1. A Short Account of Italian History of Mechanism Design

In Italy, the Industrial Revolution occurred during a period of national unification in political, social, and cultural aspects, with events that also affected academic research and training programs, as summarized in [

20].

During the first half of the 19th century, Italy still suffered significant political fragmentation, which also affected curriculum teaching, with different plans in each state. After political unification was achieved, the standardization of university programs was planned as a priority, in order to achieve a cultural unification. This required robust plans and significant adjustments in most Italian universities, especially with regards to the programming curriculum content given by teachers, who often worked in more than one university. In addition to restructuring activity, the Italian academic communities, and particularly those working in mechanical engineering, made significant contributions to Italian industrialization with regards to technical-scientific achievements, and in the organization and support of entrepreneurial initiatives.

During the first half of the 19th century, following advances of the metallurgical industry, the first significant industrialization initiative was developed in Southern Italy, within the organization of the Kingdom of the Two Sicilies, for the production of civil constructions and infrastructures, steam engines, and several types of industrial machines. While this first excellent achievement is recognized today, as briefly outlined in [

21], the academic support of those industrial initiatives is still not well known, particularly when referring to specific figures who were not only devoted to theoretical investigations and fundamental mechanical designs. At the same time, in Northern Italy, universities activated specific programs on the mechanics of machines, recognizing the significant value of scientific formation for the nascent industrial frame, as a result of more contact with neighboring industrializing European countries. Examples of this can be considered the milestone work of Giuseppe Antonio Borgnis [

22], who was formed at the Ecole Polytechnique, Paris, while also being professor at Pavia University from 1818 to 1821, and who published his famous 9-volume handbook on machines, that included the first technical dictionary on machines. Another example is the milestone work by Carlo Ignazio Giulio who, at the same time as Willis’s work, published the first Italian textbook Theory of Mechanisms [

23]. One more example of northern prolific theoretical activities is the work by Gaetano Giorgini who formed at Ecole Polytechnique, Paris, while working in Modena elaborated the first modern investigation [

24] on the theory of screw (general helicalicoidal) motion of rigid bodies, with a postscript note on the 1763 book by Giulio Mozzi.

Even more significant are works and achievements in the second half of the 19th century, because of the cultural unity of academic frames that was organized and consolidated through the Royal Application Schools for Engineers in the main universities, which further supported the maturity and growth of industrialization initiatives. In the formation curriculum of industrial engineers, Mechanics Applied to Machines was planned with a central role, as it was in all the European universities; later, the augmented discipline of Kinematics Applied to Machines was recognized as mandatory for all curricula of industrial engineering at ministry level, with the Decree of 3 July 1879.

The university sites were in Turin, Milan, Bologna, Rome, and Naples. Domenico Tessari (1837–1909) and Scipione Cappa (1857–1910) were active in Turin. It is also worthy to note that Elia Ovazza (1852–1928), who moved to Palermo in 1890, successfully started a significant center there, including a laboratory which is still of historical interest today [

25]. In Milan, Giuseppe Colombo (1836–1921) and Ugo Ancona ((1867–1936) were significant figures in mechanical engineering at the time. In Bologna, Giuseppe Barilli (1812–1894) and Francesco Masi (1852–1944) were similarly very active and well reputed. In Rome, the field was developed by Valentino Francesco Cerruti (1850–1909) and Carlo Saviotti (1845–1928). Fortunato Padula (1815–1881) and Ernesto Cavalli (1852–1911) worked in mechanical engineering in Naples, where Giovanni Battaglini (1826–1894) and Dino Padelletti (1852–1892) paid particular attention to more theoretical subjects. Emblematic is Ernesto Cavalli (1852–1911), who simultaneously worked as a teacher in Milan, Livorno, Pisa, and Naples, with the clear purpose of promoting common plans for teaching the subject of Mechanism Design.

Those academic works also stimulated initiatives for new companies since several graduates also initiated industrial activities with the help of their teachers, for example, in Milan, as discussed in [

26]. Also prominent were Giuseppe Colombo, Francesco Masi and Lorenzo Allievi (1856–1941), as emblematic examples of the cultural prolificacy and success of the formation of Mechanics Applied to Machines, with a large range of applications: Colombo was a strong promoter of the industry, as documented in the Italian technical handbook (still in use today, with modern editions), with direct entrepreneur action even at governmental levels when he was a politician with important ministerial positions; Masi was a rigorous teacher who classified the variety of mechanisms, as well as designing the innovative machines for practical implementation [

27]; Allievi, who was based in Rome, developed the milestone work [

28] on the kinematics of machines, which is still of interest today [

29]. Later, Allievi applied his skill in the management of industrial plants while considering the technical problems of the water hammer in hydraulic engineering, which he solved practically and theoretically, with a theorem ascribed to him [

30].

After the First World War, Mechanics Applied to Machines was confirmed as being of primary significance as a driving technological development, and was given a central role in the formation programs of technicians and of all engineering professions. Between world wars and during wartime, activities were carried out intensively but with very limited dissemination. Nevertheless, achievements were fundamental for advances during wartime, and at the start of the post-war booms. The major university sites before 1940 were still located in Turin, Milan, Bologna, Rome, and Naples. Modesto Panetti (1875–1957) was in Turin. Ugo Ancona and Igino Saraceni were in Milan. Aristide Prosciutto (1895–1954) was in Bologna. In Rome, Anastasio Anastasi (1877–1969) was the main teacher. In Naples, activities were coordinated by Giovanni Domenico Mayer (1868–1925). Other significant activities were in Pisa, carried out by Enrico Pistolesi (1889–1968), and in Genoa, by Agostino Antonio Capocaccia (1901–1978).

Teaching teams, which were growing in member numbers and works, were active in the most university sites; in 1940 they were present in all universities with engineering schools, such as in Turin, Milan, Genoa, Padua, Bologna, Pisa, Rome, Naples, and Palermo. In the 1950s, new schools of engineering were started in Cagliari, Trieste, and Bari, with teachers in Mechanics of Machinery. Interests spanned from today’s traditional subjects of the Theory of Mechanisms, linked to analytical and rational mechanics, to more challenging fields referring to the design and development of mechanical systems for industry and services. Specific attention was given to new subjects related to aeronautic systems, aerodynamics, biomechanics and medical devices, fluid dynamics, industrial automation, machine regulation, and finally robotics, with achievements and designs that were among the most advanced in the world. Industrial mechanical engineering was also improved by this vivacity and cultural prolificacy, with achievements in applied research and even with the formation of creative professionals and industrial managers. A brilliant example is Corradino D’Ascanio (1891–1981), who spanned design skills from mechanical industry to aeronautics and transport vehicles, referring to his pioneering helicopter designs and Vespa scooter by Piaggio [

31]. All of these Italian activities produced significant literature in national and international frames, both for teaching and research, with textbooks, such as those indicated in [

32], edited books, journals and conference papers. Even today, there are major Italian university teams working in Mechanics of Machinery in Turin, Milan, Padua, Genoa, Bologna, Rome, Naples, and Bari.

2. Modern Italian Mechanism Models in MMS Teaching

The modern teaching of the Mechanisms and Machine Science (MMS) in Italy dates back to post World War II. In this period, we witnessed the establishment of modern universities, a subdivision of knowledge into organic courses, and a formalization of the proposed contents. In Italy, the courses dedicated to the theory of mechanisms and machines take the name of “Mechanics Applied to Machines” (sometimes also known as “Machine Mechanics”, “Applied Mechanics”, “Mechanics Applied to the Arts”), with content that has remained substantially unchanged to the current day.

The structure of the applied mechanics course can normally be considered to be divided into two main parts: the Theory of Mechanisms and the Kinetics of Machines. In the first part, the machine elements and mechanisms are considered from a purely geometric aspect, that is, their kinematic composition and the transformation of movements with procedure for Kinematics and Dynamics Analysis of the mechanism functioning in theoretical and practical aspects. In the second part, aspects of the transformation of energy are considered, referring to the specific design of machine elements with the aim of determining optimal operating conditions. Often, the kinetics of machines includes a relevant part of metrology, for example, for the measurement of friction or mechanical work, which nowadays has taken on its own identity in separate specific courses.

As an example, consider the textbook written by Modesto Panetti, which is organized in three volumes. The index of the textbook probably covers most of the contents, which is addressed in the course of Mechanics Applied to Machines in most Italian universities in those years (few differences can be recognized in the theory dealt with, and in the application examples that are characterized as functions of the individual universities [

32]).

-

Volume 1: Kinematics of machines. Friction resistance and resistance of the medium. Elementary friction and lubricated pairs. Rolling pairs. Vibrations.

-

Volume 2: Gears and wheels.

-

Volume 3: Flexible organs. Funicular machines. Cableways. Transmissions with belts.

From the above list, it follows what are the main mechanisms, whose models were made for teaching purposes.

The development of Models of Mechanisms for teaching is aimed at providing a practical example of the theoretical models that are introduced during the course, so that a student can better understand the operating principle of a mechanism, mainly referring to the kinematics of the motion and force transmission. From this point of view, the models are an integration only to the technical drawings in textbooks, which, due to their two-dimensional nature, can generate difficulties in student understanding. Finally, note should be given to the application-professional nature of the teaching that was expected for a degree in engineering, and in particular for a course in machine mechanics. The first models used in universities in Italy were made of wood, as it was cheaper than metal and lighter to transport to the classroom. The models followed the well-established classification of the mechanisms as proposed by Franz Reuleaux [

33], and the subsequent elaborations of Carlo Giulio [

23] and Francesco Masi [

6,

34,

35], to cite two Italian significant contributors, as outlined in [

36]. The main models refer mainly to:

As an example,

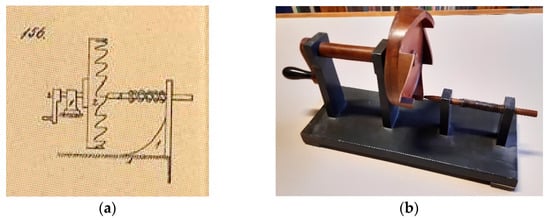

Figure 2 shows the comparison between a drawing in the treatise of Masi [

34], and the corresponding wooden model of a cylindrical cam disk, still existing in Bologna. According to the description by Masi: “The figure represents an eccentric in which the line is double curved and is placed on a cylindrical surface; hence the eccentric is also called cylindrical cam. By rotating the cam around its axis, the temple moves alternately in a direction parallel to the axis of rotation. The chain is closed by force by the action of a spring” [

5,

34]. By means of the knob on the cam axle, a student or a teacher can rotate the cylindrical cam with a continuous motion and observe the alternate motion of the output rod.

Figure 2. A model of lylindrical cam disk: (

a) in the treatise of Masi [

6]; (

b) the corresponding wooden model at the University of Bologna.

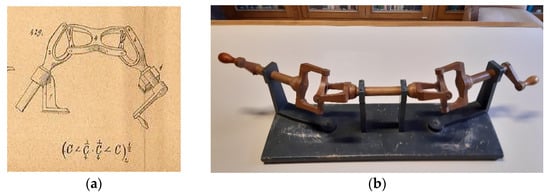

Sometimes, the models have more than one input as in the double Hooke’s joint, shown in Figure 3. The input and output shafts can be rotated with respect to the middle one, to show students the relationship between speed ratio and the input/output angular misalignment. Indeed, the model of the mechanism allows a quick and easy demonstration of the theory behind the simple drawing in Figure 3a.

Figure 3. A model of the double Hooke’s joint: (

a) in the treatise of Masi [

34]; (

b) the corresponding wooden model at the University of Bologna.

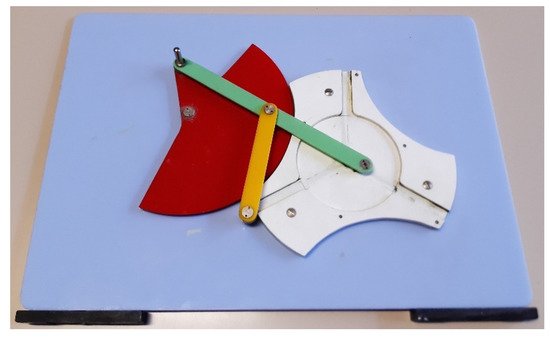

More recently, plastic materials have been used for models, such as bakelite or plexiglass. The advantages are for lighter and cheaper models than wooden ones, especially for planar mechanisms that can be obtained from the processing of plastic sheets. Figure 4 shows the model of a Geneva drive at the University of Bologna: an intermittent mechanism made by five bodies, namely the drive wheel (red), the crank (yellow), the rocker arm (green), and the driven wheel (white). The left extreme of the rocker arm is connected to the drive wheel, while there is a pin on the right one that engages in the slots of the driven wheel.

Figure 4. Intermittent mechanism model made of colored bakelite at the University of Bologna.

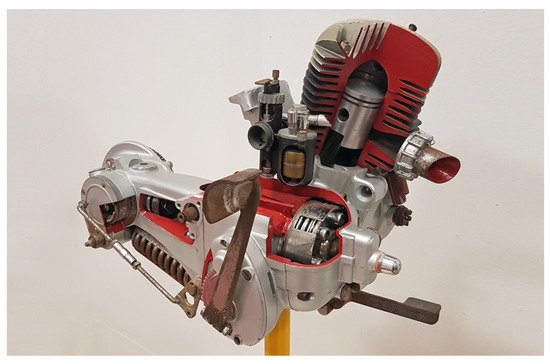

Iron models, more expensive than the previous ones, are often used to show the complexity of a real machine rather than a specific mechanism. They are models with cutaways to reveal the internal components. More realistic than previous types, these models are intended to show the real components that are the result of different types of analysis, such as the cooling fins of an engine, which have implications in the thermal analysis but not in mechanical ones.

Figure 5 shows a model of the iconic motorcycle, Lambretta, a 2-stroke single-cylinder engine, piston, head and crankcase made of aluminum alloy with a cast iron cylinder. The engine is part of the collection at the Museum of Engines and Mechanisms of the University of Palermo [

37].

Figure 5. Engine of the Innocenti motorcycle, Lambretta 125 C (1950–1951) at the Museum of Engines and Mechanisms, University of Palermo.

With the birth and diffusion of computers for personal use, the continuous increase of computational performance and decrease of the costs of the processors, 3D graphics software codes can be made available to universities and students. These 3D CAD software packages allow the modeling of rigid bodies, to assembly several bodies to model a complex mechanism, and to perform multibody analysis, combining Kinematics and Dynamics. This is the birth of the first virtual models of mechanisms: for the first time it is not possible to take in hand or weigh a mechanism model, but its details can be observed through a graphic model on a screen The advantages are the elimination of production costs (with the exception of costs related to the software license), the reduction times of model realization, the possibility of sectioning views to show the contents of an assembly, or to create an exploded view of the component. From the didactic point of view, a student can easily modify or scale the parametric CAD model to finally appreciate the different resulting kinematic behaviors. To date, the main software manufacturers offer integrated solutions, to develop the design phase of the mechanism, the kinematic analysis, the dynamic analysis, and resistance tests in the same pc environment. On the other hand, with virtual models, more practical aspects such as inertial effects or frictions are lost, together with the reality of the mechanism structure and operation with all its aspects.

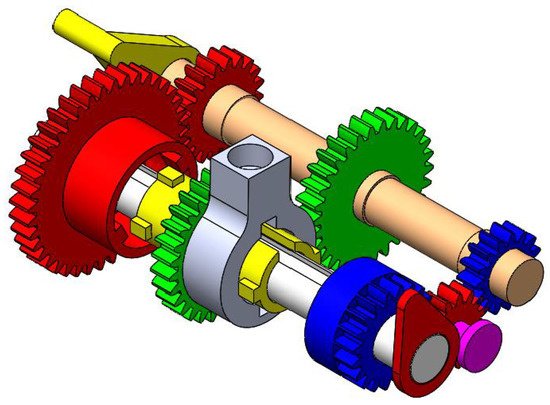

Figure 6 shows an example of a three-speed gearbox model that was developed in Solidworks environment by two students at the University of Ferrara [

38].

Figure 6. CAD model of a three-speed gearbox at University of Ferrara [

38].

Today, the possibility of building educational models is within everyone’s reach, thanks to 3D printing and the concept of additive manufacturing. Fused deposition modeling (FDM) printers of materials such as PLA and ABS are used by makers and hobbyists, and could easily be adopted by universities to model complex mechanisms and machines.

Figure 7 shows the model of a V8 engine that was developed as a final project by a Bachelor student at the University of Ferrara. The model has been designed in a CAD environment (Solidworks) and printed in ABS (Makerbot Replicator 2X) [

39].

Figure 7. Construction of a V8 engine model by 3D printing at University of Ferrara [

39].

This entry is adapted from the peer-reviewed paper 10.3390/machines10080628