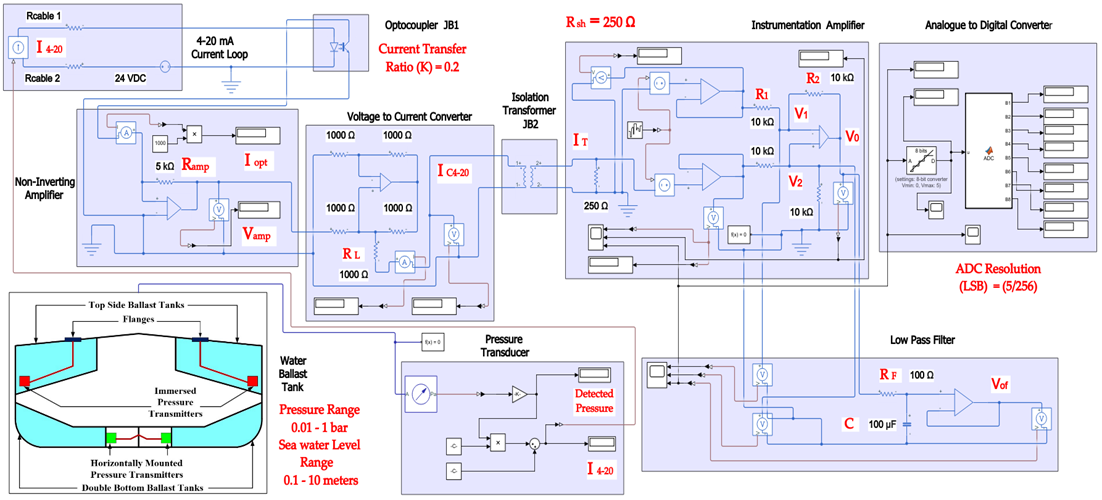

In maritime engineering applications, improved performance of instrumentation systems can be basically provided by adopting techniques to enhance the reliability of measurement/control systems based on the 4–20 mA analogue standard. This aspect will be discussed through a Simscape Simulink model illustrating methods of noise and ground loops elimination for a 4–20 mA pressure measurement current loop in the tank level measurement system on a bulk carrier commercial ship. Alternatively, improved measurement and control processes can be rendered by utilizing smart transmitters based on wired digital Foundation Fieldbus (FF) protocol. A simulation-based case study will analyze the possible options to implement non-intrinsically safe as well as intrinsically safe FF models for the tank level measurement system on a bulk carrier commercial ship. Conclusions obtained through analysis of the simulation results will characterize the behavior of FF segments in safe as well as explosive hazardous areas, highlighting the characteristics of field barriers and segment protectors used in conjunction with the HPTC (High-Power Trunk Concept) intrinsically safe model.

- 4-20 mA Analogue Standard

- instrumentation amplifier

- signal isolation

- Optocouplers

- High Power Trunk Concept HPTC

- Field Barriers

- Segment Protectors

1. The 4–20 mA Analogue Standard (Integration and Performance Improvement)

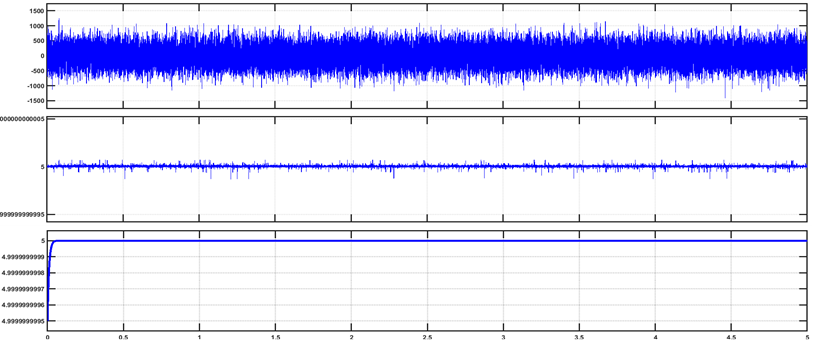

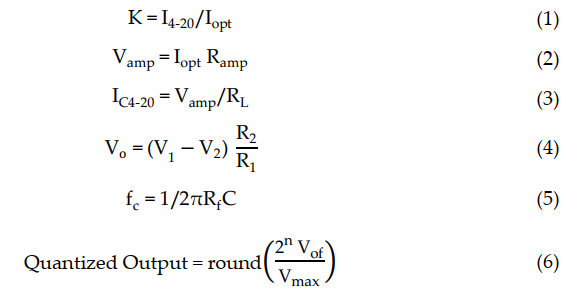

(quantized output is calculated through Equation (6) where n = 8 and Vmax = 5 VDC) and MATLAB-based function (Appendix A) to convert the detected output of the quantizer into 8 bits of binary data. The binary output of the analogue-to-digital converter can be transmitted to the CPU of the system controller through serial communication interfaces (RS 232 or RS485) or serial communication protocols such as Modbus RTU (relatively popular in maritime applications) [2].

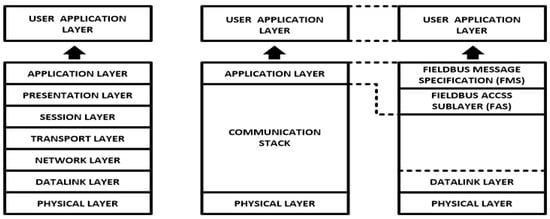

2. Foundation Fieldbus (Wired Digital Measurement and Control)

-

Statistical calculation module: The measured pressure values are applied to high-pass filter to detect any slow changes, such as set point modifications, and eliminate them while constructing the input signal noise signature. The mean value is calculated for the unfiltered signal, and the standard deviation will be calculated over the filtered signal.

-

Learning module: responsible for establishing the process baseline values based on mean and standard deviation values calculated by the previous module.

-

Decision module: it compares the measured value with the baseline, to decide if an alert/alarm should be activated or such a measured value should be ignored.

3. Proposed Foundation Fieldbus (FF) Solution

The proposed solution is based on the replacement of classical 4–20 mA pressure transmitters used in the tank level measurement system on a bulk carrier commercial ship with Foundation Fieldbus pressure transmitters. Simulation models created by Emerson Segment Design Tool and Pepperl + Fuchs Segment Checker will simulate a safe area as well as explosive hazardous areas’ operational conditions. Therefore, the proposed solution will take into account possible non-intrinsically safe as well as intrinsically safe FF models, as follows:

- Non-intrinsically safe model.

- Intrinsically safe entity model.

- FNICO (Fieldbus Non-Incendive Concept) model.

- FISCO (Fieldbus Intrinsically Safe Concept) model.

- HPTC (High-Power Trunk Concept) model.

- DART (Dynamic Arc Recognition and Termination) model

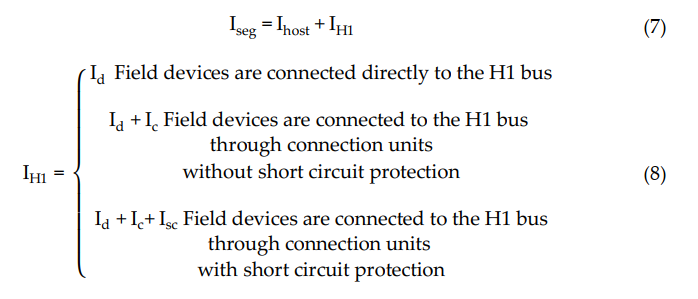

The recommended solution relies on replacement of the top side’s 10 immersed classical 4–20 mA transmitters with Foundation Fieldbus Rosemount 5400 non-contact radar transmitters and also replacement of the double bottom’s 14 classical 4–20 mA transmitters with Foundation Fieldbus Rosemount 3051 pressure transmitters. Each type of the previously mentioned models will be divided into two types of sub-models. The first one is for double bottom tanks, while the second one is for top side tanks. Each of these sub models consists of a single or multiple segments according to the requirements imposed by each sub-model. The total number of segments is determined according to the maximum allowable current withdrawn from the segment power supply. The total current consumption in a FF segment (Iseg) is the sum of current consumed by the host (Ihost) and the current consumed by the H1 bus (IH1) as indicated in Equation (7). The segment power supply should be able to withstand the sum of both currents. The maximum capacity of the segment power supply is dependent of the FF model adopted by the segment. For the non-intrinsically safe model, entity model, FISCO, FNICO, DART and HPTC (only when segment protectors are used) models, the current consumed by the H1 bus is simply the sum of the current consumed by all field devices (transmitters and actuators) if these devices were directly connected to the H1 bus without connection units such as megablocks; however, if those field devices were connected to the H1 bus through connection units, additional current will be consumed by these units. The current consumed by the connection unit is the sum of the operation current (Ic) and the current consumed by the field devices (Id) connected to the unit . In case the FF segment included connection units supporting short-circuit protection, Emerson Segment Design Tool calculates the short-circuit current (Isc) only once (near the segment terminator) at the last connection unit with short-circuit protection connected to the bus. The reason the short-circuit current is calculated only once along the H1 bus is that all field devices are connected in parallel to the same field bus, so in case a short circuit occurred, the whole H1 bus will suffer a failure.

Unlike FISCO and FNICO models, the High-Power Trunk Concept does not impose any limitations on the maximum available power at the Fieldbus trunk cable, which allows for longer cable lengths and a higher number of field devices per segment. The High-Power Trunk Concept allows for an output voltage up to 30 VDC and a maximum current up to 500 mA. The basic idea of a High-Power Trunk Concept is to provide unlimited energy to the field bus trunk; however, within the hazardous area, this unlimited energy will be distributed using energy-limiting wiring interfaces till it is delivered to the field device. HPTC does not require power supply conditioners particularly dedicated to the model, as standard non-intrinsically safe lower price power supplies can be used in the HPTC network. Energy-limiting wiring interfaces include field barriers and segment protectors. They both provide short-circuit protection as well as galvanically isolated outputs [11] (pp. 114–129) [34,35,41]. Each of these outputs acts as a FISCO or entity power supply. HPTC allows for a maximum number of four field barriers. Each of these barriers allows for up to four field devices. Therefore, HPTC allows for up to 16 field devices per segment. According to the simulation results that will be discussed later, there are two major differences between segment protectors and field barriers. The first difference is related to the available voltage at the output terminals to which field devices are connected. Segment protectors maintain constant voltage at a specific field device connected to a specific segment protector regardless of the voltage drop on the spur. Field barriers maintain constant output voltage all along the segment at the output port dedicated to a specific field device regardless of the total voltage drop on the H1 bus main trunk cable. Segment protectors are used with Zone2/Div2 applications; however, field barriers are used with Zone1/Div2 applications. Therefore, the voltage available at field barrier output terminals connected for field devices is less than the voltage available at segment protector output terminals for field devices, as will be shown in the simulation results. The second difference between segment protectors and field barriers, which was observed during simulation, is that the value of the current consumed by each field barrier is dependent of the following variants:

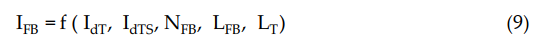

- The total current of field devices connected to the field barrier (IdT).

- The H1 bus main trunk overall cable length (LT).

- Number of field barriers included in the segment (NFB) and current consumed by each of them (IdTS).

- Length of H1 bus main trunk cable sections between field barriers (LFB).

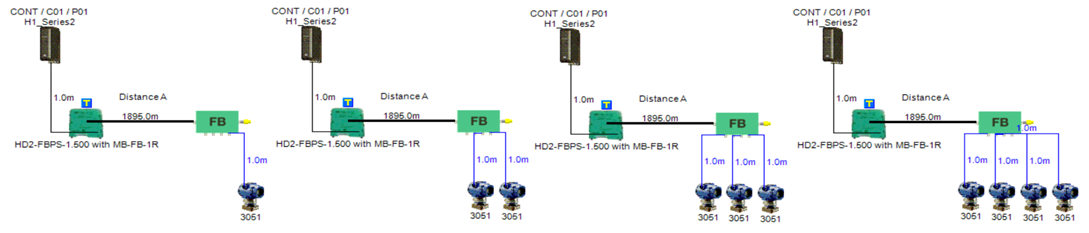

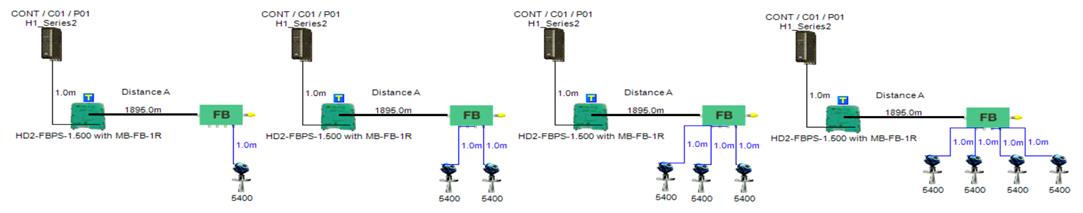

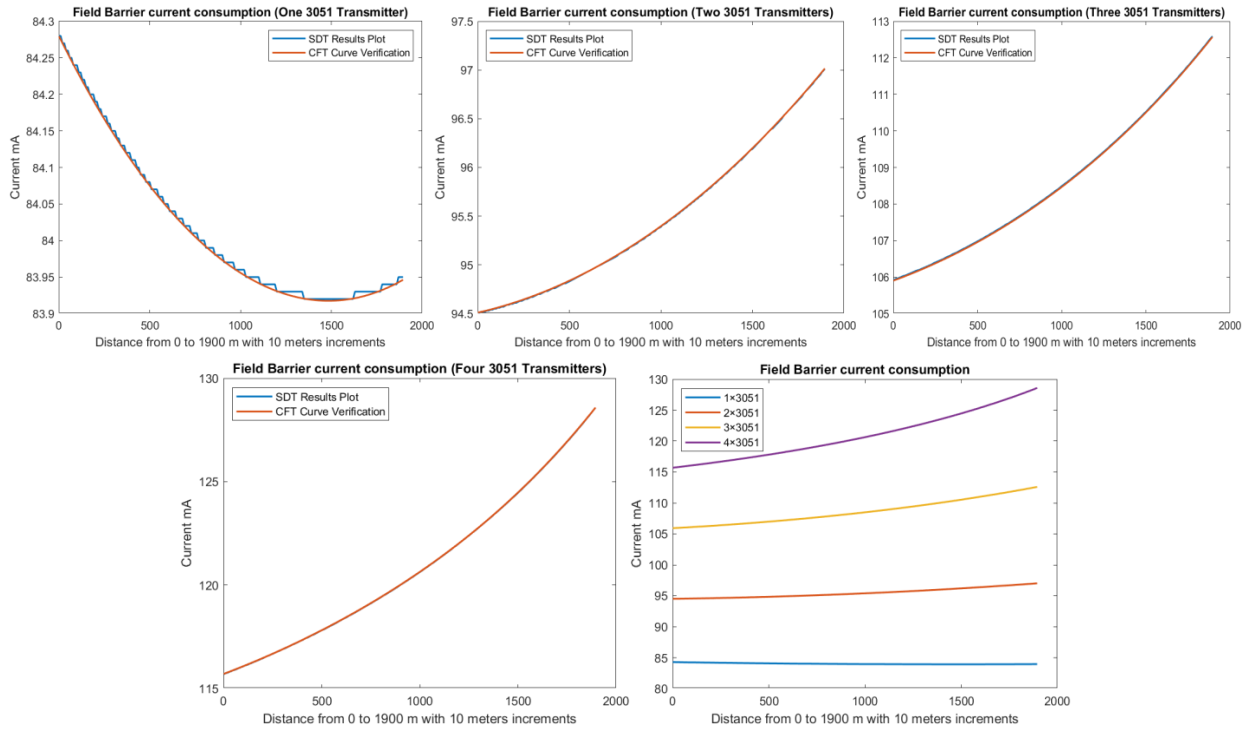

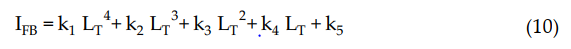

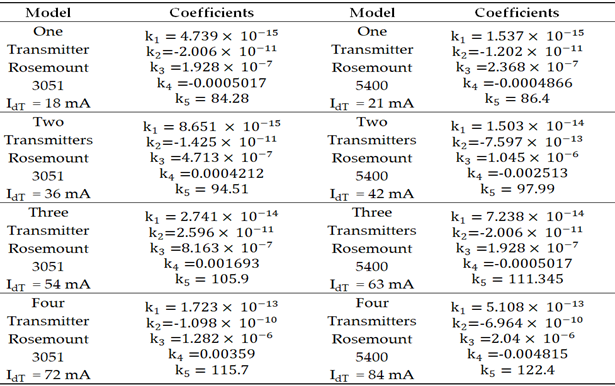

In order to define the characteristics of the relation between some of the previously mentioned variants and the current consumed by the field barrier, simple HPTC segments (Figure 6) were constructed using Emerson Segment Design Tool to derive the relation between the first two variants (IdT and LT) and the current consumed by the field barrier. Four of these segments are dedicated to Rosemount 3051 transmitters (Figure 6a), while the other four segments are dedicated to Rosemount 5400 transmitters (Figure 6b). In each of these segments, the current consumed by field barriers will be calculated with respect to the change in the distance A between the field barrier and the power supply from 10 m to 1895 m, with increments of 10 m. These calculations will be performed when one, two, three or four transmitters are connected to the field barrier. Results of these simulation models were plotted using MATLAB. Curve Fitting Tool in MATLAB was used to derive the mathematical equations describing the obtained simulation plots for each of the models in Figure 6. The mathematical equations obtained were verified by the same MATLAB code providing curves similar or identical to the simulation plots. These mathematical equations characterized the relation between field barriers’ current consumption and length of H1 bus cable (for a specific number of field devices connected to the barrier) as a polynomial relation of the fourth degree. This polynomial relation is generally described in Equation (10) where (IFB) is the current consumed by the field barrier, and (LT) is the length of the H1 bus cable between the power supply and field barrier. The values of coefficients k1, k2, k3, k4 and k5 are used to distinguish between the eight models illustrated in Figure 6a,b. The values of these coefficients for each of these eight models are indicated in Table 2. Figures 13 and 14 both illustrate the SDT (Segment Design Tool) simulation plots as well as the equation verifying curves for the models illustrated in Figure 6a,b, respectively. It would be worth mentioning that the obtained equations are applicable only for the models illustrated in Figure 6, which means that for another segment structure, where more field barriers as well as more field devices are added, the current consumed by the field barriers will be dependent of not only IdT and LT (similarly to segments in Figure 6) but also dependent of IdT, NFB and LFB.

6(a)

6(b)

Figure 6. Test segments (a,b) dedicated to deriving the relation between main FF trunk cable length and current consumed by field barriers. (a) Test segments using Rosemount 3051 Pressure Transmitters; (b) Test segments using Rosemount 5400 Radar Transmitters.

Figure 13. Illustration of current consumed by field barrier with respect to FF H1 trunk cable length when for four models in which one, two, three or four 3051 transmitters were connected to the field barriers in the models in Figure 6a.

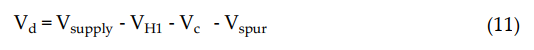

For all FF models except for the HPTC model, voltage drop at any field device in the segment can be calculated by Equation (11) where Vsupply is the available voltage from the segment power supply, VH1 is the voltage drop on the H1 bus main trunk cable from the power supply to the device, Vc is the voltage drop on the connection unit to which the field device spur is connected and Vspur is the voltage drop on the spur to which the field device is connected. For all connection units (megablocks, segment protectors and field barriers), there is no voltage difference between input and output terminals connected to the H1 bus main trunk cable. VH1 is dependent of the total current consumption in the segment and overall length of the main H1 bus trunk cable, while Vspur is dependent of spur length and field device current connected to the spur. The voltage drop on any connection unit Vc exists between the input terminals connected to the H1 bus main trunk cable and the output terminals dedicated to spur connections. In the simulated models, Vc was equal to zero in all models except for the HPTC model based on using field barriers and segment protectors. In the DART model, Vsupply will be decreased only in the first 5–10 microseconds of possible spark ignition in order to reduce the voltage delivered to the field device so that the spark would be early extinguished.

In HPTC sub-models with the segment protectors HPTC-SP-TS and HPTC-SP-DB, constant voltage was maintained at field devices, irrespective of the voltage drop on the spur. When increasing the spur length to which the field device is connected, the segment protector will increase the voltage at the output terminals to compensate the increased voltage drop on the spur. The output voltage of the segment protector is decreased from the segment protector input voltage by a reduction coefficient, the value of which for a specific field device will decrease when increasing the spur length. In HPTC sub-models with the field barriers HPTC-FB-TS and HPTC-FB-DB, output ports dedicated to connecting field devices of a specific current maintained constant voltage all along the segment, irrespective of the voltage drop on the H1 bus trunk main cable. This constant output voltage is maintained through compensating the decreased input voltage at farther field barriers by a reduction coefficient, which is decreasing from the nearest field barrier to the farthest field barrier in the segment. For an HPTC segment consisting of K connection units (field barriers or segment protectors), each (k) connection unit has N output ports for connecting field devices. For a field device (n) connected to the connection unit (k), the voltage level at the field device (VdHPkn) will be the difference between output voltage form the connection unit at the port connected to the device (VoHPkn) and the voltage drop on the spur to which the device is connected (VsHPkn). The input voltage to the (k) connection unit (ViHPk) is reduced by a reduction coefficient (KvHPkn) the value of which is dependent on the type of the connection unit, whether it was a field barrier or a segment protector. If the connection unit was a segment protector, the value of the reduction coefficient will be a function of the field device current (IdHPkn) and voltage drop on the spur to which the field device is connected. If the connection unit was a field barrier, the value of the reduction coefficient will be a function of the field device current and the sum of the voltage drops on the H1 bus main trunk cable from the power supply to the field barrier.

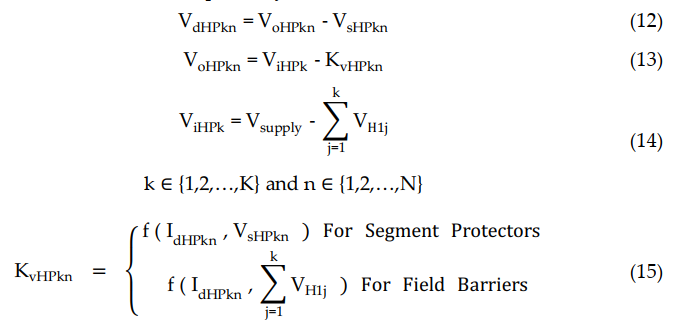

According to the simulation results obtained from Emerson Segment Design Tool, Table 3 illustrates the maximum allowable spur lengths in different Foundation Fieldbus models. For non-intrinsically safe, HPTC and DART models, maximum allowable spur length is dependent on the total number of field devices per segment; however, for entity, FISCO and FNICO models, the maximum allowable spur length in the segment is a constant value independent of the total number of field devices per segment.

This entry is adapted from the peer-reviewed paper 10.3390/s22186931