Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The new construction of numerous infrastructures and buildings, particularly in the architecture, engineering, and construction (AEC) industry, has led to an exponential increase in the demand for raw materials and energy, which is leading to the depletion of natural resources. The approach to treating these buildings at the end of life has also raised concerns worldwide. Transforming the current linear development model into a circular economy is considered an effective solution.

- building circularity

- material management

- waste reduction

1. Pre-Treatment

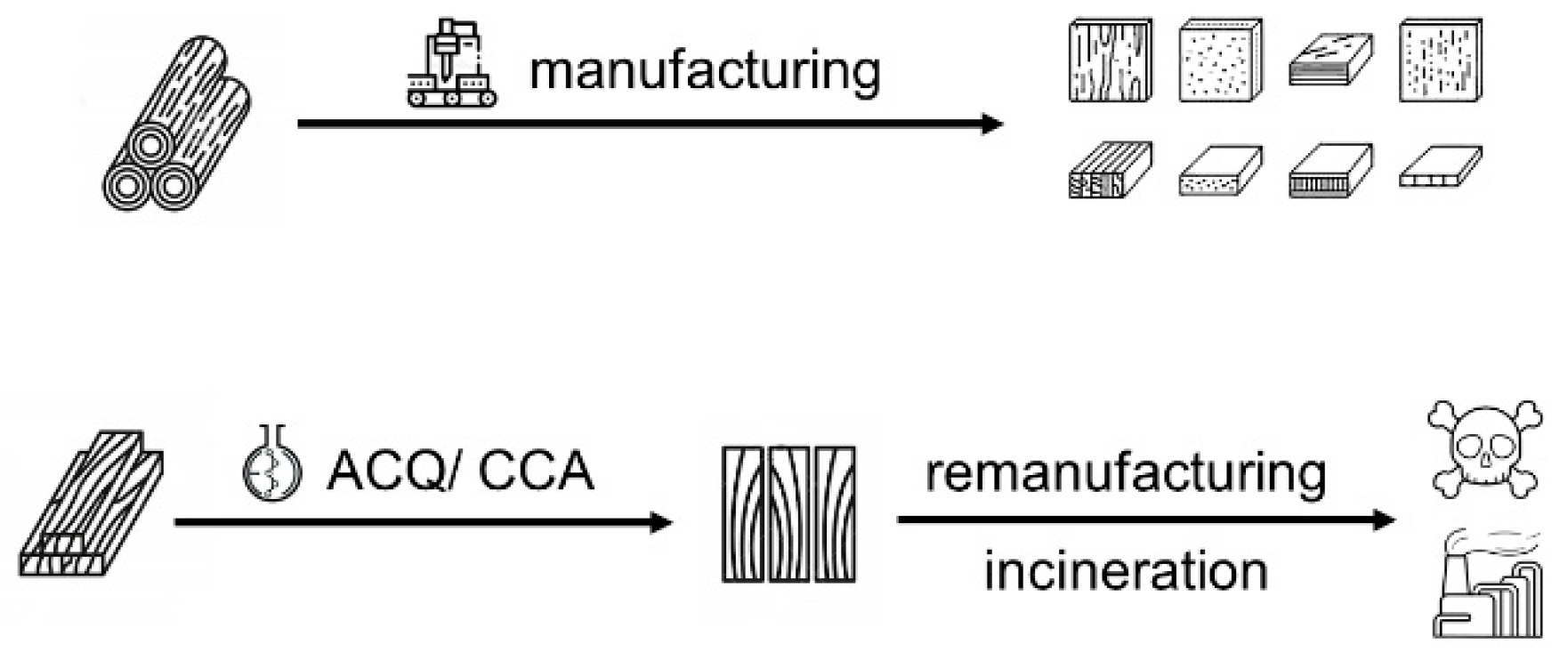

Raw materials are typically processed into building products before they are used in construction. This process, from natural resource to product, is referred to as pre-treatment and focuses on the initial transformation of the material to prepare for construction. For example, logs are processed into conventionally sized wood sheets and then bonded together with a durable, moisture-resistant structural adhesive to form glued laminated timber (GLT). Engineered wood products, such as particle board (PB), oriented strand chipboard (OSB), and medium-density fibreboard (MDF), are made from wood with adhesives (Figure 1). Another example is the smelting of the iron ore used to make metal construction products such as steel bars, bolts, and nails.

Figure 1. Pre-treatment of wood-based products.

Although this conversion process is virtually irreversible, almost all these building products have the potential to be recycled [1][2][3]. For example, MDF can be industrially milled and then reprocessed into PB [4], and steel beams can be remanufactured into reinforcing bars [3]. However, when some toxic materials are used to enhance the performance of building products, their recycling potential can become limited. For instance, wood treated with chromated copper arsenate (CCA) and alkaline copper quaternary (ACQ) preservatives. The metals contained in CCA and ACQ contaminate remanufactured products, and therefore, these woods cannot be recycled [5]. The combustion process of CCA-treated wood emits harmful gases that can be inhaled, causing acute and chronic arsenic poisoning (Figure 1). It cannot be treated by incineration and is usually disposed of in landfills [6][7]. The use of toxic materials significantly reduces the recycling potential of wood and should be avoided as much as possible.

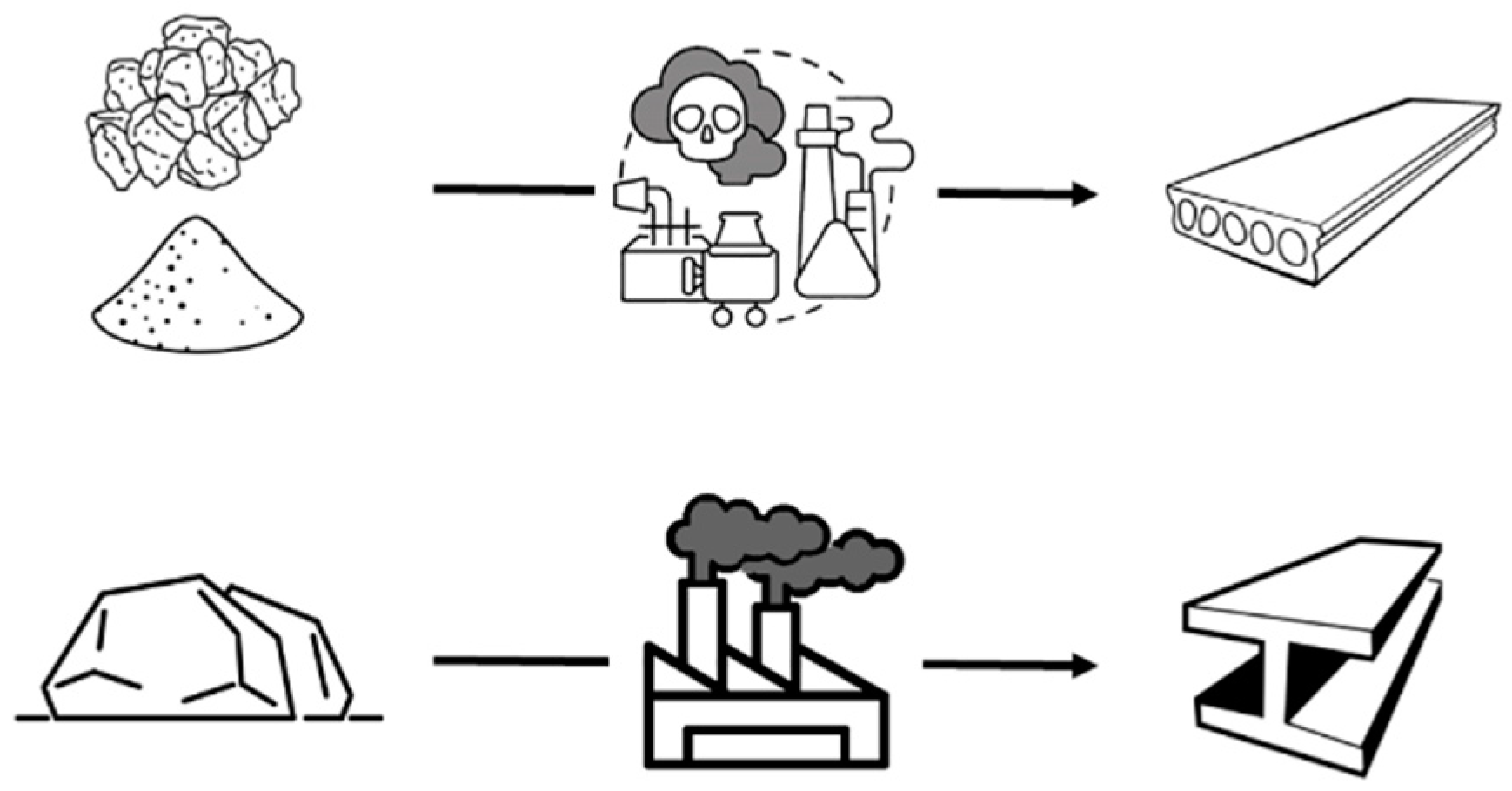

Although concrete technically has the potential to be recycled, the aggregates (gravel of different diameters) and cement (iron ore powder, clay, limestone) that make up concrete are non-renewable resources [8][9]. In addition, cement is among the most energy-intensive materials used in the AEC industry, consuming large amounts of fossil fuels and causing the production of air pollutants such as carbon dioxide, sulphur dioxide, and nitrous oxide in the manufacturing process [10]. Steel is also recyclable, but its raw material, iron ore, is not renewable, and emissions of air pollutants are also a product of the smelting process (Figure 2). In addition, the mining of iron ore can potentially cause metal contamination of groundwater [11].

Figure 2. Pre-treatment of concrete and steel products.

Obviously, such raw materials may have a direct impact on the recycling potential of building products, require excessive energy consumption, yield airborne pollutants, including CO2, increase the quantity of the carbon footprint, or impose other significant strains on the environment. Therefore, it is recommended that architects in the design phase minimise the use of products that are manufactured from non-renewable materials or that require significant energy consumption in their production and avoid the use of non-recyclable building products that contain toxic substances.

2. Composition

The composition process combines single building materials, products, components, and modules to a finished construction. The reuse of building materials and components is not directly influenced by the composition. This is reflected by the separation results after deconstruction. In other words, sustainability is determined by the material’s reversibility or ability to be converted into a reusable state. According to this analysis and with reference to the classification of whether elements can be completely separated from each other [1], the composition methods can be broadly classified into two types: physical- and chemical-fixed connections. Physical-fixed connection refers to the way materials or components are held together by force, such as nails or bolts. Such elements could be completely detached during deconstruction. Through chemical fixing, the material is usually changed at the molecular level in the composition process and is bound together as an ensemble. Such elements are difficult to separate from each other. Using this classification as a criterion, several conventional connections are listed in Table 1.

Table 1. Conventional connections for material composition.

| Connection | Reference | ||

|---|---|---|---|

| Type | Position | Method | |

| Physical fixing | OSB sheathing—timber frame | nails | [12] |

| steel module—module | bolts | [13] | |

| prefabricated concrete beam-column | steel plates, top angles, steel threaded rods | [14] | |

| prefabricated concrete wall- wall | steel U-shaped channels, bolts, nuts | [15] | |

| timber roof—wall | toe-nailed | [16] | |

| timber beam—column | mortise-tenon | [17] | |

| Chemical fixing | brick—stone (within masonry wall) |

high-grade mortar | [18] |

| steel beam—column | welding | [13] | |

| steel module—module | welding | [13] | |

| prefabricated concrete beam—column | steel connector (consists of bolting steel tubes, steel plates), casting | [19] | |

| concrete plate—beam | steel rivets, casting | [20] | |

| timber roof—wall | high-strength fibre reinforced polymers with epoxy resin | [21] | |

Physical-fixed connections are generally considered more conducive to building deconstruction than chemical fixing [22]. However, the difficulty of deconstruction varies widely for physically fixed methods as well. For example, nail fixing and riveted fixing are more challenging to remove than screw fixing [23]. Timber components connected by nails and staples are more complex to separate than those joined by friction or bolts and nuts [24]. Although chemically fixed connectors limit the separation of materials, they do not affect the recycling potential of materials if they are used only between building products made from the same raw materials. Additionally, wherever possible, it is suggested to use connecting materials that are weaker than the elements being linked. For example, mortar that is weaker than bricks can be used to build walls so that it is easier to break apart when dismantled [25]. Thus, the choice of connecting materials and methods greatly affects deconstruction capabilities and practices.

3. Decomposition

The process of breaking down a building into smaller units (room modules, components, products, etc.) with material separation is called decomposition. The final states of dismantled buildings by different methods can be divided into two categories: a mixture of multiple materials and single building elements. The former mostly result from heavy mechanical demolition, while the latter usually result from deconstruction work using manual, light mechanical, or electrical tools. Therefore, the process of decomposition can be classified as soft stripping or hard stripping depending on the methods used. Soft stripping is relatively costly and time-consuming, but the functionality of the resulting components or products can be maximised. Hard stripping is highly destructive to building materials and components, but it is less costly [26]. Table 2 lists some of the common tools used and their functions in the decomposition processes.

Table 2. Tools and methods for material decomposition. (Reproduced with permission from Table 7.1 in ref. [27], which was published by Woodhead Publishing Limited, 2013).

| Tool/Method | Function/Detail | |

|---|---|---|

| Tools for soft stripping | wrench | loosening bolts, separating metal elements |

| bow saw | precise cutting of small wooden elements | |

| pickaxe | breaking stone or brick sections | |

| pliers | cutting cables, dismantling metallic and plastic elements | |

| de-nailing gun | firing small ram to punch nails out | |

| hydraulic scissors | precise dividing of metal, plastic, wood, brick and concrete | |

| Methods for hard stripping | thermal processes | materials are fused and separating structures |

| abrasive processes | the constructed elements are cut into smaller pieces with abrasive saws | |

| chemical processes | using of highly expansive chemicals, causing fragments of constructed elements | |

| electrical processes | discharging through elements, resulting in breakage | |

| explosive | the collapse of a structure with explosives at a critical point of the structure |

Soft stripping is promoted because it makes the building components or products easier to reuse or recycle than hard stripping [27]. However, a lack of systematic deconstruction training can be a major obstacle. Workers should be trained in basic operations, large equipment control, hazardous material recognition, fall protection, rescue procedures, etc. [28]. These trainings not only ensure workers’ safety but also increase deconstruction efficiency and reduce labour costs.

As an accelerator for the replacement of hard stripping with soft stripping, the development and application of separation-related tools for building deconstruction play a significant role. The advantages of machine-assisted separation are obvious, including speed, safety, control, accuracy and transparency of work progress [29]. Most importantly, it can replace humans to split up complicated connected components, increasing the usable proportion of individual products or components after deconstruction [30].

Generally, physically fixed connections allow for soft stripping, whereas chemically fixed connections can typically be separated with hard stripping. For instance, bolted steel beams and columns can be detached by removing the bolts using a wrench. Another example is blasting, the most common way to dismantle high-rise buildings constructed of cast-in-place concrete [31]. It is important to note that methods may exist for separating components typically considered inseparable. For example, mid-infrared wavelengths could theoretically remove epoxy resin that is sensitive to its wavelength [32].

4. Post-Treatment

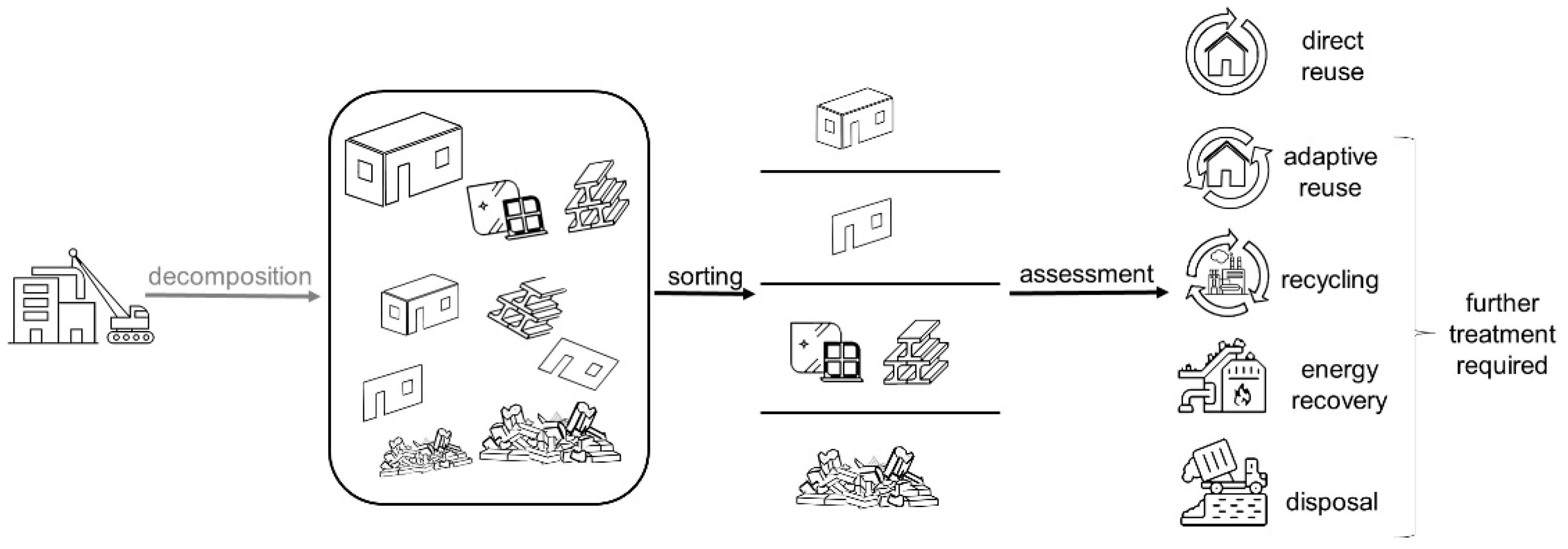

The process follows building deconstruction when all the materials have a designated destination, which refers to extending life, entering the next lifecycle or ending life and leaving the lifecycle. This process is called post-treatment. This stage includes sorting, assessment, manufacturing, and alternative designations, such as reuse, recycling, energy recovery, and disposal. Sorting classifies decomposed materials into room modules, components, pure materials, mixed materials, etc. Polluted elements are removed during this process [33]. Subsequently, the remaining materials are analysed and tested to determine their properties. For example, the shear strength of timber beams and the tensile strength of steel are tested to determine whether they can be used again. In addition, the destination of these elements is considered in relation to the corresponding ‘recipient’, for example, determining whether components for reuse exactly fit to a new building functionally and dimensionally. If complex modifications on components are compulsory for reuse, downcycling might be more appropriate based on energy consumption. By comparison, these materials will be treated in a way that maximises environmental benefits.

When components or products exactly match all requirements of the new buildings, they can be reused directly. However, some materials require minor modifications to work properly, which is called adaptive reuse. Defective elements that still have recycling potential can be used as raw materials to manufacture new products. For example, mineral wools separated from CDW are added in the production of gypsum products to enhance their flexural strength [34]. These treatments are considered good environmental practices. They offer great potential for improving and increasing resource efficiency in the AEC industry, thereby reducing energy use and associated carbon emissions [35]. Alternatively, materials that can be converted at high temperatures or through landfills into electrical or thermal energy can be returned to the building lifecycle in the form of energy. These include the incineration of combustible materials instead of fossil fuels or the collection of methane from landfills containing specific materials [36]. In contrast to the abovementioned treatments, unmanaged or haphazard disposal, including deposition of DW on open sites or direct burning, is the most inexpensive but least environmentally friendly method. Figure 3 illustrates the details of the processes of material post-treatment.

Figure 3. Processes of material post-treatment.

It is advantageous to reuse room modules, components, pure building products, and mixed materials after soft stripping. The former three have been examined for the possibility of reuse. However, most buildings are dismantled by hard stripping, and mixed materials are crushed to secondary aggregates in various applications. The transformation of these materials is a process of downcycling. For example, concrete is mostly recycled as low-quality aggregates in road construction. However, some developed countries, such as Belgium and the Netherlands, are already facing a saturated market for low-quality aggregates, with supply outstripping demand [37][38].

To prevent this from happening to the NIC in the future, the most immediate solution should be upgrading remanufacturing technology. This minimises downcycling and simultaneously increases the reuse of different types of materials. There is also a need to improve the standards and legal framework for using secondary materials. Standards and norms ensure the quality of products, while legal systems enable the government to supervise and encourage active participation in recycling by relevant practitioners [39]. In this way, the dual effect of expanding the market and guaranteeing quality will avoid the downcycling of materials and increase the overall proportion of materials reintroduced into the recycling system.

This entry is adapted from the peer-reviewed paper 10.3390/su141911941

References

- Morgan, C.; Stevenson, F. Design for Deconstruction SEDA Design Guides for Scotland: No. 1; Scottish Executive, Scottish Ecological Design Association: Edinburgh, UK, 2005.

- Brown, M.; Buranakarn, V. Emergy indices and ratios for sustainable material cycles and recycle options. Resour. Conserv. Recycl. 2003, 38, 1–22.

- Iacovidou, E.; Purnell, P. Mining the physical infrastructure: Opportunities, barriers and interventions in promoting structural components reuse. Sci. Total Environ. 2016, 557, 791–807.

- Azambuja, R.d.R.; Castro, V.G.d.; Trianoski, R.; Iwakiri, S. Recycling wood waste from construction and demolition to produce particleboards. Maderas. Cienc. Tecnol. 2018, 20, 681–690.

- Hasan, A.R.; Schindler, J.; Solo-Gabriele, H.M.; Townsend, T.G. Online sorting of recovered wood waste by automated XRF-technology. Part I: Detection of preservative-treated wood waste. Waste Manag. 2011, 31, 688–694.

- Chen, A.Y.-Y.; Olsen, T. Chromated copper arsenate–treated wood: A potential source of arsenic exposure and toxicity in dermatology. Int. J. Women’s Dermatol. 2016, 2, 28–30.

- Saxe, J.K.; Wannamaker, E.J.; Conklin, S.W.; Shupe, T.F.; Beck, B.D. Evaluating landfill disposal of chromated copper arsenate (CCA) treated wood and potential effects on groundwater: Evidence from Florida. Chemosphere 2007, 66, 496–504.

- Pacheco-Torgal, F.; Shahsavandi, A.; Jalali, S. Mechanical properties and durability of concrete with partial replacement of Portland cement by ceramic wastes. In Proceeding of the WASTES: Solutions, Treatments and Opportunities, Guimarães, Portugal, 12–14 September 2011.

- Maton, S.M.; Dabi, D.D.; Dodo, J.D.; Nesla, R.A. Forestalling the Continued Depletion of Nigeria’s Mineral Resources through Proper Conservation. Int. J. Sci. Technol. 2016, 4, 103–110.

- Babor, D.; Plian, D.; Judele, L. Environmental impact of concrete. Bul. Inst. Politeh. Din Lasi. Sect. Constr. Arhit. 2009, 55, 27.

- Jahanshahi, R.; Zare, M. Assessment of heavy metals pollution in groundwater of Golgohar iron ore mine area, Iran. Environ. Earth Sci. 2015, 74, 505–520.

- Anil, Ö.; Togay, A.; Söğütlü, C.; Döngel, N.; Karagöz, Ü.; Ediz, İ. Experimental Analysis of Hysteretic Load Behavior of Timber Framed Shear Walls with Openings. In Proceeding of the 11th International Congress on Advances in Civil Engineering-ACE, Istanbul, Turkey, 21–25 October 2014.

- Chen, Z.; Liu, J.; Yu, Y.; Zhou, C.; Yan, R. Experimental study of an innovative modular steel building connection. J. Constr. Steel Res. 2017, 139, 69–82.

- Baran, E.; Mahamid, M.; Baran, M.; Kurtoglu, M.; Torra-Bilal, I. Performance of a moment resisting beam-column connection for precast concrete construction. Eng. Struct. 2021, 246, 113005.

- Vaghei, R.; Hejazi, F.; Taheri, H.; Jaafar, M.S.; Aziz, F.N.A.A. Development of a new connection for precast concrete walls subjected to cyclic loading. Earthq. Eng. Eng. Vibr. 2017, 16, 97–117.

- Cheng, J. Testing and analysis of the toe-nailed connection in the residential roof-to-wall system. For. Prod. J. 2004, 54, 58–65.

- Ma, L.; Xue, J.; Dai, W.; Zhang, X.; Zhao, X. Moment-rotation relationship of mortise-through-tenon connections in historic timber structures. Constr. Build. Mater. 2020, 232, 117285.

- Galassi, S.; Dipasquale, L.; Ruggieri, N.; Tempesta, G. Andalusian timber roof structure in Chefchaouen, Northern Morocco: Construction technique and structural behavior. J. Archit. Eng. 2018, 24, 04018012.

- Choi, H.-K.; Choi, Y.-C.; Choi, C.-S. Development and testing of precast concrete beam-to-column connections. Eng. Struct. 2013, 56, 1820–1835.

- Mohammed, A.A.; Mohammed, O.K. Composite concrete–Unregularized timber section for flat roof construction. Structures 2020, 27, 1324–1334.

- Canbek, C.; Mirmiran, A.; Chowdhury, A.G.; Suksawang, N. Development of fiber-reinforced polymer roof-to-wall connection. J. Compos. Constr. 2011, 15, 644–652.

- Boothroyd, G.; Alting, L. Design for assembly and disassembly. CIRP Ann. 1992, 41, 625–636.

- Morgan, C.; Stevenson, F. Design and Detailing for Deconstruction: SEDA Design Guide for Scotland; Scottish Executive, Scottish Ecological Design Association: Edinburgh, UK, 2005.

- Mayer, M. Adapting residential envelope assemblies for full circularity. J. Phys. Conf. Ser. 2021, 2042, 012170.

- Crowther, P. Developing Guidelines for Designing for Deconstruction. In Deconstruction-Closing the Loop Conference Proceedings; Building Research Council: Watford, UK, 2000.

- Xiao, J.; Chen, L.; Ye, J.; Lan, W.; Zeng, L. Technology and Green Development of Demolition for Concrete Structures. J. Archit. Civ. Eng. 2019, 36, 1–10. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2019&filename=XBJG201905002&uniplatform=NZKPT&v=Noq24ajEcrFdifCZtslUeZDdOCD2eHZ2VazrRDJbBNiptc4J136A_thGtozeKej9 (accessed on 11 August 2022).

- Coelho, A. Conventional demolition versus deconstruction techniques in managing construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., Brito, J.D., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 141–185.

- Chini, A.R.; Bruening, S. Deconstruction and materials reuse in the United States. Future Sustain. Constr. 2003, 14, pagination.

- Lee, S.; Pan, W.; Linner, T.; Bock, T. A framework for robot assisted deconstruction: Process, sub-systems and modelling. In Proceedings of the 32nd ISARC: Proceedings of the International Symposium on Automation and Robotics in Construction, Oulu, Finland, 15–18 June 2015.

- Lublasser, E.; Hildebrand, L.; Vollpracht, A.; Brell-Cokcan, S. Robot assisted deconstruction of multi-layered façade constructions on the example of external thermal insulation composite systems. Constr. Robot. 2017, 1, 39–47.

- Yang, Y.; Hu, J.; Liu, X.; Dai, J.; Yao, Y. Analysis of ground vibration characteristics caused by blasting demolition of high-rise buildings. Build. Struct. 2021, 51 (Suppl. 2), 1446–1450. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2022&filename=JCJG2021S2255&uniplatform=NZKPT&v=Xmv3MT2rnnlakNoPGmTwuX3rmUxfWK8nIY3UHyh0dzlE28H9kYwTrzkvMDWVE9PO (accessed on 11 August 2022).

- Scheerer, S.; Abraham, M.; Madden, O. Study of the effects of laser radiation on epoxy resins and epoxy systems on stone, ceramic, and glass surfaces. J. Cult. Herit. 2003, 4, 223–229.

- Chileshe, N.; Jayasinghe, R.S.; Rameezdeen, R. Information flow-centric approach for reverse logistics supply chains. Autom. Constr. 2019, 106, 102858.

- Romaniega Piñeiro, S.; del Río Merino, M.; Pérez García, C. New plaster composite with mineral wool fibres from CDW recycling. Adv. Mater. Sci. Eng. 2015, 2015, 854192.

- European Environment Agency. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050; European Environment Agency: Copenhagen, Denmark, 2011; Available online: https://www.staten-generaal.nl/9370000/1/j4nvi0xeni9vr2l_j9vvkfvj6b325az/vl82fmx00szx/f=/vl5ccnyjpptu.pdf (accessed on 11 August 2022).

- Pariathamby, A.; Bhatti, M.S. Issues and Challenges in Sustainable Solid Waste Management: Global and Asian Perspective. In Advances in Waste-to-Energy Technologies; CRC Press: Boca Raton, FL, USA, 2019; pp. 21–40.

- Di Maria, A.; Eyckmans, J.; Van Acker, K. Downcycling versus recycling of construction and demolition waste: Combining LCA and LCC to support sustainable policy making. Waste Manag. 2018, 75, 3–21.

- Zhang, C.; Hu, M.; Yang, X.; Miranda-Xicotencatl, B.; Sprecher, B.; Di Maio, F.; Zhong, X.; Tukker, A. Upgrading construction and demolition waste management from downcycling to recycling in the Netherlands. J. Clean. Prod. 2020, 266, 121718.

- Liu, H.; Long, H.; Li, X. Identification of critical factors in construction and demolition waste recycling by the grey-DEMATEL approach: A Chinese perspective. Environ. Sci. Pollut. Res. 2020, 27, 8507–8525.

This entry is offline, you can click here to edit this entry!