- waste glass

- recycling

- construction materials

- sustainable concrete

1. Introduction

2. Properties of Glass

2.1. Chemical Properties of Glass

| Color | Chemical Compositions | Refs. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Na2O | Al2O3 | MgO | Fe2O3 | K2O | SO3 | TiO2 | Cr2O3 | Others | ||

| White | 70.39 | 6.43 | 16.66 | 2.41 | 2.59 | 0.32 | 0.23 | 0.19 | 0.08 | - | 0.04 (MnO), 0.02 (Cl) | [16] |

| Clear | 72.42 | 11.50 | 13.64 | 1.44 | 0.32 | 0.07 | 0.35 | 0.21 | 0.035 | 0.002 | - | [17] |

| Flint | 70.65 | 10.70 | 13.25 | 1.75 | 2.45 | 0.45 | 0.55 | 0.45 | - | - | - | [18] |

| Amber | 70.01 | 10.00 | 15.35 | 3.20 | 1.46 | - | 0.82 | 0.06 | 0.11 | - | 0.04 (MnO) | [16] |

| Brown | 71.19 | 10.38 | 13.16 | 2.38 | 1.70 | 0.29 | 0.70 | 0.04 | 0.15 | - | - | [19] |

| Green | 72.05 | 10.26 | 14.31 | 2.81 | 0.90 | - | 0.52 | 0.07 | 0.11 | - | 0.04 (MnO) | [16] |

| Type | Uses | Chemical Compositions | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | K2O | Na2O | Al2O3 | MgO | PbO | BaO | CaO | B2O3 | Others | ||

| Barium glasses | Optical-dense barium crown | 36 | 4 | 41 | 10 | 9% ZnO | |||||

| Color TV panel | 65 | 9 | 7 | 2 | 2 | 2 | 2 | 2 | 10% SrO | ||

| Soda-Lime Glasses | Containers | 66–75 | 0.1–3 | 12–16 | 0.7–7 | 0.1–5 | 6–12 | ||||

| Light bulbs | 71–73 | ||||||||||

| Float sheet | 73–74 | ||||||||||

| Tempered ovenware | 0.5–1.5 | 13.5–15 | |||||||||

| Lead glasses | Color TV funnel | 54 | 9 | 4 | 2 | 23 | |||||

| Electronic parts | 56 | 9 | 4 | 2 | 29 | ||||||

| Neon tubing | 63 | 6 | 8 | 1 | 22 | ||||||

| Optical dense flint | 32 | 2 | 1 | 65 | |||||||

| Aluminosilicate glasses | Combustion tubes | 62 | 1 | 17 | 7 | 8 | 5 | ||||

| Resistor substrates | 57 | 16 | 7 | 6 | 10 | 4 | |||||

| Fiberglass | 64.5 | 0.5 | 24.5 | 10.5 | |||||||

| Borosilicate | Chemical apparatus | 81 | 4 | 2 | 13 | ||||||

| Tungsten sealing | 74 | 4 | 1 | 15 | |||||||

| Pharmaceutical | 72 | 1 | 7 | 6 | 11 | ||||||

2.2. Physical and Mechanical Properties of Glass

| Property | Refs. | |

|---|---|---|

| Specific gravity | 2.4–2.8 2.51 (Green), 2.52 (Brown) |

[22] |

| Fineness Modulus | 4.25 0.44–3.29 |

[23][24] |

| Bulk Density | 1360 kg/m3 | [25][26] |

| Shape Index (%) | 30.5 | |

| Flakiness Index | 84.3–94.7 | [27] |

| Property | Refs. | |

|---|---|---|

| CBR (California bearing ratio) (%) | Approx. 50–75. | [28] |

| Los Angeles Value (%) | 38.4 | [25][27] |

| 24.8–27.8 | [26] | |

| 27.7 | [29] | |

| Friction Angle | critical = 38 (Loose recycled glass) | [28] |

| critical = 51–61 (Dense recycled glass) | ||

3. Fresh Concrete Properties

3.1. Workability

The smooth surface and low absorption capacity of WG are also important factors in increasing workability [30][31]. For example, Ali and Al-Tersawy [32] substitute fine aggregate in self-compacting concrete (SCC) mixes with recycled WG at levels of 10% to 50% by volume. Constant content of water–cement ratio and various superplasticizer doses have been used. They stated that slump flow increased by 2%, 5%, 8%, 11%, and 85%, with the incorporating of 10%, 20%, 30%, 40% and 50% of WG, respectively. In addition, Liu, Wei, Zou, Zhou and Jian [33] substitute fine aggregate in ultra-high-performance concrete (UHPC) mixes with recycled liquid crystal display (CRT) glass at levels of 25% to 100% by volume. Constant content of water–cement ratio and various superplasticizer (SP) doses have been used. Moreover, they stated that flowability increased by 11, 14, 16, and 12 mm, compared to the control sample, incorporating 25%, 50%, 75%, and 100% WG, respectively. Enhancing the workability by including WG is a benefit of utilizing this recycled material [34][35][36][37]. There is potential to utilize glass to create HPC in which high workability is necessary. In addition, WG can be used to boost workability rather than employing admixtures such as HRWR or superplasticizers [38][39][40][41].

3.2. Bulk Density

including waste glass into the mixes lowered workability. Nevertheless, such a decrease has been associated with sharp edges, higher glass particle aspect ratio, and angular form, with obstruction of the movement of particles and cement mortar [42][45][48][49][50][51][52].

4. Mechanical Properties

4.1. Compressive Strength

Incorporating glass waste into concrete reduces compressive strength. The researchers ascribed this behavior to (i) the sharp edges and smooth particle surfaces, leading to a poorer bond between cement mortar and glass particles at the interfacial transition zone (ITZ) [22][24][25][32][45][46][64][65][66][67]; (ii) increased water content of the glass aggregate mixes due to the weak ability of WG to absorb water [25][68]; and (iii) the cracks caused by expanding stress formed by the alkali-silica reaction produced from the silica in WG [22].

In order to better understand the impact of glass waste on the properties of the waste-glass concrete [69][70][71][72]. Omoding, Cunningham and Lane-Serff [73] investigated the concrete microstructure via SEM by replacing between 12.5–100% of the coarse aggregate with green waste glass with a size of 10–20 mm. The authors stated (i) that there is a weak connection between the waste glass and the cement matrix. This is because of a reduction in bonding strength between the waste glass and the cement paste because of the high smoothness of waste glass, consequently resulting in cracks and poor adherence between waste glass and cement paste; and (ii) as the content of waste glass increases, the proportion of cracks and voids increases in the concrete’s matrix.

However, some studies have stated that waste glass increases mechanical strength. This increase is primarily realized because of the surface texture and strength of the waste glass particles compared to natural sand [74][75][76] and the pozzolanic reaction of waste glass aggregate [77][78][79].

4.2. Splitting Tensile Strength

| Refs. | Type of Composite | Source | Type of Sub. | WG Sub. Ratio% | WG Size (mm) | w/c or w/b | Addit. or Admix. | Split ten. str. of Control (MPa) | Outcomes |

|---|---|---|---|---|---|---|---|---|---|

| [80] | UHPC | WG | F.A | 25, 50, 75, & 100 (wt.%) | ≤0.6 | 0.19 | Steel fiber & HRWRA | 11.7 | Increased by 1%, 3%, 11%, and 7%, respectively. |

| [81] | Waste glass concrete | WG | F.A | 15 & 30 (vol.%) | ≤4.75 | 0.5 | - | 4.5 | Changed by +4%, and −1%, respectively. |

| [60] | Waste glass concrete | WG | F.A | 5, 15, & 20 (vol.%) | 0.15–4.75 | 0.55 | - | 2.5 | Increased by 4%, 12%, and 24%, respectively. |

| [32] | SCC | WG | F.A | 10, 20, 30, 40, & 50 (vol.%) | 0.075–5 | 0.4 | SF & SP | 6.8 | Decreased by 9%, 15%, 16%, 24%, and 28%, respectively. |

| [82] | Cement concrete | WG | F.A | 5, 10, 15, & 20 (vol.%) | 0.15–9.5 | 0.56 | - | 3.9 | Decreased by 0%, 8%, 15%, and 23%, respectively. |

| [83] | Waste glass concrete | WG | F.A | 10, 20, 30, & 40 (wt.%) | ≤4.75 | 0.45 | - | 2.5 | Decreased by 2%, 8%, 10%, and 12%, respectively. |

| [84] | LCDGC | LCD | F.A | 20, 40, 60, & 80 (vol.%) | ≤4.75 | 0.38, 0.44, & 0.55 | - | 2.38 | Decreased by 1%, 7%, 8%, and 9%, respectively, for w/c of 0.44. |

| [63] | Waste glass concrete | CRT | F.A | 20, 40, 60, 80, & 100 (vol.%) | 4.75 | 0.45 | F.A. | 4.48 | Decreased by 6%, 6%, 13%, 15%, and 19%, respectively. |

| [85] | Waste glass concrete | WG | F.A | 25, 50., 75, & 100 (wt.%) | ≤5 | 0.5 | - | 3.6 | Decreased by 22%, 39%, 39%, and 44%, respectively. |

4.3. Flexural Strength

4.4. Modulus of Elasticity (MOE)

5. Conclusions

-

The workability of waste-glass-containing concrete mixtures for fine or coarse aggregates was less than for natural aggregate-containing mixtures. Nevertheless, despite the poorer workability, some studies found that the mixtures were still workable.

-

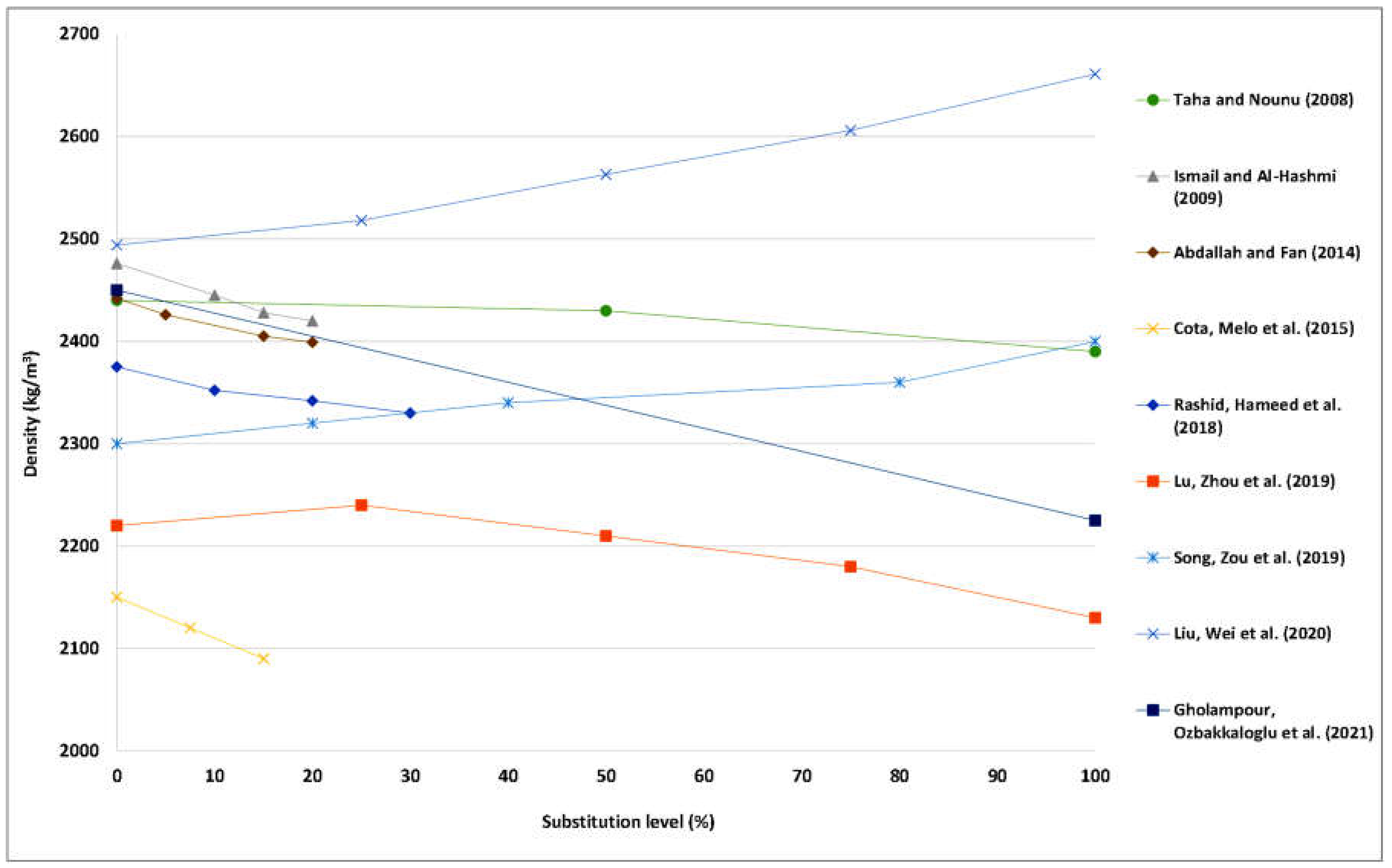

Most studies indicated that with the introduction of WG, the density of concrete decreased due to the decreased density and specific gravity of waste glass aggregates.

-

The findings of the literature have been somewhat indecisive regarding the properties of concrete, such as compressive strength, splitting tensile strength, flexural strength, and modulus of elasticity.

-

The findings revealed that the compressive strength, splitting tensile strength, and flexural strength of concrete deteriorated by integrating WG. Nevertheless, the findings concerning the elastic modulus of concrete were conflicting. This decrease was essential because of the sharp edges and smooth surface of the waste glass that caused the poorer bond between cement mortar and waste glass particles at the ITZ.

-

Studies also showed that the optimal aggregate substitution level was about 20%. In addition, the glass color does not have a substantial influence on the strength. Although the results are indecisive, WG has the possibility to be an acceptable substitute for fine or coarse concrete aggregates in concrete.

-

Adding waste glass to the concrete mixture may improve certain mechanical characteristics of concrete, reduce concrete dead load, and provide an ecological substitute for normal aggregates.

This entry is adapted from the peer-reviewed paper 10.3390/ma15186222

References

- Lu, J.-X.; Zhan, B.-J.; Duan, Z.-H.; Poon, C.S. Using glass powder to improve the durability of architectural mortar prepared with glass aggregates. Mater. Des. 2017, 135, 102–111.

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; de-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci. Rep. 2021, 11, 21525.

- Ahmed, H.U.; Mohammed, A.S.; Qaidi, S.M.A.; Faraj, R.H.; Sor, N.H.; Mohammed, A.A. Compressive strength of geopolymer concrete composites: A systematic comprehensive review, analysis and modeling. Eur. J. Environ. Civ. Eng. 2022, 1–46.

- ICG. An Economic Argument for an IYOG 2022; The International Commission on Glass (ICG): Venice, Italy, 2020.

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.H.; Qaidi, S.M.A.; de Prado Gil, J.; Martínez-García, R. Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct. Concr. 2022.

- Martínez-García, R.; Jagadesh, P.; Zaid, O.; Șerbănoiu, A.A.; Fraile-Fernández, F.J.; de Prado-Gil, J.; Qaidi, S.M.A.; Grădinaru, C.M. The Present State of the Use of Waste Wood Ash as an Eco-Efficient Construction Material: A Review. Materials 2022, 15, 5349.

- EPA. Advancing Sustainable Materials Management: 2018 Tables and Figures. Environ. Prot. Agency 2021, 1–80.

- Maglad, A.M.; Zaid, O.; Arbili, M.M.; Ascensão, G.; Șerbănoiu, A.A.; Grădinaru, C.M.; García, R.M.; Qaidi, S.M.A.; Althoey, F.; de Prado-Gil, J. A Study on the Properties of Geopolymer Concrete Modified with Nano Graphene Oxide. Buildings 2022, 12, 1066.

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502.

- Ling, T.-C.; Poon, C.-S.; Wong, H.-W. Management and recycling of waste glass in concrete products: Current situations in Hong Kong, Resources. Conserv. Recycl. 2013, 70, 25–31.

- Contrafatto, L.; Gazzo, S.; Purrazzo, A.; Gagliano, A. Thermo-mechanical Characterization of Insulating Bio-plasters Containing Recycled Volcanic Pyroclasts. Open Civ. Eng. J. 2020, 14, 66–77.

- Meyer, B. Macroeconomic modelling of sustainable development and the links between the economy and the environment. In Final Report of the MacMod project (ENV. F. 1/ETU/2010/0033) to the European Commission; Institute of Economic Structures Research: Osnabrück, Germany, 2011.

- Khan, M.; Cao, M.; Ali, M. Experimental and Empirical Study of Basalt Fibber Reinforced Concrete. In Proceedings of the Building Tomorrow’s Society, Fredericton, NB, Canada, 13–16 June 2018. Paper ID–MA39_0610035833.

- Khan, M.; Lao, J.; Dai, J.-G. Comparative study of advanced computational techniques for estimating the compressive strength of UHPC. J. Asian Concr. Fed. 2022, 8, 51–68.

- Parvez, I.; Shen, J.; Khan, M.; Cheng, C. Modeling and solution techniques used for hydro generation scheduling. Water 2019, 11, 1392.

- Dyer, T.D.; Dhir, R.K. Chemical Reactions of Glass Cullet Used as Cement Component. J. Mater. Civ. Eng. 2001, 13, 412–417.

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89.

- Karamberi, A.; Moutsatsou, A. Participation of coloured glass cullet in cementitious materials. Cem. Concr. Compos. 2005, 27, 319–327.

- Sobolev, K.; Türker, P.; Soboleva, S.; Iscioglu, G. Utilization of waste glass in ECO-cement: Strength properties and microstructural observations. Waste Manag. 2007, 27, 971–976.

- Shand, E.B. Glass Engineering Handbook; Amazon: Seattle, WA, USA, 1958.

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467.

- Park, S.-B.; Lee, B.-C. Studies on expansion properties in mortar containing waste glass and fibers. Cem. Concr. Res. 2004, 34, 1145–1152.

- Lam, C.S.; Poon, C.S.; Chan, D. Enhancing the performance of pre-cast concrete blocks by incorporating waste glass–ASR consideration. Cem. Concr. Compos. 2007, 29, 616–625.

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of recycled fine glass aggregates on the properties of dry–mixed concrete blocks. Constr. Build. Mater. 2013, 38, 638–643.

- de Castro, S.; de Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14.

- Serpa, J.d.B.D.; Jorge, P. Concrete Made with Recycled Glass Aggregates: Mechanical Performance. ACI Mater. J. 2015, 112, 29–38.

- Disfani, M.M.; Arulrajah, A.; Bo, M.W.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351.

- Ooi, P.S.K.; Li, M.M.W.; Sagario, M.L.Q.; Song, Y. Shear Strength Characteristics of Recycled Glass. Transp. Res. Rec. 2008, 2059, 52–62.

- Ali, M.M.Y.; Arulrajah, A. Potential Use of Recycled Crushed Concrete-Recycled Crushed Glass Blends in Pavement Subbase Applications; GeoCongress: Los Angeles, CA, USA, 2012; pp. 3662–3671.

- Ling, T.-C.; Poon, C.-S.; Kou, S.-C. Feasibility of using recycled glass in architectural cement mortars. Cem. Concr. Compos. 2011, 33, 848–854.

- Ling, T.-C.; Poon, C.-S. Effects of particle size of treated CRT funnel glass on properties of cement mortar. Mater. Struct. 2013, 46, 25–34.

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791.

- Liu, T.; Wei, H.; Zou, D.; Zhou, A.; Jian, H. Utilization of waste cathode ray tube funnel glass for ultra-high performance concrete. J. Clean. Prod. 2020, 249, 119333.

- Khan, M.; Ali, M. Earthquake-Resistant Brick Masonry Housing for Developing Countries: An Easy Approach. Available online: https://www.nzsee.org.nz/db/2017/P2.43_Ali.pdf (accessed on 30 July 2022).

- Khan, M.; Cao, M.; Hussain, A.; Chu, S.H. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 2021, 300, 124046.

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2022, 319, 126130.

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382.

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357.

- Emad, W.; Mohammed, A.S.; Bras, A.; Asteris, P.G.; Kurda, R.; Muhammed, Z.; Hassan, A.M.T.; Qaidi, S.M.A.; Sihag, P. Metamodel techniques to estimate the compressive strength of UHPFRC using various mix proportions and a high range of curing temperatures. Constr. Build. Mater. 2022, 349, 128737.

- Almeshal, I.; Al-Tayeb, M.M.; Qaidi, S.M.A.; Bakar, B.H.A.; Tayeh, B.A. Mechanical properties of eco-friendly cements-based glass powder in aggressive medium. Mater. Today Proc. 2022, 58, 1582–1587.

- Al-Tayeb, M.M.; Aisheh, Y.I.A.; Qaidi, S.M.A.; Tayeh, B.A. Experimental and simulation study on the impact resistance of concrete to replace high amounts of fine aggregate with plastic waste. Case Stud. Constr. Mater. 2022, 17, e01324.

- Taha, B.; Nounu, G. Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Constr. Build. Mater. 2008, 22, 713–720.

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721.

- Tayeh, B.A. Effects of marble, timber, and glass powder as partial replacements for cement. J. Civ. Eng. Constr. 2018, 7, 63–71.

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I–Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117.

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659.

- Borhan, T.M. Properties of glass concrete reinforced with short basalt fibre. Mater. Des. 2012, 42, 265–271.

- Yildizel, S.A.; Tayeh, B.A.; Calis, G. Experimental and modelling study of mixture design optimisation of glass fibre-reinforced concrete with combined utilisation of Taguchi and Extreme Vertices Design Techniques. J. Mater. Res. Technol. 2020, 9, 2093–2106.

- Al Saffar, D.M.; Tawfik, T.A.; Tayeh, B.A. Stability of glassy concrete under elevated temperatures. Eur. J. Environ. Civ. Eng. 2020, 26, 1–12.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part IV: Durability properties, cost assessment, applications, and challenges. Case Stud. Constr. Mater. 2022, 17, e01271.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part I: Developments, principles, raw materials. Case Stud. Constr. Mater. 2022, 17, e01290.

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part II: Hydration and microstructure. Case Stud. Constr. Mater. 2022, 17, e01289.

- Ahmed, S.N.; Sor, N.H.; Ahmed, M.A.; Qaidi, S.M.A. Thermal conductivity and hardened behavior of eco-friendly concrete incorporating waste polypropylene as fine aggregate. Mater. Today: Proc. 2022, 57, 818–823.

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.A.; Mohammed, A.A. Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 2022, 16, e01036.

- Qaidi, S. Ultra-High-Performance Fiber-Reinforced Concrete: Fresh Properties. Preprints 2022.

- Qaidi, S. Ultra-High-Performance Fiber-Reinforced Concrete: Applications. Preprints 2022.

- Qaidi, S. Ultra-high-performance fiber-reinforced concrete (UHPFRC): A mini-review of the challenges. Sci. Prepr. 2022.

- Rashid, K.; Hameed, R.; Ahmad, H.A.; Razzaq, A.; Ahmad, M.; Mahmood, A. Analytical framework for value added utilization of glass waste in concrete: Mechanical and environmental performance. Waste Manag. 2018, 79, 312–323.

- Gholampour, A.; Ozbakkaloglu, T.; Gencel, O.; Ngo, T.D. Concretes containing waste-based materials under active confinement. Constr. Build. Mater. 2021, 270, 121465.

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. Eng. Tech. Res. 2014, 2, 11–17.

- Lu, J.-X.; Zhou, Y.; He, P.; Wang, S.; Shen, P.; Poon, C.S. Sustainable reuse of waste glass and incinerated sewage sludge ash in insulating building products: Functional and durability assessment. J. Clean. Prod. 2019, 236, 117635.

- Cota, F.P.; Melo, C.C.D.; Panzera, T.H.; Araújo, A.G.; Borges, P.H.R.; Scarpa, F. Mechanical properties and ASR evaluation of concrete tiles with waste glass aggregate. Sustain. Cities Soc. 2015, 16, 49–56.

- Song, W.; Zou, D.; Liu, T.; Teng, J.; Li, L. Effects of recycled CRT glass fine aggregate size and content on mechanical and damping properties of concrete. Constr. Build. Mater. 2019, 202, 332–340.

- Topçu, İ.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274.

- Wang, H.-Y.; Zeng, H.-h.; Wu, J.-Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670.

- Ling, T.-C.; Poon, C.-S. Properties of architectural mortar prepared with recycled glass with different particle sizes. Mater. Des. 2011, 32, 2675–2684.

- Ali, M.H.; Dinkha, Y.Z.; Haido, J.H. Mechanical properties and spalling at elevated temperature of high-performance concrete made with reactive and waste inert powders. Eng. Sci. Technol. Int. J. 2017, 20, 536–541.

- Polley, C.; Cramer, S.M.; de la Cruz, R.V. Potential for Using Waste Glass in Portland Cement Concrete. J. Mater. Civ. Eng. 1998, 10, 210–219.

- Khan, M.; Ali, M. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 2019, 203, 174–187.

- Khan, M.; Ali, M. Optimization of concrete stiffeners for confined brick masonry structures. J. Build. Eng. 2020, 32, 101689.

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549.

- Xie, C.; Cao, M.; Guan, J.; Liu, Z.; Khan, M. Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Compos. Part B Eng. 2021, 224, 109219.

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concrete. Constr. Build. Mater. 2021, 268, 121177.

- Najm, H.M.; Ahmad, S. The Use of Waste Ceramic Optimal Concrete for A Cleaner and Sustainable Environment - A Case Study of Mechanical Properties. Civ. Environ. Eng. Rep. 2022, 32, 85–102.

- Qaidi, S. Behaviour of Concrete Made of Recycled Waste PET and Confined with CFRP Fabrics; University of Duhok: Duhok, Iraq, 2021.

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Fresh Properties; University of Duhok: Duhok, Iraq, 2022.

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100.

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Hydration and Microstructure; University of Duhok: Duhok, Iraq, 2022.

- Qaidi, S.M.A. PET-Concrete; University of Duhok: Duhok, Iraq, 2021.

- Jiao, Y.; Zhang, Y.; Guo, M.; Zhang, L.; Ning, H.; Liu, S. Mechanical and fracture properties of ultra-high-performance concrete (UHPC) containing waste glass sand as partial replacement material. J. Clean. Prod. 2020, 277, 123501.

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021, 269, 121242.

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876.

- Malik, M.I.; Bashir, M.; Ahmad, S.; Tariq, T.; Chowdhary, U. Study of concrete involving use of waste glass as partial replacement of fine aggregates. IOSR J. Eng. 2013, 3, 8–13.

- Wang, H.-Y. A study of the effects of LCD glass sand on the properties of concrete. Waste Manag. 2009, 29, 335–341.

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Ngene, B.U.; Akinwumi, I.I.; Ofuyatan, O. Strength and microstructure of eco-concrete produced using waste glass as partial and complete replacement for sand. Cogent Eng. 2018, 5, 1483860.

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Cost Assessment; University of Duhok: Duhok, Iraq, 2022.

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Durability Properties; University of Duhok: Duhok, Iraq, 2022.

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Mixture Design; University of Duhok: Duhok, Iraq, 2022.