Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Energy & Fuels

The socioeconomic development of any country is directly associated with an increase in power consumption. One of the main disadvantages of the ultra-supercritical (USC) power unit’s creation is high price due to the application of expensive heat-resistant materials for boiler, live and reheat steam pipelines in turbines.

- ultra-supercritical parameters

- heat-resistant material

- horizontal boiler

- cooled steam turbine

1. Introduction

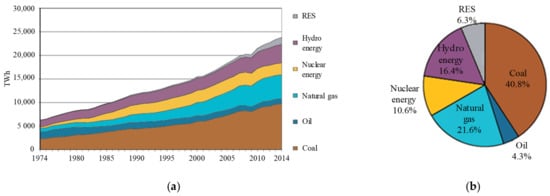

The socioeconomic development of any country is directly associated with an increase in power consumption. The traditional power industry development worldwide and in Russia is based on the use of fossil fuels. Nowadays, the main fuels used are coal, oil, and natural gas. It is worth mentioning that the tendency of hydrocarbon fuel consumption increase is constant (Figure 1a) [1,2], which leads to their exhaustion, environment pollution, and irreversible climate changes. Prospectively, it is a problem that slows down economic growth and threatens mankind’s stable development. Figure 1b shows that more than 40% of electricity production comes from coal fuels and less than 10% is based on nuclear fuels. Steam turbine units are widely used for both nuclear and thermal power plants: they produce about 50% of the world electricity. This emphasizes the high actuality of the problem of increasing the efficiency of steam turbine power plants. Therefore, the problem of increasing the efficiency of coal-fired power plants is a topical one, especially considering the widespread of steam turbine units.

Figure 1. A split of world power production between primary energy sources: (a) Changes from 1974 to 2014; (b) Power source structure for the 2014 year.

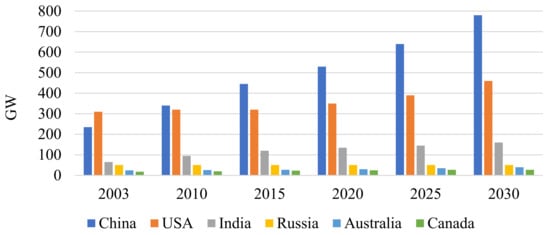

The considered equipment has reached its utmost perfection, so the cycle efficiency may be considerably improved only by an increase in the thermodynamic cycle’s initial parameters. Natural-gas-fired power plants have passed to combined cycles that allow heat supply temperatures of up to 1200–1500 °C and, thus, reach a thermal efficiency of over 60% [3,4,5,6]. Yet, there is no solution for the problem of thermodynamic efficiency enhancement by an increase in initial parameters in coal-fired and nuclear power plants. Nowadays, the most advanced steam turbine coal-fired facilities have reached a thermal efficiency level of 42–43% [7,8]. It is worth mentioning that the total installed power of coal-fired steam turbine facilities every year demonstrates a stable increase (Figure 2) [9,10]. This may be explained by the use of large resources of hard fuels in many countries and the coal price staying constant for many years. Thus, the power industry has a goal to increase the efficiency of coal-fired power plants, which will save fossil fuel resources and reduce the contribution of more expensive fuels, natural gas, and oil products. In addition, it allows environmental harm reduction by the mitigation of toxic NOx and SOx and greenhouse CO2 emissions. Therefore, it is important to find promising ways to improve steam turbine power units.

Figure 2. Growth of coal-fired power plants’ installed power.

The next step is the transition from the currently widespread supercritical (SC) initial parameters of 24 MPa and 540 °C to the ultra-supercritical (USC) ones of around 30 MPa and 600 °C. The main drawback of the transition to USC steam parameters is a remarkable increase in the expensive structure materials’ contribution to the total metal expenses. These materials are used for the boiler super-heater, direct and intermediate steam pipelines, and the turbine high-temperature compartments.

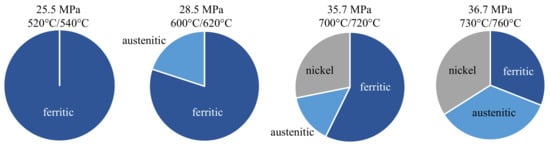

Figure 3 shows the changes in applicable structure materials that follow the transition from SC to USC parameters. Heat-resistant alloys with high nickel contents predominate [11] over the martensite steels that have better thermo-physical performance and are used in SC conditions.

Figure 3. Changes in the streel assortment for power facilities at different steam parameters.

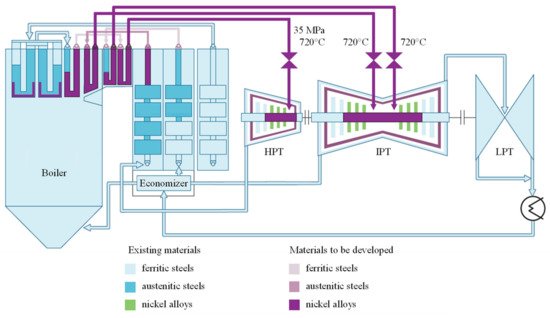

Figure 4 shows the heat-resistant materials’ distribution over the steam turbine facility elements in a USC facility. The main elements that need a transition from the traditional materials to the new heat-resistant and heat-proof ones are the steam superheating surfaces, especially the superheater exit panels, boiler steam collectors, high-temperature live and superheated steam pipelines, check and control valve blocks, turbine internal housings, first stages, and rotors. Therefore, an increase in the initial parameters of steam turbine power units requires a whole range of new alloys and equipment production technologies.

Figure 4. Heat-resistant materials in the USC power facility equipment.

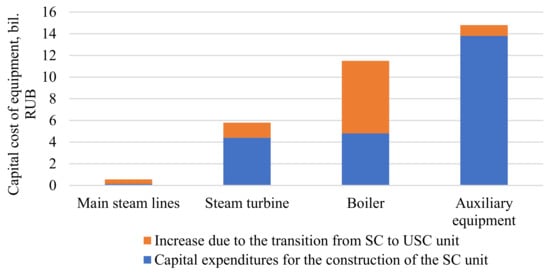

Works on thermal efficiency improvement in the coal-fired power plants are actively being undertaken in many countries [12,13,14,15]. World leaders have already put into operation steam facilities with ultra-supercritical steam parameters of p0 = 32 MPa initial pressure and t0 = 600–620 °C initial temperature [16,17]. These facilities with an efficiency level of 43% are being introduced in large scales in European Union countries, Japan, the USA, and China [18]. The next step in the efficiency improvement needs a transition to a higher level of the initial steam parameters, USC with p0 = 34–36 MPa initial pressure and t0 = 700–760 °C initial temperature. The same leading countries of the EU, Japan, USA, and China actively developed this direction of USC power facilities’ improvement [19,20,21]. The main equipment manufacturers, power production, and research companies have taken part in these programs. The new operation conditions require the development of new materials. In addition to this, the financial factor slows down the introduction of high-temperature power plants, which is due to an increase in the contribution of expensive heat-resistant materials to the metal consumption expenses. The ratio of traditional turbine materials’ cost to that of the heat-resistant steels and alloys cost is 1/5 regarding SC and 1/43 regarding USC. The increase in heat-resistant materials’ contribution is a source of increase in power facilities’ price that results in problems regarding the improvement in financial efficiency despite the remarkable thermal efficiency increase and better environmental performance. The straight steam parameters’ increase from 540 to 720 °C in temperature, together with the pressure rise from 23.5 to 35 MPa, increases the power facility’s price to 20–25% [22]. Figure 5 shows the price increase in the main and auxiliary equipment that follows the SC to USC transition. The main steam pipeline price grows more than three times, the turbine and auxiliary equipment are 30% and 10% more expensive, respectively, and the boiler price is more than two times higher. Therefore, the current methods for increasing the coal-fired power plants’ efficiency require a significant increase in the unit price and may not be economically viable in regions with lower fuel prices.

Figure 5. Increase in power facility equipment price caused by the transition to USC.

Thus, one of the key directions of high-temperature power facility improvement and provision of their competitiveness is the reduction in heat-resistant steels’ and materials’ consumption for main equipment manufacturing.

2. Competitiveness Improvement of High-Temperature Steam Turbine Power Plants

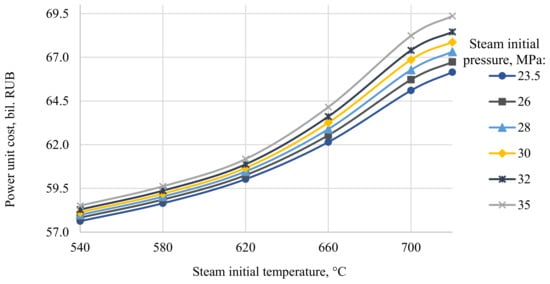

Figure 12 shows changes in the facility construction cost concerned with the initial steam parameters changes. The steam temperature increase at a constant pressure remarkably influences the power facility cost. The increase in steam temperature from 540 to 720 °C and pressure from 23.5 to 35 MPa increases the power facility construction cost from RUB 57.6 to 69.4 billion. Therefore, the transition from SC to USC increases the facility cost by 20.4%.

Figure 12. Influence of the initial steam parameters on the cost of a coal-fired power plant.

Financial assessments (Table 2) show that the new technical solutions devoted to the cost reduction in high-temperature power facilities allow a block cost reduction of RUB 10.5 billion. Therefore, the USC power plant price becomes similar to that of the traditional SC power plant.

Table 2. Financial effects of the proposed technical solutions’ application.

| Technical Solution | Cost, bil. RUB | Cost Reduction, bil. RUB | |

|---|---|---|---|

| 1 | Coal-fired steam turbine USC power facility, traditional design | 69.09 | - |

| 2 | Coal-fired steam turbine USC power facility, horizontal boiler | 68.65 | 0.44 |

| 3 | Coal-fired steam turbine USC power facility, horizontal boiler, and two-tier LPT | 68.34 | 0.31 |

| 4 | Coal-fired steam turbine USC power facility, horizontal boiler, two-tier LPT, and cooled turbine | 66.74 | 1.59 |

| 5 | Coal-fired steam turbine USC power facility, horizontal boiler, two-tier LPT, cooled turbine, and new design technology | 66.05 | 0.68 |

| 6 | Hybrid power facility with hydrogen steam superheating, two-tier LPT, cooled turbine, and new design technology | 58.59 | 7.46 |

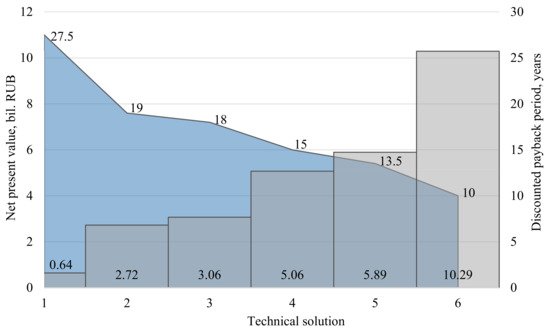

The new technical solutions influence the financial performance of the high-temperature power facilities’ construction. Figure 13 shows discounted payback periods (blue color) and discounted payment flow (gray color) values according to different contents of the applied technical solutions.

Figure 13. Financial performance of projects for high-temperature facilities construction.

The transition to higher steam parameters improves power production efficiency and reduces fuel expenses. On the other hand, it requires larger capital investments, amounts of depreciation, and maintenance expenses. The proposed solutions reduce the capital investments but do not hurt the power production efficiency, so Figure 13 demonstrates the discounted payback period shortened from 27.5 to 10 years and an increase in the discounted payment flow from RUB 0.64 to 10.29 billion.

5. Conclusions

The significant cost of high-temperature steam turbine power facilities is caused by the large consumption of expensive heat-resistant materials and is one of the key problems of these power plants’ introduction. A prospective way to overcome the problem is the development of solutions ensuring technology availability and financial feasibility. In this study, the following solutions for high-temperature steam turbine power facilities were developed and assessed:

- -

-

Horizontal boiler design that reduces the high-temperature pipelines’ length by three times or 150 m for the most widespread designs, which leads to a corresponding decrease in steam lines’ cost;

- -

-

Application of a cooled steam turbine that reduces heat-resistant materials’ consumption by allowing the operation of metal at 600 °C and allows the maintenance of the high thermal efficiency level of the power cycle;

- -

-

Smaller consumption of heat-resistant materials achieved by the transition of steam superheating from boiler surfaces to the external hydrogen–oxygen combustion chamber;

- -

-

Smaller material consumption in high velocity powerful steam turbines by the application of two-tier last LPT stages with an up to 40% higher flow capacity at 87.1% efficiency.

To assess the economic potential of the proposed methods, a cost analysis model was developed on the basis of power equipment costs of metal and manufacturing. According to the results of the calculations, an application of all of the proposed methods allows for a reduction in the high-temperature power facility cost by RUB 10.5 billion or 15%. The discounted payback period is reduced from 27.5 to 10 years and the net present value increases by RUB 9.6 billion or 16 times.

In further research, the experimental study of physical processes occurring in the flow path of full-scale equipment should be considered. Oxy-hydrogen combustion with a water steam diluent in high-pressure combustors is of special scientific interest. Moreover, gas dynamic and strength tests of two-tier flow paths are actual tasks that should be performed.

This entry is adapted from the peer-reviewed paper 10.3390/inventions7020044

This entry is offline, you can click here to edit this entry!