170-018-2281-6.

- Honghui Wang; Ray Y. Zhong; Guijie Liu; Weilei Mu; Xiaojie Tian; Dingxin Leng; An optimization model for energy-efficient machining for sustainable production. Journal of Cleaner Production 2019, 232, 1121-1133, 10.1016/j.jclepro.2019.05.271.

- Xingzheng Chen; Congbo Li; Ying Tang; Li Li; Yanbin Du; Lingling Li; Integrated optimization of cutting tool and cutting parameters in face milling for minimizing energy footprint and production time. Energy 2019, 175, 1021-1037, 10.1016/j.energy.2019.02.157.

- Shi, K.N.; Zhang, D.H.; Liu, N.; Wang, S.B.; Ren, J.X.; Wang, S.L. A Novel Energy Consumption Model for Milling Process Considering Tool Wear Progression. J. Clean. Prod. 2018, 184, 152–159. https://doi.org/10.1016/j.jclepro.2018.02.239.

- Tian, C.; Zhou, G.; Zhang, J.; Zhang, C. Optimization of Cutting Parameters Considering Tool Wear Conditions in Low-Carbon Manufacturing Environment. J. Clean. Prod. 2019, 226, 706–719. https://doi.org/10.1016/j.jclepro.2019.04.113.

- Xie, N.; Zhou, J.; Zheng, B. Selection of Optimum Turning Parameters Based on Cooperative Optimization of Minimum Energy Consumption and High Surface Quality. Procedia CIRP 2018, 72, 1469–1474. https://doi.org/10.1016/j.procir.2018.03.099.

- Jihong Yan; Lin Li; Multi-objective optimization of milling parameters – the trade-offs between energy, production rate and cutting quality. Journal of Cleaner Production 2013, 52, 462-471, 10.1016/j.jclepro.2013.02.030.

- Verma, A.; Rai, R. Energy Efficient Modeling and Optimization of Additive Manufacturing Process. 2013 International Solid Freeform Fabrication Symposium,; University of Texas at Austin: Austin, TX, USA , 12-14 August 2013. https://doi.org/10.26153/tsw/15427.

- Richard Barlow; Larry Hunter; Optimum Preventive Maintenance Policies. Operations Research 1960, 8, 90-100, 10.1287/opre.8.1.90.

- Weigang Xu; Le Cao; Energy efficiency analysis of machine tools with periodic maintenance. International Journal of Production Research 2014, 52, 5273-5285, 10.1080/00207543.2014.893067.

- Karnouskos, S.; Colombo, A.W.; Martinez Lastra, J.L.; Popescu, C. Towards the Energy Efficient Future Factory. In Pro-ceedings of the 2009 7th IEEE International Conference on Industrial Informatics, Cardiff, Wales, UK, 23–26 June 2009; pp. 367–371. https://doi.org/10.1109/INDIN.2009.5195832.

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Iden-tifying the Current Trends and Future Perspectives. Process. Saf. Environ. 2018, 117, 408–425. https://doi.org/10.1016/j.psep.2018.05.009.

- Weigang Xu; Le Cao; Energy efficiency analysis of machine tools with periodic maintenance. International Journal of Production Research 2014, 52, 5273-5285, 10.1080/00207543.2014.893067.